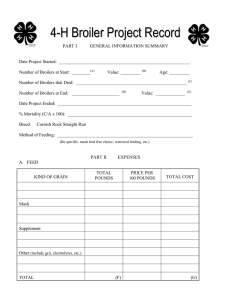

Livestock Investigative Report Name of Student: Ahmad Ali Student Registration Number: 1605220180 Name of School: ASJA BOYS’ COLLEGE, CHARLIEVILLE. Title: The effect of deworming on Broiler production at ASJA Boys’ College Charlieville, Trinidad and Tobago. Duration of Project: 1/5/24 – 9/6/24 Teacher’s Name: Mr. Rasheed Mohammed Contents INTRODUCTION ....................................................................................................................... 3 PROBLEM STATEMENT, HYPOTHESIS AND AIM .................................................................... 3 METHODOLOGY....................................................................................................................... 4 EXPERIMENTAL DESIGN ......................................................................................................... 6 DATA COLLECTION .................................................................................................................. 7 BROILER PRODUCTION PRACTICES ..................................................................................... 8 RESULTS. ................................................................................................................................13 DISCUSSION............................................................................................................................18 CONCLUSION, RECOMMENDATIONS AND LIMITATIONS .....................................................20 REFERENCES .........................................................................................................................21 INTRODUCTION The name of the livestock are Chickens, specifically broilers. Scientifically referred to as Gallus gallus domesticus, they originated from Southeast Asia (Wikipedia). Domestication would’ve occurred around 5400 years ago through its primary origin, the Red Junglefowl. According to Ancient DNA (n.d.), they came to the Caribbean when the Dutch and Portuguese slave traders brought them here. Broilers are bred specifically for meat production (Chicken Wikipedia, n.d). According to Free Food Facts (n.d.), their nutritional facts are as follows: Serving Size: 100 grams, Calories: 144 kcal, Protein: 28.04 grams, Total Fat: 3.57 grams, Cholesterol: 86 mg, Sodium: 328 mg, Carbohydrates: 0 grams, Dietary Fiber: 0 grams, Sugars: 0 grams, Water Content: 67.78 grams. According to Douglas (2017), the broiler industry generates an estimated $1.2 billion annually from the purchase and consumption of broilers. Large-scale broiler farming is considered highly profitable, providing farmers with significant income opportunities. For human consumption, broilers can be sold either as live birds or processed carcasses, and they are commonly available in poultry shops and markets (Weever et al., 1998). Historical data and literature reveal a wide variety of management practices used in broiler production. These practices vary depending on environmental factors, husbandry systems, and the specific breed being raised (Aviagen, 2015; Hubbard, 2015; Cobb-Vantress, 2013; Hi-Pro Feed, (n.d.) Broilers are typically reared using one of three popular systems: 1. Deep-litter system 2. Extensive or free-range system 3. Semi-intensive system In a study described by Aviagen (2005), broilers are raised using the intensive deep-litter system at ASJA Boys’ College in Charlieville, as noted by Husbandry (2015) and Cobb-Vantress (2013). To examine the impact of deworming on broiler production, this system is employed within the school. PROBLEM STATEMENT, HYPOTHESIS AND AIM Problem Statement At ASJA Boys’ College Charlieville the response of broilers to deworming is not known. Hypothesis The weight of broilers is affected by deworming. Aim To determine the effect of deworming on weight gain of broilers at ASJA Boys’ College Charlieville. METHODOLOGY Materials Tools and Equipment Table 1 – Materials used in the Project ACTIVITY MATERIALS USED Set up of brooder Cardboard box, Sawdust, Newspapers, Water trough, Broiler starter Cleaning of brooder Newspaper, Garbage bag, Sawdust Transfer of chicks from brooder to chicken cage Saw dust Feeding Broiler starter, Broiler finisher Provision of water to broilers Water, Nutrival powder, Dewormer Weighing of broilers Five broilers Cleaning of chicken cage Garbage bag Changing the bedding of the chicken cage Garbage bad, Saw dust Slaughter and dressing Feed bad, Plastic bags Disposal Garbage bags, Feed bag Table 2 – Tools and Equipment Used in the Project ACTIVITY TOOLS AND EQUIPMENT USED Set up of brooder Light bulb, Extension cord, Rod for light bulb, Water