Tyre cord - TEXTILE LIBRARY

advertisement

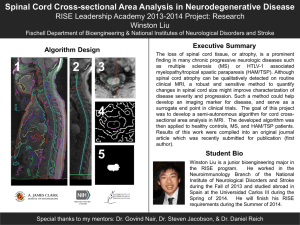

Tyre cord Technical textiles CONTENTS Introduction Parts & structure of tyre cord Function of parts Classification of tyres Raw material in tyre cord Properties of raw material Structure of tyre cord fabric Types of tyre cord Tire cord manufacturing Manufacturing process Uses of tyre cord Advantages of tyre cord Comparison with other material New Developments Cost of tyre cord INTRODUCTION • Tyre is a pressure vessel and cord keeps it dimensionally stable. • Tyres have to carry heavy loads, steel and fabric cords are used in the construction to reinforce rubber compound and provide strength. • Tyre yarns of polyester, rayon, nylon, aramid, glass, or steel are twisted to 5 to 12 turns per inch. PARTS & STRUCTURE OF TYRE CORD • • • • • • • • • • • TREAD RIB GROOVES SIPES SHOULDER CAP PLIES STEEL BELT RADIAL PLIES BEAD CHAFFER BEAD TREAD BLOCK FUNCTION OF PARTS OF TYRE • Tread – it is thick layer (approx. 18-20 mm) of rubber which comes into contact with road. • Rib – it is designed for noise suppression. • Grooves – to traction in all weather, directional control, cool running and all rolling resistance. • Sips – serves as the support for the wheel moving on the road. • Shoulder – upper portion of the side wall just below the tread edge that affects tyre heat behavior and cornering characteristics. • Cap plies – main load baring components layers of fabric cord extending from bead to bead to reinforce the tyre and maintain the shape. FUNCTIONS OF PARTS OF TYRE • Steel belt –located below cap plies to increase tensile strength of tyre. steel belt or layer provides well balanced combination of rubber & fabric. Thickness is 0.2 to 0.38 mm. this are the steel cord plated with copper or zinc. • Radial plies – thin layer of rubber inside the tyre containing compressed air tube. • Sidewall –portion between tread to bead. it is rubber sheet 1.5 to 3.5 mm thick protecting tube from any kind of mechanical or physical damage and moisture penetration. • bead chafer – narrow strip of flex material around the outside of the bead that protects tyre against wear & tear and prevent dirt and moisture from getting into the tyre. • Bead – structure composed of high tensile strength steel wire which holds the tyre assembly onto the rim of the wheel for handling performance. RAW MATERIAL IN TYRE CORD VISCOSE RAYON ARAMIDE TEXTILE MATERIAL Polyester NYLON 6 & 66 PROPERTIES OF NYLON 66 • Nylon 66 tends to form strong interchain hydrogen bonds. This results in a stronger & more crystalline polymer that softens or melts at relatively higher temperature. • It has a higher tenacity and is less subjected to shrinkage. • Better fatigue resistance. • Higher resonance frequency. • No flat spotting. Structure of Tyre Cord Fabric The tyre cord fabric is comprised of warp cords oriented in the longitudinal direction and weft yarns oriented in the lateral direction. The warp cords are used in reinforcing pneumatic tires. TYRE CORD MANUFACTURING • The cord fabric consists of yarns of a linear density of 500 tex in warp and common cotton yarns with a linear density of 16.6-25 tex in weft. • The properties of cord depend on the number of plies of thinner and number of twists to be given in yarn. Processing of Tyre Cord • Most tyre companies produce tyre cord from high tenacity continuous filament yarn supplied by various fiber manufacturers. MANUFACTURING PROCESS Steps of manufacturing tyre cord1. Spinning- By melt spinning we get filaments. 2. Twisting Its purpose is to• To prevent filament breakage. • Improved coherence of yarns. • To improve fatigue resistance. • To improve weaving workability. 3. Cabling- It is done by ply cable winding machine. Yarn tension of about 0.02 cN/tex is recommended. 