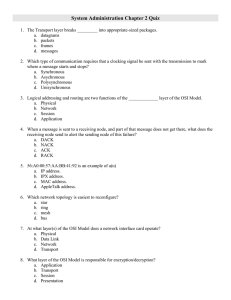

CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 1 of 11 Revision: 2 11507 General Design and Fabrication Practices, Process Equipment Handling Explosives EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G123 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 2 of 11 Revision: 2 Table of Contents 1. Scope ............................................................................................................................................................. 3 1.1 Introduction ...................................................................................................................................... 3 1.2 Applicability ..................................................................................................................................... 4 2. General Guidelines ...................................................................................................................................... 4 3. Fastening and Joining ................................................................................................................................. 5 3.1 Welding ............................................................................................................................................ 5 3.2 THREADED FASTENERS ............................................................................................................. 8 3.3 OTHER JOINING DEVICES AND PROCESSES ......................................................................... 8 4. SURFACE FINISHES ................................................................................................................................ 8 5. ELECTRICAL COMPONENTS ............................................................................................................... 8 6. ELECTRICAL GROUNDING AND BONDING..................................................................................... 8 7. MATERIALS OF CONSTRUCTION ....................................................................................................... 8 8. CASTINGS................................................................................................................................................... 9 9. SPECIAL APPROVAL OR EXCEPTIONS............................................................................................. 9 10. EQUIPMENT CONSTRUCTION AND FABRICATION INSPECTION ............................................ 9 11. 10.1 Photographs ...................................................................................................................................... 9 10.2 Pre-Contract Meeting and Job Discussion ....................................................................................... 9 10.3 Intermediate Inspections................................................................................................................. 10 10.4 Final Inspection .............................................................................................................................. 10 References .................................................................................................................................................. 10 11.1 BAE Standards ............................................................................................................................... 10 11.2 Other References ............................................................................................................................ 10 EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G124 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 3 of 11 Revision: 2 Revision History ECO NUMBER REVISION NUMBER 1 ECO-001000 2 DATE APPROVED 12-2009 6/3/2021 DESCRIPTION OF CHANGE Updated to new format. Updated notes about PT, Weld map example and additional weld X-rays when welds fail X-ray inspection. 1. Scope 1.1 Introduction 1.1.1 The design and fabrication of process equipment for Holston Army Ammunition Plant (HSAAP) to handle high-energy explosives requires the application of principles and practices not normally found in the chemical processing industry. 1.1.2 For obvious reasons, emphasis is placed on designing equipment and processes to maximize the safety of those that must operate and maintain them. Also of concern in design is the prevention of lost production capability (that can result from explosions). Normal concerns in design work (i.e. economy, efficiency, ease of fabrication, etc.) are considered important, but are addressed only after the above requirements are satisfied. 1.1.3 Explosives manufactured and processed at HSAAP are usually in a particulate form. Depending on the processing stage, explosive particles may be found in water slurry, acid or solvent slurry or solution, or in some stage of drying (from moist cake to dry powder). Also, TNT (in molten form) is processed. At various processing stages, explosives can be found as coatings on the equipment, dry and hard-packed into pockets or crevices, and (in some cases) having migrated into service lines connected to the equipment. The variety of forms and behavioral characteristics of these explosives explains (to a degree) the unusual design requirements contained in this standard. 1.1.4 Generally speaking, explosives are more sensitive to initiation as the liquid amount (water or acid) involved decreases. Initiation sources commonly encountered in equipment design are impact, friction, and electrostatic discharge. Thermal heating and impingement are also possible initiation sources. Electrical arcing is also a possible initiation source. Therefore, electrical equipment of the proper hazardous area classification must be used. The design and fabrication guidelines presented in this standard are directed at prevention of these initiation sources. 