09. Best Maintenance Practices in 21 MW & 16 MW Steam

advertisement

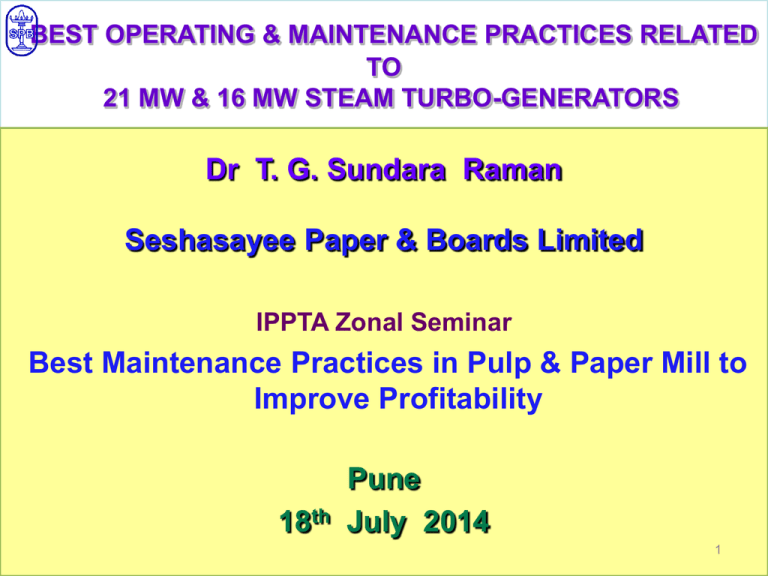

BEST OPERATING & MAINTENANCE PRACTICES RELATED TO 21 MW & 16 MW STEAM TURBO-GENERATORS Dr T. G. Sundara Raman Seshasayee Paper & Boards Limited IPPTA Zonal Seminar Best Maintenance Practices in Pulp & Paper Mill to Improve Profitability 18th Pune July 2014 1 Steam turbo-generators Generator Winding Section • Power generation enhancement is directly related to increase in current produced [I**2] • In turn , it heats up the core winding [stator and rotor]. • It results in winding temperature increase. • Heat is dissipated to air in closed circulation on the exterior enclosed air duct. • Hot air in turn is cooled by cooling water flowing inside the finned tubes of the heat exchanger. • The cycle continues with windings being kept below a set temperature with alarm set at 85 deg C and trip at 95 deg c. Steam turbo-generators in SPB –Erode Unit • CPP- 21 MW Double Extraction Condensing Steam Turbo-generator of BHEL • Chemical Recovery Complex- 16 MW Extraction Back Pressure Steam TurboGenerator of BHEL Power input rating of the Generators Rated Power 21 MW 16 MW Power Factor 0.80 0.80 Power input [MVA] 26.25 20.0 CASE -1 21 MW STEAM TURBO-GENERATOR 21 MW STG Air Water Circuit -Existing . 21 MW Steam Turbo-GENERATOR Temperature record of Generator Winding and other related temperatures PF : High [0.97-0.98 ] Before Cleaning of HX After Cleaning of HX 05/06/14: 14 h 19/06/14 : 20 h 0.97 0.98 MW 15.3 15.3 #1 C 85.3 77.2 8 #2 C - - - #3 C 88.1 80.1 8 #4 C 76.1 73.6 3 #5 C 72.9 65.2 8 #6 C 86.7 78.3 8 #7 C 87.5 79.4 8 #8 C 89.6 81.2 8 Cold air temperature C 54/56 49 6 Hot air temperature C 65/66 58/59 7 CW in temperature C 37 35 2 CW out temperature C 42 39 3 Date/Time P.F. Power Generation Temperature reduction ,°C Winding Temperature 100 21 MW ST GeneratorTem perature Schedule [Before & After Cleaning of Air & Water Sides] Temperature Deg C 90 80 70 60 50 40 30 20 W1 W2 W3 W4 W5 W6 W7 W8 Bef Clean After Clean Cold Air Hot Air CW in CW out CASE -2 • 16 MW STEAM TURBO-GENERATOR 16 MW STG Air Water Circuit -Existing Power input rating of the Generators 21 MW 16 MW Rated Power Power Factor 0.80 0.98 0.80 0.98 Power input [MVA] 26.25 20.6 20 16.3 16 MW Steam Turbo-GENERATOR Temperature record of Generator Winding and other related temperatures IMPACT OF HIGH & LOW PF ON WINDING & AIR TEMPERATURES Temperature increase ,°C 0.98 0.81 13/06/14 11/06/14 After After MW 11.13 10.7 #1 C 72.2 81.8 10 #2 C 74.0 82.7 9 #3 C 73.0 83.5 10.5 #4 C 75.0 83.7 9 #5 C 71.7 82.5 9 #6 C 73.6 83.5 10 Cold air temperature C 42/41 44.6/44.4 3 Hot air temperature C 59.6/55.6 62.2/58.8 3 CW in temperature C 27 28 CW out temperature C 34 35 Power Factor Date/Time Cleaning of HX Power Generation Winding Temperature ΔT : 7°C 16 MW ST GeneratorTem perature Schedule Temperature Deg C 90 [Impact of High & Low P.F.on Winding Temperatures] 80 70 60 50 40 30 20 W1 W2 W3 W4 W5 W6 W7 W8 PF :0.98 PF:0.81 Cold Air Hot Air CW in CW out 21 MW Generator Issue : High Winding Temperature • High Cooling water inlet temperature of ~ 36 37°C due to poor cooling tower performance. • Cooling water chemical treatment need to be improved & should be commensurate with the operating COC. • All the 8 