Uploaded by

m.farooq

OTDR Testing Explained: Fiber Optic Cable Troubleshooting & Measurement

advertisement

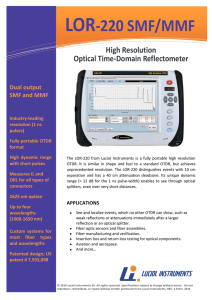

What is OTDR Testing? (optical time domain reflectometer) OTDR Testing Terminology Types Specifications View Products Use Selector Tool Contact an Expert OTDR Testing An Optical Time Domain Reflectometer (OTDR) is an instrument used to measure and create a visual representation of a fiber optic cable route. The measurement data can provide information on the condition and performance of fibers, as well as any passive optical components along the cable path like connectors, splices, splitters and multiplexers. Troubleshoot Fiber Optic Cable Failures with OTDRs The OTDR is also a fiber testing tool for troubleshooting fiber optic cable failures by locating the distance to the fault and identifying the type and cause of the fault, including breaks, bends, bad connectors, and any excessive insertion loss “events”. To do this an OTDR uses the effects of Rayleigh scattering and Fresnel reflection to measure the condition of a fiber link, and while single-ended (uni-directional) tests can be performed, dual-ended bidirectional OTDR testing improves measurement accuracy event detection and is required to comply with the IEC and ITU-T testing standards. Predictive OTDR Measurements Along with the Rayleigh scattering method used to characterize fiber links, OTDR can also use Raman and Brillouin scattering effects to predict breaks, monitor fiber health, and prevent service outages through temperature and strain measurements. These three techniques form a powerful combination for managing fiber cabling networks or utilizing the fiber for Distributed Fiber Optic Sensing. How Does an OTDR Work? (A wavelength is the distance between two corresponding points on a wave, such as from crest to crest or trough to trough. Short wavelength higher frequency, and vice versa. Unit is lambda λ which is = c x f c is the speed of light) (The amplitude of a wave is its maximum displacement from its equilibrium position. It represents the wave's strength or intensity and is measured from the center line (equilibrium) to the crest (highest point) or trough (lowest point). A larger amplitude indicates a more powerful wave carrying more energy) The OTDR sends a pulse of light energy (optical power), generated by a laser diode, into one end of an optical fiber. A photodiode measures the returning light energy or optical power reflected and scattered back (backscattered) over time and converts it into a measurement value that is displayed as a graph (or trace) on a screen. Optical pulse with width is send and when the width increases and the amplitude goes down, its dispersion which is then converted to delay. Short pulse can be used for short distance and will have high accuracy (resolution) Long pulse can be used for long distance and will have low accuracy (resolution) The location of each event and the overall cable length are calculated based on the round-trip time of the light pulse traveling through the fiber core and the reflected/backscattered light returning to the OTDR detector. The insertion loss is calculated from the proportional amplitude change of the reflected/backscattered light. (In fiber optics, backscatter light is the portion of light that is reflected or scattered back towards the light source (transmitter) as it travels through the optical fiber. This phenomenon occurs due to imperfections and variations in the fiber's refractive index, causing light to scatter in various directions, including backward) In fiber optics, insertion loss (IL) refers to the reduction in optical signal power that occurs when a device, such as a connector or splice, is inserted into a fiber optic link. It's a measure of how much signal strength is lost when the light passes through the device, and it's typically expressed in decibels (dB) What is Insertion Loss in fiber optics? Insertion loss means the amount of signal power that is lost when you connect (or "insert") a fiber optic component into a system. In other words: whenever you join two fibers, or connect a fiber to a device (like a connector, splice, or coupler), some light gets lost. This loss is measured in decibels (dB). Example: Imagine you have a flashlight shining through a clear plastic tube: At the start, 100% of the light goes in. At the end, if you measure, maybe only 95% of the light comes out. That 5% loss is because of the connector or splice — we call that insertion loss. In numbers: Input power: -10 dBm Output power after connector: -11 dBm Insertion loss = (-10) – (-11) = 1 dB So the connector caused 1 dB insertion loss. SEC OTDR Testing Analogy: 1) First we will conduct fiber inspection and cleaning using Viavi P5000i which is a microscopic fiber inspection tool with usb to attach to laptop. There are 2 types of cleaning DRY and WET with alcohol (after wet we must always go to dry inspection) Important Concepts for OTDR testing. Attenuation The reduction in optical power of the light signal as it is transmitted. Fiber attenuation is expressed in decibels per kilometer (dB/km). The degradation in a transmitted light signal may be due to bending, splices, connectors/connections, or the absorption and scattering properties of the fiber itself. Backscatter A term used to describe the dispersed reflection of light back in the direction from which they originated. The amount of backscatter is one indicator of total fiber attenuation, since light traveling back to the source represents a loss in