Ahmed Mohamed El-Sayed - The Six International Conference of

advertisement

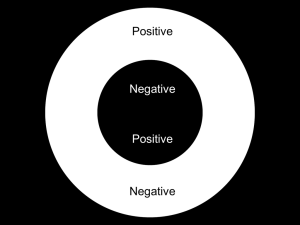

Faculty of Science Physics Department Thin Film Lab Influence of TiO2 Nanoparticles on performance of Fabricated Organic Zener diode Presented By Ahmed Mohamed El-Sayed El-Mahalawy Thin Film laboratory, Physics Department, Faculty of Science, Suez Canal University, Ismailia, Egypt Organic Semiconductors Organic Semiconductors Inorganic Semiconductors Lighter, more flexible, compatible with plastic substrates and have high electron mobility. Rigid and should be prepared on glass, Si, GaAs, ….or any rigid substrate. Disadvantages Biodegradable, and not explained in details yet Needs high vacuum techniques and high cost Processing No vacuum and no high temperature processes(60-120oC) Ultra Clean room Cost Low cost in high large production $5 / ft2 Very high cost $100 / ft2 Advantages Organic Electronics Revolution Organic FET Organic LED Organic RFID Organic PVC First Organic Microprocessor (2015) Experimental Work 0 10 20 80 60 30 20 (C14 H4 O6) 40 o 50 60 (215) 100 40 (300) 500 120 (116) 1000 140 (204) 1500 160 (211) 2000 Spin coated Tio2 (004) Intensity (Arb.Unit) 2500 (200) Intensity (Arb.Unit) 180 (200) As-deposited NTCDA thin film 3000 (101) 200 (100) 3500 70 (2 ) 1- Thin films of NTCDA were prepared using physical vapor deposition technique Edwards E306A 80 0 10 20 30 40 50 60 70 80 2degree) 2- Thin films of TiO2 were prepared using spin coating unit as interlayer between NTCDA and NiTTP Preparation of Organic Zener Diode Characterization the Prepared Devices • The current–voltage (I–V) characteristics of the fabricated devices were investigated at room temperature by using a computerized electrometer 6517B under dark condition -5 -6 1.25x10 2.5x10 NiTPP/NTCDA diode Forward Baising Reverse Baising -6 1.00x10 -5 2.0x10 Forward Baising Reverse Baising -5 -7 1.5x10 7.50x10 -7 5.00x10 -5 1.0x10 -7 2.50x10 -6 5.0x10 0.00 I(A) I(A) NiTPP/TiO2/NTCDA diode -7 -2.50x10 -7 -5.00x10 0.0 -6 -5.0x10 -5 -7 -1.0x10 -6 -1.5x10 -6 -2.0x10 -7.50x10 -5 -1.00x10 -5 -1.25x10 -6 -1.50x10 -16 -14 -12 -10 -5 -8 -6 -4 -2 0 2 V(Volt) 4 6 8 10 12 14 16 -2.5x10 -16 -14 -12 -10 -8 -6 -4 -2 0 2 V(Volt) 4 6 8 10 12 14 16 8 5x10 -10 NTCDA/NiTTP NTCDA/TiO2/NiTTP NTCDA/NiTTP NTCDA/TiO /NiTTP 2 -12 8 4x10 R(Ohm) ln(I,A) -14 -16 8 3x10 8 2x10 -18 -20 8 1x10 -22 -16 -14 -12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12 V(volt) 0 -16 -14 -12 -10 -8 -6 -4 -2 0 2 4 6 V(Volt) Commercial zener diodes Our prepared organic zener diode 15Volt (RD16S ) 15volt( with and without TiO2) Reverse current 21 μA (RD2.0S to RD120S and 1N5221B - 1N5263B) 1.4 μA (without interlayer)and 21 μA (with TiO2 interlayer) Dynamic resistance 3.2 ×104Ω (RD2.0S to RD120S 1.1×106Ω (without interlayer) 2.9 ×104Ω (with TiO2 interlayer) Breakdown voltage 8 10 12 Conclusion • Organic zener diode was successfully fabricated using NTCDA as (N-type semiconductor) and NiTTP as (P-type semiconductor) • TiO2 nano-particels interlayer improved the performance of NTCDA/NiTTP zener diode which was comparable to commercial zener diodes. Future work • We are going to complete this experiment by investigating the effect of interlayer thickness. • We are planning to exploit sensitivity of NTCDA in fabrication gas sensors in the form of diode • We are planning to use this potential organic material NTCDA in photovoltaic applications in elastic forms. The Only Published Organic Zener Diode