Alternative DC storage Examples

This is a photographic template – your photograph should fit precisely within this rectangle.

Alternative DC Storage Examples

Beyond the Lead Acid Battery

© 2008 Eaton Corporation. All rights reserved .

Power Quality Applications

Typical UPS system block diagram

Genset

AC

Automatic

Transfer Switch ATS

Long-term AC alternate source

Double Conversion UPS System

Rectifier

AC/DC

Inverter

DC/AC

540 VDC

480

VAC

Utility

AC

Critical

AC output

DC Energy Storage

2

2

Alternatives to Standard Storage

3

3

Alternatives to Standard Storage

Generator

Preferred method to provide long ridethrough (5-48 hours)

Maintenance is required

Noise and exhaust are concerns

Be sure to size properly with UPS

Vendor should have UPS interface experience

4

4

Alternatives to Standard Storage

Batteries

For now, batteries are the least expensive mid- term solution

They can also be the weakest link

Service life is always an issue

Hazardous materials disposal is a challenge

Frequent testing and constant monitoring is a requirement

Size and weight are inconvenient in a datacenter

5

5

Flywheel DC Energy Storage

• Can be deployed as the primary DC source or in parallel with traditional batteries in a Battery Hardening configuration.

• It is different from typical chemical batteries in that frequent cycles do not reduce its life

• Produces high power output for short durations (20 – 90 seconds)

6

6

UPS TOPOLOGIES

7

7

1 x 160KVA/144kW UPS

1 VDC XE flywheel

No Batteries

TV Broadcast

Selection Criteria

Green initiative

Improved reliability

Do not like batteries

Floor space / footprint

8

8

Decatur Memorial Hospital IL IT Application

1 x 160KVA/144kW UPS

1 VDC XE flywheel

No Batteries

Selection Criteria

• Green initiative

• Improved reliability

• Do not like batteries

• Floor space / footprint

9

9

University of Florida Proton Therapy Institute - Gainesville

2 x 750KVA/675kW UPS

8 VDC XE flywheels

No Batteries

Selection Criteria

Small footprint

Reduced Maintenance Cost

10

10

Gundersen Lutheran Hospital - IT Application

Strives for 100%

Renewable Energy

The hospital, based in La Crosse,

Wis., is halfway toward its 2009 goal, which amounts to $409,000 in annualized savings

1 x 550KVA/495kW UPS

2 +1 future VDC XE flywheels

No Batteries

Selection Criteria

Small footprint

Green / Sustainability

Reliability

Reduced Maintenance Cost

11

11

University of Massachusetts Medical School - Data Center

2 x 825KVA / 750kW UPS

8 VDC XE VYCON Flywheels

No Batteries

Selection Criteria

Small footprint

Green / Sustainability

Reduced Maintenance Cost

Reliability

12

12

Delta Dental Insurance - Data Center

Selection Criteria

Floor space / footprint

Redundancy

Extend battery life

Improved system reliability

Ride through to Generator

Battery Hardening

2 x 500kVA / 450kW UPS

4 VDC XE VYCON Flywheels

Batteries

Dual Bus

13

13

Bremerton Naval - Modular Solution for IT

825kVA / 750kW UPS

5 VDC XE Flywheels

Outdoor Enclosure

Selection Criteria

Floor space / footprint

HVAC requirement reduced

Reduced maintenance

Improved system reliability

Ride through to Generator

14

14

The Principles of Kinetic Energy

KE ~ m (rpm)

²

(for rotational motion)

•

Low Speed

• More mass means more energy

• Double mass = double energy

• “Low-speed” 1800 to 8000RPM

•

High Speed

• More energy by higher rpm

• Double rpm = quadruple energy

• “High-speed” 36000 to 55000RPM

All Flywheels are operated well below their design limitations

15

15

Flywheel Technology Evolution

•

First Generation Design -

• Low speed (8,000 RPM)

• High maintenance with down time required

• Lengthy commissioning and start up procedure

• Large flywheel mass (800 LBS)

• High standby power losses

• Bearings

16

16

Active Power FLYWHEEL

250kW Motor/Generator/Flywheel

Field replaceable ball-bearing cartridge

Field coil

Magnetic bearing integrated into field circuit

Flywheel, motorgenerator rotor

Air-gap armature

Smooth back-iron, no slots and low loss

No permanent magnets enables high tip-speed and high output power

17

17

Flywheel Technology Evolution

•

Second Generation Design

• Ultra high speed - 52,000RPM

• Liquid cooled - circulation pump

• Mid range power density

• Small composite flywheel mass (60 Lbs)

• No recovery from drop out event

• Down time to service internal vacuum / filter

• Bi Annual service with shut down year 1

18

18

Flywheel Technology Evolution

•

Third Generation Design – VYCON

• High speed - 36000 RPM

• Air cooled

• Small steel alloy flywheel mass (120lbs)

• Annual service requirement

• 15 mins.