1.1.5 NOTES: 1.1.5.1 Please read this OSI Engineering Standard carefully 1.1.5.2 All requirements in this OSI Engineering Standard apply to the item(s) being fabricated, constructed or supplied for the specific purchase stated. 1.1.5.3 Prior fabrication or construction requirements performed on previous purchases do not apply if there is a contradiction to this OSI Engineering Standard. EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G125 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 4 of 11 Revision: 2 1.1.5.4 All exceptions to all OSI Engineering Standards must be in writing and included in the Purchase Agreement. 1.1.5.5 Equipment construction and fabrication inspections, including x-ray options are required unless otherwise stated in writing in the Purchase Agreement. 1.1.6 1.2 DG-0035 was created and to be used in conjunction with 11507 to help provide clarity around the intent of 11507 Applicability 1.2.1 This standard is to be used for the design and fabrication of all process equipment handling explosive material within the Holston and Radford Army Ammunition Plant. 2. General Guidelines 2.1.1 OSI is contractually obligated to incorporate the requirements of Army Safety Manual AMC-R 385-100 and Federal Occupational Safety and Health Act (OSHA) into its designs and installations. 2.1.2 Surfaces exposed directly to the explosives shall be smooth and free of discontinuities. Surface finishes shall be as stated in the specifications or on the drawings. There shall be no cracks, crevices, or protrusions that could promote growth of explosives crystals. (See Paragraph 3.1. for welds and Paragraph 8.0. for castings) 2.1.3 Process-wetted surfaces shall have no points where explosives particles can be exposed to the action of two metal parts moving relative to one another (either in impact or sliding motion). This includes cracks in metal parts that can produce relative movement of sides during thermal expansion and contraction. The use of threaded fasteners in following locations must be avoided: 2.1.3.1 Where exposed directly to the process 2.1.3.2 In a position to fall (or end up) in the process 2.1.3.3 Where the process may splash (or be dropped) onto them 2.1.4 The elimination of threaded fasteners may require extensive design (or redesign) of existing equipment to meet this requirement. Dead-ended bolts and cap screws are not permitted, except where authorized by OSI. All threaded fasteners that absolutely cannot be eliminated must be approved (in writing) by OSI before fabrication begins. 2.1.5 Process equipment shall be designed to permit easy visual inspection and clean up of all parts exposed to explosives. The use of hollow shafts (or support members) is to be avoided. Solid shafts are required, as are solid types of structural shapes for supports. Hollow members (even when the ends have been welded shut) have been found to contain enough explosives to be classified as serious safety hazards, especially when welding repairs are performed. 2.1.6 Larger, more complicated pieces of process equipment shall be designed so there are no areas that could trap personnel in the event of an emergency. EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G126 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 5 of 11 Revision: 2 2.1.7 In general, the factors of safety, service factors, and specifications (used in process equipment design) should exceed industry practice for similar equipment. Explosives processing equipment must be as safe and reliable as practicable. 2.1.8 The use of thermal insulation on explosives processing equipment is not permitted without OSI written approval. 2.1.9 Electrical components used on explosives processing equipment must meet NEC requirements. (See Paragraphs 5. and 6.) 2.1.10 When designing process equipment, the occurrence of parts rotating relative to one another is unavoidable. In such cases, the design strategy that must be followed is to minimize the hazard potential. To accomplish this, the designer may either: 2.1.10.1 Reduce the probability for contact between rotating and stationary part by designing in adequate clearances 2.1.10.2 Reduce the probability of explosives entering the "hazard zone" between the rotating and the stationary part (by flushing, shielding or positioning). 2.1.11 The designer may also select a combination of the two basic approaches. If the "clearance" technique is chosen, the designer must size the various components so that the specified clearance is positively maintained (under all possible operating conditions). When specifying a flushing liquid, the fluid used must be compatible with the process and there must be safeguards to insure the flush is maintained. 2.1.12 A gasket should be placed between all non-moving touching parts where explosives could be expected to accumulate. This can be inside a machine (or vessel) or outside (where explosives could be spilled or washed into joint). 3. Fastening and Joining 3.1 Welding 3.1.1 EXPLOSIVE WELD REQUIREMENTS 3.1.1.1 All welds on process equipment that are directly exposed to (or wetted by) the process, in a position where the process may splash (or drop) on weld seam, or indicated on the drawings or in the specifications, shall be of a quality to meet explosive weld standards, as described below. 3.1.1.2 The purpose of this procedure is to produce parts free of any internal enclosed pockets (or voids) within the weld, between parent metals, or between weld beads (where explosives may collect). This is accomplished through high quality, continuous, full-penetration welds. The welds are to be applied on both sides, where possible. 