Post Harvest Physiology

advertisement

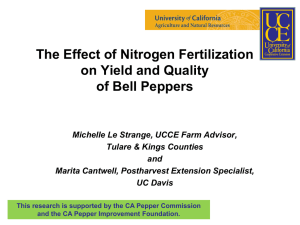

POSTHARVEST HANDLING OF BRAMBLES PENELOPE PERKINS-VEAZIE NCSU KANNAPOLIS NC penelope_perkins@ncsu.edu DIFFERENCES FROM OTHER CROPS • • • • MUST BE FULLY RIPE MUST PICK INTO FINAL CONTAINER NO WASHING RAPID COOLING AND COLD CHAIN CRITICAL • NO MECHANICAL SORTING • CONSUMERS EAT WITHOUT WASHING SYSTEMS 1. ON FARM/FARMERS MARKET -U Pick -Pick into larger containers (quart) -Softer varieties can be used 2. SHIPPING -Pick into small containers (pint) -Cold chain management is critical -Use only firm varieties STEPS FOR QUALITY PREHARVEST • VARIETY SELECTION • CONTAINER • HARVEST/HANDLING SYSTEM FIRST STEP IN POSTHARVEST LIFE: VARIETY SELECTION FIRMNESS: GET IT OFF THE PLANT WITHOUT LEAKING SHAPE AND SIZE: ROUND/LONG, LARGE /SMALL (WHAT FITS YOUR PACKAGE AND MARKET?) SHELF LIFE: DECAY RESISTANCE, TRANSPORT RESISTANCE OTHER DEFECTS: SUNBURN, RED DRUPE FIRMNESS (COMPRESSION) LBS FIRMNESS FOR EACH COMMODITY 6 5 FIRM 4 3 SOFT 2 1 0 BLUEBERRY STRAWBERRY BLACKBERRY RASPBERRY FIRMER IS MORE RESISTANT TO BRUISE AND LEAK SELECTIONS NATIONAL SHIPPING NAVAHO NATCHEZ APACHE ARAPAHO OUCHITA CHESTER THORNLESS NUMBER OF BERRIES PER PINT 40 NAVAHO 40 ARAPAHO 35 CHESTER 30 OUACHITA 25 APACHE 25 NATCHEZ CONTAINERS • PLASTIC CLAMSHELL • ½ PINT, PINT, 12 AND 18 OZ (NO MORE THAN 3 LAYERS) • VENTED ON TOP AND SIDES • UPICK/FARMERS: QUART AND LARGER CONTAINER STACKABLE 2 LB BASKET FOR LOCAL ONLY CLAMSHELL WITH ROUND HOLES CLAMSHELL WITH SLITS MASTER FLATS OR CARTONS REINFORCED CORNERS SIDES STACK VERTICALLY FORCED AIR VENTS HOLD 12 CLAMSHELLS MASTER WITH AIR VENTS TOP FLAT GUARD PICK FULL BLACK, FIRM BE GENTLE! KEEP FRUIT SHADED WHILE PICKING 70F 80F SHADED SIDE N-S PLANTING DON’T OVERFILL MOLDS/FUNGAL PICK EVERY 2-3 DAYS TO AVOID OVERRIPE AND DECAYED FRUIT PICK OFF OVERRIPE/DECAYED FRUIT AND DISCARD BOTRYTIS-GRAY MOLD OTHERS: ANTHRACNOSE, RUST, CLADISPORIUM, FUSARIUM, YEASTS RUST PREHARVEST INJURY POSTHARVEST AVOID THESE FRUIT WHEN PICKING HEAT/BRUISE SUNBURN RAIN DAMAGE RED DRUPE PACKING SYSTEM 1 PICK INTO CLAMSHELL PLACE CLAMSHELLS IN TOMATO BOX TRANSPORT TO SHED CHECK/REPACK FRUIT IN CLAMSHELLS PLACE IN MASTERS AND PUT IN COLD ROOM PACKING SYSTEM 2 FIELD ONLY PICK INTO CLAMSHELLS BRING TO FIELD PACKHOUSE SORT FOR LEAK, DAMAGE PLACE INTO REEFER PACKING GUIDE CHART SANITATION: CONSUMERS DON’T ALWAYS WASH FRUIT! PROVIDE WASH STATION AS WELL AS TOILET FACILITIES STEPS FOR QUALITY POSTHARVEST • COOLING • CA/MA • TRANSIT COOLING BLACKBERRIES • DELAYS DECAY • REDUCES RESPIRATION/WEIGHT LOSS • CAN CAUSE CONDENSATE IF CHANGES IN TEMPERATURE OCCUR COOLING IS THE MOST EFFECTIVE PRETREATMENT FOR BLACKBERRY SHELF LIFE ! DISEASES • RHIZOPUS (LEAKY ROT) >41 F • BOTRYTIS (GRAY MOLD) >32 F • ANTHRACNOSE >41 F TEMPERATURE INCREASE RESPIRATION INCREASES WEIGHT LOSS INCREASES DECAY INCREASES 14 12 10 8 6 4 2 0 RESPIRATION RATE DAYS LIFE 32 41 68 CONDENSATION • WARM AIR HOLDS MORE MOISTURE THAN COLD AIR • AS AIR COOLS, WATER FALLS OUT ONTO COLDEST SURFACE • PLASTIC COOLS FASTER THAN FRUIT COOLING • ROOM/ REEFER COOLING • FORCED AIR COOLING http://www.storeitcold.com/ ROOM COOLING: ALLOW AIR MOVEMENT BETWEEN BOXES AND FLATS VENTS IN MASTER FOR AIR FLOW WITHIN CARTON COLD ROOMS • RAILWAY CARS + ELECTRIC MOTOR + DIESEL GENERATOR • SELF-CONSTRUCTED • USED RESTAURANT COLD/FREEZER ROOMS • OFTEN FA IS INSIDE A LARGER COLD ROOM • CONVERT AC UNIT TO COOLING (COOLBOT) http://www.storeitcold.com/ COOLING ROOM DIAGRAM STEEL OR AL FRAME SUPPORTS, 2 M CENTERS 10 CM EVAPORATOR UNIT METAL CLADDING, CAULKED POLY U FOAM DOOR 7.5 CM REINFORCED CONCRETE FLOOR 5 CM CONCRETE SUB FLOOR AL CHANNEL, SLIDING DOOR TRACK, FOAM, RUBBER SEAL SOLID RUBBER LOWER SEAL FORCED-AIR COOLING FORCES COLD AIR THROUGH DIRECTED PATHS IN BOXED FRUIT • CAN BE FIELD PORTABLE • ROOM PORTABLE • BUILT-IN CURTAIN FA FANS STORAGE AFTER COOLING • KEEP NEAR 32 F • KEEP RELATIVE HUMIDITY >90% • HOLD NO MORE THAN 2 DAYS EXTRA LABELING FOR CORRECT TEMPERATURE AVOIDING WEAK LINKS IN THE COLD CHAIN 1. COOL AS QUICKLY AS POSSIBLEMAKE SEVERAL SMALL TRIPS TO COOLER 2. KEEP PRODUCT COOLER IN FIELD-USE SHADE, ADD MIST SYSTEM (WHERE LOW HUMIDITY) 3. PAY ATTENTION TO AIR FLOW, STACKING, BOX VENTS COLD CHAIN (CONT) • LOAD INTO REFRIGERATED TRANSIT AS QUICKLY AS POSSIBLE • UNLOAD INTO REFRIGERATED STORAGE QUICKLY • MEASURE/MONITOR TEMPERATURE AT EACH STEP USING RECORDERS MA OR CA STORAGE • MUST BE HELD AT 0-5 C (32-41 F) TO BE EFFECTIVE • BLACKBERRIES NEED 5-10% OXYGEN AND CAN TOLERATE 10-20% CARBON DIOXIDE MA OR CA STORAGE • USED DURING TRANSPORT (3-5 DAYS) • EXCELLENT CONTROL OF GRAY MOLD • KEEPS FRUIT IN ‘SUSPENDED ANIMATION’ PALETTE MA USING FILM OVERLAY WITH INJECTED CO2 MA VERSUS TEMPERATURE POSTHARVEST LIFE OF BLACKBERRIES (DAYS) STORAGE TEMPERATURE 68 F 41 F 32 F AIR 1 3 7 MA 2 4 10 LOW TEMPERATURE IS MORE EFFECTIVE THAN MA SUMMARY • CONTROL HARVEST OPERATION • REDUCE FIELD HEAT LOAD • KEEP FRUIT COOL DURING STORAGE AND TRANSIT • USE MA ONLY IF A PREMIUM PRICE SOURCES OF INFORMATION • BRAMBLE PRODUCTION GUIDE (CORNELL UNIVERSITY) • SMALL SCALE POSTHARVEST HANDLING PRACTICES (UC-DAVIS) • POSTHARVEST TECHNOLOGY OF HORTICULTURAL CROPS (UCDAVIS) SOURCES-WEB SITES • NORTH CAROLINE STATE http://www.bae.ncsu.edu/programs/exte nsion/publicat/postharv/ • UNIV CALIFORNIA-DAVIS AND UCKEARNEYSVILLE http://postharvest.ucdavis.edu/ • USDA HANDBOOK 66 http://www.ba.ars.usda.gov/hb66/contents. html