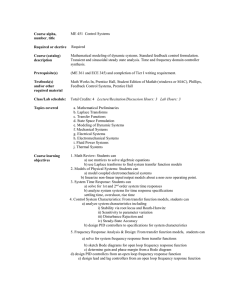

Delta Company for Fertilizers and Chemical Industries Training Report Submitted By: Kareem Mohamed Elarby Hassanin Ali 803089481 – MTE Level 400 Training Supervisor: Mohamed Nabeih Hakem Training Period: August 29, 2024, − September 28, 2024 Company Overview: Delta Company for Fertilizers and Chemical Industries specializes in the production of nitrogenous fertilizers and compound fertilizers. Company Address: Talkha, Dakahlia A. Most important fertilizers and chemical industry factories in Egypt: 1. Afco Misr Company for the manufacture of phosphate and biological fertilizers and chemicals ► The company is considered one of the most important fertilizer and chemical companies in Egypt, as all the products issued by the company are ISO 9001 certified for quality, and the Egyptian Standards and Quality Authority, and all products are registered and under the supervision of the Ministry of Agriculture and the Central Laboratory for Organic Agriculture. ► Among the most important products offered by the company are fully soluble potassium sulfate, triple granulated farmer’s superphosphate, granular monolithic superphosphate, fine Mono superphosphate, granulated agricultural sulfur, fine agricultural sulfur, and original soil conditioners. ► The company also provides vegetable and animal compost, mixture compost, vegetable compost and agricultural gypsum, and it has a wide reputation in Egypt and the Middle East countries. 2. Shams Fertilizers and Chemicals Company The company is one of the fertilizer and chemical companies in Egypt affiliated to the Dakahlia Group, and it is one of the largest groups specialized in the poultry and agricultural field in Egypt and the Middle East region. ► The company provides organic fertilizers, including poultry compost, animal compost, animal compost, poultry compost, regular fertilizers such as potassium sulfate, urea phosphate, phosphoric acid, compound elements and microelements, and their various compositions, and specialized fertilizers, including algae extracts, root stimulants, and humic acids. ► It provides all the various agricultural pesticides that are used to eliminate all agricultural pests that harm agricultural crops. The company is located in 11 Ramo Buildings, ninth floor, Nasr Road, Nasr City, Cairo. 3. Rocket Fertilizers and Chemicals Company ► Rocket Fertilizers and Chemicals Company specializes in the manufacture and production of fertilizers, fertilizers and plant growth regulators with new and advanced technology from the finest international raw materials, which keep pace with the rapid and continuous development in the agricultural field by providing a new level of quality. ► The company is keen to keep pace with production, with new types of genetically hybrid seeds with high productivity, which require providing nutrients in an easy-to-absorb form for the plant, and thus returns to the farmer and investor in the agricultural field high productivity, while maintaining the economic quality of the crops. ► The company offers the new generation of fertilizers, not depending on the percentage of nutrients in the fertilizer, but rather in the form in which the element is found, in a way that facilitates its absorption and access to the plant through foliar and root spraying, which reduces the number of treatment times, saves costs, and thus increases the economic return on investment. in the agricultural field. 4. Fertilizers and chemicals export companies in Egypt. - B. through the diversity of fertilizer and chemical companies in Egypt, as well as the companies exporting these materials, including the Egyptian company Methanex, which specializes in methanol production, is one of the most important companies, in terms of exports, which amounted to 339.228 million dollars, accounting for 17%. of the total exports of those companies. Information about delta factor The Nasr Company for Fertilizers and Chemical Industries was established in 1946 in Suez and continued to operate until the 1967 aggression. By 1975, a design was made for the urea production plant (1725 tons / day), including the ammonia production unit (1200 tons / day), which began operating in 1980. On 1-7-1998, the Delta Fertilizer Company was established in Talkha, divided from the Nasr Fertilizer Company. Table of Contents 1. Introduction 2. Objective 3. Training Topics 3.1 Principles of Industrial Control 3.2 Measurement Devices for Industrial Process Variables (Pressure, Temperature, Level, Flow) 3.3 Control Valves 3.4 Introduction to Industrial Controllers (e.g., Programmable Logic Controllers - PLC) 4. Training Program 4.1 First Week: Open Loop and Closed Loop Control Systems 4.2 Second Week: Local and Remote Measuring Devices 4.3 Third Week: Differentiation Between Various Control Systems (PLC, DCS) 4.4 Fourth Week: Types of Signals (On/Off and Continuous Signals) 5. Control Systems 5.1 Background 5.2 Open Loop and Closed Loop Control Systems 5.3 Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) 6. On-Off Control System 7. Pressure Gauges 7.1 What is a Pressure Gauge 7.2 Types of Pressure Gauges 8. Conclusion 9. List of Symbols and Units 10. References Time Comments 1st week Get to know Open loop and closed loop control system. 2nd week Recognize Local and remote measuring devices. 