Personal Protective Equipment - SCTE Penn

Personal Protective Equipment and

Ladder Safety

Personal Protective Equipment

When to wear or use!

Types PPE We Use

• Head Protection

▫ Hard Hat

• Eye Protection

▫ Safety Glasses

• Foot Protection

▫ Boots

• Personal Protection

▫ Reflective Clothing

H

EAD

P

ROTECTION

• Why do we wear hard hats?

▫ Protect us from overhead hazards

Electrical

Object

• When should we be wearing a hard hat?

▫ When there is an overhead hazard.

▫ At Armstrong we are required to wear them at all times when outside in the field as well as in unfinished basements and attics.

H

EAD

P

ROTECTION

• Maintenance and Care

▫ Your hard hat should be kept clean and inspected regularly.

▫ If it cannot be cleaned with soap and water, replace the hard hat; do not use solvents.

▫ No paint, decals, names or unauthorized material should be attached

▫ No holes shall be bored or punched through any part of the hard hat.

Eye Protection

• Safety glasses should be worn at all times while working in the field including while working in customers homes.

• They are also required when working in the office or warehouse and performing any task where there is the possibility of eye injury.

• All safety glasses must meet requirements of

ANSI Z-87.1-2003.

Eye Protection

• Maintenance and Care:

▫ Safety glasses and goggles should not be left lying around or stored among tools where they can be damaged.

▫ To clean eye protective devices, use soap and hot water only. NEVER use any solvents, gasoline or similar cleaning substances which could cause skin or eye irritations.

R

EFLECTIVE

S

AFETY

V

EST

• All workers exposed to the risks of moving roadway traffic or construction equipment must wear high-visibility safety apparel.

• High-visibility safety apparel must meet the class two or three requirements of

ANSI 107-2004.

F

OOTWEAR

• Employees working in the field

▫ a minimum 8" upper

▫ arch support

▫ Defined heel.

• Employees involved in warehousing operations

▫ Steel or safety toe boots

G

LOVES

• Work Gloves

▫ Leather, leather faced or cloth work gloves are recommended whenever climbing a pole or working with coarse materials such as cable, wire, rope, etc.

▫ Gloves shall NOT be worn when working around the moving parts of machinery.

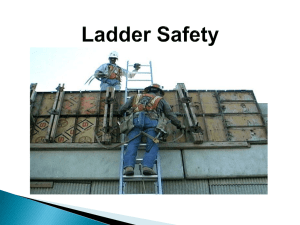

Ladder Safety

General Rules for all Ladders

• Only Fiberglass ladders should be used; metal or wood ladders are not acceptable.

• Why not metal or wood?

▫ Metal ladders are conductive

▫ Wood ladders are heavy, less durable, must be coated, and can become conductive.

General Rules for all Ladders

• What is wrong in the picture?

• Care must be taken to select the proper size and type of ladder for the job.

• Ladders shall only be used for the purpose intended by the manufacturer.

General Rules for all Ladders

• When ascending or descending ladders, workers are to face the ladder and use both hands to hold on.

• Employees shall maintain three points of contact at all times while ascending and descending.

• Materials shall never be “hand carried” up or down a ladder.

General Rules for all Ladders

• Ladders should not be used horizontally as runways or scaffolds.

• Ladders must not be stored near radiators, stoves, steam pipes, or in places where they may be subject to extreme heat or dampness.

• Ladders must not be stored in a vertical position.

General Rules for all Ladders

• Defective or damaged ladders must not be used and must be taken out of service.

• If a ladder is taken out of service because of a defect, waiting for repair, or being discarded, it will be marked "DANGEROUS-DO NOT

USE."

General Rules for all Ladders

• Never leave a ladder upright unattended!

▫ What could happen?

• Never try to "hop" or "walk" a ladder.

Reposition the ladder after descending it first.

• Never outreach while working on a ladder. If you must extend your breastbone beyond the ladder rail to reach an object, descend the ladder and reposition.

Ladder Inspection

• How often should you inspect your ladder?

▫ EVERYDAY before use.

Ladder Inspection

• The inspection should include the following items:

Hardware Accessories

Cables

Rivets

Working pole strap

Ropes

Damaged or loose rungs

Working footpads

Fittings

Side rail connections

Acid or alkali damage Rung-to-side rail connections

Working strand hooks Fully operational spreader

Ladder Inspection

• Do you think this guy inspected his ladder?

Rules for Extension Ladders

• Never put your hands through rungs when raising or lowering.

• Never climb any higher than three rungs from the top of the fly section. You could lose your balance.

• Belting On – Not OSHA requirement but a good idea!

▫ At the pole

▫ On a Mid-span

Handling

• Always Plan Ahead!

▫ Before picking up your ladder plan your route.

▫ Inspect it for overhead and tripping hazards

Look for holes and depressions in the ground.

Avoid tree branches, overhead drop wires, and other aerial obstructions.

▫ Use caution when moving ladders in high traffic areas.

Setup

• Ladders should be setup at approximately a four-

to-one ratio.

▫ That is, for every four feet high the ladder extends, it should be one foot out at the base.

• An arm extension will be close.

Setup

• Feet should be set properly

Firm Base Soft Base

Set the feet on the pads Set on the spikes and seat the ladder in the ground.

Setup

• Only ladders that are equipped with a strand hook/v-rung assembly should be used on a pole or strand.

• When a ladder is placed on the strand, the strand hooks must be “engaged” with the strand.

Setup

• Extend the ladder at least three rungs (three foot minimum) above any roof, eave or parapet if you must step onto the roof.

• Always check to be sure the extension locks are properly seated.

Setup

• What should we do before climbing a ladder using a pole for support?

▫ Inspect the pole

Prod test

Hammer test

Hand-line test

Setup

• Protect your ladder from traffic.

▫ When possible avoid setting your ladder up where it is exposed to traffic.

▫ If absolutely necessary to setup your ladder where it is exposed to traffic use you van to shield your ladder.

▫ Don’t put you van to close to your ladder.

Transportation

• There are many types of ladder transportation fixtures on the vehicles we use. However, there are a few common denominations needed to safely move our ladder from job to job.

▫ The fixture must be substantial in strength to support the weight of the ladder.

▫ At no time should the ladder be allowed to slide forward or backward possibly falling off the vehicle.

▫ Using makeshift tie downs, such as ground wire or drop cable, to fasten the ladder to the vehicle is prohibited.

Rules to Observe

• Spreaders must be fully extended and locked before climbing.

• A stepladder should not be used in place of an extension or straight ladder.

Rules to Observe

• Employees must not stand on the top step of a stepladder.

• When the ladder is not high enough for the job, get a taller stepladder or use another type of ladder.

Rules to Observe

• Tools or materials should not be placed on the steps of ladders.

• All ladders should be kept clean of dirt and grease.

Yes, the upcoming pictures are staged!

What’s wrong in this picture?

What’s wrong in this picture?

What’s wrong in this picture?

What’s wrong in this picture?

What’s wrong in this picture?

Please be Safe!