MSE 404 Presentation 12-7

advertisement

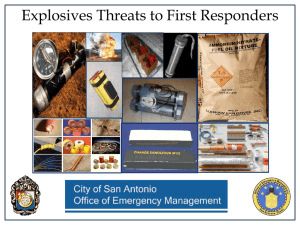

Erin Morris Mining Engineering Outline What I do Why I’m here Basics of Explosives Definitions Classifications Initiation & Sensitivity Insensitive Munitions Polymers in Explosives Binders Plasticizers Special Uses What I do Master’s in Mining Engineering Emphasis in Explosives What is a Mining Engineer Doing Here? • Explosives Engineering is a combination of many other sciences and engineering technologies: (Cooper) Chemistry Materials Thermodynamics Electricity and Electronics Fluid Dynamics Meteorology Aerodynamics Biology Mechanics Physiology The Basics Explosive: “A substance which can be initiated by friction, impact, shock, spark, flame, heating or simple application of an energy pulse; and undergoes a rapid chemical reaction evolving a large amount of heat and exerting a high pressure on its surroundings.” (Agrawal and Hodgson) An explosion will either produce a shock wave, throw fragments, or both www.youtube.com/watch?v=2imofil5GbM&feature=related Definitions Deflagration vs. Detonation Deflagration is a thermal decomposition (burning) Detonation is thermal decomposition completed at shock velocities (burning + shock) Brisance: Speed at which reaction occurs Shattering potential of an explosive Depends on explosive composition and degree of confinement of the blast Classifications Low Explosives Slow reaction with a gradual, extended shock wave and low fragment velocities Low brisance; releases a large amount of energy, but long duration allows energy to dissipate Expansion of the gases used to move projectiles (Propellants) Classifications High Explosives Violent reaction with a short duration, high pressure shock wave and large fragment velocities High brisance; used solely for destructive power High Explosives Trinitrotoluene (TNT) Cyclo-1,3,5-trimethylene2,4,6-trinitramine (RDX) Pentaerythritol tetranitrate (PETN) Initiation & Sensitivity Primary Explosives Very sensitive to heat, impact, friction or static electricity; easily detonated Used in blasting caps to trigger larger secondary charges Secondary Explosives Less sensitive; requires more energy (primary explosive) to be detonated Used in large quantities, more powerful than primary explosives Insensitive Munitions Two goals in design of future explosives Increase performance Decrease hazards during transport and storage Many ways to accomplish this New designs Packaging and mitigation devices Make explosives less sensitive to accidental initiation Polymers in Explosives Functions: Binders Plasticizers Products: Rocket Propellants Plastic-Bonded Explosives (PBXs) Putties, Rubberized & Extrudable Explosives Can be inert or energetic Binders Some consider dynamite as the first use of binders in explosives Alfred Nobel absorbed nitroglycerin into a porous medium (diatomaceous earth) to reduce its sensitivity and allow for safe handling Modern dynamites use a variety of absorbents and additives PBXs Today cross-linked polymers are used to provide a matrix to bind explosives to other components Plastic-Bonded Explosives (PBXs) Polymeric binder coats and suspends the crystals of a powdered explosive Mixture cured to create a tough elastomer which can absorb and dissipate energy from friction and shock Combined with plasticizers, allows PBXs to be pressed and machined Common PBXs Binders in PBXs Plasticizers Plasticizers are mixed with finely powdered explosives to create putties Putties can be molded into almost any shape by hand, and retains its shape unsupported after molding The most common putty explosive in the United States is Composition C-4 Composition C-4 “Special” Uses Rubberized Explosives Mix of RDX or PETN with plasticizers and rubber-type polymers that can be rolled into thin sheets Sheets can be cut to shape, bent, and glued to surfaces DOE LX-02-1 Composition “Special” Uses Extrudable Explosives RDX or PETN mixed with Sylgard 182 silicone rubber and curing agent, forms a thick viscous material that can be extruded After extrusion, temperature can be raised to polymerize and cure the Sylgard Another version from North American Explosives is packaged in small tubes to fit a standard caulking gun Key Point to Remember Name the 2 functions of polymers used in explosives and describe how they work in plastic-bonded explosives (PBXs). Binder Plasticizer In plastic-bonded explosives (PBXs), a binder coats and suspends the crystals of a powdered explosive. This mixture is cured to create a tough elastomer which can absorb and dissipate energy from friction and shock. References Agrawal, J.P., and Hodgson, R.D. 2007. Organic Chemistry of Explosives. John Wiley & Sons, Ltd. Chichester, West Sussex, England. Baird, J. 2010. Class notes, unknown author. Cooper, P. W. 1996. Explosives Engineering. WileyVCH Inc. New York, NY, USA. Provatas, A. 2000. “Energetic Polymers and Plasticisers for Explosive Formulations – A Review of Recent Advances.” DSTO, Aeronautical and Maritime Research Laboratory. Melbourne, Victoria, Australia. www.youtube.com/watch?v=2imofil5GbM&feature=related