3 - MCDA

advertisement

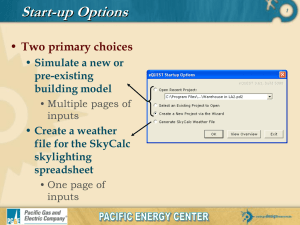

COMMON NON-STRUCTURAL FAILURES State of Michigan P.A. 54 Approval # Pending Class Category: Specialty Registration Category: BI or Bo/PR but no inspector registration Hours Approved: 3 Instructor – Larry Pickel: Approval # 121 DISTINCTION BETWEEN CONSTRUCTION RELATED FAILURES STRUCTURAL • Relates to the primary structural framing system • Failure to carry or transfer imposed loads • Result is partial or total collapse of the structure • Primarily related to footings, foundations, beams, rafters, trusses and joists NONSTRUCTURAL • Relates to either nonstructural or localized component elements • Failure results in additional hazards to occupants short of total collapse • Begin as problems, maintenance issues • Eventually may grow to become a structural failure STRUCTURAL NONSTRUCTURAL Many nonstructural failures will eventually become structural failures given enough time and lack of attention Many nonstructural failures will remain so if addressed in a timely manner by competent personnel FACTORS CONTRIBUTING to CAUSES of NONSTRUCTURAL FAILURES LAPSES or CARELESSNESS IGNORANCE Lack of proper coordination; general negligence; conscious risk taking RISK ECONOMY Lack of sufficient information; lack of competence; lack of supervision or precedent UNUSUAL OCCURRENCES In first cost; in maintenance Earthquakes; extreme storms, fires; floods; explosions; sabotage Based upon: The Nature of Structural Design & Safety Building Failure Blockley, D.I. McKaig, Thomas H. RELATIONSHIP OF MAIN CODES DEALING WITH NONSTRUCTURAL FAILURE IBC B 101.4.5 B 102.6 B 103.3 B 3401.3 & 3.2 IPMC B 101.4.6 B 102.6 B 201.3 + R 102.7 IRC R 102.7 IFC B 101.4.5 Property maintenance. The provisions of the International Property Maintenance Code shall apply to existing structures and premises; equipment and facilities; light, ventilation, space heating, sanitation, life and fire safety hazards; responsibilities of owners, operators and occupants; and occupancy of existing premises and structures. B 101.4.6 Fire prevention. The provisions of the International Fire Code shall apply to matters affecting or relating to structures, processes and premises from the hazard of fire and explosion arising from the storage, handling or use of structures, materials or devices; from conditions hazardous to life, property or public welfare in the occupancy of structures or premises; and from the construction, extension, repair, alteration or removal of fire suppression and alarm systems or fire hazards in the structure or on the premises from occupancy or operation. R 102.7 Existing structures. The legal occupancy of any structure existing on the date of adoption of this code shall be permitted to continue without change, except as is specifically covered in this code, the International Property Maintenance Code or the International Fire Code, or as is deemed necessary by the building official for the general safety and welfare of the occupants and the public. Administration Exterior /Interior PME Fire safety IPMC IFC 1 3 5- 6 7 1 3 6 7 8 9 10 CORRELATION OF PRIMARY CODE SECTIONS Administration General precautions Services / systems Fire resistance rated construction Interior finishes Fire protection systems Means of egress CODE APPLICATION Administration 1 PM IPMC: 101.2 Scope. The provisions of this code shall apply to all existing residential and nonresidential structures and all existing premises and constitute minimum requirements and standards for premises, structures, equipment and facilities for light, ventilation, space, heating, sanitation, protection from the elements, life safety, safety from fire and other hazards, and for safe and sanitary maintenance; the responsibility of owners, operators and occupants; the occupancy of existing structures and premises, and for administration, enforcement and penalties. Administration IFC: 1 F 101.2 Scope. This code establishes regulations affecting or relating to structures, processes, premises and safeguards regarding: 1. The hazard of fire and explosion arising from the storage, handling or use of structures, materials or devices; 2. Conditions hazardous to life, property or public welfare in the occupancy of structures or premises; 3. Fire hazards in the structure or on the premises from occupancy or operation; 4. Matters related to the construction, extension, repair, alteration or removal of fire suppression or alarm systems. General 1 102.2 Maintenance Equipment, systems, devices and safeguards required by this code or a previous regulation