Delayed Product Differentiation

advertisement

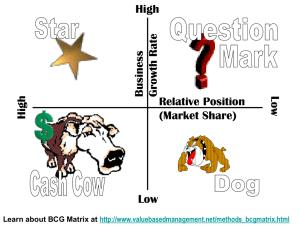

Delayed Product Differentiation Ahu SOYLU Outline Definition of Delayed Product Differentiation Literature Review Proposed Methodology Introduction Firms have to increase product variety in order to be profitable in the market. Increased product variety makes predicting demand extremely difficult Forecast errors are much greater at individual product level than at aggregate level As product variety increases, the likelihood of correlation among product forecasts increases, making forecasting more difficult. Difficulties Deciding how much inventory to carry Predicting equipment capacity requirements Forecasting component requirements Increase in the number of suppliers Shorter product life cycles Increased variability makes inventory, equipment capacity, component, supplier and product changeover management more difficult. The Challenge To minimize the extent in which product variety increases variability in the operating environment. Standardization is the answer. Swaminathan(2001) describes four standardization approaches. Non-Modular Product Modular Standardization Approaches Part Standardization Process Standardization Maximize component commonality across products Delay customization as late as possible Product Standardization Procurement Standardization Carry a limited number of products in the inventory Leverage equipment and part commonality across parts Non-modular Modular Process Standardization Approaches Process Standardization Delay customization as late as possible Delayed product differentiation benefits the manufacturers by, Increasing their flexibility by enabling them to commit their WIP to a particular product at a later time Decreasing their costs of complexity by reducing the variety of components and processes within the system. Delayed Product Differentiation Multiple end-products may share some common components or processes at initial stages. At some point, specialized components or processes are then used to customize WIP into different end products. 1 2 Common operations k Literature Review The concept of delayed product differentiation was first introduced in the marketing literature by Alderson (1950). Shapiro and Heskett (1985), Zinn and Bowersox (1988), Zinn (1990), van Doremalen and Zinn(1991) Lee et al.(1993) exemplified delayed product differentiation by means of deferring the localization process for the deskjet printer at Hewlett-Packard. Lee et al. (1993) North American DC Vancouver Plant 1 month European DC Far East DC Inventories are kept in finished goods form. With factory localization, because of long lead time, the DCs had limited ability to respond to fluctuations in the demand for different versions of the product. With DC localization –a generic product customized at DCs- a reduction of 18% in total inventory investment was achieved. Literature Review Lee (1994) showed that inventory savings are greater when the demands for different products are negatively correlated. Lee (1996) described a model for capturing inventory reduction in an adaptation of multi echelon system. The model assumes no buffer stocks, the inventory reduction comes from finished goods inventory. Literature Review Lee and Tang (1997) developed a model which complements Lee’s(1996) model in the following ways: Holding inventories at different points is allowed Not only decrease in the finished goods inventory but also other factors (i.e. design cost, processing cost, inventory cost, lead times) were also examined Specific approaches such as standardization, modular design and process restructuring are examined. Basic Approach Redesign Process for Delaying Product Differentiation Conditions for Effectiveness Standardization Design a part that is common to all products. Effective when the investment cost and incremental processing cost required for the standardization are low. Modular Design Divide a part into 2 modules-the first module is a common part and the assembly operation of the second module is deferred. The number of modules increases. However, this approach is effective when the incremental lead time, incremental processing cost and unit inventory holding cost are low. Process Restructuring: Postponement of Operation Divide an operation into 2 steps- the first step is common to all products and the execution of the second step is postponed Effective when the lead time of the common step is significantly longer than the second step that is being delayed. In addition, this approach is effective when the second step is a high value added activity Process Restructuring: Reversal of Operations Reverse the order of 2 Effective when deferring the high valueoperations. As a result, the added operation by reversing the first operation is common operations to all products. Literature Review Garg and Tang (1997) are first to examine delayed product differentiation with multiple points of differentiation. Product Differentiation Point T1 Family Differentiation Point T2 T3 The effects of early and late postponements are examined in both centralized-single decision maker for WIP and finished goods- and decentralized control models. Multiple Points of Differentiation In centralized control model; Both early and late postponements results in inventory savings which increase as the amount of time by which the point of differentiation delayed is increased. Early postponement is preferred when the demand correlation is high. In decentralized control model; Lead times determines the decision of early or late postponement. If T2<T1, early postponement, if T3<T2 late postponement is beneficial. If T1>T2>T3 both early and late postponement are beneficial. Literature Review Aviv and Federgruen (2001) examine the design for postponement concept under unknown demand distributions. Yan et. al. (2002) examine the effect of sequencing and merging operations on the reduction of safety stocks. Further research is welcomed on models covering other cost factors with less assumptions. Proposed Model The model I propose incorporates both the benefits of delayed product differentiation and supply contracts. The product is shipped to the retailers without customization. The retailer is equipped with the customization knowledge and performs the customization step. The manufacturer takes the unsold goods back at the end of the period. The benefits of risk pooling are also put in use. Proposed Model Generic Products Manufacturer Retailers The manufacturer is supplied with full information on demand patterns. The centralized control benefits can be achieved with supply contracts. The returned goods to manufacturer can be shipped to another retailer or customized. Proposed Model The reliability between the retailer and the manufacturer should be high in order to prevent technology. The setup cost of customization should be small, customization step should be easy to perform. Questions & Answers