3.1.1.3 The mating edges of metals to be welded shall be beveled and an adequate rootgap provided (to allow for full-penetration welding). EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G127 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 6 of 11 Revision: 2 3.1.1.4 The welds shall be continuous, with full-joint penetration (i.e. the molten metal of the weld bead on one joint side must be fully contacted by the weld on other joint side), leaving no voids, pits, cracks or crevices in connection). 3.1.1.5 Welding rings, lapped joints, or "seal" welded joints are unacceptable. (See Page 6 for examples of acceptable and unacceptable weld joints) 3.1.2 WELD SURFACE 3.1.2.1 All weld surfaces, both sides of all welds (where accessible) must be 100% dye penetrant tested (PT) and documented in accordance with ASME Code, Section VIII, Division 1. It is important that the dye penetrant examination and repairs are completed on a particular weld before radiograph examination is done on the same weld. 3.1.2.2 Weld surfaces shall be free of cracks, pits, crevices, pinholes, weld spatter, impurities, etc. Any imperfection shall be repaired by grinding out the imperfection and refilling the weld. All surface imperfections shall be reexamined after repair. 3.1.2.3 The final surface finish (of a weld exposed to the explosives process) shall match the finish requirements of the metal surfaces that the weld joined. Undercutting or grinding flush of the parent metal and weld is not permitted. 3.1.2.4 All weld discoloration shall be removed. 3.1.3 RADIOGRAPHY (X-RAY) REQUIREMENTS 3.1.3.1 A specified percentage of all explosive weld joints (based on the total length) shall be randomly radiograph-examined. All welds includes (but is not limited to) nozzle connections to vessels, nozzle pipe welds, seam welds, baffles, gussets, or any other welded joints. 3.1.3.2 Any ASME Code x-ray requirement shall be in addition to the explosive x-ray requirements and will not count toward the total percentage of x-rays required. 3.1.3.3 An OSI Engineering Inspection Representative will determine which weld joints are to be x-rayed after welding is complete. The welds selected to be x-rayed are to be identify on approval drawings and labeled to create a weld map. Below is an example of a weld map labeling. EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G128 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 7 of 11 Revision: 2 3.1.3.4 Welds must be x-rayed prior to assembly or further fabrication, if it is not possible to x-ray later. Intermediate inspections for the OSI Engineering Inspection Representative shall be planned to observe fit-up and to select x-ray points of completed welds. 3.1.3.5 Radiograph examination shall be accomplished successfully before the pressure test (if applicable). 3.1.3.6 The radiograph film shall be U.S. manufactured, Class I type. 3.1.3.7 Radiograph interpretation shall be performed by a Level III x-ray technician certified by ANST or equivalent, unless noted otherwise. 3.1.3.8 Interpretation Sheets and radiograph film shall be submitted to the Buyer for review. 3.1.4 WELD ACCEPTANCE CRITERIA 3.1.4.1 Weld Surface: See Paragraph 3.1.2. 3.1.4.2 Weld Interior: All requirements (as stated above) shall be met. Furthermore, the acceptance criteria for indications seen only by x-ray are: Any one indication shall not exceed 0.030” in size, and no more than five indications (0.030" or less) are allowed in an inch of weld. When evaluating indication size, the tail shall be included. Indications may be from imperfections due to porosity, slag, or tungsten. 3.1.4.3 Other interior weld acceptance criteria shall meet the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Paragraph UW-51. 3.1.4.4 Unacceptable welds must be repaired and re-examined. 3.1.4.5 For each unacceptable weld, two additional welds (of same size) must selected be x-rayed and tracked per the weld map labeling (3.1.3.3) EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G129 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 8 of 11 Revision: 2 3.2 3.3 THREADED FASTENERS 3.2.1 The use of metallic and non-metallic threaded fasteners in and around explosives processing equipment is to be avoided. There are basically two concerns with the use of threaded fasteners. One is the initiation source produced by turning fasteners with explosives contaminated threads. The other is the possibility of a fastener loosening during operation and falling into the explosives product. The elimination of threaded fasteners may require extensive design (or redesign) of existing equipment to meet this requirement. All threaded fasteners that absolutely cannot be eliminated must be approved (in writing) by OSI before fabrication can begin. 3.2.2 The prevention of threaded fasteners loosening during equipment operation is addressed in OSI Engineering Standard 05051. OTHER JOINING DEVICES AND PROCESSES 3.3.1 Other joining devices and processes may be used with special approval by OSI (in writing) on a case-by-case basis. 4. SURFACE FINISHES 4.1.1 The surface finish for explosives process equipment shall be specified by OSI in the specification or on drawings and shall be consistent with ANSI B.46.1. 5. ELECTRICAL COMPONENTS 5.1.1 All electrical components used in explosives processing equipment must meet same requirements as the other mechanical components where exposed directly to explosives. 5.1.2 In addition, every electrical component used on explosives processing equipment must be approved by a certified testing agency (i.e. UL or FM) for use in the appropriate electrical hazardous area classification. 6. ELECTRICAL GROUNDING AND BONDING 6.1.1 Electrostatic bonding shall be provided at each point on a piece of explosives processing equipment where a relatively non-conductive element (i.e. a gasket) is placed between two conductive metal parts. The resistance to ground from any point on a piece of equipment shall not exceed 10 ohms. 6.1.2 Conductive belts and hoses used on explosives processing equipment shall have a resistance to ground not exceeding 1,000,000 and 250,000 ohms respectively. 