Chapter 17: Glass and Glazing

advertisement

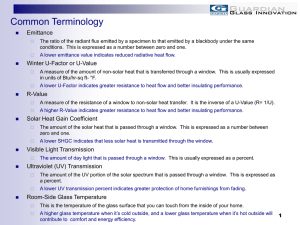

Chapter 17 Glass and Glazing Glass Benefits of Using Glass Allows entry of natural light Provide “views” of exterior environment Entry of sunlight provides warmth Disadvantages and/or Design Considerations Limits occupant’s privacy Lower resistance to thermal transmission heat in the summer & Cold in the winter Initial & operating costs Glass History Material used for Centuries Early Processes (10th Century) Crown Glass Heated glass blown into sphere Reheated & spun on “punty”(rod) Sphere becomes a “disk” Cooled & cut into pieces Cylinder glass Heated glass blown into sphere Swung like a pendulum Elongated into a cylinder Ends cut off, split lengthwise Reheated, opened, flattened into rectangular sheet Cut into pieces Neither had high “optical” quality Glass History (cont.) Plate Glass Introduced in the 17th Century Process Molten glass cast into frames Spread into sheets by rollers Cooled Each side ground / polished Larger sheets of High optical quality Costly (until process was mechanized) Glass History (cont.) Drawn Glass Replaced cylinder glass, early 20th century Flat sheets of glass drawn directly from a molten glass container Production Process Continuous production line - highly mechanized Drawn glass Ground & Polished (plate) To finished sheets of glass Glass History (cont.) Float Glass Process invented in 1959 in England (produced in US, 1963) Has become a worldwide standard Largely replaced drawn & plate glass Production Process (Glass “floated” across a bath of molten tin) Ribbon of Float Glass Process Benefits •Surfaces parallel •High Optical Quality (Comparable to Plate) •Brilliant Surface Finish •Economical •Virtually all flat glass produced Terminology Glazing - “...installation of a transparent material (usually glass) into an opening” I.E. “Glass & Glazing” Glazier A glass installer Lites (lights) Individual pieces of glass Glass as a Material Major ingredient - Sand (silicon dioxide) Strength Individual fibers stronger than steel, but less stiff In larger sheets - microscopic imperfections inherent with manufacturing process significantly reduce its strength Cracks propagate from these imperfections near the point of maximum tension Types of Breakage Thermal Stress Breaks Mechanical Stress Breaks Glass Thicknesses Range of Thicknesses 3/32” Single strength 1/8” Double strength Up to 1”+ Thickness Required is Determined by: Size of Glass Lites (span) Maximum Design (Wind) Loading Acceptable Breakage Rate (most always some breakage) Wind Testing Common on tall Buildings - Purpose: Establish expected loads Mockup for a 24 Story Condo Tempered Glass Ordinary Glass - Annealed glass cooled slowly under controlled conditions to avoid internal stresses Tempered Glass Annealed glass that is: Reheated Surfaces cooled rapidly, core cooled more slowly Induces permanent compressive stresses in edges & faces and tensile stresses in the core Result: 4 times as strong in bending More resistant to thermal stress & impact Tempered Glass When Tempered Glass Breaks: The sudden release of the internal stresses: Produces small square edged particles (as opposed to sharp, jagged pieces) Strength & breakage characteristics make it well suited for: Exterior Doors Floor to Ceiling Sheets of Glass All-Glass Doors, Glass walls (ex; handball courts), basketball backboards Disadvantages More Costly Process may cause noticeable distortions Cutting & Drilling must be prior to tempering Uses of Tempered Glass Heat-Strengthened Glass Substitute for Tempered Glass Lower Cost, but Less of the desirable qualities of tempered Lower strength Less desirable breakage characteristics Process Similar, however Lower induced stresses Less strength (only twice annealed) Breakage characteristics more similar to annealed Laminated Glass Sandwiching Transparent interlayer (PVB) Between layers of glass (can be multiple