Testing the Hardness of Various Polymers

advertisement

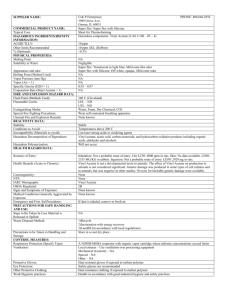

Testing the Hardness of Various Polymers Procedure Question Does molecular weight, concentration, and structure affect the hardness of a polymer? Structure Related to Hardness Step 1: Put on protective goggles and latex gloves. Step 2: Label each micro slide according to its solution i.e. Poly (vinyl acetate) M.W 100,000. Write down observations (shake bottle and record characteristics). Step 3: Label the pipettes 7 centimeters using the permanent marker. Step 4: Collect one solution and cast it onto the opposite side of the micro slide (away from the writing). Step 5: Repeat the steps for the remaining 7 solutions. Write observations and record viscosity. Step 6: Let the polymers dry for two days Step 7: Put on protective goggles and latex gloves. Step 8: Scratch each micro slide by using the following items: fingernail, toothpick, tab of a soda can, razor blade Step 9: Record observations Polyvinyl Alcohol on a micro slide Hypothesis If the molecular weight and concentration increases, then the hardness will also increase. Poly (vinyl alcohol) has a lower molecular weight than polystyrene, therefore it will not be as hard as polystyrene. Figure 2 Table 2 Materials 8 pipettes, 8 micro slides, Polyvinyl Acetate on a micro slide Goggles, Latex gloves, Poly (vinyl acetate) M.W. 100,000 Poly (vinyl acetate) M.W.170,000, Poly (vinyl acetate) M.W. 260,000 Poly (vinyl acetate) 1 g/40 mL Poly (vinyl acetate) 5 g/40 mL Polyvinyl acetate) 10 g/40 mL Poly (vinyl alcohol) Polystyrene Ruler Marker Razor blade Toothpick Tab of a Soda Can A toothpick, a razor, and a tab of a soda can Data Analysis/ Discussion Our hypothesis was not completely supported by the data. After the polymers were cast and had hardened, we tested for hardness using a fingernail, toothpick, tab of a soda can, and a razor (Table 1). Like expected, the polymers with the lowest molecular weight scratched easily with a fingernail and a toothpick (Table 2 and Figure 3). The highest molecular weight of 260,000 scratched with a tab of a soda can. Next, we did the scratch test in polymers that varied only in concentration. As predicted, the polymers with a lower concentration of 1 g/ 40 mL and 5g/ 40 mL scratched with a toothpick, while 10 g/ 40 mL scratched only with the razor. The hypothesis regarding poly (vinyl alcohol) and polystyrene was rejected due to the fact that both of those polymers scratched with the razor. In our hypothesis, we thought that poly (vinyl alcohol) would not be as hard as polystyrene because of its structural differences as seen in Figure 1. Conclusion Based on our results, molecular weight, concentration, and structure does affect the hardness of a polymer. As seen in (Figure 3 and 4), the polymers that had both the highest molecular weights and concentrations not only expressed the highest levels of viscosity, but also scratched with the sharpest objects. Although the structures of poly (vinyl alcohol) (M.W 2,000) and polystyrene (M.W 190,000) are very different, when testing its hardness, the results were the same. In our hypothesis, we had stated that if the molecular weight, and concentration were greater then the polymer would be harder. The data largely supported the hypothesis as seen in Table 2 and Figures (3). However, the hypothesis for was rejected because Poly (vinyl alcohol) was as hard as Polystyrene. Table 1 Figure 1 Melissa Santiago, Bianca Randolph, DaVaun Green, & Jason Rivas Poly (vinyl alcohol) Figure 3 Polystyrene Poly (vinyl acetate) Figure 4