UBD1

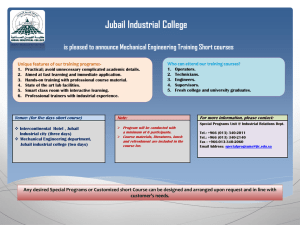

advertisement

Engineering Inc. Underbalance Drilling Rotating Heads & Rotating BOP’s Rotating Heads Rotating BOP’s Used to divert the return flow stream down the blooey line, flow line or to the choke manifold. Rotating Drilling Heads Two types of systems; hydraulic active (RBOP) and mechanical sealing (RH) Both are used successfully in air and underbalanced wells Rotating Head Mechanical Sealing Type TT96-90 Gas and Air Drilling 6 Rotating Head Mechanical Sealing Mechanism TT96-93 Drilling Fluid Description 7 Rotating BOP Hydraulic Active RBOPTM Kelly Packer Closing Unit TT96-93 Drilling Fluid Description 117 Manufacturers • • • • • • • • • Williams Smith Grant Shaffer RSBOP (Varco) Northland Inter-Tech RBOP TESCO1 Alpine - Technicorp Lynn International Others Mechanical Seal Rotating Heads Pressure Ranges Low 300psi Medium 700psi High 1500psi Very High 3000psi Static pressure ranges are twice as high Mechanical Sealing Rotating Heads Kelly Bushing Drive Bushing Swing Bolt Clamp Stripper Rubber Grant - Smith Conventional Rotating Head Williams Model 9000 Kelly Driver 500 psi rotating Bearing Assembly 1000 psi static Up to 200 rpm Stripper Rubber Bowl TT96-93 Drilling Fluid Description Geothermal model two stripper rubbers 13 Negative Impact to Stripper Rubber Elements The purpose of the stripper rubber is to provide a seal around the kelly as it rotates and to seal around the drill pipe while tripping in or out of the hole. Stripper Rubber Composition Natural- Air, Mist, Foam, Gas Polyurethane- Oil Based below 140 F Nitrile - Oil Based above 140 F Butyl - Geothermal and H2S Negative Impact to Stripper Rubber Elements Kelly condition is critical. Surface conditioncheck wear pattern on corners Bent Kelly’s Alignment Rig to Stack Alignment is critical Check Daily Suspect to excessive element usage Other Negative Impacts Drill pipe identification grooves Pitting and abrasion on drill pipe Tong and slip die damage Some hardbanding Mills and bits Other Negative Impacts Extreme cold Extreme heat Age Sun light Low Pressure Rotating Head TT96-90 Gas and Air Drilling 20 Medium Pressure RDH Pressure to 700 psi Single or Dual Element Lower Mounting Spools from 7 1/16” 2000 psi to 13 5/8”5000 psi. Outlet Flanges are 7 1/16”-2000/3000 psi Grant - Smith High Pressure MODEL 7000 Williams model 7000 is also designed to handle today’s most demanding underbalanced drilling requirements. It is available in explosion proof and offshore models and comes with a side outlet flange. This unit is also equipped with a captive space vent for purging the system in sour gas applications. DUAL ROTATING STRIPPER RUBBERS Are designed to automatically seal tighter as pressures increase. The bottom rubber wears first, leaving the top rubber in newer condition for added safety. WATER COOLED SEALS Maximize the operating life of the bearing assembly. POSITIVE OIL LUBRICATION provides continuous flushing to keep debris out of te bearings and seals and maintains lubrication up to 2300 psi. HYDRAULIC OPERATED CLAMP Provides a continuous closing force to compensate for operating stress. For use on rigs with top drives or Kellys CALL FOR SIZES AVAILABLE MODEL 7000 COMPONENTS U.S. Patent No.5,662,181 “Rotating Blowout Preventer” REMOTE MODULAR POWER UNIT MODEL 7000 EXPLODED CUT-AWAY VIEW REMOTE MONITORING CONTROL CONSOLE MODEL 7000 ROTATING CONTROL HEAD Rotating Head Schematics Single Element Dual Element Main Components Hydraulic Oiler Lubricator/ And cooling System Heavy Duty Rotating Drilling Head Bearing Assembly Contains large heavy duty tapered roller bearings Bearing Chamber sealed with low pressure seals against atmospheric pressure Separate high pressure seal assembly to contain wellbore pressure Drive Assembly and Stripper Rubber Elastomers available for oil, gas or geothermal drilling Available in single or dual element systems Combination one piece drive assembly and stripper rubber KELLY DRIVERS • Available to fit all Kelly sizes and shapes • Designed with vertical bolts or snap ring • Supplied with each complete rotating control head • Steel or poly inserts available • Available for all models MODEL 8000/9000 STRIPPER RUBBERS • Standard • Heavy duty • Oil resistant Stripper rubber usage is determined by the operating pressures, Kelly and drill pipe conditions and stack alignment. MODEL 9200 GEOTHERMAL STRIPPER RUBBERS • Drill collar (1) (1) • Drill pipe (2) (2) Stripper rubber usage is determined by the operating pressures, Kelly and drill pipe conditions and stack alignment. 