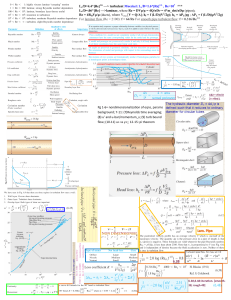

Viscous Flow in Pipes Introduction • Flow of viscous, incompressible fluid in pipes and ducts will be considered. • Pipe is of round cross section, duct is not round. • Basic components of a typical pipe system include pipes, fittings, valves, pumps or turbines. • Even simple pipe systems are quite complex in terms of analytical considerations. • “Exact” analysis of the simplest pipe flow topics (such as laminar flow in long, straight, constant diameter pipes) and dimensional analysis considerations combined with experimental results for the other pipe flow topics will be used. General Characteristics of Pipe Flow • Unless otherwise specified, we will assume that the conduit is round (pipe). • Pipe is assumed to be completely full of the flowing fluid. • For open-channel flow (b), gravity alone is the driving force – water flows down a hill. • For pipe flow (a), gravity may be important, but the main driving force is a pressure gradient along the pipe. • If pipe is not full, it is not possible to maintain this pressure difference. Laminar of Turbulent Flow • Flow may be laminar, transitional, or turbulent (figure). • For laminar flow in a pipe there is only one component of velocity, V = ui • For turbulent flow predominant component of velocity is also along the pipe, but it is unsteady (random) and accompanied by random components normal to the pipe axis, V = ui + vj + wk (figure). • Pipe flow characteristics are dependent on the value of the Reynolds number Re VD • Reynolds number range for which laminar, transitional, or turbulent pipe flows are obtained cannot be precisely given. • Flow in round pipe is laminar if Re is less than approximately 2100 • Flow is round pipe is turbulent if Re is greater than approximately 4000 Entrance Region and Fully Developed Flow • Region of flow near where fluid enters the pipe is termed the entrance region • Fluid typically enters the pipe with a nearly uniform velocity profile at section (1). Entrance Region and Fully Developed Flow • As the fluid moves through the pipe, viscous effects cause it to stick to the pipe wall (no-sip condition). Boundary layer in which viscous effects are important is produced along the wall. Initial velocity profile changes with distance along pipe, x. Entrance Region and Fully Developed Flow • Beyond section (2) velocity profile does not vary with x. Boundary layer has grown in thickness to completely fill the pipe. Entrance Region and Fully Developed Flow • Viscous effects are of considerable importance within the boundary layer. • For fluid outside the boundary layer (within inviscid core) viscous effects are negligible Entrance Region and Fully Developed Flow • Dimensionless entrance length: le 0.06 Re for laminar flow D le 16 4.4 Re for turbulent flow D Entrance Region and Fully Developed Flow • Flow between (2) and (3) is termed fully developed. • Fully developed flow is interrupted by bend, valves etc. Beyond the interruption flow gradually begins its return to its fully developed character. Pressure and Shear Stress • Flow in horizontal pipe is driven by pressure difference. • Nonzero pressure gradient is a result of viscous effects (if viscosity were zero, pressure would not vary with x). Work done by pressure forces is needed to overcome the viscous dissipation of energy through the fluid. • In fully developed flow region viscous force exactly balances pressure force (fluid flows with no acceleration). • In non-fully developed flow regions fluid accelerates or decelerates (velocity profile changes). Thus, in the entrance region there is a balance between pressure, viscous, and inertia (acceleration) forces. • Magnitude of the pressure gradient, p/x, is larger in the entrance region than in the fully developed region, where it is constant, p/x = –Δp/l < 0 (figure) • Laminar flow differs from turbulent due to different nature of shear stress in laminar and turbulent flows. Fully Developed Laminar Flow • Velocity profile in fully developed flow is the same at any cross section of the pipe. • If velocity profile is known, other flow information such as pressure drop, head loss, flowrate and the like can be obtained. • Details of the velocity profiles are different for laminar and turbulent flows. • Equation for velocity profile in fully developed