Lean Six Sigma Techniques for Inventory - Federal Center

advertisement

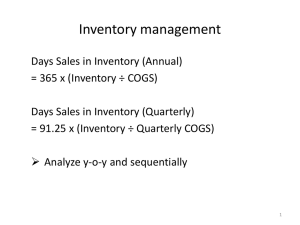

Lean Six Sigma Techniques for Inventory Management Please use the following two slides as a template for your presentation Norman Pugh-Newby, CPPA, PMP at NES. Manager Deloitte FCC NPMA MEETING March 27th 2012 Outline • • • • • Lean Six Sigma - Short Overview Inventory Management Issues Excess & Obsolete Inventories 10-Step Solution Process Conclusion What is Lean Six Sigma • Lean Six Sigma is a combination of two separate but complementary process improvement methodologies with an Enterprise Level perspective What is Lean • Lean Concepts grew out of the Toyota Production System (1960s) • Lean’s goal is to eliminate all forms of waste in the process and engage employee creativity • The currency of lean is time Simplicity • Requires process mapping Waste Reduction – ID value added step in process Efficiency – ID non-value added steps What is Six Sigma • Six Sigma dates back to the 1920’s and work done on Statistical Process Control in the US • Six Sigma’s goal is to understand customer need and deliver perfection every time • Six Sigma’s currency is consistency Consistency Reduced – Reduce variation in process Variability – Reduce defects Effectiveness – Produce consistently good product Six Sigma DMAIC Approach Define Measure Analyze Improve Control • Define: Define the problem • Measure: Gather information on the current system • Analyze: Analyze data and current process to identify root causes • Improve: Develop and implement a solution • Control: Validate results, standardize new process, and monitor results of new process How Do Lean & Six Sigma Blend • Both require an organizational paradigm shift in how we view work • Both aim to reduce operational costs • Lean reduces waste in the process then Six Sigma creates consistency to reduce your defect rate • Together they add both efficiency and effectiveness to a process • Generally you “lean” a process first then apply six sigma tools LSS Inventory Applications • Ensuring system parameters are accurate • Demonstrate relationships between inventory investment and lead time/demand variation • Verify inventory valuation • Identify & eliminate root causes of inventory discrepancies • Elimination of excess & obsolete inventory • Improving cycle counting accuracy & efficiency Excess & Obsolete Inventory • A symptom of issues with inventory management • Improvement strategies often have a short-term focus – – – – Sell below standard cost Donate to charity Sell for scrap Pay to remove • Improvement strategies often fail to identify root causes – Excess & obsolete inventory quickly return to former levels – Endless cycle of building up excess and disposing of excess • Multi-billion dollar problem Excess & Obsolete Inventory • Benefits of a solution: – Private Sector: Firms that can generate a given level of profit with a lower level of investment in inventory will generate higher cash flows and better ROIs – Federal Sector: Minimizing inventory investment maximizes available funding for executing validated mission requirements – Optimize capital investment of which inventories are a key component 10-Step Solution Process* • • • • • • • • • • Align Project to Business Goals Clearly Define Project Goals Ensure Buy-In from Stakeholders Identify Variables Collect Data Identify Root Causes Develop Improvement Plan Develop Standard Operating Procedure (SOP) Implement Improvement Plan Develop Control Strategies *Adapted from, Martin, J. W. (2007). Lean Six Sigma for supply chain management. New York, NY: McGraw-Hill. 1. Align Project to Business Goals • Be strategic in marketing your Excess & Obsolete inventory project by focusing on potential long-term business benefits • Align the project with your senior managements’ goals and objectives • Typical business benefits include: – Cost Savings – Cost Avoidance – Benchmarking • All your great work can sometimes be in vain without proper alignment of your project with to your organization’s business goals 2. Clearly Define Project • Project Charter – Objectives – Scope – Overall Approach – to include choice of inventory model for the analysis • Communications plan • Current State Process • Risk Assessment 3. Ensure Buy-In From Stakeholders • Ensure everyone understands the fundamentals of Lean Six Sigma, but vary your focus based on the audience • Executive Training Sessions – Emphasize strategic focus – Emphasize Enterprise benefits • Champion Training – Emphasize Operational effectiveness • Other