downstream signal intensity. In OTDR testing, for ‘healthy’ fiber the amount of backscattered light is only about one-millionth of the test pulse. Reflectance A measure of the proportion of light reflected by abrupt changes in material density. Connectors/connections, air gaps and breaks will reflect light back, allowing the OTDR to determine the position, condition, and signal loss from these components/events. The magnitude of a reflection will depend upon the degree of change in the index of refraction. Refraction Refraction is the bending of light waves as they pass from one transparent material type to another. The amount of light reflected is determined by the differences in the index of refraction of two fibers and is mostly an issue associated with connectors but can also effect mechanical splices where an index matching gel is used. OTDR Testing Process Performing an OTDR test requires some basic setup, programming, test execution, and reporting processes to be followed. Power on the OTDR and verify the battery is charged and the test display is functioning. Clean and inspect the ends of all fibers under test, launch cables, connectors, and adapters. Carefully connect the launch cable to the test port of the OTDR at one end and the fiber under test at the opposite end. Select a pre-programmed test configuration (or setup), based on the network type and test conditions, or set/adjust the test parameters as necessary. Manual OTDR test parameter settings typically include the following: o Range: Sets appropriate range (distance) based on the overall fiber length o Pulse Width: Sets the duration of each laser pulse emitted o Acquisition Time: Simply means how long the OTDR spends collecting light signals from the fiber to make the trace (the graph). (i) If the acquisition time is short, the OTDR gives a quick result, but the trace may look noisy (less clear). (ii) If the acquisition time is longer, the OTDR averages more signals, so the trace looks smoother and clearer o Sets the time duration for averaging the measurements of reflected or backscattered light o Refractive Index: Adjusts for the index of the cable material being tested o Loss threshold when a fiber is tested there will be some minor impurities also which are not that significant so they are ignored and we keep a loss threshold not to count them .settings for the system and individual elements or “events” Initiate the OTDR acquisition to obtain the test results and graphical “trace” Store and/or upload test results as necessary Carefully disconnect all cables, connectors, and adapters Insertion loss for different connectors: Rule of Thumb: 0.2–0.3 dB per connector is ideal. Anything >0.5 dB usually indicates. Acceptable maximum (per standards) = ≤ 0.5 dB for single-mode, ≤ 0.75 dB for multimode o o o o Dirty connector end face. Poor polishing. Bad alignment. Connector damage. IL = Insertion loss, RL= Return loss Example: Link Loss Budget If you have: 4 connectors (each ~0.25 dB) → ~1.0 dB loss. 2 splices (~0.1 dB each) → ~0.2 dB loss. Fiber attenuation (~0.35 dB/km @ 1310 nm, single-mode). Total link loss = connectors + splices + fiber length. This is why keeping connector loss low (≤0.3 dB) is critical. OTDR Best Practices A launch cable (also called launch fiber) in OTDR testing is like a starting runway for light. When you test a fiber with an OTDR, the very beginning of the fiber (near the connector) often looks messy on the trace, making it hard to measure properly. So, we attach a long extra fiber (the launch cable) between the OTDR and the real fiber under test. This gives the OTDR enough “runway” for the light to settle down, so we can see the first connector and the rest of the fiber clearly. Before launch or reference cables and the fiber under test are connected for measurement, fiber cleaning and inspection practices are of the upmost importance. Mating connectors between launch cables, the fiber under test, and OTDR must be compatible to minimize reflectance. Imagine a hose bib with a loose or crooked connection to the hose itself, causing water to leak and spray backwards from the junction. This is similar to the impact of an incorrect OTDR connection, when air gaps allow too much light to be reflected back and overload the photodiode. The use of a receive cable at the far end of the fiber under test is another recommended best practice and specified in the IEC and ITU-T test standards in order to accurately measure the end connector. To measure and qualify a connector it must be mated with another connector so that when an OTDR test is performed light passes through the connector end face into the end face of the receiving mated connector and receiving fiber, providing an optical linkage that allows losses to be measured for the end connector. The best handheld OTDR tools include features for one touch operation and applications tailored for different skill levels and network types. The VIAVI SmartOTDR Handheld Fiber Tester delivers improved productivity with automated pass/fail test results. Interpreting the OTDR Test Results Once the OTDR test is completed, the instrument will display the OTDR results in both numeric and graphical formats. The graph, also called a trace, will show where each connector/connection, splice, bend or break is located, along with the signal loss (in dB) and reflection characteristics of each element. Advanced VIAVI OTDR test equipment with features like SmartLink Mapper (SLM) also translate this trace data into an icon based linear view where each element and event is represented