or code under which the structure or premises was constructed, altered or repaired shall be maintained in good working order. PM CATEGORIES OF NONSTRUCTURAL FAILURES FAILURE of MATERIALS Wood, masonry & concrete FAILURE of FAILURE of ENVELOPE or COMPONENTS Roofing, ice dams, flashing, siding, EIFS SYSTEMS Plumbing, mechanical, electrical FAILURE of FIRE SAFETY MEASURES Occupancy, construction type, fire resistance, fire protection systems, means of egress CLASSIFICATION of ENGINEERING MATERIALS CERAMICS ORGANICS IONIC BOND COVALENT BOND Inorganic, nonmetallic, crystalline compounds Positive and negative ions in a stable arrangement Chemically inert High melting points Brick, tile, cement, stone, clays, gypsum, glass An organic, non-crystalline material Mutual sharing of outer valence electrons Bond easily altered by heat or force Low strength, low melting points COMPOSITES Made of two or more materials from other groups Usually one material acts as a binder, one acts as a reinforcement Concrete, fiberglass, alloy steel METALS METALLIC BOND An inorganic substance made up of one or more metallic elements Close packed, crystalline structure Ions are stable within a dispersed “sea” Strong, high melting points Copper, iron, aluminum, zinc, tin Wood, plastics Mainly carbon + hydrogen atoms also known as hydrocarbons. Hydrocarbons arranged in long chains: Natural: wood, cotton, wool, silk Synthetic: thermoset & thermo plastic COMMON NONSTRUCTURAL WOOD FAILURE WHITE ROT BROWN ROT INSECT DAMAGE Sometimes mistakenly referred to as “dry” rot – a misnomer since moisture is required for rot to occur OTHER MASONRY FAILURE of MATERIALS Ceramic material-clay or shale formed, dried and fired Extruded (stiff mud) – Major method of production All bricks have similar chemical compositions Clays all composed of silica and alumina with metallic oxides in varying amounts Brick construction considered homogenous. Bonded into integral mass by mortar, grout, steel. Behavior of the “combination” that determines integrity. Assembly more important than component. Interaction of materials determines performance. COMMON NONSTRUCTURAL MASONRY FAILURES CRACKING WALL MOVEMENT EFFLORESCENCE LOSS OF INTEGRITY MASONRY CRACKING “Nonstructural cracking” leads to structural cracking Cracking associated with thermal / moisture movement. Expansion contraction cycle. Stresses built up in walls that must be resolved. Wide variety of cracking patterns. Most common are vertical and horizontal shear pattern. Cracks typically open and close cyclically. Damage always left behind. Unit nature of masonry – lots of edges and surfaces. Inherent weak nature of the mortar / masonry bond. Typical shear failure modes, both vertical and horizontal. Vertical usually due to settlement. Horizontal due to wind or expansion/contraction cycles. Cracking associated with horizontal shear Between upper wall and wall entering the ground Differing rates of thermal expansion Cracks will take line of least resistance Vertical / diagonal cracking at end walls Usually due to thermal movement No tensile strength in wall to “pull” end wall along Classic 45° shear crack pattern radiating from atop a window lintel and near the end of the building Common thermal / moisture masonry wall crack Thermal expansion crack showing loss of vertical mortar integrity and opening for further damage Cracking associated with water penetration Cracks at or along areas near sills and lintels Can be due to use of dissimilar materials Can be due to poor detailing Can be due to loss of integrity of lintel itself Exterior / Interior 3 304.2 All metal surfaces subject to rust or corrosion shall be coated to inhibit such rust and corrosion and all surfaces with rust or corrosion shall be stabilized and coated to inhibit future rust and corrosion. Oxidation stains shall be removed from exterior surfaces. Surfaces designed for stabilization by oxidation are exempt from this requirement. PM Thermal crack at mortar joint showing exposed reinforcing Cracking associated with rusting or iron/steel Corrosion of embedded metals creates rust Expansive force builds up on surface of metal Places pressure on surrounding masonry / displaces it Rusted shelf angle Movement begun by rusting of shelf angles and lintels at perimeter of structure Window lintel corrosion causing movement Rusting lintels causing a swelling of the surrounding brick surfaces MASONRY EFFLORESCENCE Efflorescence is a process. Visible as a crusty, white salt deposit leached to the surface. Requires presence of salt and moisture Salts are present