Preventing Introduction, Growth and Cross

advertisement

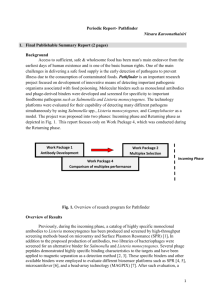

Preventing Introduction, Growth and Cross-Contamination of Listeria monocytogenes ©2006 Department of Food Science - College of Agricultural Sciences at Penn State University Penn State is committed to affirmative action, equal opportunity, and the diversity of its workforce. This publication is available in alternative media on request. Contamination Introduction – LM is brought into the facility from an outside source Growth – LM present in the facility/food has the ability to multiply Cross-contamination – LM present in the facility/food is transferred to another food or surface Introduction of LM Non-food items Vendors Rodents/Pests Retail Facility Contaminated Food Employees Customers Retail establishments are open to the public Restrictions & controls should be designed to complement normal operations Introduction of LM Employees – Sources Ill employees Unclean hands, clothing – Prevention Good personal hygiene Restriction of ill employees Training Introduction of LM Vendors – Sources Ill vendors Unclean hands or clothing – Prevention Restriction from high risk areas Training/vendor agreements Introduction of LM Customers – Sources Ill customer Unclean hands – Prevention Facilitate proper handing of food – Tongs, single use paper – Instructions for proper handing Introductions of LM Rodents/Pests – Sources Feces Rodents/pest carrying LM on feet and body – Prevention Pest control program Maintenance of indoor and outdoor facilities Introduction of LM Contaminated Food – Sources Raw products (meat, poultry, fruits, vegetable) Ready-to-eat foods – Prevention Vendor assurances (HACCP plan, testing) Vendor audits Introduction of LM Non-food Items – Sources Contaminated packaging, other supplies – Prevention Receiving standards Growth of LM Since it is not possible to eliminate all sources of LM in the retail environment, preventing growth is essential – On Food – On Equipment – In the Environment Controls to Prevent Growth 1. Adequate time and temperature controls 2. Proper cleaning and sanitation 3. Good personal hygiene Time/Temperature Controls Cold Holding (Refrigeration) 41ºF for 7 days OR 45ºF for 4 days – LM can grow at refrigeration temperatures, so holding time is important – Control of LM growth is the basis for 2005 Food Code cold holding temperature/time combinations 9 log10 cfu/ml 8 7 47.7F 6 38.3F 34.7F 5 33.4F 4 0 10 20 30 40 50 60 Time (days) Growth of Listeria monocytogenes CFA 433 in chicken broth when o incubated at 47.7. 38.3, 34.7, and 33.4 F. Adapted from S.J. Walker et al. (1990). Time/Temperature Control Date Marking – Requires active managerial control – Applies to: Certain high risk foods Foods held for greater than 24 hours – After prepared by a food establishment – After opened, if a processed food Estimated Reduction of Cases of Listeriosis from Limits on Refrigeration Temperatures Cases of Listeriosisa Maximum Refrigerator Temperature Media n 5th Percentile Baseline 2105 ¾ 7 °C (45 °F) maximum 656 331 761 5 °C (41 °F) maximum 28 1 126 b 95th Percentile c a c ¾ Values for the median, upper and lower uncertainty levels. The baseline uses the full empirical distribution of refrigerator temperatures from the Audits International (1999) survey. c The baseline number of cases of listeriosis is fixed based on CDC surveillance data. b Source: FDA/CFSAN and USDA. 2003. Quantitative Assessment of Relative Risk to Public Health from Foodborne Listeria monocytogenes among Selected Categories of Ready-to-Eat Foods Time/Temperature Controls Hot holding – Minimum of 135ºF No temperature control – Can be held for no longer than 4 hours at ambient temperatures Cleaning & Sanitation Prevention of LM growth requires a sanitation program that is: – Properly designed – Properly carried out Target areas – Food contact equipment at room temperature – Refrigerated storage & display cases Controls to Prevent Cross-Contamination Cleaning & Sanitation Good Personal Hygiene Proper Flow of Food & Employees Cleaning & Sanitation To prevent cross-contamination – Always clean between working with raw and ready-to-eat products – Regularly clean to reduce chance that contaminated product transfers to uncontaminated product Personal Hygiene Handwashing stations – Easily accessible to promote frequent handwashing – Properly supplied Appropriate training – Employees should understand concept of cross-contamination Proper Flow of Food Facility design – Separation of raw and ready-to-eat areas – Adequate storage and work space Refrigeration Preparation tables Display cases Flow of Employees Facility design – Location of hand washing facilities – Locations of locker & rest rooms – Separation of raw and ready-to-eat areas Designated tasks for employees Designated work areas Flow of Employees Refuse Storage Receiving Locker / Rest Rooms Dishwashing Area Refrigerated Storage Cooler Dry Storage Employee Entrance Prep Table Prep Table Handwashing Sink Service Area / Cooler Customer Entrance Prevention of LM Prevent – Introduction – Growth – Cross-contamination