Small Engine Theory

advertisement

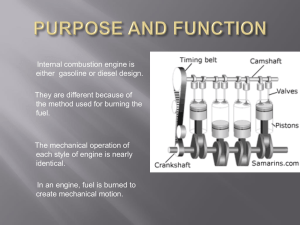

Small Engine Theory What is the purpose of a Small Engine? When does a small engine Get classified into a large engine? Internal Combustion Engine Internal: To happen inside Combustion: Burning of some sort of fuel and air. Engine: Converts heat energy into a useful mechanical energy. Four Main Parts Piston Connecting Rod Cylinder Crankshaft Piston A plunger that slides in the cylinder converting heat energy into mechanical energy Light weight material (Aluminum alloy) so it can spin at high revolutions per minute. Must withstand pressures up to 2,000PSI Must withstand heat up to 1,200 F Must not expand Connecting Rod Used to connect the piston to the crankshaft I-Beam construction, saves weight and makes the rod stronger. Connecting rod cap is bolted to the end with the use of two hardened bolts. Piston pin connects piston to the connecting rod Cylinder Made from Aluminum alloy or Cast iron TWO PARTS OF THE CYLINDER ARE: Cylinder Head Cylinder Block Cylinder Head Houses the combustion chamber and the spark plug. I-Head (OHV) Houses:all the above plus valves, seats, valve guides, intake and exhaust ports, rocker stud, pushrod guide plate. Cylinder Block The foundation for all moving parts. Houses the cylinder: the area the piston moves up and down in. Houses the crankshaft Makes-up the crankcase, area where the crankshaft rotates. Houses the following in a L-head engine; Valves Valve Seats Intake and Exhaust Ports Valve Springs and Retainers Tappets Camshaft Crankshaft Made of nodular steel. Changes Reciprocating motion into rotary motion. Parts PTO JOURNAL ROD JOURNAL MAGNETO JOURNAL COUNTER-WEIGHTS FLYWHEEL Carries the crankshaft through the three non power producing strokes. A heavy weight; takes a lot of energy to start and stop Provides the crankshaft with inertia. COMBUSTION CHAMBER Area in the cylinder head where fuel and air are burned. Spark plug is always located in the combustion chamber. Fuel A combustible that will burn effectively in the combustion chamber Types Gasoline (petro) Diesel Propane Compressed natural gas Fuel Stages Liquid Atomized Purchased and delivered to the carburetor in this state. Carburetor mixes with air in this state. To the proper stochiometric ratio of 14:1 air to fuel Vaporized Fuel becomes a gas in the combustion chamber on the compression stroke Valve train All components that allow for the transfer of fuel and air both fresh and burnt. Valves Open and close the combustion chamber. Seals the combustion chamber. Allows for the transfer of fuel and air. Valve seats Inserts in the block or head that allow the valves face to rest on, and to cool and seal the combustion chamber. Made from high carbon steel to withstand high heat and pressure. Valve guide Tube like structure in the head or block that guides the valve, and is concentric with the valve seat. Valve spring Used to keep the valve closed. Valve Retainers Used to retain the valve spring onto the valve. Camshaft Used to open and close the valves at the proper time (phasing), for a specific length of time (duration). Driven by the crankshaft. Gear, chain or belt driven Tappets/ Lifters Used to transfer the motion of the camshaft to the valve (L-head) or the push-rod (ohv) Passageways Fuel and Air must pass into and out of the combustion chamber. Fresh fuel and air is called INTAKE Burnt fuel and air is called EXHAUST Cylinder head passageways are called PORTS MANIFOLD passageways are called RUNNERS Four stroke cycle Intake Compression Power Exhaust Intake stroke Piston moves down from TDC to BDC. Cylinder creates a vacuum. Fuel and Air rush into the cylinder when the Intake Valve opens. Cylinder is now filled with the fresh fuel and air charge. Exhaust valve stays closed. Compression Piston moves from BDC to TDC. Fuel and Air is squeezed so tight that heat is generated. Fuel becomes Vaporized. Intake and Exhaust valves are closed. Power Piston moves from TDC to BDC. Fuel and air is Ignited by the spark plug. Fast burning of the fuel creates a tremendous heat and pressure increase. Pressure forces the piston down with 2000 PSI of Force. Both the Intake and Exhaust valves are closed. Exhaust Piston moves from BDC to TDC Exhaust valve opens, Intake stays closed Burnt fuel and air is forced out of the exhaust Ports and exhaust manifold Runners. Four stroke cycle HEAD AND BLOCK CLYINDER BLOCKS ALUMINUM BLOCKS CYLINDER SLEEVES GREY IRON CYLINDER HEADS Alloys RECIPROCATING PISTONS RINGS AND RODS PRESSURE AND TEMPERATURE PRESSURE AND VOLUME ENERGY CAMSHAFT CAM PHASING COMBUSTION CHAMBER TURBULANCE GASKETS