in the mortar, bricks and blocks. Salts are carried to the surface and left behind after the evaporation of the water Efflorescence and water damage on brick steps Resultant loss of surface material due to excessive efflorescence and moisture movement Internal efflorescence and damage due to moisture migration MASONRY LOSS OF MASS INTEGRITY Unit masonry, mortar and reinforcement act as a unit and failure of any part usually results in subsequent failure of the assemblage. Localized failure areas caused by a variety of sources. Loss of integrity due to moisture migration and improper tooling of the joints Extensive loss of bond between brick and mortar. Hard, low suction brick; high cement mortars; improper tooling of the joints. Spalling and movement due to moisture penetration of the masonry wall CONCRETE FAILURE of MATERIALS 3–8% Air Coarse Aggregates Cement 15 % 31 % Fine Aggregates 28 – 30 % Water 18 – 21% COMMON NONSTRUCTURAL CONCRETE FAILURE TYPES DUSTING SCALING CRAZING CRACKING BLISTERS DELAMINATION DISCOLORATION Some cracks do lead to progressive deterioration. CATEGORIES OF NONSTRUCTURAL FAILURES FAILURE of MATERIALS Wood, masonry & concrete FAILURE of FAILURE of ENVELOPE or COMPONENTS Roofing, ice dams, flashing, siding, EIFS SYSTEMS Plumbing, mechanical, electrical FAILURE of FIRE SAFETY MEASURES Occupancy, construction type, fire resistance, fire protection systems, means of egress COMMON NONSTRUCTURAL BUILDING ENVELOPE FAILURES ROOFING ICE DAMS FLASHING SIDING EIFS Estimated that 99% of envelope failures involve intrusion of WATER Some effects of unwanted water on the building: • Adds weight to the structural system Increases /alters load distribution path • Creates energy loss adding to energy bills Wets materials as it moves Damages building skin and interior Creates new gaps and paths for air / water • Sustains rotting and corrosion of materials Frequently hidden and silent damage • Degrades connections and attachments Weakens connecting materials at joints ROOFING FAILURE of ENVELOPE or COMPONENTS Common roofing system types: • BUILT-UP ROOFING (Multi-ply) • MODIFIED BITUMEN • SINGLE PLY MEMBRANE Elastomeric (EPDM) bonded by adhesives Thermoplastic (PVC) heat welded • ASPHALT SHINGLES Exterior / Interior 3 304.7 Roofs and drainage. The roof and flashing shall be sound, tight and not have defects that admit rain. Roof drainage shall be adequate to prevent dampness or deterioration in the walls or interior portion of the structure. Roof drains, gutters and downspouts shall be maintained in good repair and free from obstructions. Roof water shall not be discharged in a manner that creates a public nuisance. PM BUILT-UP ROOFING PROBLEMS Old reliable commercial roofing system. Buildings with low-slope or “flat” roof structures. Started in the 1840's. Often referred to as "tar and gravel" roofs. Multiple plies of roof felts laminated together with bitumen. Felts are organic-fiber, fiberglass, or polyester felt. Top-surfacing or a glaze coat of asphalt, gravel or slag. Some use a granule-surfaced cap sheet. Blisters are the result of a void created either between the felt plies or the membrane and substrate. Membrane surface then slides, exposing bitumen / plies Splitting of a built-up membrane develops from the bottom up. No real advanced warning. General cause is a concentration of stress. Insulation boards move, buildings settle, substrates shrink and roofing cannot accommodate the movement. Small hole (Possibly from a careless dropped screw driver) in built-up roof with 72 Lb. granulated cap sheet. Blisters in this asphalt mopped built-up roof membrane system caused from age and from standing water weight. Recent ceiling damage to the Unity Temple in Oak Park, Illinois designed by Frank Lloyd Wright. The result of a flat roof, decayed over time, and drywall directly attached. MODIFIED BITUMEN ROOFING PROBLEMS Asphalt-based, close cousin of the Built-up-Roof (BUR) . Originated in Europe in the mid 1960's. Used in the United States and Canada since approx. 