trough, Feed trough Cleaning of brooder Hand fork, Transfer of chicks from brooder to chicken cage Transfer of chicks from brooder to chicken cage Chicken cage Feeding Feed hopper, Scale, Bucket, Feed tray Provision of water to broilers Waterers Weighing of broilers Scale Cleaning of chicken cage Hand fork, Push broom, Scoop Changing the bedding of the chicken cage Scoop, Hand shovel Slaughter and dressing Knife, File, Table, Pot, Stove, Barrel, Water hose, Gas tank, Slaughtering cones, Scale Disposal Push broom, Scoop, Shovel EXPERIMENTAL DESIGN At ASJA Boys’ College in Charlieville, an investigation was conducted in a poultry pen from May 1st to June 9th, 2024. Twelve 12-day-old chicks were initially raised in a brooder for three weeks before being moved to the poultry pen. The pen was evenly divided into two sections, labeled "Treatment" and "Control." Six chicks from the brooder were placed in the Treatment section, while the other six were assigned to the Control section. The chicks in the Treatment group were dewormed, whereas those in the Control group were not. All other conditions, including spacing, litter management, equipment, and water and feeding routines, were kept identical in both sections of the pen. Figure 1: Showing layout of the Experimental Area Treatment Control DATA COLLECTION Over the duration of the experimental period, the following data were collected, recorded, tabulated, and used to detail the graphs whenever necessary. Broiler Livability The total number of surviving broilers were recorded each week, throughout the entire duration of the project. The weight of the feed was recorded until the end of the experimental period every time the broilers were fed. Average Feed Consumption Every day before the broilers were fed, the weight of the feed was recorded and then placed in the feed hopper which was then consumed. The average feed consumption was calculated as follows: Average feed consumption = weekly feed consumption Number of birds Broiler Live Weight Five (5) broilers were randomly chosen on sight each week, from each pen to obtain their weights. After the weights were obtained, they were then calculated to find the average weight and then the results were recorded. Feed Conversion Ratio (FCR) The following formula below was used to determine the feed conversion ratio for the broilers. (Ramharracksingh, 2011). Feed conversion ratio = weekly feed intake (KG) Weekly weight gain (KG) Other Observations Over the entire duration of the project, the broilers were heavily monitored, and every other observation was recorded. BROILER PRODUCTION PRACTICES 1. Setup of Brooder. A suitable area was selected to place the brooder. Saw dust was then placed on the bottom, along with newspaper on top of the dust. A waterer was filled, and one spoon of nutritional powder was added. To ensure that the chicks drank water, they were held by their beaks and placed in the waterer, which was then placed in the brooder. Broiler starter was placed in the brooder on a food tray and some feed were scattered so the chicks can begin pecking. An incandescent bulb and an extension cord with a socket was placed over the box as a heat source for warmth for the chicks. Finally, they were selected at random to measure their weight by placing them on a scale. 2. Cleaning of Brooder. On a daily basis, the brooder was cleaned, and the feed and water tray were washed. The newspapers were also replaced daily, and the chicks were given fresh food and water. This allowed the chicks to grow healthy. Picture 1 showing washing of feeder for brooder 3. Transfer of Chicks from Brooder to Cage. After a week of observation, we saw that the chicks no longer needed a heat source for body temperature to be regulated. As such, they were placed in a cage for the rest of their life cycle. 4. Deworming. In the Treatment section, six chicks were dewormed, but in the Control section, they were not. Following the manufacturer’s instructions and specifications, the chicks in the Treatment section were only dewormed once throughout the growing period. For the first 2 days of separation during week 3, the measurement is 14.8 grams per gallon. Picture 2 showing the dewormer used 5. Housing and Security. The brooders were kept in a chicken pen at the back of the school’s auditorium, away from the other children attending school and to prevent Praedial Larceny (the act of Agricultural Theft.) The pens were locked and opened when required for added security. 6. Ventilation. By placing the pen in a spot where sufficient ventilation and protection was provided, this prevented weather changes during the day and throughout the growing period. 