layers) Bonded under heat & pressure PVB - Polyvinyl Butyral Soft interlayer Can be clear, colored, and/or patterned Improves resistance to sound transmission Upon breakage - PVB holds pieces of glass together Uses? Skylights (overhead glazing) Reduce noise (hospitals, classrooms, etc.) Security glass (typically has multiple layers) Glass PVB Layer Skylight @ the Bellagio Hotel Hurricane Resistant Glass Large Missile Impact Test Laminated and Tempered Fire Rated Glass Required for: Fire rated doors Rated Window and wall assemblies Glass Types Specially Tempered Glass (rated for 20 minutes) Wired Glass (mesh of wire in glass, rated for 45min.) most common, but changes the appearance of the opening Optical Quality Ceramics (20min. to 3hr) Wire Glass Spandrel Glass Interior face Ceramic based paints w/ pigmented glass particles (frits) applied Heated / Tempered to form a ceramic coating Opaque Lite Match or contrast other glass Often tempered - resist thermal stresses behind light Purpose Conceal structure behind glass / curtainwall Spandrel Glass (view from the inside) Spandrel Glass (view from the outside) Spandrel Glass Tinted & Reflective Glass Why tint or apply a reflective coating to glass? Reduce glare from sunlight Reduce solar heat gain Architectural look - Aesthetics Clear Float Glass Absorbed & Reradiated as Heat Outside 85% +/sunlight enters Inside Tinted Glass Reradiated Outside Reradiated Inside Result: •Lower Cooling Costs •Less “sunlight” Glare for people Fading FF&E Tinted Glass Process Chemical elements added to the molten glass Colors available Grays, bronzes, blues, greens, golds, etc. Clear (untinted) Glass Lightly tinted glass Lightly tinted glass Tinted glass Reflective Glass Thin films of metal or metal oxide placed on the surface of the glass Film purpose: Glass Reflect sunlight Reduce solar heat gain Changes Appearance Colored Mirror effect Can be placed on either face, However, often on the inside face Reflective Film Reflective Glass Reflective Glass Reflective Glass Shading Coefficient “Ration of total solar heat gain through a particular glass compared to heat gain through double-strength clear glass.” Shading Coefficient = Heat gain of a Glass type Heat gain thru Clear (double-strength) Tinted glass range: .5 to .8 Reflective glass range .3 to .7 Visible Transmittance “Measures the transparency of glass to visible light (rather than solar heat gain) Ranges: Clear Glass Tinted & Reflective .9 < .9 Glazing Luminous Efficacy (Ke) Ke = Visible Transmittance Shading Coefficient High Ke High amount of solar heat blocked while Considerable amount of sunlight allowed to enter Green & blue glass Low Ke Similar amounts of solar heat & sunlight blocked Darker interior (less light) Bronze, gold, & grays Glass & Thermal Transmission Single Pane Glass 1” Polystyrene “Well” Insulated Wall Thermal Transmission 1/5 of Glass 1/20 of Glass Disadvantage of Glass: Higher Initial & Operating Costs, Reduced Comfort Insulating Glass Two or more sheets of glass separated by an air space Double Glazing: Two (2) sheets Triple Glazing: Three (3) sheets (somewhat uncommon) Primary purpose of additional sheets of glass Improve insulating value - reduce thermal transmission Two (2) sheets - cuts heat loss in half (1/3 for 3 sheets) Increases initial cost but: Reduces operating costs Increases comfort Provides additional architectural options Insulating Glass Spacer (Spline) •Separates the glass •Often Metallic Air Space Glass Air Space •Dry Air or •Inert Gas (such as Argon) Sealant Spacer •“Seals” Unit •Prevent air escape & moisture penetration Glass •Clear, reflective and/or tinted Sealant Insulated Glass (tinted) Insulated Glass (tinted) Metal Spline Low-Emissivity Glass Low-E Glass Insulated Glass Improves thermal performance Ultra-thin, transparent, metallic coating Generally placed on: The #2 or #3 position in insulating glass or The #4 position in laminated glass inside 