Health and Safety in the Enviornment

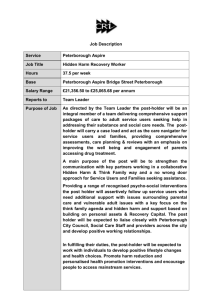

advertisement

Our Journey To Zero Harm L.A.P.A. - NZ Napier November 2014 PROGRAMMED’S SCOPE OF WORK Painting Audio Visual Golf course construction Manage facilities (BHP House, Gatton Prison, Rottnest Island, Schools…) Public Housing maintenance Landscaping Supply and Management of labour (SPC, CCA, Pac Brands...) Water distribution Ships Mechanical & Electrical construction Energy assessment and abatement Diversity of safety culture / expectations >$1,400,000,000 sales >10,000 employees >1,000 contract sites >100 offices Caption Behaviour - Definition “What we do OR What we don’t do” Organisationally Managerially / Supervisory Individually Business Imperatives Cost Delays Quality Equipment Reliability Customers Safety First of the Equals Incident - Definition An Unplanned Event that results in or could have resulted in: An injury Damage to product and / or equipment Loss of product A delay or other loss that impacts on the customer ….a negative Proposition Unsafe work practices – are inefficient! Incident Probability 1 30 300 3,000 30,000 Fatality Slips due to moisture, falls, rolls and hits the back of his skull and dies. Lost Time Slips due to moisture, falls, breaks his arm Medical Treatment First Aid Near Miss Slips due to moisture, falls and sprains his ankle Unsafe Acts & Conditions Person climbs onto a truck rather than using correct height access equipment Slips whilst climbing on the truck, bruises his leg on the framework Management Zero Harm activities Line of sight reviews – Board, ExCo, Divisional, State….. Operational accountability Critical Risk Standards Life Saving Rules System Categories Beliefs Just Culture Effective Supervision & Safety Qualified Supervisors Culture Web Safety Beliefs All injuries are preventable Lets plan and undertake work as if all injuries are preventable and watch this belief prove to be true Working safely is a condition of employment It is a condition of employment at Programmed that you do not work or allow work to be done unsafely – regardless of the positon you hold. You see it you own it! Safety Beliefs Employee action and involvement is essential Everyone must be involved in job planning, tool box talks, safety conversations, and equipment inspections. Are you? Have you asked the questions today, “What could go wrong and how cold anyone be injured doing this work?” I will get the level of safety I demonstrate I want The emphasis is on I. What does your behaviour say is acceptable and safe in the work place? Question - What could go wrong And, How could I or anyone else be injured as we……? Caption Effective Supervision – Journey to Zero Harm Effective Supervision – Journey to Zero Harm Operational excellence Safety excellence is a discipline OPERATIONAL DISCIPLINE EVERYONE DO IT RIGHT EVERY TIME OPERATING EXCELLENCE Our Journey To Zero Harm L.A.P.A. - NZ Napier November 2014