Gardening with Greenhouses - Solitude Springs Farm & Vineyard

advertisement

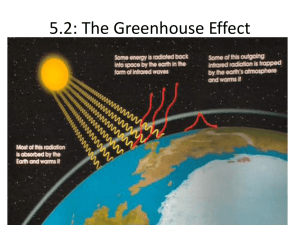

Gardening with Greenhouses Aaron Stierle Solitude Springs Farm & Vineyard Spring 2013 Greenhouses and Concept • Transparent to translucent structures constructed to trap heat and moisture • “Greenhouse effect” - where the short wavelengths of visible light from the sun pass through a transparent medium and are absorbed, but the longer wavelengths of the infrared reradiation from the heated objects are unable to pass through that medium • A major part of the efficiency of the heating of an actual greenhouse is the trapping of the air so that the energy is not lost through convection Greenhouse Effect Benefits • • • • • • Longer growing season Warmer temperatures for heat-loving plants Earlier harvests Can grow greater variety of plants Reduced water consumption Reduced (in some cases) pesticide use Disadvantages • • • • Can overheat – require ventilation Excessive moisture can lead to fungal diseases Require water during rainy season Require annual and seasonal maintenance – Annual maintenance: repair/replace transparent cover, structural preservative treatment, cleaning – Seasonal maintenance: winter snow removal, dust removal during dry season, etc. • Voles can be a problem Construction Ideas • Many options are available – Frame: wood, metal, PVC pipe – Shape: Gothic, peak roof, lean-to, high tunnel, low tunnel – Glazing: glass, rigid plastic panels, clear plastic sheeting (Visqueen). – Size: small (6’ x8’) to large (48’ x 96’) Examples Fig 1. Gothic, polycarbonate Fig 4. Hoop house/high tunnel Fig. 2 Peak, Visqueen, wood Fig 5. Glass, wood Fig. 3 Glass, metal Fig 6. Lean-to, wood, polyc. Foundation • Permanent structures benefit from a foundation • Simple hoop houses (low tunnels) use 2’ or 3’ rebar pounded into the ground and pressuretreated wood to help hold the rebar in place • Anchored cinderblock walls can also serve as a foundation, but frost heaving on permafrost can disrupt them. Foundation/Floor • “Floating” concrete pad – concrete pad poured on gravel bed • Typar/geotextile floor – use durable plastic fabric tacked down with ground staples to prevent weeds and form a floor to walk on, self-draining • Elevated wood floor – use pressure-treated plywood over floor joists and posts • Provide for drainage! Framing • Wood: – Use pressure-treated wood to prevent rot from moisture condensation. Do NOT use CCA treated wood (not marketed since 2003) – Readily available and easy to cut into shapes – Relatively lightweight, but expensive – Use appropriate dimensions to support snowload, can intercept a significant portion of sunlight Framing • Metal: – Strong and durable – Needs proper treatment and maintenance to prevent rust if aluminum is not used – Can use old military-style double-hung aluminum windows as walls of greenhouse – Use caution if covering metal frames with plastic sheeting to prevent tears or snags Framing • Plastic – PVC pipe is readily available, relatively strong, rot resistant, and easy to work with – Typical cross-section is a half circle – Maximum size is limited by strength of PVC pipe – May require removal of the cover during the winter. – End wall construction can be complicated – Can break during very cold weather if hit Shape • Gothic arch: – Sheds snow, maximizes height – Can be difficult to build end walls – Requires bending glazing panels • Peak roof: – Sheds snow if roof pitch is 45 degrees – Best if supported under peak, reduces accessibility • Lean-to: – Attached to a structure Shape • High tunnel: – – – – Rounded top (with or without sidewalls) Greater vertical space available Prone to damage from wind and/or snow; UAF Most successful in snowy/windy climates if cover removed during winter – Maintenance and ventilation can be difficult due to excessive height (often 12 ft high or greater) and sheer volume of interior – Costly to buy, ship, and erect; winter removal – Popular with growers of specialty crops Shape • High tunnel (con’t): – Some have elaborate mechanisms to roll up sidewalls to assist with ventilation – Hoop houses are low-cost version that use PVC pipe and polyethylene plastic sheeting • maximum height only in center and decreases rapidly toward edges • Moderately resistant to wind damage during growing season; hail/heavy rain can be a problem Shape • Low tunnel: – Cheapest, easiest to install; occasional cover replacement – Mini hoop-house design – half circle arch; maximum height only in center and decreases rapidly toward edges – Resistant to wind damage during growing season; hail/heavy rain can be a problem – Usually 3-4 ft high and wide; no end walls or modifications for ventilation – Cover a single row or a raised bed Glazing • Glass: – Long-lasting and no need to replace unless broken – Durable, unaffected by mold or mildew – Can have very high light transmission rates – Very expensive, unless using old windows Glazing • Plastic greenhouse panels (polycarbonate) – Moderately long-lasting; contain UV inhibitors – Precut to standard sizes – Replacement is usually not difficult – Expensive ($1.40/ sq. ft), but typically more durable than glass – Double layer “corrugated” designs add insulating quality – Vary in amount of light transmitted Glazing • Visqueen (clear polyethylene plastic sheeting) – Relatively cheap (5¢/sq. ft.), readily available in a variety of sizes and thicknesses – Lightweight and easy to work with – Varies in light transmissivity, but generally lower than glass and polycarbonates – Least durable, lowest insulating value, tends to billow in wind – Rapidly degrades (<3 yrs) in sunlight Size • Smaller sizes are excellent for backyard gardener • Larger sizes used by commercial growers • Bigger isn’t always better – Ventilation requirements increase with size – More work to keep clean and organized – Repair/replacement costs increase with size • But, sometimes . . . Greater thermal mass Size • Considerations: – What do you want to grow? Compact vs. vining vs. tall plants – What are the heat requirements of your choices – Rectangular shapes tend to generate more heat than square shapes of same floor space when oriented E-W. – Is ground sloping or level? Erecting on sloping surfaces may void greenhouse warranty Size • Considerations (con’t): – What will it shade when erected? – Can all gardening implements be stored inside for the winter? (Dual purpose) – Will it need to be portable/moved – Others? Drawbacks • Excess moisture – Air movement is key to avoiding moisture problems – Ventilation reduces humidity, but also reduces temperature – Portable fans are useful, automatic ventilation mechanisms – Mold and mildew grow rapidly in wet, sunny locations – Some plants (e.g., tomatoes) prone to fungal diseases if foliage remains wet Drawbacks • Reverse greenhouse effect: – Colder temperatures inside the greenhouse than outside. – Occurs during spring and fall when clear skies allow heat to radiate out of the greenhouse, while windy conditions maintain warmer temperatures outside the greenhouse – Occasionally can cause frost damage – Opening greenhouse can mitigate; requires vigilance Drawbacks • Insect infestations: – Greenhouses often shield crops from insects and reduce the amount of pesticides used – However, introducing infested plants into the warm, moist, and crowded structure can spell disaster if not treated immediately; close proximity of plants with similar resistance to disease and insects allows them to spread fast Benefits • • • • • Growing varieties not suited to our climate Extending the growing season Reduced water and pesticide use Reduced cost of food by growing it yourself And it is Locally Grown! And then there was plenty . . .