Uploaded by

Garrett Smithers

Honda 4-Stroke Engine Disassembly & 4 Bar Mechanism Lab Manual

advertisement

UNIVERSITY OF WOLLONGONG

Faculty of Engineering & Information Sciences

School of Mechanical, Materials, Mechatronic & Biomedical Engineering

MECH226 – MACHINE DYNAMICS

Spring Session - 2025

Laboratory Experiment 3 – In Person

Partial Dismantling and Assembly of a Honda 4 Stroke Engine

and Associated 4 Bar Mechanism Analysis

Arrangement

Each lab session can facilitate 8 separate groups with a maximum number of 24 students, i.e. 3

students per group. You will be advised if COVID-related circumstances change, given the nature

of this evolving situation. After completing the lab sessions, you will be required to answer further

questions and submit a single report per group. You will also be required to prepare 60 second

group video clip to explain and discuss the lab.

Aim

The aim of this laboratory experiment is make the student familiar with:

- disassembly and assembly of a combustion engine

- the different methods available for velocity and acceleration analysis

- the application of both kinematic and force analysis to a typical dynamic system

General Procedure

First the engine will be disassembled while taking notes on how the parts were connected

(Section A). The relevant dimensions and masses will then be measured (Section B). Thereafter,

the engine will be assembled in roughly the reverse order of disassembly, using the notes taken

during disassembly (Section C).

Equipment

- Honda four stroke engine

- Calliper, scale

- Tools (in the drawer)

- Stop watch

Planned Experiment Duration

120 minutes

1

Report (worth 75% of lab, only submit 1 per group)

The report is due one week after your lab class takes place.

The report is to be submitted in pdf format to the upload link made available under the Week

10 Lab Practice 3 Section in Moodle with a name following the format: Group_x_Lab_3.pdf,

where ‘x’ is your group number in week 12.

Only 1 group member needs to submit it, so do not upload duplicate files.

The report is to be no more than 13 pages total (including title page) to avoid mark penalties.

Please number the pages and use reasonable font size, line spacing, margins, etc.

Given the nature of the calculations may rely heavily on sketches, for this report you are

permitted to include scans (not photos) of your work. If you do not have access to a scanner, a

mobile application such as CamScanner may be used if needed. If you do scan your work,

ensure it is clear when in pdf format, as it will not be considered for marking if illegible.

The report is to follow the format: (1) title page (include lab name, group member names and

student numbers), (2) a brief introduction (including the aim and purpose of the lab), (3)

responses to all questions of Section A and B, and Section D: Tasks 1-6 (including all

calculations, or example calculations if repetitious, tables, etc.), (4) a brief conclusion/

reflection on the lab, and (5) references.

Table 2 of Task 6 must be filled out and included in your report, otherwise a 50% overall

mark penalty will be applied. Please note, if included but some values are missing because

your group was unable to determine certain values, this penalty will not apply.

Marks will be allocated for the quality of the report, namely: following the above structure

(important), analysis (appropriate use of theory, calculations, etc.), presentation (formatting,

labelling figures and tables correctly, etc.), and academic writing (language, grammar, etc.).

There will be mark penalties for not following any of the above dot points or indication of any

plagiarism.

Video Presentation (worth 25% of lab, only submit 1 per group)

The video is due one week after your lab class takes place (same due date as report).

The video is to be submitted in mp4 format to the upload link made available under the Week

10 Moodle folder with a name following the format: Group_x_Lab_3.mp4, where ‘x’ is your

group number.

Only 1 group member needs to submit it, so do not upload duplicate files.

The video is to be precisely 60 seconds long, with each student contributing an equal duration

of screen time (for 3 students, that is ~20 seconds each, with very brief title frames and

transitions allowed if desired).

The video is to include: (1) an explanation the experiment, (2) explanation of the analysis

conducted in the lab report, and (3) commentary on potential applications of the discussed

theory and what knowledge/ benefit has been acquired from this lab practice. The structure of

the video is flexible and each point here may vary in duration, provided each group member

maintains their fair share of screen time.

Marks will be allocated for the quality of the video, namely: covering the above points

(important), timing (i.e. precisely 60 seconds long or not), video quality (framing, lighting,

audio quality, etc.), and explanation (in terms of use of language, presentation, and technical

soundness).

There will be mark penalties for not following any of the above dot points or indication of any

plagiarism.

2

Section A, Disassembly of the Engine (during lab)

1. Disconnect the spark plug lead. Undo the cylinder head bolts and

nuts, and remove the cylinder head and cylinder head gasket. Note

the alignment of the gasket.

2. Measure the top and bottom position of the piston relative to the top

of the block while rotating the crankshaft (Note: this is twice the

crank radius).

Piston Top Dead Centre: …………

Piston Bottom Dead Centre:…………

3. Note the alignment of the piston in the cylinder …. There is a marker

indicating how the piston should be installed in the cylinder.

4. Unbolt and remove the crankcase cover (take care not to damage the gasket in

this process).