as an easy-to-read icon, with pass/fail information visible immediately, and the name of each component/event clearly shown. SmartLink Mapper also provides customized applications and icons for applications like FTTH, PON networks, or Fiber to the Antenna (FTTA). The overall fiber length and link loss are displayed once a test run is completed. If loss thresholds were initially set, Pass or Fail will be indicated for each element of the fiber link. Types Although feature sets, size, and cost vary significantly, there are three main categories of OTDR test equipment available on the market today. Benchtop This term typically describes the OTDR test equipment used in laboratories and production facilities. Benchtop devices can be placed on a laboratory workbench or in a production test bay, and usually have a larger display, more available expansion ports for applications like MPO testing, and a direct AC (outlet) power source. Benchtop OTDR test equipment may be used when a high level of accuracy, sensitivity or long-range measurement (with its inherent high power pulse intensity) is required. Hand-held OTDR As the name implies, hand-held OTDR test equipment is lightweight (less than 1kg), portable, typically battery-powered, and optimized for use in the field. The user interface is usually simple and straightforward so that technicians can easily learn to operate the OTDR. Hand-held OTDR meters can also integrate additional tools needed for fiber certification and troubleshooting, such as Visual Fault Locators (VFL), Optical Power Meters (OPM), and compact fiber inspection microscopes. Connectivity options including Wi-Fi or Bluetooth can be used to transfer test results and work orders quickly. Embedded or Rack-Mounted OTDR Embedded OTDRs are designed and manufactured with a small form factor that can be integrated easily within network monitoring equipment. Rack-mounted OTDRs are combined with an optical switch to automatically rotate across many fibers. A programmed test routine can prioritize critical fibers and important customers. These fiber monitoring applications can be used for either in-service or dark fiber monitoring. Specifications OTDR specifications are important to understand so one can choose the right OTDR for a dedicated application. Dynamic range Expressed in decibels (db), the dynamic range is defined as the difference between the initial power level reflected from the fiber when set to maximum pulse width and the upper level of the noise floor of the detector. The dynamic range determines the maximum observable length of a fiber. Event dead zone The event dead zone (EDZ) is the minimum distance that the OTDR can detect between two reflective events (typically two connections). In the case where the reflective events are more closely spaced than the EDZ, the OTDR will show them as one event. Attenuation dead zone The attenuation dead zone (ADZ) defined in the IEC 61745 standard is the minimum distance after a reflective (e.g. connector) or attenuation (e.g. splice) event, where a non-reflective event (splice) can be measured. Much like the EDZ, the ADZ is dependent on the pulse width. Wavelengths An OTDR sends a pulse of light based on to the wavelength(s) used for transmission when the fiber link is operational. The typical wavelengths are 850 nm and 1300 nm for multimode fiber and 1310 nm, 1550 nm and 1625 nm for single-mode fiber. Filtered 1625 nm or 1650 nm wavelengths can be used for in-service maintenance testing to avoid interference with the live traffic wavelengths. Bidirectional OTDR Testing An inherent benefit of OTDR testing is that it requires access to only one end of the fiber optic cable to perform. Because the distance and attenuation measurements are based on optical light backscattering and Fresnel reflection principles, scattered and reflected light photons can be analyzed at the same location where the test signal originated. To minimize the impact of errors and uncertainty that can accompany conventional unidirectional testing, bidirectional OTDR testing methods have been developed to enhance the accuracy and precision of this important test methodology. As the name implies, bidirectional OTDR testing is a method of optical fiber characterization and loss testing that is performed from both ends of the fiber run. How it Works: In addition to the OTDR equipment and fiber optic cable under test, a basic OTDR test configuration also includes a launch cable and a receive cable. The launch cable connects the OTDR test port to the fiber run under test and is referred to as a “pulse suppressor”, since it serves to stabilize the initial light pulse from the OTDR before it enters the tested cable. The receive cable connects at the far end of the run and provides a mated fiber connection/junction, with an appropriate run-out segment, allowing the losses of the terminating connector to be assessed. The existence of these launch and receive cables creates a symmetrical configuration at both ends of the run. In bidirectional OTDR testing, the same fiber characteristics are measured again, using the same (or an additional) OTDR at the opposite end of the run and averaging or combining the results with those obtained in the initial direction. Bidirectional fiber testing can often produce more accurate results than unidirectional testing, based on the test methodology itself. Since Rayleigh backscattering is used to quantify attenuation and signal loss events, the backscatter coefficient of the fiber must be known and programmed into the OTDR. These