Stakeholder Training – Emphasize impact on their area of operation 4. Identify Variables • Begin process by asking relevant questions to help you understand how the system works: – How do demand variation and lead time impact inventory? – Is my excess inventory linked to particular suppliers? – How do lot size impact inventory? – What are your current safety levels? – What is my desired target for excess and obsolete inventory? • Define your critical input variables, Xs [Y = f(X)] 4. Identify Variables (EOQ MODEL) Demand rate Inventory Level Order qty, Q Reorder point, R 0 Lead time Order Order Placed Received Lead Time time Order Order Placed Received 16 5. Collect Data • Develop comprehensive data collection plan – – – – Requirements planning Inventory record files Warehouse management system Current metrics • Extract data from IT system/s • Validate system data by conducting a manual count of inventoried items associated with problem • Collect management data, e.g., lead time, lot size, expected demand and its variation, forecasting accuracy, on-time delivery • Organize/align data with inventory model 6. Identify Root Causes • Construct a value stream map for the entire inventory process • Use an inventory model to analyze inventory population to understand how key process input variables impact excess and obsolete inventory, i.e., key process output variables • Calculate target maximum inventory balance for every item and location in population of interest based on each items safety level, lead time, and demand variation • Develop a fishbone diagram to support the root cause analysis process 6. Identify Root Causes Fishbone Diagram Problem: Excess & Obsolete Inventory 6. Identify Root Causes (continued) Some typical root causes associated with excess and obsolete inventory include: • Long lead times – Large Lot Sizes • Poor forecasting accuracy – Inaccurate historical demand data – Poor forecasting model methodology • Poor management – No early warning mechanism to identify build up of excess – No system in place to ensure oldest inventory issued first 7. Develop Improvement Plan • Develop countermeasures to eliminate root causes • Incorporate countermeasures into implementation alternatives • Use cost benefit analysis to select implementation solution • Test solution • Develop pilot plan • Implement pilot and analyze results • Develop full scale improvement plan 8. Develop SOP • Distill important concepts, techniques, and requirements into a format that can be readily used by supply personnel in their regular work • Clearly delineate the various roles and their associated responsibilities and expected performance standards • Don’t rush the SOP! If you do you will have problems during implementation: – – – – Build a team Get organizational support Review and test SOP Ratify and approve SOP 9. Implement Improvement Plan • Leverage SOP to support your implementation plan: – Publicize your SOP and emphasize the significance of the changes being implemented by the SOP – Distribute as needed and make it readily accessible to potential users and stakeholders • Implement change management: – Conduct training classes to ensure personnel understand their roles and have the knowledge and skill to implement – Get buy-in from implementers regarding the change • Develop a mechanism to monitor performance, identify potential problems, and provide support during the implementation process 10. Develop Control Strategies • Monitor and control implementation plan – Sustain monitoring (metrics, control charts) – Show improvement is sustainable. • Assess change effectiveness – Compile before and after operational metrics to validate the success of the implementation – Show impact in senior leader metrics to emphasizes enterprise benefit • Conduct after action review and record lessons learned • Reward key contributors – Builds esprit de corps – Sustains support for the implementation Conclusion • Typical benefits of LSS projects to reduce and eliminate excess and obsolete inventory include: – Accurate demand data – Effective inventory management modeling – Checks to spot and fix excess problems quickly – Effective procedures to issue oldest stock first – Permanent reduction in excess and obsolete inventory – Higher cash flows and better ROIs for private sector firms – Maximizes available funding for executing validated mission requirements in federal sector Questions? Please Contact: Norman A. Pugh-Newby CPPA, PMP Deloitte Financial Advisory Services (m) 240-460-4499 npughnewby@deloitte.com 8. Develop SOP