5. Rotate the crankshaft and observe the operation of the engine components.

Several points to note:

- The timing marks (centre-pops) on the crankshaft and camshaft gears these are used in the installation of the camshaft to ensure that the valves

operate at the correct phase of the piston cycle. Verify that they are

correctly aligned. This will be important when you reassemble the

engine. (Not very obvious in this engine …. Look carefully)

- Investigate the governor system. This uses centrifugal force as the

camshaft rotates, and in the standard set-up of this engine is used to

control the throttle setting (the control levers associated with component

have been disconnected for these engines to simplify dismantling)

6. Undo the end cap and lubricator (black tab on the bottom) from the

connecting rod and note the marks on the end cap and connecting rod. These

items must be reassembled in the same way during the assembly of the engine.

7. Push the piston and connecting rod up and remove them from the engine. Note that the piston

rings spring out as the piston exits the cylinder. During re-assembly of the piston into the

cylinder, the piston rings will need to be compressed to fit – ask for assistance if needed.

8. Disassemble the connecting rod from the piston by taking out the wrist pin and nylon buttons.

Put the wrist pin back in the piston and connect the big end bearing half and the lubricator of

the connecting rod to the rest of the connecting rod for the measurements to be taken in

section B.

3

Section B, Measurements on the disassembled engine

(during lab)

1. Make the following measurements on the connecting rod (ensure that "big end" end cap and

lubricator are bolted to the connecting rod):

• Mass

Ans: ……………………….

Diameter of the big end and wrist pin bearing journals

Big end dia.: ………………………

•

Wrist pin dia.: ………………………

Length between bearing centres

Ans: ……………………….

•

Equivalent point masses at wrist pin and big end bearing (static) by using the scale

(Tip: measure one point and take the difference with the total mass to find the other).

Eq. mass at wrist pin: ………..…. Eq. mass at big end: ……….……

2. Ensure that the wrist pin with its retainers is assembled in the piston and determine the mass of

the piston assembly using the scale.

Ans: ……………………….

3. Measure the cylinder bore.

Ans: ……………………….

4. Determine the inertia of the (already setup) connecting rod with lubricator by measuring the

period of oscillation under gravitational acceleration – as done in laboratory experiment 1.

Use the table below for your results. See the notes of lab 1 to recall necessary formulae.

Table 1 – Connecting rod pendulum data

No of Periods

Observed

10

(fill Io after lab)

Total

Time [s]

Period

[s]

Io

[kg·m2]

10

10

10

5. Using the provided head-block, determine the volume of the part of the combustion chamber

inside the head using the available water, pipettes, and scale. Note: 𝜌𝑤𝑎𝑡𝑒𝑟 = 1 𝑔/𝑐𝑚3 .

𝑚𝑤𝑎𝑡𝑒𝑟 = ……………….

→

𝑉ℎ𝑒𝑎𝑑−𝑏𝑙𝑜𝑐𝑘 = ……………….

6. Similar to Question 5, determine the volume surrounding the valves in the combustion

chamber.

𝑉𝑣𝑎𝑙𝑣𝑒𝑠 = ……………….

7. Trace the head gasket on a piece of paper and measure the thickness of the head gasket.

Later, you will need to approximate the head gasket (internal) area and finally volume.

4

Section C, Reassembly of the engine

(during lab)

Assembly of the engine is more or less the reverse of the dismantling procedure. Use the notes

and sketches taken in Section A for reassembly.

1. Spray the bearing components inside the crankcase with the lubricant supplied (for the

purposes of this laboratory experiment, the oil normally present in the crankcase has been

drained).

2. Reassemble the engine, reversing the above dismantling procedures. Note in particular the

following:

-

-

-

Care must be taken in using the ring compressor and installing the piston in the cylinder,

check with tutor before attempting this step if you need assistance.

Ensure that the connecting rod end cap (note the marks on the connecting rod and end cap)

and lubricator are installed in the correct orientation, use your sketch taken in Section A

Check that the cam followers are in place, and that the cam shaft and crank shaft gears are

in the correct alignment (centre pops line up). Rotate the engines slowly by hand and

confirm that the valves are operating.

The crankcase cover plate must be eased up flush with the crankcase BY HAND before

the bolts are inserted and tightened. Force is NOT required for this step, just precise

alignment. This should be done with the piston at TDC, both valves closed. This ensures

that the valve springs are not providing a load on the cam shaft.

For each component (i.e. side-plate and cylinder head) FINGER TIGHTEN ALL bolts

first, before commencing to tighten with the T-bar and socket.

DO NOT OVERTIGHTEN THE SIDEPLATE AND CYLINDER HEAD BOLTS.

The aluminium thread in the block can easily be stripped. Report on this sheet any stripped

threads on your engine.

3. Ask the tutor to check the assembled engine and load the carburettor tube with a small amount

of petrol

4. Test run your engine by pulling firmly on the starter chord. While one team member pulls on

the chord another team member should control the throttle position. The engine will only run

briefly with the small amount of petrol that has been supplied (which is appropriate as the

engine does not have its standard oil lubrication supply). Ask the tutor for assistance if you

experience difficulty starting your engine.