laminar flow (and other important results) can be derived: – from F = ma applied directly to fluid element, – from Navier-Stokes equations of motion, – from dimensional analysis. • Regardless of method used results are the same Fully Developed Laminar Flow Consider steady, fully developed, laminar flow of an incompressible, viscous fluid in a horizontal pipe. Velocity variation in radial direction, combined with fluid viscosity, produces shear stress If gravity force is neglected, the pressure varies only in x direction. If pressure decreases in x direction, then p2 p1 p p 0 Fully Developed Laminar Flow Apply Newton’s second law of motion to cylindrical fluid element. p 2 l r Basic pipe flow is governed by a balance between viscous and pressure forces. (a) Fully Developed Laminar Flow Shear stress varies from zero (at r = 0) to the wall shear stress (at r = D/2) 2 r w D Pressure drop and wall shear stress are related by 4l w p D (b) (c) For laminar flow of Newtonian fluid du dr (d) Fully Developed Laminar Flow Combining eqs. (a) and (d) and integrating obtain velocity profile (details) pD 2 2r u r 1 16 l D 2 2 2r V c 1 D (e) where Vc is the centerline velocity (V at r=0) . In terms of wall shear stress: 2 wD r u r 1 4 R (f) R 2Vc Q udA 2 (g) Volume flowrate: Average velocity Q Vc pD 2 V A 2 32 l back (h) Fully Developed Laminar Flow Volume flow rate: D 4 p Q 128 l (i) Thus, for a horizontal pipe the flowrate is (a) directly proportional to the pressure drop, (b) inversely proportional to the viscosity, (c) inversely proportional to the pipe length, (d) proportional to the pipe diameter to the fourth power The flow is termed Hagen-Pouseuille flow and equation (e) is commonly referred to as Poiseuille’s law Fully Developed Laminar Flow For nonhorizontal pipes Fully Developed Laminar Flow For nonhorizontal pipes p l sin D 4 Q 128 l Fully Developed Laminar Flow Darcy friction factor Fully Developed Laminar Flow p From equation (h) 32 lV D2 Dividing by V 2/2 we obtain p or 1 V 2 2 32 l D 64 2 1 V 2 2 l V 2 p f D 2 f p D l V 2 2 where Darcy friction factor For laminar flow l 64 l Re D VD D f 64 Re or f 8 w V 2 Fully Developed Laminar Flow Consider energy equation for the flow considered p1 V12 p2 V22 1 z1 2 z2 hL 2g 2g where kinetic energy coefficient α accounts for nonuniform velocity profile. For fully developed flow α1 = α2 and With p l sin 2 l r p1 p2 z z2 hL 1 hL 2 l 4l w r D Head loss in a pipe is a result of the viscous shear stress on the wall Fully Developed Laminar Flow. Summary Velocity profile pD 2 2r u r 1 D 16 l 2 2 wD r u r 1 4 R Centerline velocity and average velocity pD 2 Vc 16 l Vc pD 2 V 2 32 l Poiseuille’s law D 4 p Q 128 l Head loss hL 2 l 4l w r D p l sin D 4 Q 128 l Fully Developed Turbulent Flow Transition from Laminar to Turbulent Flow Transition from laminar to turbulent flow in a pipe occurs at 2100 < Re < 4000 Turbulent Shear Stress Turbulent flow parameters can be described in terms of mean and fluctuating parameters. If u = u(x,y,z,t) is x component of instantaneous velocity, then its time average value is u 1 t0 T u x, y, z, t dt t 0 T The fluctuating part of the velocity, u’ is that time-varying portion that differs from the average value u u u or u u u more details Turbulent Shear Stress du ? dy du dy du ? dy Turbulent Shear Stress du dy (a) Laminar flow shear stress caused by random motion of molecules. du ? dy Turbulent Shear Stress du dy (a) Laminar flow shear stress caused by random motion of molecules. (b) Turbulent flow as a series of random, three-dimensional eddies. Turbulent Shear Stress • Laminar flow involves randomness on the molecular scale. • Turbulent flows involve random motions of finite-sized particles. It consists of series of random, three-dimensional eddy type motions. • These eddies range in size from very small to fairly large diameter. They move about randomly, conveying mass with an average velocity u u y • Eddy structure greatly promotes mixing within the fluid and greatly increases transport of x momentum across the plane A-A. • Thus, finite parcels of fluid (not individual molecules as in laminar flow) are randomly transported across this plane, resulting an a relatively large shear stress. • Random velocity components that account for this momentum transfer (hence, the sear force) are u’ (for the x component of