3rd week Differentiate between various control system, such as (stand-alone controllers, PLC, DS) 4th week Learn about different types of signals for variables in the site (On/Off and continuous signals) 1. Training Program 1st Week: Open Loop and Closed Loop Control Systems During the first week, we explored the differences between open loop and closed loop control systems. Figure 1 shows a simple block diagram of an open loop control system. 2nd Week: Local and Remote Measuring Devices The second week involved learning about various local and remote measuring devices used in the industry. 3rd Week: Differentiation Between Various Control Systems (PLC, DCS) In the third week, we focused on understanding the differences between Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS). 4th Week: Types of Signals (On/Off and Continuous Signals) The final week covered different types of signals such as On/Off and continuous signals used in control systems. 2. Introduction This technical report provides an overview of the training conducted at Delta Company for Fertilizers and Chemical Industries. The training focused on the fundamentals of industrial control systems and practical knowledge in managing various types of industrial equipment and processes. 3. Objective The objective of this training was to gain hands-on experience in control systems and to understand the different aspects of industrial automation used in chemical industries. 4. Training Topics ► 4.1. Principles of Industrial Control This section covers the basic principles of industrial control, including the types of control systems and their applications. ► 4.2. Measurement Devices for Industrial Process Variables Training included learning about devices used to measure critical process variables such as pressure, temperature, level, and flow. ► 4.3. Control Valves Understanding the role of control valves in managing fluid flow and pressure in process industries. ► 4.4. Introduction to Industrial Controllers An overview of industrial controllers, focusing on Programmable Logic Controllers (PLC), their applications, and how they are programmed. 5. Control Systems ► 5.1. Background A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. ► 5.2. Open Loop and Closed Loop Control Systems Control systems are broadly classified into open loop and closed loop systems. Figure 2 illustrates a closed loop control system with negative feedback. ► 5.3. Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) PLCs and DCSs are vital in industrial automation for controlling various processes. Table 1 compares PLCs and DCSs based on their features and applications. ► 5.4. On-Off Control System An on-off control system is a simple type of control system often used for its simplicity and ease of implementation. Figure 3 depicts a typical on-off control system used in industrial applications. The following figure shows the block diagram of negative feedback closed loop control system. The error detector produces an error signal, which is the difference between the input and the feedback signal. This feedback signal is obtained from the block (feedback elements) by considering the output of the overall system as an input to this block. Instead of the direct input, the error signal is applied as an input to a controller. So, the controller produces an actuating signal which controls the plant. In this combination, the output of the control system is adjusted automatically till we get the desired response. Hence, the closed loop control systems are also called the automatic control systems. ► The differences between the open and the closed loop control systems are mentioned in the following table. Open Loop Control Systems Closed Loop Control Systems Control action is independent of the desired output. Control action is dependent of the desired output. The feedback path is not present. The feedback path is present. These are also called non-feedback control systems. These are also called feedback control systems. Easy to design. Difficult to design. These are economical. These are costlier. Inaccurate. Accurate. ► Programmable logic controllers (PLC) and Distributed Control Systems (DCS). In the world of industrial automation, Programmable logic controllers (PLC) and Distributed Control Systems (DCS) are used to control or automate a process or a machine. They monitor the field signals and operator inputs and make decisions based on how they are programmed. PLC stands for “Programmable Logic Controller” Historically a PLC was in discrete control of manufacturing processes. The whole discrete logic used to be implemented with relay circuitry. Most of the inputs and outputs for discrete control are binary, meaning they have only two states: On and Off. ► DCS stands for “Distributed Control System” DCS’s were designed to control processes, not discrete operations. As such, a large number of the inputs and outputs are analog like a 4-20mA signal or 0-10V signal. In Literary meaning, a Distributed Control System (DCS) refers to a control system usually of a process or manufacturing system, in which the controller elements are not central in location (like the brain) but are distributed throughout the system with each component sub-system controlled by one or more controllers. Process plants used to have long series of panel mounted Single Loop Controllers (Analog/PID controllers). ► PLC vs DCS With emerging technologies, the difference