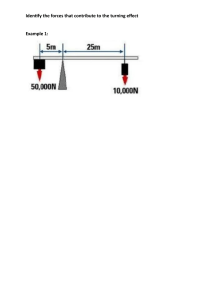

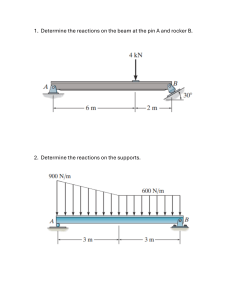

TECHNOLOGY: Structures GRADE TEACHERS 8 TERM 2 Topic WHAT I am going to teach? CAPS: 1. Tension; compression; bending; torsion; shear. 2. Reinforcing 3. Beam orientation to withstand forces DATE: Methodology HOW I am going to TEACH? Read and discuss the content on page 130 to 140. Explain new vocabulary. Allow learners to do practical activities to explore beams better. WEEK: 5 Resources WHAT I am going to use? MST Technology Teacher’s guide page 130 to 140 or http://www.mstworkbook s.co.za/technology/gr8/t ableofcontents.html Physical examples of different beams Time: 2 Hours Same as above. PARENTS Same as above. Tips to parents. Let your child read the content page aloud and make notes of concepts. MST Technology workbook (Learner’s guide page 130 to 140) (http://www.mstworkboo ks.co.za/technology/gr8/ tableofcontents.html) Stop, ask questions and explain new words. New words could be written down on a piece of paper and then stuck up on the wall to recap later. LEARNERS’ ACTIVITIES Learners engage with the content and participate in the discussion. Learners identify different forces and experiment with examples. Learners complete the worksheet Informal Assessment Complete the questions in the worksheet. STRUCTURES CONTINUED 1|Page Content Tension Compression Bending Torsion Shear force Explanation Two pulling forces, directly opposing each other, that stretch an object and try to pull it apart. For example, pulling on a rope. Two pushing forces, directly opposing each other, that push against an object and try to compress it. For example, pushing on an empty can. When the forces are aligned towards each other, they are called compression forces If an uneven force is applied to an object, it will tend to change shape and bend. For example bending a metal wire. Torsion is the twisting of an object due to an applied torque (turning force) Shearing forces are unaligned forces pushing one part of a body in one specific direction, and another part of the body in the opposite direction. pillar A tall vertical structure of concrete, wood, or metal, used as a support for a building or heavy bridge Beam A beam is a structural element that primarily resists bending loads applied to it Reinforcing To make a structure withstand large tensile and compressive forces, another type of strong material is put inside the structure Reinforced concrete To make concrete withstand large tensile and compression forces, steel rods or mesh is placed in the concrete when the wet concrete is poured into a shape or mold. Page 131 and 132 Plywood Plywood is a made by glueing many thin layers of wood on top of one another. The grain in each layer is at a right angle to the grains in the layers above and below it. Plywood can therefore withstand large tensile forces in both directions. Page 133 2|Page Elastic When you stop pushing or pulling an elastic material, it returns to its original shape Fracture If a material is bent too far it will crack (fracture). I-beam Beams can be shaped in special ways to make them resist bending. The shape called an I-beam is a shape that resists bending very well. Complete the worksheet in your classwork book: (pages 137 to 140 Learner’s workbook) You will have to read the pages and understand the explanations before you will be able to answer the questions. Investigate: What forces act inside a beam that bends? The pictures shows an imagined idea that wood is made of a lot of little blocks that are connected by springs. 1. What happens to the imaginary springs when a tensile (pulling) force acts along the length of the beam? 2. What happens to the imaginary springs when a compressive (pushing) force acts along the length of the beam? 3. In the picture below, what type of force acts along the top of the beam when it bends down? 4. What type of force acts along the bottom of the beam when it bends down? 5. Is there a tensile or compressive force acting along the middle of the beam when it bends down? 6. Look at the thick beam (top right). There are seven rows or layers of blocks connected with springs. The layers are numbered. (a) Which two layers of the beam help it the most to resist bending? (b) Does the middle layer of a beam help it to resist bending? 3|Page 7. Which beam will bend the least if the same load is applied to both beams? 8. What will happen to beam C when there is a sideways force? Consolidation Engineers wanted to design a new shape for a beam that will resist bending more than beam A, but without buckling like beam C. They knew that the material in the middle of a beam does help a lot to resist bending, because it does not stretch or compress a lot in the middle of a beam when it bends. So they took the design of beam A, and removed some material from the middle and rather added it to the top and bottom, where there will be more stretching and compression. In this way, they made the beam taller, but they also added short horizontal parts at the top and the bottom to prevent the beam from buckling sideways. This is shown in the pictures Because an I-beam resists bending better, a lighter and cheaper I-beam can be used to carry the same load as a rectangular beam. That also means that less steel will have to be made, so less energy will be used to make steel. In this way, clever design of material helps to reduce the negative impact of technology on the environment. Rectangular beam I-Beam 4|Page