coefficients may vary from fiber to fiber, or even within a single fiber. The resulting effect can be misinterpreted as excess signal attenuation or even negative attenuation (gain) at junctions between sections in a fiber run. This variation can be compensated for by averaging the results for end to end loss and individual loss at each connection or splice, using a bidirectional OTDR test. Benefits If the transition at a fiber junction results in a fiber with a lower backscatter coefficient transitioning to a fiber with higher coefficient, the result could be a masking of the actual loss at the interface or splice. This masking or distorting effect is also known as a gainer since the amount of observed backscattering will be higher after the loss event than before it. Conversely, if the transition is from a higher backscatter coefficient segment to a lower one, the resulting signature might incorrectly show a higher loss event at this same location. Averaging the values obtained from opposite sides can provide a more accurate quantification of loss. Another benefit of bidirectional optical fiber testing is the mitigation of dead zones, where the initial Fresnel reflection from an event, such as a splice or connector, has temporarily blinded the OTDR detector rendering it unable to see reflections and backscatter from additional events directly behind the splice or connector. Since the effect of dead zones tend to occur more frequently closer to the OTDR measuring again from the opposite direction will allow an accurate assessment for the portion of cable that was included/masked in a dead zone during the first measurement. Long-haul fiber optic cable runs, such as terrestrial networks between cities and countries, require powerful OTDRs with a higher dynamic range in order to accurately assess the fiber span unidirectionally. Using bidirectional fiber testing such as bidirectional OTDR is an excellent way to improve the test integrity over these very long distances. By combining OTDR measurements obtained from each end, the impact of test pulse degradation at the farthest points from each OTDR can be minimized. Rather than averaging the results, another analysis method used for long-haul applications involves utilizing the OTDR acquisition from each end of a cable run for those sections closer to each end, then creating a composite OTDR trace, where the two acquisitions effectively meet in the middle of the link. Bidirectional OTDR Testing Drawbacks Despite the advantages in accuracy and range to be garnered through bidirectional OTDR testing, the additional complexity that can accompany this method needs to be considered. In a basic bidirectional test configuration using a single OTDR device, the OTDR must be transported from one end of the fiber run to the other to complete the testing. Even when duplicate OTDRs are utilized, bidirectional testing can add additional set-up time, transportation costs and analysis to the OTDR test process. Bidirectional OTDR testing may improve the quality and accuracy of measurement data overall, but it is important to recognize that bidirectional fiber testing will not compensate for setup issues such as unclean connections, incorrect test parameters 0r excessive noise in the OTDR trace. Since bidirectional OTDR requires a duplication of tests, there are more opportunities for errors and inconsistencies. Methods As the advantages and challenges involved in bidirectional OTDR have emerged over the years, creative solutions, in the form of new and innovative test methods, have been developed. Benefits in accuracy and range may be seen from many of these methods, along with improved efficiency and consistency. Conventional Bidirectional OTDR Testing The method referred to as “traditional” or conventional bidirectional OTDR testing is the simplest and requires the least amount of equipment. Two independent measurements are performed using the same OTDR. The first measurement is performed by connecting the OTDR to the launch cable while the receive cable is in place at the opposite end, but not connected to a test device. Leaving all cables in their original positions, the OTDR is then disconnected from the cable under test and moved to the opposite end. By connecting to the receive cable, the same measurement can then be repeated in the opposite direction. It is important for all optical fiber segments in the tested configuration to remain in the same order during both tests, so that the averaging of loss data obtained from the two tests will be relevant. Automated Bidirectional OTDR Testing The time, complexity and analysis required for conventional bidirectional OTDR can be significantly reduced using automated bidirectional OTDR test methods. By employing a master OTDR test device in tandem with a remote device connected at the opposite end of the fiber run, communication between the two OTDRs will ensure identical test setup configurations, fiber connection continuity, and ease of data acquisition and compilation. The convenience of an automated test can improve test speed while greatly reducing error rates. If an all-in-one test solution is used, the same automation features can also be used to perform OTDR testing at multiple wavelengths (to improve fiber bend detection) and include bidirectional insertion loss and optical return loss testing. Other Bidirectional OTDR Testing Methods Additional bidirectional OTDR methods have been developed over time to improve efficiency or potentially reduce the amount of test equipment needed. One such method is