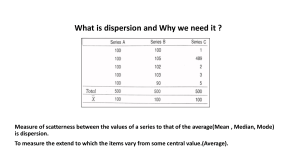

PROCESS ENGINEERING No. Dokumen DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 Revisi Halaman B 1 dari 10 PEMBERI KERJA : PT. LIKUID NUSANTARA GAS KONTRAKTOR : PT GT LADANG TEKNIK NAMA PROYEK : FEED FOR MINI LNG PLANT LOKASI : Pasuruan Industrial Estate Rembang NO. KONTRAK : LNG-01-SPK-240123-YFT00 B 17 Jul 2023 Issued for Approval RB FNS UT A 21 Jun 2023 Issued for Review RB FNS UT Prepare Review Approve REV TANGGAL STATUS PT GT LADANG TEKNIK Review Approve PT. LIKUID NUSANTARA GAS FEED FOR MINI LNG PLANT Document No. Revision Page B 2 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 LEMBAR REVISI REV TANGGAL HAL. KETERANGAN A 21 June 2023 All Issued For Review B 17 July 2023 All Issued For Approval FEED FOR MINI LNG PLANT Document No. Revision Page B 3 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 DAFTAR ISI 1. GENERAL ........................................................................................................................... 4 2. OBJECTIVE ........................................................................................................................ 4 3. DEFINITION AND ABBREFIATION .................................................................................... 4 3.1 Definition ................................................................................................................... 4 3.2 Abbreviation.............................................................................................................. 5 4. REFERENCES, DOCUMENTS, CODES AND STANDARDS ............................................. 5 5. GENERAL DESIGN CONDITION AND CRITERIA.............................................................. 5 6. 7. 5.1 Environmental Data .................................................................................................. 5 5.2 Fluid Composition .................................................................................................... 5 5.3 Fluid Data .................................................................................................................. 6 5.4 Vent Data ................................................................................................................... 6 CALCULATION METHOD................................................................................................... 6 6.1 Vent Load .................................................................................................................. 6 6.2 Dispersion Study ...................................................................................................... 6 RESULT .............................................................................................................................. 7 FEED FOR MINI LNG PLANT Document No. Revision Page B 4 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 1. GENERAL PT. Likuid Nusantara Gas (PT LNG) plan to build Mini LNG Plant. The Plant capacity is 2.5 MMSCFD. The Plant is design to process natural gas by separating the impurities and liquify it into LNG. The plant also have 40 ft Isotank filling station and also have VGL filling station. The plant located in Pasuruan Industrial Estate Rembang, East Java. The plant location is stated in picture below. Picture 1.1 Mini LNG Plant Location 2. OBJECTIVE This document is developed to describe dispersion of gas during venting operation for Mini LNG Plant Pasuruan owned by PT Likuid Nusantara Gas. 3. DEFINITION AND ABBREFIATION 3.1 Definition PT LNG : PT Likuid Nusantara Gas, as Project Owner PROYEK : Mini LNG Plant Pasuruan CONSULTANT : PT GT Ladang Teknik MIGAS : Badan pemerintah Indonesia yang bertanggung jawab dalam hal menerbitkan ijin operasi dan pengelolaan untuk fasilitas Minyak dan Gas. PT PGS : PT Penta Gas Solusi, Technology Provider that supply Mini LNG Plant main process. FEED FOR MINI LNG PLANT Document No. Revision Page B 5 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 Certification Agency 3.2 4. : Third Party Inspection Agency as MIGAS representative. Abbreviation P&ID : Piping & Instrument Diagram NPSH : Process Control Systems LLL : Low Low Level HHLL : High High Level REFERENCES, DOCUMENTS, CODES AND STANDARDS Code and Standard that use in this calculation are: API STD 520 Sizing, Selection, and Installation of Pressure- Relieving Devices in Refineries API STD 521 Pressure-Relieving and Depressurizing Systems 5. GENERAL DESIGN CONDITION AND CRITERIA 5.1 Environmental Data The environment data for West Batara Facility are as follow: 5.2 Temperature : 35oC Relative Humidity : 85% (average) Wind Speed : 5 m/s. 2.5 m/s, dan 1.5 m/s (estimated) Fluid Composition Fluid composition used are describe as follow: Table 4. Fluid Specification ITEM Nitrogen Carbon Dioxide Methane Ethane Propane I-Butane N-Butane I-Pentane N-Pentane Hexane + UNIT % Mole % Mole % Mole % Mole % Mole % Mole % Mole % Mole % Mole % Mole VALUE 0.024 0.930 97.531 0.723 0.433 0.118 0.128 0.050 0.039 0.024 FEED FOR MINI LNG PLANT Document No. Revision Page B 6 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 5.3 Fluid Data Fluid data for vent dispersion study is taken from the worst case of PSV outlet rate at pipeline area. FLUID DATA Gas Flow Rate Pressure Temperature 5.4 UNIT kg/hr MMSCFD Barg o C VALUE 6566 7.893 1.38 35 Vent Data Vent data that will be used for simulation are: 6. 6.1 Type of Vent : Vent Stack Vent Height : 10 meter Dimension : 6 inch Angle Discharge : 90 degree CALCULATION METHOD Vent Load The source of disposed gas is coming from PSV at pipeline area. Load of this PSV shall be the basis of designing Vent Stack. 6.2 Dispersion Study The Analysis of vent stack dispersion is performed by DNV PHAST 8.4 simulation software. This software shall simulate gas dispersion that will occur when venting operation is conducted. Simulation will be conduct base on passcuil F (night condition) and pascuil D (day condition). FEED FOR MINI LNG PLANT Document No. Revision Page B 7 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 7. RESULT Result of Cloud Dispersion Side View Graphic Analysis is summarize in table below. This calculation use the longest section as the basis. Table 1. Cloud Dispersion Side View Graphic Analysis Case Day Night Day Night Day Night Day Night Wind Speed 1.5 m/s 2.5 m/s 5 m/s 10 m/s a. Wind Velocity 1.5 m/s Day Cloud distance for concentration Cloud Elevation (HFL) (LFL) (50% LFL) 0.41 m 1.8 m 3.94 m 10-28.14 m 0.50 m 1.81 m 3.59 m 10-27.20 m 0.50 m 1.91 m 4.13 m 10-24.42 m 0.53 m 1.84 m 3.76 m 10-23.55 m 0.40 m 2.04 m 4.36 m 10-19.97 m 0.42 m 1.91 m 3.95 m 10-19.41 m 0.53 m 2.1 m 4.70 m 10-16.75 m 0.55 m 1.98 m 4.30 m 10-16.4 m FEED FOR MINI LNG PLANT Document No. Revision Page B 8 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 Night b. Wind Velocity 2.5 m/s Day Night FEED FOR MINI LNG PLANT Document No. Revision Page B 9 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 c. Wind Velocity 5 m/s Day Night d. Wind Velocity 10 m/s Day FEED FOR MINI LNG PLANT Document No. Revision Page B 10 of 10 DISPERSION STUDY FMLP-LNG-GTL-PRO-CALC-005 Night