1975. Blend of synthetic rubberized polymers with asphalt. Use of fiber-reinforced base sheets. Increased resistance to brittleness at cold temperatures. Numerous surfacing options include a factory applied mineral surface, gravel surface, “cool roof” coatings. Older version of a modified bitumen roof Example of seams done very well, smoothly Single largest problem - defective lap seams. Open seams occur due to inadequately heated asphalt. Positive bond rarely achieved with lower temperatures. Membrane shrinkage is another inherent weakness. SINGLE-PLY MEMBRANE PROBLEMS Grown in popularity as a preferred commercial system. Membranes are large, strong, flexible sheets. Membranes are joined by adhesives or heat welded. Predominately synthetic polymer. Generally consistent quality of membrane/accessories. Importance in following manufacturers instructions. Many membranes highly-reflective “cool roof” surface. Membranes prior to welding into monolithic seams Single ply PVC membrane roofing system Problems include shrinkage of the membrane, especially in those laid loose or ballasted. Durable bonds are difficult to achieve with certain chemically inert membranes. Incorrect flashings and failure of flashings caused by shrinkage of the membrane. Mechanical damage such as puncturing from surface traffic, tools, and from below from protruding fasteners. Flashing laid in a non-shingle fashion has failed and begun to affect this early EPDM membrane roof ASPHALT SHINGLE PROBLEMS Asphalt granules Slow the flow of water Reduce the erosion across the shingle Shield the asphalt from direct sunlight Developed over a century ago. Originally organic base of wood fiber and asphalt. Today fiberglass reinforced shingles dominate market. Available in basic “three-tab” design Middle-range “dimensional” or “laminated” shingle Thickest are “top-of-the-line” heavyweight BARESPOTS Loss of mineral granules on the surface of the shingle. Loosening of a protective coating – reduces shingle life. Granules protect shingle from sunlight and slow runoff. Shingles become porous where granules are washed off. May cause shingle to leak into substrate material. Freeze / thaw cycles may accelerate in areas of granule loss. Some damage may be caused by workers / walking. Some loss due to storms / hail. Some loss due to other conditions including blistering. Massive area of loss from multiple factors including weather An under-ventilated attic, showing the roof surface granule loss from being “baked” from beneath. BLISTERS Small areas of bubbling shingle surfaces. Tops usually loose granules and begin to expose substrate. Some manufacturers claim blistering is aesthetic only. Some insist it is not a manufacturing defect. Potential shingle wear pattern at blister sites. Characteristic of granule loss at these areas. Estimated by some 5% - 15% shingle life reduction. Blister has deteriorated and “popped” exposing substrate. BUCKLING aka. FISHMOUTHING Distortion of the shingle generally in the center. Curves upward in similarity to the mouth of a fish. Isolated cases can occur when nails are under-driven. Isolated cases also occur when nails back out of a deck. General views of a fish mouth buckling pattern Larger areas usually indicate a systemic building problem. Usually combination of roof moisture / ventilation defects. Occur typically over butt joints between individual shingles. Excessive under-roof moisture usually suspected. Poorly or un-vented attic of roof cavity. Moisture escapes at the joints and at the surface mid-tab. Moisture loss “uneven” and leads to an isolated raised portion. CLAWING Leading edge of the shingle strats to draw under itself. Creates a “clawing” like profile. Typically as shingles age - generally only near end of life. Diagram of typical clawing pattern CRACKING Actually a tearing of the shingles in most cases. Cited by some as the principal current problem with fiberglass-based roof shingles. Some due to lack of compliance with ASTM Standards. Fiberglass mat may lack tear resistance capability. Variety of patterns: horizontal and vertical. Also possible due to excessive bonding of adhesives. Creates a single, large, stiff roof membrane diaphragm. Roof is not resilient, is unable to flex with movement. Freeze / thaw temperature cycles important variant. CUPPING Raised edges curl downward leaving concave center. Normal wear pattern showing up on shingle with age. Shingle has become fragile and near the end of life. Extremely fragile, cupped edges. CURLING Curling up at the edges of the shingle tab. Again usually due to aged, worn out shingles. Curled and cupped shingles may be present on same roof. Cupped and curled roofing surface GROWTHS Algae, fungus, lichens, moss all may grow on shingles. Hold moisture against the roof surface. Accelerate deterioration during freeze / thaw cycles. Much more than a simple cosmetic issue. Moss related to absence of sunlight / presence of shade. Lichens much stronger to grip than moss. Cleaning process risks more harm to shingle surface. A roof in need of complete replacement showing growth along with advanced shingle decay