Novel current mirrors application in high side current

advertisement

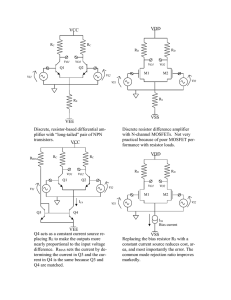

Novel current mirrors application in high side current sensing in multichannel power supplies L. P. Dimitrov G. M. Mitev Nuclear Electronics Lab., Institute for Nuclear Research and Nuclear Energy, Bulgarian Academy of Sciences Reasons for high-side current measurement Rh Iout V Load Um Iin Iout V Load Um Iin Rl • Application specific requirements • Possibility to use “common return” load connection • Possibility to detect output short-circuit conditions • Possibility to measure output leakage currents Problems introduced by high-side current measurement Rh Iout V Load Um Iin • The measurement schematic must be capable of working under the full output voltage • The measurement schematic must have low power consumption Present high-side current measurement solutions • Complex differential amplifier and level shifter circuits – excellent measurement characteristics – require separate high-voltage power supply, usually drawn from the output • Specialized ICs for current sensing in industrial applications – well suited for measurement of larger currents – poor power efficiency in the sub-mA range Goals and tasks • Find a simple and cheap approach for highside current monitoring – evaluate the specifics of using current mirrors for high-side current measurement in detector power supplies – research and analyze suitable schematics – build a test circuit and measure its characteristics Principles of measurement Uin R2 R1 Ub Q2 Ifb Ufb Um R3 R4 I3 Io • Wheatstone bridge, automatically balanced by an active transistor • Balance condition for the Wheatstone bridge Ub=0 • Assuming Ifb=0 um R 2 um io R3 R1 k Types of current mirrors Iin Q1 Iout Iin • Widlar current mirror Iout Q3 Q4 Q2 Q1 Q2 – very simple structure – handicapped by the Early effect – the currents differ by 2*Ib • Wilson current mirror – relatively simple structure – very good current parity Widlar current mirrors schematic R1 Uin Uo R2 Q2 Q1 Q3 Q4 R3 R4 Um • Strong dependence between Um and Uin • Nonlinear for small currents R1 Uin Uo R2 Q2 Q1 Q6 Q5 Q7 Q8 Q3 Q4 R3 R4 Um Wilson current mirror schematic • Minimal dependence between Um and Uin • Almost linear in the range Simulation setup • Wheatstone bridge – R1=100Ω, R2=15kΩ – R2/R1=150 – R3=63kΩ – k=(R1.R3)/R2=420 • Current mirrors – high-side mirror - BC556 transistor pairs – low-side mirror – BC546 transistor pairs – R4=R3 Test board setup • Wheatstone bridge – R1=100Ω, R2=15kΩ – R2/R1=150 – R3=63kΩ – k=(R1.R3)/R2=420 • Wilson current mirrors – high-side mirror – FMMT558 transistor pairs – low-side mirror – FMMT458 transistor pairs – R4=R3 Experimental results U/I 10 10V 1 50V Um [V] 0.1 100V 0.01 150V 200V 0.001 250V 0.0001 300V 350V 0.00001 0.001 0.01 0.1 Iout [mA] 1 10 Temperature response U/I 10 100(35°C) 1 Um [V] 350(35°C) 0.1 100(25°C) ` 0.01 350(25°C) 100(15°C) 0.001 350(15°C) 0.0001 0.001 0.01 0.1 Iout [mA] 1 10 Results analisys • The results clearly show that the Wilson current mirror based schematic is well suited for current measurements in a dynamic range of 2.5 decades • The thermal response over the working range is negligible • The power consumption of the circuit is very small, determined by the R2/R1 ratio Conclusion • The presented circuit is suitable for highside current monitoring in detector power supplies • It has the potential to reduce the component count, board space and manufacturing costs of power supply units • It provides for increased power efficiency, with little or no sacrifice of measurement accuracy