known as “loop back” testing. Rather than situating a second OTDR at the far end of the fiber run, a loopback cable connects one fiber to a second fiber which also requires testing. In this way, an OTDR test pulse can be sent down one fiber and continues through the loop back and down the second fiber too, thus testing both fibers uni-directionally at the same time. To gain the benefit of bidirectional OTDR testing, both fibers (including the loop back) are then tested in the opposite direction from the same location. This method can use a traditional OTDR approach such as in case 1) where a single OTDR is moved from the first to the second fiber to manually test in each direction and the results are manually combined or an automated OTDR approach such as in 2) where two OTDRs are used, one connected to each fiber to automatically test each direction and combine test results. Tools There are currently a wide variety of bidirectional OTDR test tools available to facilitate efficient and versatile fiber testing. OTDR and multi-use test devices can be easily configured for automated bidirectional OTDR and other bidirectional fiber testing at the push of a button. Test instruments positioned at either end of the fiber run can communicate and share data nearly instantaneously via Ethernet, WiFi or mobile hotspots. These devices also include on-board report generation for convenience and speed. Integrated test solutions can perform bidirectional fiber tests using multiple wavelengths from a test single port to deliver more efficient test workflow, saving precious time during the installation and acceptance testing phase, as well as streamlining troubleshooting and maintenance. A high level of accuracy, repeatability, and automation provides a reliable solution for many fiber qualification and characterization applications. With the advent of OTDR, our ability to see inside thousands of miles of microscopic fiber has catapulted fiber optic communications technology to unprecedented heights. Bidirectional OTDR once represented a calculated trade-off between data integrity and convenience. New and improved bidirectional OTDR testing methods and devices have changed the conversation, providing additional capabilities and timesaving features that make precision fiber characterization the new industry standard. CD – Chromatic Dispersion What it is: Different colors of light (like red, blue, green) travel at slightly different speeds in the fiber. Problem: Over long distances, the light pulses spread out and blur together, making it hard to tell 1s and 0s apart. Definition: The spreading of an optical pulse as it travels down the fiber because different wavelengths (colors) of light travel at slightly different speeds. Impact: o Pulse broadening → inter symbol interference (ISI). o Limits distance and data rates (especially above 2.5 Gbps and more severe at 10 Gbps, 40 Gbps, 100 Gbps). Measurement units: ps/nm·km (picoseconds per nanometer per kilometer). Testing: CD test sets send multiple wavelengths through the fiber and measure the delay difference between them. PMD – Polarization Mode Dispersion What it is: Light can vibrate in different directions (polarizations). In fiber, one direction may travel faster than the other. Problem: This also smears the signal, especially at very high speeds. Think of it like: Two runners starting together, but one always runs slightly faster — over time, they’re no longer side by side. Definition: The spreading of an optical pulse caused by different polarization modes of light traveling at slightly different speeds due to fiber imperfections or stress. Cause: Asymmetries in the fiber core, bends, twists, and environmental stresses. Impact: o Random pulse spreading → system penalties at high bit rates. o Particularly problematic for ≥10 Gbps systems. Measurement units: ps/√km (picoseconds per square root kilometer). Testing: PMD test sets measure differential group delay (DGD) between the two principal polarization modes. CD (Chromatic Dispersion): Wavelength-dependent delay. PMD (Polarization Mode Dispersion): Polarization-dependent delay. Both cause pulse broadening and limit the maximum distance/data rate of optical links, so they’re routinely tested in long-haul and high-speed networks (10G, 40G, 100G+) AP – Attenuation Profile What it is: How much the light signal fades (weakens) as it travels along the fiber. Problem: If the signal gets too weak, the receiver can’t read it. Think of it like: Your voice getting quieter as you shout down a long tunnel. ✅ So, Fiber Characterization (CD/PMD/AP) is simply checking: Do all the colors of light arrive together? (CD) Do all polarizations stay aligned? (PMD) Does the light stay strong enough? (AP) This helps engineers know if a fiber can carry fast internet speeds reliably. Some Additional information: MPO: multi fiber connector and is used for data center. Fiber identifier FI 10/11/60: live fiber identifier. (i) FI-60 as power meter and identifier, power meter with light source can find losses. MTS-4000 modular otdr with 46db distance. ONA-800 modular otdr with 50db distance. B module is for 140km C module is for D module 200km (i) (ii) (iii) If less then < 40 go with Smart OTDR If b/w 40 to 45 we go with MTS-4000 with B module If more then 46 to 50 we go with ONA800 fiber test. Note: SEC standard for launch cable is 1000mtr. MTS-5800 is a multi protocol tester (WDM). It can measure from layer 2 to layer 4 frames, packet, segment, TCP/UDP. It can support upto 100Gbps but to have 400Gbps then use ONA-800 n/w tester.