1 2 3 4 Reflects selected wavelengths of light & heat radiation Allows entry of most short-wave (sunlight) Reflects most longer-wave infrared radiation from objects and humans inside the building Result: Reduced heating & cooling load, increased comfort Thermal Performance Data Obtained from PPG Glass Add Argon 13% Improvement Add “special” spacer Add Low-E Glass 6% Improvement 33% Improvement Clear, insulated, alum. spacer, air filled Glass with Changing Properties Thermochromic glass (darker when warmed by the sun) Photochromic (darker when exposed to bright light) Electrochromic (changes transparency with electricity) Photovoltaic (generates electricity from sunlight) Self-Cleaning Glass Proprietary product w/ coating of titanium oxide Catalyst allowing sunlight to turn organic dirty into carbon dioxide and water Plastic Glazing Sheet Materials – acrylic & polycarbonate More expensive, higher coefficients of thermal expansion Glazing - Small Lights Design Considerations Low stresses from wind loading Low stresses from thermal expansion / contraction Glazier’s points & Putty Wood Stop Snap-in Glazing Beads & Synthetic Rubber Gaskets Glazing - Large Lites Design Considerations Greater spans, Larger wind loads Greater stresses from thermal expansion / contraction Minor Frame irregularities can induce stresses Design Objectives Effectively support glass weight (w/o inducing abnormal stresses) Support glass against wind pressure (both positive & negative) Isolate glass from from the supporting frame & building structure Allow for independent expansion/contraction (glass & supports) Separate glass from support materials that could induce stress or cause abrasion Glass Support & Isolation from Frame Setting Blocks •Synthetic Rubber •Set @ the bottom edge •Often two/lite @ quarter pts. Centering Shims •Synthetic Rubber •Center Lite •Isolate Lit from the Frame Mullion Bite Support against Wind Pressure •Bite •Too little - pop out •Too much - stress w/ glass deflection •Supporting Mullion •Support Glass •Transmit loads to structure Gaskets •“Seals” the Glass (1st line of defense) •“Isolates” glass (from abrasion) •Allows for Thermal Expansion/Contraction •Accommodates Structure/Support deflection Anchorage of Glass to Mullion(s) ‘Dry’ Glazed Lite (using compression) Mullions being anchored to the structure Insulated Glass Gaskets Glass being installed Retainer (compression) strips installed Finished Installation (Snap on Covers applied over the retainer strips) Lock-Strip Gasket Structural Silicone Flush Glazing Mullions on the “inside” of the Glass Glass adhered by Silicone Sealant or Retainer Structural Silicone Flush Glazing Structural Silicone Flush Glazing Butt-Joint Glazing •Head & Sill with conventional frames •Vertical Mullions eliminated •Vertical joints - caulked Butt-Joint Glazing Truss-like Mullions with ‘architectural qualities’ to support wind loading on a tall entrance Weeps / “Drainage” System Sampling of Mullion Colors Aluminum & Glass L.C. Tempered & Laminated Glass Glass support & anchorage Suspended Glazing System Structural Glazing System (exterior) Structural Glazing System (interior) Glass Mullion System tempered glass Glass & Design Methods to compensate for its poor thermal properties Double & triple glazing Low E coatings Low conductivity gas fills Tinting, reflective coatings Curtains, shutters Window sizing & orientation on the building Shading or overhangs Glass & the Building Codes Codes concerned with: Structural Adequacy wind & impact loads Providing natural light in habitable rooms may require a certain glass area as a % of floor area Safety concerns with breakage skylights, overhead glazing, in or near doors, “clear” sheets of glass that could be mistaken for an opening Use of laminated, tempered, etc. Prevention of fire maximum glazed area, wire glass Energy consumption may require double glazing, storm windows, limit the maximum % of glazed area