7000 SERIES STRIPPER RUBBERS Model 7100 Stripper Rubbers • Heavy duty Stripper rubber usage is determined by the operating pressures, Kelly and drill pipe conditions and stack alignment. Model 7000 Stripper Rubbers • Heavy duty • Oil resistant CASING STRIPPER RUBBERS • Used to strip casing in the well • Seals tight against bowl gasket using quick-lock clamp • Assures diversion of mud and gas through the flowline outlet • Available for any size casing up to 13 3/8" • Assures safety of rig personnel Available for all models LOGGING ADAPTER • Makes logging faster and easier • Seals tight against bowl gasket using quick lock clamp • Features 7" - 9 5/8" rounded threaded collar to receive logging lubricator Available for all models SPACER SPOOLS • • • • Constructed of casing and flanges For models 8000 and 9000 series only Permits height to be changed to desired length Used under rotating head to raise flowline outlet to proper height Available in all sizes Specify flange series and height when ordering TO ONLY BE USED ABOVE ANNULAR BOP FLOWLINE FLANGES • Used to connect flowline to Rotating Head • 7 1/16" - 3000 - w / swages from 6" - 12" • 11" - 3000 - w / swages from 6" - 12" Available for all models PIPE WIPER HOLDER • Holds dual split or single pipe wiper rubbers • Keeps drill pipe clean • Keeps drilling mud in the hole • Saves mud and clean up time • Rubber can be installed or removed at any time • Welds to all sizes of drilling nipples Available for all models OILER - LUBRICATOR • Operates from the rig’s air supply • Supplies constant flow of filtered oil to bearings and seals • Insures long life of bearings and seals • Supplied with each complete rotating control head • Available for models 8000, 9000 and 9200 only DRILLING NIPPLE • Used to trip without bearing assembly • Seals tight against bowl gasket using quick-lock clamp • Helps contain drilling mud while tripping • Can be extended or cut to desired length Available for all models SNUBBING ADAPTER • Used to nipple-up the snubbing unit • Permits snubbing without removal of the rotating control head bowl • Used for models 7000,7100 and IP1000 • 7 1/16” flange connection TEST PLUG Used to test the drill stack Available for all models RBOP - Oil Tools International • • TT96-93 Developed by SealTech, Oryx Energy, Clayton Williams and Exxon Designed for use in High GOR wells, Wells With H2S and High Pressure Wells. Drilling Fluid Description 42 Wellhead Pressure Control Active pressure unit Multiple pressure settings Simple quick packer change 2000 psi static RBOP Schematic Wellhead Pressure Control Quick-Change Packer Assembly Kelly Drive Assembly Inner Packer Outer Packer Bearing Hydraulic Fluid Inlet Surge Bottle Seal Outlet Flange Bottom Flange Wellhead Pressure Control Simple quick packer change Redundant element sealing Multiple pressure settings Rig floor operation RBOP Closing Unit TT96-93 Drilling Fluid Description 117 Shaffer Rotating Blow-Out Preventer • 2,500 psi rotating - 5,000 psi static Shaffer PCWD TT96-93 Drilling Fluid Description 52 Passing a Tool Joint Techcorp 3000 Inner Replaceable Element TESCO DOUBLE ANNULAR Not a rotating preventer Uses two small modified Shafer packers Used like a rotating preventor Rotating Heads and Rotating Blow Our Preventers SUMMARY Rotating Drilling Heads Low - High Pressure Systems Hydraulic Activated Systems Not API certified as a blowout preventer Sealability is electronically hydraulically actuated as a function of wellbore pressure Shop serviced bearing assembly Mechanical Interface Systems Not API certified as a blowout preventer Stretch-interface seal maintained, assisted with wellbore pressure Wellsite replaceable bearing assembly Hydraulic Lubricator Systems Hydraulic Active System Seal is hydraulically actuated as a function of wellbore pressure and lubricates the bearing Usually a common oil reservoir cools bearing Mechanical Interface System Seal is activated by well pressure Circulating system for high pressure used to lubricate and cool bearing -does not activate elements Rotating Drilling Heads High Pressure Systems Hydraulic Activated Systems Pressure to activate is controlled by sensor or manually. Seal is totally controllable. Mechanical Interface Systems Seal is always active and increases with increasing well pressure. “No pressure” seal is function of stretch fit. END