4. Weaving- 100 or 1500 cords with 3-1 pick per cm of light Cotton, Rayon, PET yarn threads. A type of fabric is obtained in one direction of warp as far stronger than in the other direction. 5. Dipping- During Tire cord dipping process an Adhesive was applied & the fabric is treated under controlled condition of time. After dipping fabric passes through vacuum suction lines to remove the excess dip before entering a drying oven, where water is removed. 6. Vulcanization- It is a process by which rubber is heated with sulphur to create a network of chemical cross-links M/C INFORMATION Tyre Cord fabric manufacturing is carried out on special looms:1. Heavy power looms TT-160 2. Automatic loom AT-175K 3. CTE175-KM Specifications of loom Loom width- 190 - 200 cm (approx) Cloth take-up upto 550 mm or on demand with batching up to 1200 mm. Single warp beam up to 280 cm Weft insertion rate up to 550 MPM Tyre comparision • Aircraft vs. passenger tyre applications: Passenger tyre: all-season tyre, which is built to endure long-term wear while providing adequate performance in almost all conditions. TYPE OF TYRE CORD NYLON TIRE CORD RAYON TIRE CORD TIRE CORD FABRIC POLYESTER TIRE CORD STEEL TIRE CORD PROPERTIES • Nylon tyre cord fabric 1. Optimum reinforcing material 2. High tenacity 3. High toughness 4. Superior fatigue resistance 5. Good adhesion to rubber PROPERTIES • Rayon fabric 1. High initial modulus 2. Improves testing temper about 70-30 degree Celsius Fabric quality is based on its strength, stretch, shrinkage & elasticity • Polyester tyre cord fabric 1. High strength 2. Low shrinkage 3. High modulus 4. Increase extensibility • Steel fabric 1. Tensile strength 2. Elongation 3. Stiffness 4. Superior corrosion resistance 5. High modulus USES OF TYRE CORD FABRIC POLYESTER - MAINLY USED FOR PASSENGER CAR AND LIGHT TRUCK RADIAL TYRES. NYLON- ARE USED AFTER BEGINNING OPERATION OF VEHICLE UTILIZING TYRES. TO REDUCE PRODUCTION COST. ARE USED IN TYRES IN TRUCK, BUS & OFF ROAD VEHICLES. STEEL- IT IS USED INSIDE TYRES. Applications of tyre cord • • • • • • • • • • • Applications Automotive Exterior Passenger car tires Bus and truck tires Earth mover, off the road Industrial tires Agricultural / farm tires Agricultural & excavator tracks Snowmobile tracks Motor cycle tires Advantages & uses of tyre cord Advantages: • Meeting the highest performance, safety, environment and cost criteria • Innovative constructions for a longer tyre life • Enhanced wire-to-rubber adhesion for higher safety • Stronger wires and new cord constructions that lead to lower costs, lower weight and fuel savings Uses of tyre cord • Best reinforcement material: reducing friction Wears between cord threads during compression, bending & stretching Also greatly improves fatigue resistance, endurance life & pressure holding performance. Deals with: Geotextiles & civil engineering. •Innovative constructions for longer life Polyester tyre cord fabric: leads to high break strength, dimensional stability, good in humidity, good creep resistance, high modulus etc. Deals with: hot water bottles , conveyer belt fabric, high modulus low shrinkage yarn. Market view & price ratio of tyre cord • Market Forecast - Tire Cord and Tire Fabric Mills: Market forecasts show the long term outlook for the Tire Cord and Tire Fabric Mills industry. The following fiveyear forecast utilizes advanced econometric techniques that take into account both short-term and long-term industry trends. DEVELOPMENTS & SCOPE OF CORD FABRIC • For high load lifting capacity cord is made for steel yarn. • Cord is manufactured of glass fibers in some countries. • In recent years, cushion cord fabric for these tyre is usually made from stiff fibers with the minimum elongation • belts reinforced with kevlar aramid fiber • Improved rubberized fabric sheets used in waterproof covers, flexible storage bins , frictional surface etc. THANK YOU