5

Section D, Analysis

(after lab)

All the calculations and results of this section should be described in your report. Make sure you

describe method employed, the results and (if this is mentioned in the task) discuss the results.

Task 1, Determination of Inertia of Connecting Rod with Lubricator

Calculate the centre of gravity and the inertia of the connecting rod, using the equivalent point

masses (Section B-1), see [pp. 614, 615, eqn (13.9c) of Norton] or [pp. 440, 441, eqn (9.54) of

Mabie & Reinholtz] . Also determine the inertia using the results from the oscillation experiment

(Section B-4).

Compare the two results for inertia and give a brief discussion in your report (max 10 lines).

Task 2, Velocity and Acceleration Analysis

Using Unit Vector OR Graphical Analysis techniques determine the:

- velocity and acceleration of the piston

- velocity and acceleration of the connecting rod big end bearing centre

- angular velocity and angular acceleration of the connecting rod

While no longer a requirement, you may like to compare both analysis techniques to verify

against one another before moving on to the force analysis. This can prevent major errors in the

later force analysis, and should serve as good practice for your final exam.

For this analysis take 𝜙 = (5 + N1) degrees (angle of crank to the vertical) on the power stroke,

and an engine speed of (2750 + 10 N2) RPM.

Where:

N1 = {(the last 2 digits of the student number of one of the group members) / 2} rounded to the

nearest integer.

N2 = the last 2 digits of the student number of another group member

With most groups having 3 group members, you may elect two of the student numbers to use

for this task. The same goes for groups of any other size, if permitted for special circumstances.

See lecture notes, Norton sections 13.2 - 13.9, or Mabie & Reinholtz Ch. 8 for a review of the

relevant theory and application.

Task 3, Inertia Force Analysis

Determine the magnitude and direction of the inertia force on the piston and the inertia force and

torque on the connecting rod, which occurs in the angle and at the rpm determined in task 2. [NB

assume the cg of the crank is at O2 (pivot point), due to the counterweight, and hence there is no

inertia force acting on the crank.] Use either Unit Vector OR Graphical Analysis.

Task 4, Joint Force Analysis

Using the principle of superposition [See lecture notes, section 13.9 Norton, or section 9.6 Mabie

& Reinholtz], determine the joint forces at both ends of the connecting rod, the side force on the

piston, and the torque output from the crankshaft. For this analysis, determine a gas pressure from

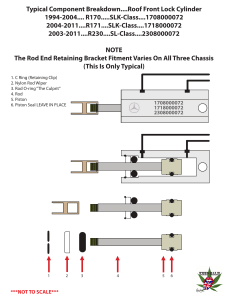

the accompanying Figure 1, appropriate to your crankshaft angle, and apply the resulting force to

the piston. Use either Unit Vector OR Graphical Analysis.

Task 5, Compression Ratio

Calculate the compression ratio of this engine, using the measurements taken in Section B-5. Also

calculate the compression ratio from Figure 1. Discuss briefly the results of your calculations.

6

3500

compression

Pressure (kPa abs)

3000

power stroke

exhaust stroke

2500

intake stroke

2000

1500

1000

500

0

0

25

50

75

100

125

150

Volume (cc)

175

200

225

250

Figure 1 – PV Diagram for Honda G200 Engine at ≈ 3000 – 4000 rpm

Note: Minimum volume occurs at 0° top dead centre (TDC) - Determine the increase in volume for your specific crank shaft angle, and hence find

the relevant gas pressure to use in the analysis (this will be on the upper curve). Atmospheric pressure acts on the bottom of the piston.

7

Task 6, Results table

Enter your results into the below table. A word document containing the table (to make it

easy to reproduce in your report) can be found in the Week 10 folder on Moodle. It is

mandatory to provide a summary of your results in this table. Failure to do so will incur a

50% mark penalty.

Table 2 – Results table

Basic Measurements used in the analysis

Crank Radius (mm)

Conrod Length (mm)

Engine Speed (RPM)

Crank Angle for analysis (deg)

Task 1

By Point Mass

Method

By Oscillation

Method

Units

Inertia of Connecting Rod

Task 2

Method used: (indicate whether graphical or unit vector →)

Units

Velocity of Piston

Acceleration of Piston

Velocity of Big End Bearing Centre

Acceleration of Big End Bearing Centre

Angular Velocity of Connecting Rod

Angular Acceleration of Connecting Rod

Task 3

Method used: (indicate whether graphical or unit vector →)

Units

Inertia Force on Piston

Inertia Force on Connecting Rod

Inertia Torque on Connecting Rod

Task 4

Method used: (indicate whether graphical or unit vector →)

Gas Pressure

Gas Force

Side Force on Piston

Force at Wrist Pin (little end bearing)

Force at Crank Pin (big end bearing)

Torque output at crankshaft

Task 5

Compression Ratio (from lab measurements)

Compression Ratio (from Figure 1)

8

Units