Physics of the Pinewood Derby

advertisement

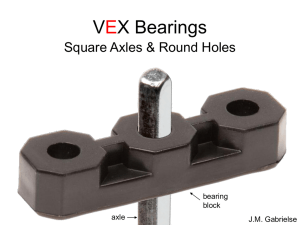

The Physics of Pinewood Derby Indiana State University John Swez, Ph D Presenter 1 What effects negate a winning race? • Wheel/Axle Friction including Friction between the wheel and the rail • Aerodynamic Friction • Loss of M g h • Track Differences • Excessive Wheel UnBalance 2 Read Your Rules! Rules Differ from District to District Excerpts from Wabash Valley District Rules regarding Wheels and Axles “The wheels must be from the official BSA Pinewood Derby Kit or official replacement wheels.” “The axles must be from the official BSA Pinewood Derby Kit or official replacement.” “Axles must be firmly attached to the base of the car.” “No suspension system may be used.” “Wheels must not be altered in any way. Mold projections on the wheel treads may be removed by sanding lightly but the profile of the tire may not be altered. The act of “shaving “ the wheels will be grounds for disqualifying. “ “The wheels must be attached to the car with the axles (nails) provided in the kit(s). No cars will be accepted in the District Derby where added fender liners that contact the wheels, bearings, bushings, washers, hubcaps, solid axles or spacers are used as part of the wheel assembly.” “The official wheel width is 0.034 “. All four wheels must be vertically mounted on the sides of the car.” 3 Winning Pinewood Derby cars from Pinewood Pro 4 Reducing Rolling Wheel Friction Reduction of Friction on the axle surface and behind the head of the axle (nail) The axle (nail) surface can be polished using the above jig and progressing in the direction of coarse to finer abrasives. Sandpaper coarse to very fine grit (400 to 1200 grit) is a suggestion. Then use metal polish, jewelers rouge and comet (or similar abrasive cleaner). Add water to make a thin paste. 5 Metals used in Pinewood Derby axles are relatively soft. Nail and rod-type axles can be hardened with heat. When heated to a red-hot state and then immediately dropped into a cup of water, the axles will increase in hardness such that the lubricant will have little or no effect on the metal. Axle Warning: Adult Supervision Must Be Used! Sequence Remove Burrs and Form Taper Grooving (optional) Heat with propane torch and Quick Chill in Tap Water(Hardening) Polishing 6 Grooving (Optional) The area of contact between the wheel and the axle creates friction. This area can be reduced by creating a few grooves in the axle at the location where the wheel touches the axle. Not only is the area reduced, but the grooves provide a reservoir for the lubricant. Grooving should be performed before hardening. Note that the act of “grooving” seems not to be prohibited in the Wabash Valley District rules. First place the wheel on the axle and make a pencil mark on the inside of the wheel hub then remove the wheel. Place the axle in the chuck of a drill, mount the drill securely and start it. Using the file make two or three slight grooves on the axle between the axle head and the pencil mark. Do not make deep grooves.** ** Note! Some people have used a tap to make threads inside the hub of the wheel to reduce the area of contact. This has a disadvantage of the threads causing the wheel to move from side to side. Under interpretation of the Wabash Valley District Rules this may be illegal. “Wheels may not be altered in any way.” 7 Lubrication (use proper gloves for handling) The Wabash Valley District Pinewood Derby Rules for 2010 on Lubrication: “Lubrication – Only graphite powder or the new BSA white-lube T102/polytetra fluoroethylene may be used to lubricate wheels. “ “NO GRAPHITING OF THE CAR PRIOR TO CHECK-IN IS ALLOWED INSIDE THE BUILDING” The following is taken from Pinewood Derby Times - - Volume 1 page 24 1. Insert a wheel onto the axle. 2. Hold the axle with the wheel hanging towards the ground. 3. Deposit some lube into the gap between the axle and wheel hub. 4. Tap the wheel gently to help move the lube down into the wheel hub. 5. With one hand firmly grasp the axles and hold the axle horizontal to the ground. 6. With the other hand, spin the tire firmly, but not so much as to drop the wheel/axle. 7. Repeat step 6, nine more time. After performing this procedure the first time, keep the wheel axle pairs as a unit until they are attached to the car. 8 Other Important Areas to Lubricate 1.Inner and outer sides of the wheel hubs 2.Inner and outer edges of the wheels 3.Wheel Tread 4.Car Body 5.Clean-Up Only certain types of lubrication should be used. Check with your District Rules 9 The placement of lead weights (Make Mgh as large as possible) M g h (Mass in kilograms, g = 9.8 m/s/s and h is height in meters. Mgh is potential energy measured in joules (a physics unit of energy). I recommend using lead weights. Lead is quite dense, easily shaped and inexpensive. On the downside, lead is toxic if taken internally. Use care after working with lead: (1) wash your hands after handling lead, (2) Keep lead away from food and food preparation areas, (3) Collect and use (recycle) Any remaining lead pieces, and (4) Do not melt lead unless you have a professional do it. In some cars with the rear axle slot nearer to the rear use this slot. You want the rear axle allow the center of gravity of the car to be located closer to the rear end. The optimal balance point is generally 1” to 1 ¼” j front of the rear axles. Center of gravity can be found by balancing the pinewood derby car on a ruler edge. 10 Other Useful Hints 1. Use a #44 drill bid (available at your local building supply or hardware store) for relocating axles. 2. Blow all lubricant off (esp. if using dry graphite powder) before taking your car in. Do this step outside. 3. Use Elmer’s white or yellow glue for wood to wood parts. Use quick drying epoxy for weights, etc. 4. Pay attention to balance. Test your car out on a makeshift track. Look for excessive vibration, movement from side to side. 11 Data Run Using the Derby Magic1 Single Lane test track 1The Derby Magic Company 2785 Walnut Lake Rd. West Bloomfield, MI 48323 248-432-2754 After a week of work (sanding, filing, tuning up, assembly) the Pinewood Derby Magic test track is operational. Here is some first run data. Drop in to S-135 to see it operational. 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 2/26/2010 Date 15:47 15:48 15:49 15:50 15:51 15:53 15:54 15:55 15:57 15:58 2.1599 2.1587 2.1725 2.1618 2.1679 2.1649 2.1752 2.1693 2.1717 2.1717 Time (s) First successful run Car 59 un-lubricated Courtesy of Joe Harder All data in seconds Average 2.16736 seconds Std. Deviation 0.00574 seconds Standard Deviation of 6 milliseconds is not bad! It shows repeatability. 12 13 14 15 16 Two cars were made identical. Car 01 has a raised right front wheel Car 02 is made normal 18 If you desire a copy of this PowerPoint Presentation you can go to my web page at: newton.indstate.edu/swez Look for a Link here Derby Track in Room S-135 of the Science Building at ISU