Electrical Accidents in Mining

advertisement

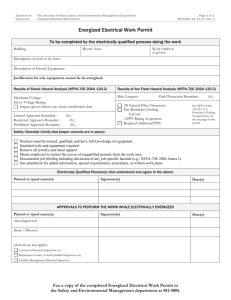

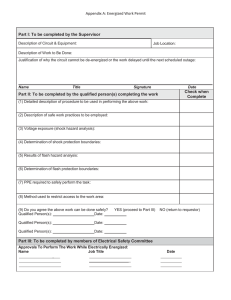

Critical Risk Awareness Don’t Gamble With Safety Electrical – Goldstrike, October 2012 Electrical Incidents in Mining Electrical accidents on mine sites are rarely true accidents and can often be fatal. During the last decade, 41 miners died in accidents that could have been prevented by ensuring that all electrical components are deenergized Electrical Accidents in Mining 2011: A miner with 22 years of mining experience was electrocuted while welding to connect two pipes together. He was working in the ceiling of the filter room of a preparation plant. This area, where the welding was being conducted, was wet and the illumination was limited. The victim contacted an energized welding electrode. 2008: A 24-year-old electrician with 4 years mining experience was fatally injured when he cut into an energized shuttle car trailing cable. The victim was attempting to make an electrical repair on the shuttle car when he used a cable cutter tool to cut into an energized lead. Electrical Incidents at Barrick Unfortunately, Barrick has not escaped electrical incidents. – In 2011-12 Barrick NA experienced 24 electrical incidents. – One of those incidents involved an electrician using an incorrect meter to determine the voltage on a piece of equipment. This resulted in a potentially fatal arc flash at the point of contact. – Another incident involved backing a water truck into a energized overhead high voltage line. – Energized line in cable tray cut without deenergizing. What are we doing? Because of these incidents, we have introduced changes to reduce the possibility of electrical incidents. – Written the NARBU Arc Flash standard – Equipped electrical technicians with proper test equipment – Incorporated electrical review in all new or major maintenance projects through the MOC (Management of Change) process. – Increased training for electrical maintenance personnel to recognize risks. Pay Attention to Electrical Risks Summary Summary and Questions – Always use proper PPE and equipment – Perform proper Lock Out – Tag Out Procedures – Follow the NARBU Arc Flash standard prior to conducting all electrical work. – Only trained and qualified personnel to perform electrical work. – Do proper FLRA and walk-around prior to working with energized high voltage lines. – Questions?