515 Gas Valve Selection

advertisement

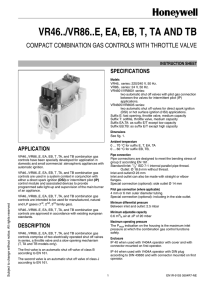

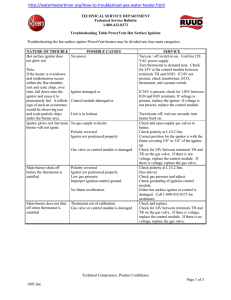

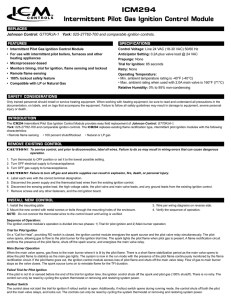

White-Rodgers Gas Furnace Valves Education You Can Build On When To Replace A Gas Valve? • The valve should be replaced if any of the following occur: – The outlet pressure remains above the set point or fluctuates • NOTE: The manifold regulation should stabilize after about 20 seconds and stay within +/- 10% of the set pressure setting – The regulation setting cannot be adjusted – The valve will not open to allow main gas flow – The gas valve has been subjected to water flooding • NOTE: When servicing a gas furnace it is important that the inlet and the outlet pressures be checked with an accurate pressure gauge – You cannot visually look at a main burner flame to determine if the pressures are within the manufacturers specifications – Always check the gas valve with a water and soap bubble solution after servicing to ensure there are no leaks Selection Criteria Questions What is the Ignition Source? Options • Direct Burner Ignition • Direct Spark Ignition • Hot Surface Ignition • Proven Pilot / Intermittent Pilot • Standing Pilot What is the Furnace Input / Valve Rating? • Look at the rating plate on the furnace What are the opening characteristics? • Opening Curve • NOTE: All White-Rodgers Universal Gas Valves come with Nat. to L.P regulator spring conversion kit and reducing bushings for adapting to pipe size • Fast/Standard Open or Slow • Stages • Single Stage or 2 Stage Application by Ignition Source Direct Burner Ignition W-R Valve Hot Surface Ignition (HSI) Direct Spark Ignition (DSI) Proven / Intermittent Pilot 36H or 36J 36H or 36J 36H Resistive element that heats up to light the gas with direct or indirect flame sensor Ground electrode, with spark electrode flame sensor Standing / Continuous Pilot 36C Ignition Source Majority of Usage current furnaces Selected applications Pilot burner to ground, with a spark electrode and flame sensor A traditional pilot burner with a thermocouple no spark electrode or flame sensor Mostly rooftop applications No longer used in OEM production Rated Valve Capacity Pressure Drop: Range of Regulation: Pressure differential is the agency rated amount of gas (BTU’s) that can pass through the gas valve based on inlet and outlet pipe size. Is the minimum and maximum BTU/Hr capacity of the valve to maintain regulation pressure settings. Pressure Drop Capacity W-R Valve Gas Flow (KBTU/HR) 250 Pipe Size 200 150 36J 100 36H 50 0 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Differential Pressure (In. W.C.) 2.0 36C Range of Regulation KBTU/HR (Min to Max) N.G. L.P. ½x½ 40 to 210 60 to 340 ½x¾ 30 to 290 81 to 648 ¾x¾ 50 to 400 81 to 648 ½x¾ 30 to 290 30 to 469 ¾x¾ 50 to 400 50 to 648 Application By Opening Characteristics Fast Open Slow Open 2-Stg Fast Open 2-Stg Slow Open 36J22 36J24 36J54 36J55 36H32 36H33 36H64 36H65 36C03 Fast Open Fast rise to full outlet pressure upon energizing the valve Slow Open Slow increase of gas to full outlet pressure for smoother ignition Two-Stage Open Low pressure 1st fire stage and then full outlet pressure on a call for 2nd Stage Heat Can be fast or slow open on both stages Note: These are Typical Family Model Numbers. Verify Specific Type Numbers Before Replacing A Control. Universal Valves You Should Not Be Without Model Number 36J22-214 36J24-214* 36J54-214 36J55-214* Ignition Source Direct Burner Ignition (HSI / DSI) N.G. Capacity 140,000 L.P. Capacity 226,800 Pipe Size ½x½ Opening Curve Stages Fast 1 Slow 1 Fast 2 Slow 2 * 36J valve is offered in a -614 Version that gives you a 90° Bottom Outlet—Primarily used in Carrier Furnaces 36H32-304 36H32-423 36H33-412 36H64-463 260,000 Direct Burner Ignition Or Proven Pilot 300,000 421,000 486,000 ½x¾ ¾x¾ 36H65-401 36C03-300 36C03-433 Standing Pilot Fast 1 Fast 1 Slow 1 Fast 2 Slow 2 230,000 372,600 ½x¾ Fast 1 280,000 453,600 ¾x¾ Fast 1 98% of Furnaces manufactured in the last 10 years can be repaired using the “J” valves listed above!