velocity) and v’ (for the rate of mass transfer crossing the plane). Turbulent Shear Stress Shear stress on plane A A is given by du u v lam turb dy If flow is laminar, than u v 0, and above equation reduces to laminar shear stress For turbulent flow it is found that turbulent shear stress, turb u v, is positive. Hence, shear stress is greater in turbulent flow than in laminar flow. Term of the form u v or vw, etc. are called Reynolds stresses. Note, turbulent shear stress depends on the fluid density Turbulent Shear Stress Structure of turbulent flow in a pipe. (a) Shear stress. (b) Average velocity more... Dimensional Analysis of Turbulent Flow Most turbulent pipe flow information is based on experimental data and semiempirical formulas, even if flow is fully developed. Fundamental difference between laminar and turbulent flow is that the shear stress for turbulent flow is a function of the density of the fluid, (Reynolds stresses). For turbulent flow there is a relatively thin viscous sublayer formed in the fluid near the pipe wall. If a wall roughness element protrudes sufficiently far into (or even through) this layer, the structure and properties of the viscous sublayer (along with Δp and τw) will be different than if the wall were smooth. Thus, for turbulent flow pressure drop is the function of the wall roughness. Pressure drop for steady, incompressible turbulent flow in a horizontal round pipe of diameter D can be written in functional form as p F V , D , l , , , where V is the average velocity, l is the pipe length, and ε is a measure of the roughness of the pipe wall. Dimensional Analysis of Turbulent Flow In dimensionless form: VD l p , , 1 2 V D D 2 where ε/D is a relative roughness. Assuming that pressure drop is proportional to the pipe length we have p l Re, 1 2 D D V 2 With where f p D l V 2 2 pressure drop can be written as l V 2 p f D 2 f Re, D Dimensional Analysis of Turbulent Flow For laminar fully developed flow, the value of f is f = 64/Re, independent of ε/D. For turbulent flow, functional dependence f = φ(Re, ε/D) is a complex one that cannot, as yet, be obtained from theoretical analysis. Results are obtained from experiment and presented in terms of curve-fitting formula or graphical form. From energy equation for steady incompressible fully developed flow in constant diameter (D1 = D2 so that V1 = V2) horizontal pipe follows that l V2 hL f D 2g This equation, called the Darcy-Weisbach equation, is valid for any fully developed, steady, incompressible pipe flow – whether pipe is horizontal or on a hill. Friction Factor Functional dependence of friction factor, f, on Reynolds number and relative roughness is obtained from experiments conducted by J. Nikuradse in 1933. Original data of Nikuradse were correlated by L.F. Moody and C.F. Colebrook and presented in Moody chart and Colebrook formula D 1 2.51 2.0 log 3.7 f Re f Typical roughness values for various pipe surfaces are given in table Example 8.5 Air under standard conditions flow through a 4.0-mm-diameter drawn tubing with an average velocity of V = 50 m/s. For such conditions the flow would normally be turbulent. However, if precautions are taken to eliminate disturbances to the flow (the entrance to the tube is very smooth, the air is dust free, the tube does not vibrate, etc.), it may be possible to maintain laminar flow. (a) Determine the pressure drop in a 0.1-m section of the tube if the flow is laminar. (b) Repeat the calculations if the low is turbulent. Example 8.5 Air under standard conditions flow through a 4.0-mm-diameter drawn tubing with an average velocity of V = 50 m/s. For such conditions the flow would normally be turbulent. However, if precautions are taken to eliminate disturbances to the flow (the entrance to the tube is very smooth, the air is dust free, the tube does not vibrate, etc.), it may be possible to maintain laminar flow. (a) Determine the pressure drop in a 0.1-m section of the tube if the flow is laminar. (b) Repeat the calculations if the low is turbulent. Solution With density and viscosity known, Reynolds number: Re VD 13700 (a) If the flow were laminar, then f = 64/Re = 0.00467, and the pressure drop: l V 2 p f 0.179 kPa D 2 Example 8.5 Air under standard conditions flow through a 4.0-mm-diameter drawn tubing with an average velocity of V = 50 