6.1.3 When necessary, rotating metal parts in a piece of explosives processing equipment may be grounded using loose, sliding metallic rings. These rings should be positioned as far from exposure to the explosives as possible and kept wet. 7. MATERIALS OF CONSTRUCTION 7.1.1 The factors considered in selecting materials for use in fabricating explosives processing equipment are: compatibility with the explosives product, strength, resistance to corrosion, cleanliness and cleanability, ease of fabrication, availability and cost. EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G130 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 9 of 11 Revision: 2 7.1.2 Examples of materials that should not be selected are: asbestos, fiberglass, glass, materials containing fiberglass or glass fibers, ceramics, and materials that are classed as static generators. 8. CASTINGS 8.1.1 Due to the nature of the casting process, minor pitting might be difficult to avoid. Where possible, the quality required in Paragraph 2.3. should be maintained. OSI realizes that minute voids could be present. In these cases, the following exceptions will be granted: One pit, (maximum of 0.004" diameter and 0.004" deep) will be allowed for every 4 square inches of surface area (average). The minimum distance between pits to be 1". Cracks are not allowed. 9. SPECIAL APPROVAL OR EXCEPTIONS 9.1.1 Any deviation taken to the requirements and specifications requires OSI approval (in writing). 10. EQUIPMENT CONSTRUCTION AND FABRICATION INSPECTION 10.1 Photographs 10.1.1 Starting with receipt of materials until final inspection a minimum of four (4) weekly digital photographs are required. 10.1.2 Submittal of weekly photographs is not dependent upon progress. Photographs must be sent regardless of progress. 10.1.3 Photographs shall be e-mailed to the OSI Engineering Inspection Representative in an acceptable format. 10.1.4 The photographs shall include but not limited to materials inventory, metal cut, metal formed, welding fit-up, tack welding, welding, machining, grinding, polishing, dye penetrant testing, x-ray, hydrostatic testing, shipping fixtures and/or crates, loading for shipment, etc. 10.1.5 Failure to provide photographs will delay milestone payments if applicable. 10.2 Pre-Contract Meeting and Job Discussion 10.2.1 This meeting is intended for new Contractors that are not familiar with OSI construction and fabrication requirements, and it is optional for OSI to request this meeting. However, a Pre-contract meeting and job discussion may be requested by the Contractor before any job start. 10.2.2 At the pre-contract meeting and job discussion it is expected that the Contractor have his representatives present for every facet of the job including management, sales representatives, engineers, quality control personnel, shop personnel, and all proposed subcontractors. 10.2.3 There will be a thorough discussion of all specifications, drawings, OSI Standards and inspections. EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G131 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 10 of 11 Revision: 2 10.3 Intermediate Inspections 10.3.1 Intermediate inspections will be scheduled for strategic “hold points”; such as, milestone payments, specific points of construction and fabrication, specific points of testing, etc. 10.3.2 OSI will determine the intermediate inspection “hold points.” 10.3.3 It will be the Contractor’s responsibility to notify OSI fourteen (14) days ahead of time for an intermediate inspection so that travel arrangements can be made. 10.4 Final Inspection 10.4.1 Final Inspection will include a detailed review of all construction and fabrication. 10.4.2 It will be the Contractor’s responsibility to furnish the necessary labor, tools and machinery for the OSI Engineering Inspection Representative to accomplish a thorough inspection. 10.4.2.1 The first step of final inspection will be a general visual inspection to verify construction and fabrication completeness, for example, nozzles, manways, supports, lugs, agitators, motors, fasteners, gaskets, etc. 10.4.2.2 Next will be a detailed dimensional check, level, plum, straight, visual welding inspection, finish, paint, etc. 10.4.2.3 Review dye penetrant test results, x-ray test results, hydrostatic test reports and/or witness, review mil spec reports. 10.4.2.4 Either prepare a repair plan of action or approve for final shipment. 11. References 11.1 BAE Standards 11.1.1 16450-8 – Electrostatic Bonding for Process Piping 11.1.2 05051 – Securing Fasteners in the Explosives Plant 11.2 Other References 11.2.1 Army Safety Manual AMC-R 385-100 11.2.2 Federal Occupational Safety and Health Act (OSHA) 11.2.3 National Electrical Code (NEC) 11.2.4 ASME Boiler and Pressure Vessel Code, Section VIII, Paragraph UW-51 "Radiographic Examination of Welded Joints 11.2.5 ANSI B.46.1 11.2.6 DG-0035 Explosive Service Equipment Design Guide EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G132 of G872 CUI CUI OSI ENGINEERING STANDARD Title: General Design and Fabrication Practices, Process Equipment 11507 Handling Explosives Current Approved Date: June 3rd 2021 PAGE 11 of 11 Revision: 2 UNACCEPTABLE ACCEPTABLE EXPORT CONTROLLED DATA. This document contains technical information whose export is governed by the U.S. Export Administration Regulations (EAR). This information must not be transferred to a foreign person/entity without proper authorization of the U.S. Government. Violations may result in administrative, civil or criminal penalties. TF Page G133 of G872 CUI