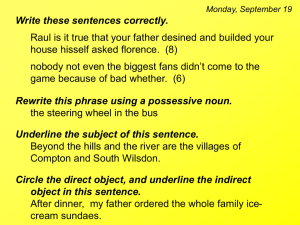

summer training presentation

advertisement

Sona Koyo Steering Systems Limited (SKSSL) the flagship company of The Sona Group, is currently the largest manufacturer of steering systems for the passenger car and utility vehicle market in India. Its collaborator and partner, JTEKT Corporation, is the market leader in Japan and in the recent past announced a merger with Toyota Machine Works. Post this merger, JTEKT will become the world's largest steering systems manufacturer. The company also has a technical collaboration with Mando Corporation, Korea. As part of Sona Koyo Steering Systems Ltd's (SKSSL) globalization strategy, the company has acquired a position in Fuji Autotech. France, SAS, the 4th largest steering system supplier in Europe. Via Fuji Autotech, The Sona Group footprint extends to Eastern Europe and South America. 38/6, Delhi-Jaipur Road, NEAR HERO HONDA CHOWK, Gurgaon (Haryana), India 38 Km from New Delhi, 22 Km from Delhi Airport, 10 Km from Maruti Udyog Ltd. Total Site Area 56,970 square meters Total floor Area 14,125 square meters PLANT -1 PLANT -2 PLANT - 3 PLANT - 4 Power Rack and Pinion Steering Tilting and Collapsible Column System Clutch Driven Plates Power Re-circulating Ball Screw Steering System Ball Joints Electrical Power Steering System Tie Rod Ends Manual Rack and Pinion Steering System Suspension Components Warm forged Synchronizer Rings Assembly Universal Joints Cold Forged Steering Studs Propeller Shafts Cold Forged Ball Studs Rear Axle Assemblies Cold Forged Case/Socket Sub-differential Assemblies Cold Forged Spiders and Yokes Rigid Type Collapsible Column Assembly RACK AND PINION STEERING (RPS) RECIRCULATING BALL TYPE STEERING (RBS) In the rack and pinion type steering, the steering main shaft has a steering pinion at the lower end. This steering pinion meshes with the steering rack. As the steering wheel is turned, the steering pinion rotates to move the steering rack to the right or left. The movement of the steering tack is transmitted to the knuckle arms via the steering rack ends and the tie rod ends. The rack-and-pinion gear set does two things: It converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels. It provides a gear reduction, making it easier to turn the wheels. THE AUTOMOTIVE STEERING COLUMN IS A DEVICE INTENDED PRIMARILY FOR CONNECTING THE STEERING WHEEL TO THE STEERING MECHANISM BY TRANSFERRING THE DRIVER'S INPUT TORQUE FROM THE STEERING WHEEL. A STEERING COLUMN MAY ALSO PERFORM THE FOLLOWING SECONDARY FUNCTIONS: Energy dissipation management in the event of a frontal collision; Provide mounting for: the multi-function switch, column lock, column wiring, column shroud(s), transmission gear selector, gauges or other instruments as well as the electro motor and gear units . Offer (height and/or length) adjustment to suit driver preference. The cross-shaped inner member of a universal joint is sometimes called a spider. Universal joints allow for a small variable angle between the axis of the transmissions output shaft and the axis of the propeller shaft, and between the axis of the propeller shaft and the axis of the input shaft of the rear axle (1)The spider (6) ends (3) are called gudgeon. Around the gudgeons there are rollers (4) kept in place by a cap (5), that allows them to roll freely. The Circlip (7) fits into the (2) hole in the yoke and lock the cap. An axle is a central shaft for a rotating wheel or gear. In some cases the axle may be fixed in position with a bearing or bushing sitting inside the hole in the wheeler gear to allow the wheel or gear to rotate around the axle. In other cases the wheel or gear may be fixed to the axle, with bearings or bushings provided at the mounting points where the axle is supported. A straight axle or the front axle is a single rigid shaft connecting a wheel on the left side of the vehicle to a wheel on the right side. The axis of rotation fixed by the axle is common to both wheels. Such a design can keep the wheel positions steady under heavy stress, and can therefore support heavy loads. Straight axles are used on trains, for the rear axles of commercial trucks, and on heavy duty off-road vehicles. The axle can be protected and further reinforced by enclosing the length of the axle in a housing. In split-axle designs, the wheel on each side is attached to a separate shaft. Modern passenger cars have split drive axles. In some designs, this allows independent