7. Nutrition. For the first 3 weeks, broiler starter was fed to the broilers. For 3 days, finisher was slowly brought in and mixed with the starter in different amounts. One spoon of Nutrival Powder (nutritional powered vitamin) was added to the water in a one-gallon waterer. After the waterers were washed each day, the broilers consumed fresh water. Picture 3 measuring out the feed for the broilers 8. Litter Management. A shovel and a rake were used to turn up the litter to prevent caking and compacting. Clean saw dust was used regularly to replace the wet and compressed litter. Using the unwanted litter from both pens, we fertilized the school’s plants. 9. Health Management. To ensure maximum health for all the brooders, the feeders and waterers were washed every day. Picture 4 showing the washing of the feeder RESULTS. 1. Broiler Livability Shown in the table below is the number of broilers that survived during the experiment period. Table 3 – Livability over the Experimental Period Time (weeks) number of broilers survived Time (weeks) 4 5 6 Treatment 6 6 6 Control 6 6 6 Starting off in Week 4, we see that there were no mortalities in both the Treatment and Control Sections. In Week 5, there is no change from Week 4, and the same result is shown in Week 6. Graph of Broiler Livability Broiler Livability. 7 6 6 6 6 6 6 6 Number of Broilers 5 4 3 2 1 0 Week 4 Week 5 Week 6 Weeks Treatment Control 2. Feed Consumptions Every day, the feed was weighed and recorded. To calculate the excess feed that remained from the previous day, the average feed consumed per bird was weighed. The amount of feed fed increased every day as the broilers grew. Table 4 shows the average feed consumption. Table 4: Average Feed Consumption Time (weeks) 4 5 6 Total average feed consumption Average Feed Consumption Per Bird(g) Treatment section 960g 1190g 1300g 1150g Control section 815g 1000g 1190g 1001g Table 4 shows that in Week 4, the feed intake in the Treatment Section was 960 g while in the Control Section, it was only 815 g. This makes a difference of 145 g more of feed consumption in the Treatment section. In week 5, we observe that the feed intake was at 1190 g in the Treatment area but only 1000 g in the Control area. A difference of 190 g more is seen for the Treatment section. In Week 6, we see 1300 g of feed was consumed in the Treatment section but only 1001 g in the Control section. There was 110 g more in the Treatment area. Finally, we averaged 1150 g of feed intake in the Treatment section and 1001 g in the Control section. A difference of 149 g more in the Treatment section. Graph of Feed Consumption Grams consumed Average Feed Consumption 1400 1200 1000 800 600 400 200 0 1190 1000 960 1300 1190 1150 1001 815 Week 4 Week 5 Week 6 Week Number Treatment Control Average 3. Average Broiler Live Weight Table 5: Average live weight/bird over the experimental period Time (weeks) Average Treatment section 2000g 2250g 2900g 4 5 6 Weight(g) Control section 1850g 2290g 2575g Table 5 shows that in Week 4, the birds of the Treatment area weighed 2000 g while in the Control area, they weighed 1850 g. The broilers in the Treatment area were 150 g heavier than those in the Control area. In Week 5, we see that the weight of broilers is 2250 g, however the control section weightings show an increase of 40 g more than the Treatment section, weighing 2290 g. In Week 6, we saw that the Treatment section birds weighed 2900 g, but the Control section birds only weighed 2575 g. There was a difference of 325 g heavier in the Treatment area. Graph of Average Broiler Live Weight Average Broiler Live Weight 3500 2900 Weight in Grams 3000 2575 2250 2290 2500 2000 2000 1850 1500 1000 500 0 Week 4 Week 5 Week 6 Week Number Treatment Control 4. Feed Conversion Ratio An average weekly feed intake was recorded every Thursday after weighing. This information was used to calculate the FCR (Feed Conversion Ratio). Table 6 shows both sections’ feed conversion ratios. Table 6: Broiler Feed Conversion Ratio Over the Experimental Period. Time (Weeks) 4 5 6 Overall Feed Conversion Ratio Treatment section Control section 2.08: 1 2.27: 1 2.14: 1 2.29:1 2.23: 1 2.30: 1 2.12: 1 2.29: 1 In Week 4 of Table 6, we see that in the Treatment section, 2.08 units of feed are required for 1 unit of body weight gain whereas in the Control section, 2.27 units of feed are required for 1 unit of body weight gain. The Control section needs 0.19 units more of feed to produce 1 unit of weight. Week 5 shows us that the Treatment section, 2.14 units of feed is needed for 1 unit of body weight gain, but in the control section, 2.29 units of