• no down time

• High power density

• Full recovery from drop out event

19

19

High Speed, Steel Flywheel Module

Permanent Magnet Motor-Generator

Magnetic Levitation

20

20

VDC – Simplified One Line

IGBT Power Converter

Soft Start

To UPS

Battery

Input

Flywheel Module

DC Monitoring Motor Generator Controls

Power Conversion Module Controller Magnetic Levitation

Controller

Control

Panel

21

21

Battery Hardening

Battery “Whiplash” Prevented

Float Voltage

Grid Disturbance w/ flywheel

Nearly 99% of all voltage sags and outages last less than 8 seconds

Gen

Coup de fouet = Whiplash

98% of disturbances

< 10 sec.

0

10

20

Time

(Seconds)

• Flywheel provides voltage support eliminating battery whiplash

• Increasing battery life, Improving UPS reliability & Reducing service

22

22

Battery Hardening

23

23

Alternatives to Standard Storage

Supercapacitors, Turbines and Fuel Cells

All these promising technologies offer continuous power

But some can’t handle large step loads and many are rather inefficient

Typically too expensive vs. batteries (for now!)

Supercaps (some) utilize KOH electrolyte with same disadvantages as batteries

Acidic hazards

Disposal concerns

Gassing on overcharge

24

24

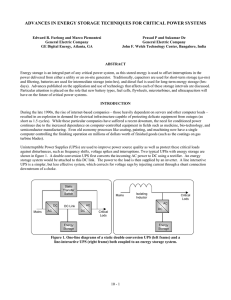

Comparison with other storage devices(1) item

Energy density

(Wh/kg)

Power density

(W/kg)

Discharge rate

Cycle Life

Shelf Life

Over discharge

Environment

Conventional

Capacitor

<0.1

10,000

~ 100,000

~ 0.1sec

>500,000

5 ~ 10year

○

○

EDLC

0.2

~ 10

100 ~ 5,000

0.1sec

~ 1min

>500,000

10 ~ 15year

○

○

Battery

( Lead-Acid )

10 ~ 40

50 ~ 130

10min ~ 10h

200 ~ 2,000

3 ~ 5year

×

×

Battery

( Li-ion

40 ~ 80

)

100 ~ 300

10min ~ 10h

~ 10,000

5 ~ 10year

×

△

25

25

Comparison with other storage devices(2)

Conventional Capacitor

Cup bucket

EDLC drum

Lead-Acid Battery

Water in the cup can be applied at one time but volume is not sufficient enough for fire fighting

Not applicable

Best option for fire fighting

Not applicable

Sufficient amount of water in the drum but can not be applied at one time for fire fighting

EDLC is best storage device for charge and discharge of large amount of electricity in a short period of time !

26

26

Dynamic Voltage Compensator (system)

Back up commercial power

EDLC high speed switch

Inverter

Load

Sag compensation mode

Rated Output

Dip comp. time

Rated Voltage

Operation

Switch over

Storage

Efficiency

10,000kVA

1sec

3φ 6,600V

On-line method

No interruption

( Less than 2msec )

EDLC over 99%

Module

600S1-70C-11P

292 × 600 × 395H

EDLC Panel System ( W : 28m-H:2.6m-D:2.3m

)

27

Application for Electric railway (system)

Regeneration & Peak cut

CAPAPOST ( W : 4.1m-H:3.1m-D:5.0m

)

EDLC Bank(600S1-70C × 36P × 8S )

28

Power System Stabilizer (system)

Peak cut & Regeneration

Electric Power system

~ junction

Power constant

Load fluctuation

Stabilize the sharp fluctuations by PSS engine generator

(assume) junction

+

EDLC

Load

SG SG

Load

DE DE to supply engine

Battery engine storage

自立範囲

EDLC

Storage

Input transformer

AC/DC

EDLC

AC6600V 100kVA

29

29

30

30