between PLC and DCS has become quite marginal. In spite of that here are a few differences between them. PROGRAMMABLE LOGIC CONTROLLERS (PLC) DISTRIBUTED CONTROL SYSTEMS (DCS) Speed of response PLCs can respond to a change within one-tenth of a second. DCS are slower than PLCs. Typical respond time of DCS is 30ms. IO capacity A PLC is capable of handling a few hundred IOs. When it comes to analog IOs, it can handle tens of them. A DCS can handle thousands of IOs. It can handle hundreds or even thousands of analogs IOs and PID functions Logic development PLC can programmed be programmed based on our application. DCS comes with built-in control functions that need to be configured based on the application. Redundancy PLCs can be made redundant with additional hardware which makes them more expensive than DCS. Redundancy is a default feature of distributed control systems. Architecture PLCs have a simple and flexible architecture. A PLC system consists of controllers, IO modules, HMIs and an engineering software. DCS systems are less flexible. They come with controllers, IO systems, database servers, engineering and operating servers. Application PLCs are best suited for dedicated applications that changes less often. DCS is suitable for complex processes that require advanced process control capability. Cost Less expensive. More expensive. 6. On-off control system - In an industrial plant, a closed-loop control system has the role of keeping a measured physical signal to a predefined value (setpoint). The physical signal, also called controlled variable, can be of any kind, electrical (voltage, current, power), mechanical (position, speed, force, torque), hydraulic (pressure, flow) or thermal (temperature). The difference between the controlled variable (measured) and the predefined value is called error. - The input of the controller is the error, and the controller output is an actuation signal which is sent to an actuator. The controlled variable is further measured with a sensor and the information is fed back to the controller. Closed loop (feedback) control system - The difference between the setpoint and the plant output (measured) occurs because of the disturbances which affect the plant (process). The role of the controller is to reject these disturbances and keep the plant output (controlled variable) to the predefined value (setpoint). - The ways in which the controller reacts to the error are called control laws or control modes. In industrial applications there are several control laws used, most of them being on-off control, PID control or other more advanced laws (fuzzy, neuro-fuzzy, optimal, etc.). - The on-off control is the simplest form of a controller, which switches ON when the error is positive and switches OFF when the error is zero or negative. An on-off controller doesn’t have intermediate states but only fully ON or fully OFF states. Due to the switching logic, an on-off controller is often called a bang-bang controller or a two-step controller. - Regardless of the size of the error, the output of the on-off controller can only be fully ON or fully OFF, it is not proportional with the error. - Let’s take as an example the temperature control of an industrial oven. The temperature inside the oven is measured with a sensor and feed back to the controller. Based on the error (difference between setpoint temperature and measured temperature), the heating elements are turned ON or OFF by the controller. There are no intermediate values of the heating element, they are fully ON or fully OFF. 7. Pressure Gauges 7.1. What is a Pressure Gauge? The devices used for measuring pressure are called pressure gauges. Gauge pressure is the pressure relative to atmospheric pressure. For pressures above atmospheric pressure, gauge pressure is positive, and for pressures below atmospheric pressure, gauge pressure is negative. These devices are also known as pressure meters or vacuum gauges. A manometer is a device that uses the surface area and weight of a liquid column to measure and indicate pressure. Most gauges calculate the pressure relative to atmospheric pressure as the zero point, which is why this form of reading is known as gauge pressure. Pressure gauges can be analog or digital. 7.2. Types of Pressure Gauges Pressure gauges are designed depending on the usability and purpose, whether for commercial or industrial purposes. Some common types of pressure gauges include Bourdon Tube Pressure Gauge, Diaphragm Pressure Gauge, Capsule Pressure Gauge, Absolute Pressure Gauge, Differential Pressure Gauge, Bellows Pressure Gauge, Manometer Pressure Gauge, Piezometer Pressure Gauge. 8. Conclusion The training at Delta Company was instrumental in enhancing my understanding of industrial control systems and their applications in real-world scenarios. 9. List of Symbols and Units Symbol Unit Description mA Milliampere Electric current V Volt Electric potential °C Degree Celsius Temperature psi Pounds per square inch Pressure P Pascal Pressure at any point Pa Pascal Atmospheric pressure ρ kg/m³ Density of the fluid g m/s² Acceleration due to gravity h m Height of the fluid column 10. References ► Ogata, K. (2010). Modern Control Engineering. Prentice Hall. ► Johnson, C. D. (2006). Process Control Instrumentation Technology. Pearson Education. ► Bolton, W. (2015). Programmable Logic Controllers. Newnes.