feed is needed for 1 unit of body weight gain. 0.19 units of feed are required in the Control section. In Week 6, our observations show 2.23 units of feed are required for 1 unit of body weight gain in the Treatment area, but the Control section needs 2.29 units of feed for 1 unit of body weight gain. There is a difference of 0.15 units more in the Control area. Overall, the Treatment section needs 2.12 units of feed to produce 1 unit of body weight gain, whereas the Control area needs 2.29 units of feed to produce 1 unit of body weight gain. A difference of 0.17 units is needed by the Control area. Graph of the Feed Conversion Ratio Feed Conversion Ratio Units (to 1 unit of body weight) 3 2,8 2,5 2,27 2,08 2,14 2,29 2,23 2,3 2,12 2 1,5 1 0,5 0 Week 4 Week 5 Week 6 Overall Week Number Treatment Control 5. Other Observations. At the end of the experiment, there were no deaths. The broilers in the Treatment area ate more feed than those in the control area. In the control section, we saw that on some days, there was more feed leftover, and some days had none remaining. DISCUSSION. 1. Broiler Livability Both the treatment and control sections experienced no bird mortality, as the broilers were provided with excellent care. The areas were well-ventilated, and the litter was routinely turned and replaced to maintain cleanliness. Feeders and waterers were thoroughly cleaned daily, and Nutrival powder vitamins were added to their diet to reduce stress. According to Cobb-Vantress (2012), high survival rates in broilers are achieved when proper feeding practices are followed, and sanitation is consistently maintained. 2. Feed Consumption Commercial Poultry Nutrition Effect of vitamin E in heat-stressed poultry | World's Poultry Science Journal | Cambridge Core Both the Treatment and Control birds were fed adequately during the course of the experiment. As time went on, birds in the Treatment section were consuming more feed than those in the Control section. This is due to the vitamins, supplements and heat stress that they might have incurred. According to two sources, Leeson and Summers (2005) Commercial Poultry Nutrition and Cambridge University Press and Assessment (2011), stress-relief supplements can reduce oxidative stress (also caused by heat) which can enhance feed efficiency. 3. Average Broiler Weight Comparative effects of dietary functional nutrients on growth performance, meat quality, immune responses, and stress biomarkers in broiler chickens raised under heat stress conditions - PMC The broilers’ weights were steadily increasing in the Treatment section, and the Control section almost matching up. With a temporary drop in weight in the Treatment section on Week 5, the broilers in the Treatment section were heavier than those in the Control area. This is possible due to dietary supplementation to decrease the heat stress levels. According to the National Library of Medicine (2021), dietary supplementation helps to reduce stress levels and promote growth performance. 4. Feed Conversion Ratio RossTechNote-FCRJuly2011.pdf In the Treatment section, the broilers were more efficient in the conversion of feed to live weight than those in the Control section. According to Aviagen Ross Tech Note (2011), incorporating a balanced diet, feed additives, maintaining housing conditions, managing health and engaging in selective breeding can improve the FCR of broiler chickens. 5. Other Observations The broilers in the Treatment were overall better than the ones in the Control section. Their average live weight, feed conversion ratio and average feed consumption statistics were generally better than those in the Control section. CONCLUSION, RECOMMENDATIONS AND LIMITATIONS 1. Conclusion Based on the findings from the experiment conducted at ASJA Boys’ College Charlieville, it is recommended that broilers be dewormed to ensure they grow more healthily, experience less stress, and consume feed more efficiently. 2. Recommendations It is suggested that broilers at ASJA Boys’ College Charlieville be dewormed after the brooding phase. This practice can improve feed efficiency and promote better weight gain. Additionally, increasing the sample size would enhance the accuracy of the results. To further optimize costs, the school could consider purchasing more affordable feed and selling the manure for added income. 3. Limitations The experiment had several limitations: 1. 2. 3. 4. Due to budget constraints, only twelve (12) broilers were included in the study. The small sample size prevented making more generalized conclusions. The experiment was not repeated, limiting the reliability of the results. Seasonal variations were not considered, as the experiment was conducted at a single time of year and location. 