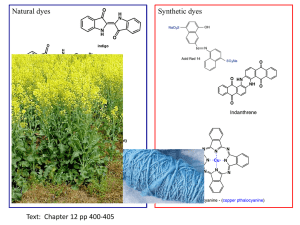

Viscose Filament Yarns: A Comprehensiv e Guide Introduction Viscose filament yarns (VFY) have gained immense popularity in the textile industry due to their silk-like feel, high absorbency, and eco-friendly nature. Derived from natural cellulose, viscose filament yarns offer a sustainable alternative to synthetic fibers. This article explores the properties, manufacturing process, applications, advantages, and market trends of VFY. What is Viscose Filament Yarn? Viscose filament yarn is a type of regenerated cellulosic fiber made from wood pulp. It is known for its softness, sheen, and excellent drape, making it a preferred choice for high-end textiles. VFY is available in different grades, including bright, dull, and semi-dull variants, catering to diverse fabric needs. Manufacturing Process of Viscose Filament Yarn The production of viscose filament yarn involves several key stages: 1. Raw Material Selection: The process begins with high-quality wood pulp, primarily sourced from fast-growing trees such as eucalyptus, bamboo, and pine. 2. Pulp Processing: The wood pulp is treated with chemicals to extract cellulose, which is then converted into alkali cellulose. 3. Xanthation: The alkali cellulose reacts with carbon disulfide, forming cellulose xanthate. 4. Spinning Solution Preparation: The cellulose xanthate is dissolved in a diluted sodium hydroxide solution to create a viscous liquid known as viscose. 5. Filtration and Aging: The viscose solution is filtered to remove impurities and aged to enhance its properties. 6. Extrusion and Coagulation: The solution is forced through spinnerets into an acid bath, where it solidifies into fine filaments. 7. Stretching and Drying: The filaments are stretched to improve tensile strength and then dried to remove excess moisture. 8. Winding and Packaging: The final yarn is wound onto spools and prepared for distribution. Properties of Viscose Filament Yarn Viscose filament yarn possesses unique characteristics that set it apart from other fibers: • Silk-like Appearance: VFY has a smooth and lustrous texture, making it a cost-effective alternative to silk. • High Absorbency: The yarn absorbs moisture efficiently, enhancing comfort and breathability. • Softness and Drape: Its excellent drape makes it ideal for flowing garments and luxurious fabrics. • Biodegradability: Unlike synthetic fibers, VFY decomposes naturally, reducing environmental impact. • Dyeability: It takes dyes well, resulting in vibrant and long-lasting colors. Applications of Viscose Filament Yarn Viscose filament yarn is used across various industries due to its versatile properties. Some common applications include: 1. Textile Industry: o Used in making sarees, dresses, and traditional garments. o Preferred for lingerie and innerwear due to its soft texture. o Ideal for home textiles such as curtains, upholstery, and bed linens. 2. Automotive Industry: o Employed in seat covers and interior fabrics for a luxurious feel. 3. Industrial Uses: o Used in manufacturing ropes, tire cords, and conveyor belts. o Applied in medical textiles such as bandages and surgical gowns. 4. Embroidery and Weaving: o VFY is widely used for embroidery work, enhancing the aesthetic appeal of fabrics. Advantages of Viscose Filament Yarn • Eco-Friendly: Derived from natural cellulose, VFY is a sustainable alternative to synthetic fibers. • Cost-Effective: It offers the luxurious feel of silk at a fraction of the cost. • Versatile: Suitable for a wide range of applications, from fashion to industrial use. • Comfortable: Its breathable nature ensures superior comfort in all climates. • Easy to Dye: Absorbs colors effectively, producing vibrant and rich hues. Challenges and Limitations Despite its numerous advantages, viscose filament yarn has some challenges: • Water Sensitivity: VFY tends to lose strength when wet, making it less durable compared to synthetic fibers. • Wrinkle-Prone: It wrinkles easily, requiring frequent ironing. • Environmental Concerns: The manufacturing process involves chemical treatments, necessitating eco-friendly production methods. Market Trends and Future Prospects The global demand for viscose filament yarn is rising due to increasing consumer preference for sustainable textiles. Key trends include: • Eco-Friendly Innovations: Manufacturers are adopting production processes to minimize environmental impact. greener • Blended Fabrics: Blending VFY with other fibers like cotton and polyester enhances fabric properties. • Growing Fashion Industry: The demand for high-quality, luxurious fabrics is fueling the growth of VFY in fashion textiles. Conclusion Viscose filament yarn is a remarkable textile material offering sustainability, affordability, and versatility. Its silk-like appeal, superior absorbency, and ecofriendly nature make it a preferred choice for various applications. As the demand for sustainable textiles grows, VFY is expected to play a crucial role in shaping the future of the textile industry. By embracing innovation and adopting environmentally friendly practices, manufacturers can ensure the continued success of viscose filament yarn in global markets.