Solar Cell Fundamentals Lab – Lecture 8 – Anti

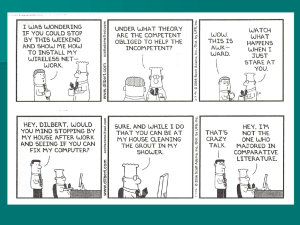

advertisement

There are no FREE lunches Anti-reflective coating A anti-reflective coating is deposited on the top side to help transmit more of the incident sunlight Because the top side conductor has been already fabricated and only low temperature process can be used, the typical process to deposit anti-reflective coating is PECVD PECVD • • • • • Plasma Enhanced Chemical Vapor Deposition PECVD is used extensively in the manufacture of microelectronic devices because it allows for lower temperature processes Just like in sputtering, a plasma is formed in an electric field The plasma allows for the deposition or growth of films at lower temperature than would normally be required in just a CVD process Trion ORION III PECVD tool Typical PECVD Process • The wafer is loaded in into the vacuum chamber • The chamber is pumped to vacuum conditions • The wafer is heated to deposition temperatures (300oC typical) • Gas are introduced that will acts as precursors to the film growth Typical PECVD Process (continued) • Chamber pressure is regulated to provide an equilibrium pressure ( gas in, pumping out) • RF power is applied to the chamber creating a plasma • A film is grown based on the gases introduced For our solar cell • We will be using SiO2 as the antireflective coating • There are better anti-reflective coatings but not available in the Cameron clean room such as SiN or ITO Trion ORION III PECVD Chamber lid open Heated substrate stage Can accommodate up to 8” wafers Trion ORION III water chiller and dry (no oil) chemical vacuum pump Trion ORION III process gas cabinet TEOS (tetraethylorthosilicon) SiO2 precursor The blue tint to the solar cell is the anti-reflective coating