Energy Management System Implementation Case Study

advertisement

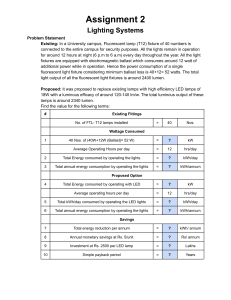

Energy Management System Implementation Case Study Yunus Moola 14 October 2014 Acknowledgements • Willard Batteries/Powertech • NCPC-SA/ IEE Project (UNIDO) • AIDC 2 Introduction Powertech Batteries is a manufacturer and supplier of world class lead acid batteries for the automotive industry. We are known for our green batteries in more ways than one. As part of our commitment for a sustainable future we have embarked on the “Go green go Willard” campaign in association with Food and trees for Africa. We have also embarked on the ISO 50001 journey 3 Scope & Boundaries 4 Objectives, Targets & Action Plans Objectives • 5% reduction in energy usage (includes electricity, gas and diesel) in 2013 • Paper – 5% in 2013 • Water – 2.5% in 2013 SEU Plate Making Target Savings (kWh) 364,227 Action Plan (kWh) 1306800 BM 77014 0 TBS 222830 817344 Charge room 303871 693505 5 Energy Management Team The team is made up of representatives from each SEU and ‘experts’ from the various disciplines. 6 Significant Energy Users Plate Making, BM, TBS, Charge Room EnPI & Baseline Actual Savings Recorded Action Energy Savings (kWh) Replacement of curing ovens 1 306 800 Replacement of bag filters 817 344 Replacement of old chargers 693 505 Various small projects 922 722 Total 3 740 421,379 9 Challenges Sustaining habit changes is the biggest challenge to this process and continuous reminders and threats, although very time consuming, is the only way to overcome this challenge. 10 Lessons Learned • Energy saving is not so difficult it just needs a bit of lateral thinking. • There is always competition for limited capital resources and a well-planned, coordinated and methodical approach is necessary to overcome any challenges. Highlights Implementation Period 2011 - 2013 Total Number of project 43 Monetary savings in ZAR R 2 805 000 per annum Energy savings in KWh 3740421,379 per annum Total investment made ZAR Approx. R 9 million Payback time period in years 3.2 years GHG Emission Reduction (ton CO2) 3 740 tons per annum ISO 50001 Certification • A plan has been laid out for the implementation of ISO 50001 • The process of implementing ISO 50001 will begin in 2015 • Certification Target Date = 2016 13 Thank you ?