suspension of the left and right wheels, and therefore a smoother ride. Even when the suspension is not independent, split axles permit the use of a differential, allowing the left and right drive wheels to be driven at different speeds as the automobile turns, improving traction and extending tire life A drive shaft, driveshaft, driving shaft, propeller shaft, or shaft is a mechanical component for transmitting torque and rotation, usually used to connect other components of a drive train that cannot be connected directly because of distance or the need to allow for relative movement between them. Drive shafts frequently incorporate one or more universal joints or jaw couplings, to allow for variations in the alignment and distance between the driving and driven components. There are a couple of key components in power steering in addition to the rack-and-pinion or recirculating-ball mechan THERE ARE A COUPLE OF KEY COMPONENTS IN POWER STEERING IN ADDITION TO THE RACK-AND-PINION OR RECIRCULATING-BALL MECHANISM. The hydraulic power for the steering is provided by a rotary-vane pump (see diagram below). This pump is driven by the car's engine via a belt and pulley. It contains a set of retractable vanes that spin inside an oval chamber. As the vanes spin, they pull hydraulic fluid from the return line at low pressure and force it into the outlet at high pressure. The amount of flow provided by the pump depends on the car's engine speed. The pump must be designed to provide adequate flow when the engine is idling. As a result, the pump moves much more fluid than necessary when the engine is running at faster speeds A power-steering system should assist the driver only when he is exerting force on the steering wheel (such as when starting a turn). When the driver is not exerting force (such as when driving in a straight line), the system shouldn't provide any assist. The device that senses the force on the steering wheel is called the rotary valve. The key to the rotary valve is a torsion bar. The torsion bar is a thin rod of metal that twists when torque is applied to it. The top of the bar is connected to the steering wheel, and the bottom of the bar is connected to the pinion or worm gear (which turns the wheels), so the amount of torque in the torsion bar is equal to the amount of torque the driver is using to turn the wheels. The more torque the driver uses to turn the wheels, the more the bar twists. The input from the steering shaft forms the inner part of a spool-valve assembly. It also connects to the top end of the torsion bar. The bottom of the torsion bar connects to the outer part of the spool valve. The torsion bar also turns the output of the steering gear, connecting to either the pinion gear or the worm gear depending on which type of steering the car has. As the bar twists, it rotates the inside of the spool valve relative to the outside. Since the inner part of the spool valve is also connected to the steering shaft (and therefore to the steering wheel), the amount of rotation between the inner and outer parts of the spool valve depends on how much torque the driver applies to the steering wheel. When the steering wheel is not being turned, both hydraulic lines provide the same amount of pressure to the steering gear. But if the spool valve is turned one way or the other, ports open up to provide high-pressure fluid to the appropriate line. It turns out that this type of power-steering system is pretty inefficient. Let's take a look at some advances we'll see in coming years that will help improve efficiency EPS in modern cars can significantly reduce fuel consumption when compared to cars using hydraulic solutions. Industry studies have shown that EPS can save up to 85 percent of the energy normally needed to steer a vehicle with conventional hydraulic systems. The result is fuel consumption reductions of up to 0.3 liters per 100 kilometers driven. EPS is so efficient because the system is only activated when steering support is really needed. As a result, a permanent engine load is not required. EPS systems also can help ensure safer driving. The steering torque is adapted to the vehicle’s speed and optimized for different driving situations. For example, during low-speed driving maneuvers, such as parking, EPS provides a higher level of assistance than it does at higher speeds, when electronic power assist is gradually reduced to enable more direct steering and better feedback from the road.