coolers are on line. 16 MW Generator Issue : High Winding Temperature • CW temperature differential across generator had gone up from 4°C to 7°C. • More than heat dissipation, probably cooling water flow through generator cooler would have dropped. CW flow restriction needs to be looked into & cleared. Winding temperature increase Due to • Stator & Rotor Core heat losses directly proportional to square of increasing current • Copper & Iron Core heat loss with increase in Winding temperature associated with the above • Frictional Heat & Field Losses • Reduced Power factor results in Reactive Power loss • Harmonic current heat losses Heat loss reduction achieved through • Increase in Power Factor • Reduced Generation load • Harmonic loss reduction Winding temperature reduction Achieved through • Lowered hot air temperature • Lowered cold air temperature • Lowered inlet cooling water temperature • High cleanliness of air ducts & HX exterior • Minimal dirt/deposits over the winding coils • Ensuring Quality cooling water devoid of suspended impurities & foulant ( scales). MEASURES ADVOCATED • Quality cooling water to be ensured • Periodic cleaning of heat exchanger tubes ( waterside) • Occasional cleaning of air side/duct off dust/dirt • Occasional cleaning of winding coil exterior ( during annual shut of the STG), if there is approach. • Cooling tower & chemical conditioning of CW to be in order. CONCLUSIONS & RECOMMENDATIONS • Quality cooling water to be ensured • Periodic cleaning of heat exchanger tubes ( water-side) • Occasional cleaning of air side/duct off dust/dirt • Occasional cleaning of winding coil exterior ( during annual shut of the STG), if there is approach. CONCLUSIONS & RECOMMENDATIONS • Ensure desired rate of cooling water flow ( say to maintain 2.5 to 3.5 Deg C temperature differential) • Cooling tower & chemical conditioning of CW to be in order. • High Power factor leads to lowered heat losses from the Generator resulting in reduction in Winding temperatures. • All of the above if practiced on a sustained basis would ensure longevity of the Generator unit , thereby resulting in 100% availability of the same. GALVANIC CORROSION OF HX & MITIGATIONAL MEASURES Cathodic Protection • Tube sheet and finned tubes are of different materials. • Hence there will be Galvanic Corrosion due to high Electrochemical Potential difference between the materials resulting in corrosion of tube sheet. • Hence Zinc anode ( sacrificial anode) pieces are installed over the tube sheet cover to ensure longevity life of tube sheet/tubes. WAY FORWARD • For ensuring Winding temperatures to be well within the recommended limits , be it at full load or low power factor operation of the Generator, both water and air sides are to be cleaned off deposit/silt/foulant on sustained basis. • As for cooling water, the quality should be good devoid of foulant; the cooling water temperature should be preferably <34°C & the flow should be maintained to have low temperature difference (say 3 to 4 °C). • Zinc bars attached to the tube sheet should be checked at any available opportunity to be healthy • The successful operating concept shall be extended to all Generator Air water Heat exchangers for increased Productivity . Good Maintenance . Practice Ensures Productivity 27