m/s. For such conditions the flow would normally be turbulent. However, if precautions are taken to eliminate disturbances to the flow (the entrance to the tube is very smooth, the air is dust free, the tube does not vibrate, etc.), it may be possible to maintain laminar flow. (a) Determine the pressure drop in a 0.1-m section of the tube if the flow is laminar. (b) Repeat the calculations if the low is turbulent. Solution With density and viscosity known, Reynolds number: Re VD 13700 (a) If the flow were laminar, then f = 64/Re = 0.00467, and the pressure drop: l V 2 p f 0.179 kPa D 2 (b) If the flow were turbulent, then from table ε = 0.0015 mm so that ε/D = 0.000375. From Moody chart, with Re = 1,37x104 and ε/D = 0.000375, f = 0.028. Pressure drop: l V 2 p f 1.076 kPa D 2 p 43.7 kN/m 2 (1) l h1 p 43.7 kN/m 2 h2 (2) (1) Answer p 43.7 kN/m 2 h 18.5 m (2) Minor Losses Minor Losses Losses occur in straight pipes (major losses) and pipe system components (minor losses) Major losses can be calculated by use of friction factor obtained from Moody chart Minor losses are given in terms of loss coefficient, which is defined as KL hL p 1 2 V V 2 2g 2 Then pressure drop V 2 p K L 2 and head loss V2 hL K L 2g Minor Losses In most cases of practical interest the loss coefficients for components are function of geometry K L geometry Minor losses are sometimes given in terms of an equivalent length, leq In this terminology, head loss through component is given in terms of the equivalent length of pipe that would produce the same head loss as the component. That is leq V 2 V2 hL K L f 2g D 2g or leq KL D f where D is based on the pipe containing the component Minor Losses Entrance flow conditions and loss coefficient. (a) Reentrant, KL = 0.8, (b) sharp-edged, KL = 0.5, (c) slightly rounded, KL = 0.2, well-rounded, KL = 0.04 Minor Losses Flow pattern and pressure distribution for a sharp-edged entrance Minor Losses Entrance loss coefficient as a function of rounding of the inlet edge Minor Losses Exit flow conditions and loss coefficient. (a) Reentrant, KL = 1.0, (b) sharp-edged, KL = 1.0, (c) slightly rounded, KL = 1.0, well-rounded, KL = 1.0 Minor Losses Loss coefficient for a sudden contraction Minor Losses Loss coefficient for a sudden expansion Noncircular Conduits Noncircular duct calculations are based on hydraulic diameter Noncircular duct Dh 4A P Noncircular Conduits Fully Developed Laminar Flow Friction factor f C Re h where constant C depends on the shape of the duct, and Reh is based on hydraulic diameter Re h VDh Hydraulic diameter is also used in definition of relative roughness, ε/Dh , and head loss l V2 hL f Dh 2 g Noncircular Conduits Fully Developed Turbulent Flow Calculations for fully developed turbulent flow in ducts of noncircular cross section are usually carried out by using the Moody chart data for round pipes with the diameter replaced by the hydraulic diameter and the Reynolds number based on the hydraulic diameter. Such calculations are usually accurate to within about 15%. If grater accuracy is needed, a more detailed analysis based on the specific geometry on interest is needed Single Pipes Problem Solutions END Supplementary slides Typical Pipe System back (a) Experiment to illustrate type of flow. (b) Typical dye streaks back Time dependence of fluid velocity at a point back Pressure distribution along a horizontal pipe back Turbulent Flow Time average of the fluctuations is zero u Average of the square of fluctuation is positive u 2 t0 T 1 t0 T 1 t0 T 1 u u dt udt udt Tu Tu 0 t t t 0 0 0 T T T 1 t0 T 2 u dt 0 t T 0 Average of products of the fluctuations, such as u v , may be zero or nonzero (either positive of negative) back Turbulent Velocity profile In viscous sublayer (law of the wall) u yu* u* v In overlap region yu * u 2.5ln 5.0 * u v where friction velocity: u* Typical structure of the turbulent velocity profile in a pipe w back Turbulent Velocity profile In outer turbulent layer (power-law velocity profile) u r 1 Vc R 1 n Exponent, n, for power-law velocity profiles back Turbulent Velocity profile Typical laminar flow and turbulent flow velocity profile back Flow in the viscous sublayer near rough and smooth walls back Moody Chart back back back Turbulent Flow Time-averaged, u , and fluctuating, u, description of a parameter for turbulent flow