5. The experiment may have been influenced by the equal distribution of male and female broilers across the sections. REFERENCES Cobb-Vantress. 2012. Cabb Broiler Management Guide. Siloam Springs, AK: Cobb-Vantress. http://www.cobb-vantress.com/docs/default-source/management-guides/broiler-management guide.pdf (accessed June 20, 2024). Habbard. 2015. Hubbard Broiler Management and Feeding Guide. Jamaica: Hi-Pro Farm Supplies. https://www.jamaicabroilersgroup.com/assets/Hi-Pro_Broiler_Book.pdf (accessed May 29,2024) Ragoonanan Sahadeo. 1994 CXC Agriculture. San Fernando, Trinidad: Caribbean Education Publishers Trinidad and Tobago, National Agricultural Market Information System. Undated. Historical Monthly Average Retail Prices 2016. National Agricultural Marketing and Development Corporation. http://www.namistt.com/ (accessed May 29, 2024) Weever, F.,J. J. L. M. Phillp-Neri. Y McIntosh, N. Henery, W. Archer, L. Vickerie, and E. O’D. Williams. 1998. Agricultural Science in Secondary Schools in Guyana Book 1. Georgetown: Ministry of Education. Willemsen, M. (2009). Strategic deworming programs in poultry flocks. International Hatchery Practice, 23(5), 13-15. http://www.positiveaction.info/pdfs/articles/hp23.5p13.pdf (accessed June 5, 2024) Phiri, I. K., Phiri, A. M., Ziela, M., Chota, A., Masuku, M., & Monrad, J. (2007). Prevalence and distribution of gastrointestinal helminths and their effects on weight gain in freerange chickens in Central Zambia. Tropical Animal Health and Production, 39(4), 309-315. https://link.springer.com/article/10.1007/s11250-007-9021-5 (accessed June 5, 2024) Forbes – How Chickens came to the Americas (n.d). Ancient DNA Explains How Chickens Got To The Americas (Accessed 23/1/25) Broiler – Wikipedia (n.d) Broiler - Wikipedia Accessed (23/1/25) Free Food Facts – Broiler Chicken Nutritional Facts (n.d.) Nutrition Facts - Broiler Chicken Accessed (23/1/25) Chicken – Wikipedia (n.d) Chicken - Wikipedia Accessed (23/1/25) COST ANALYSIS In the Treatment Section (Pen A), a cost analysis was conducted on broilers, which included six (6) birds. These broilers were raised with a spacing greater than the recommended 1 square foot per bird and were managed in line with the production practices outlined earlier in the document. COMPLETE BUDGET Projected Income Table 5 shows the projected income for this project as $409.50 from the projected sale of six (6) broiler birds sold at $25.00 per kg live weight with a project average weight of 2.73kg each. Table 5 – Projected Income for Broilers C 6 Birds weighing at 2.75kg (6lbs) each Total Quantity 16.38kg live weight Projected Unit Cost ($) $25.00 per kg live weight Income Total Cost ($) $409.50 $409.50 Table showing total cost of the 6 birds weighing an average of 2.75kg (6lbs) in each pen. Projected Expenditure The estimated expenditure for this project is $385,00 Table 6 – Projected Expenditure for Broilers Reared at ASJA Boys College Charlieville. Item Broiler Chicks Broiler Starter Broiler Finisher Electrolyte Quantity Unit Cost ($) 6 $15.00 ¼ Bag $300.00 ½ Bag $280.00 2 Packs $40.00 Total Expenditure Table showing total expenditure of all the broilers reared. Projected Profit/Loss Total Cost ($) $90.00 $75.00 $140.00 $80.00 $385.00 The projected profit/loss was calculated using the formula below: Projected Profit/Loss = Projected Income – Projected Expenditure = $409.50 - $385.00 = $24.50 Project Profit = $24.50 Therefore, we expect to make a profit of $24.50 from the sale of 6 (6) broiler birds. Actual Income – Expenditure Statement This section comprises of the Actual Income, Actual Expenditure and Actual Profit/Loss. Actual Income The actual Income earned for the project was $441.42 Table 7 – Actual Income for Broilers Reared at our school Item 6 broiler birds weighing at 2.83 kg each. Quantity 16.98kg live weight Unit Cost ($) $26,00 per kg live weight Total Income Table showing total income for the broilers reared at our school. Total Cost ($) $441.48 $441.48 Actual Expenditure The actual expenditure was $324.50. Table 8 – Actual Expenditure for Broilers Reared at our school. Item Broiler Chicks Broiler Starter Broiler Finisher Nutrival Powder Quantity Unit Cost ($) Total Cost ($) 6 $12.00 $72.00 ¼ Bag $270.00 $67.50 ½ Bag $250.00 $125.00 1.5 packs $40.00 $60.00 $324.50 Total Expenditure Table showing actual expenditure for the broilers reared at our school Actual Profit/Loss In this a profit of $116.92 was made. Actual Profit/Loss = Total Income – Total Expenditure = $441.48 - $324.50 = $116.98 Actual Profit = $116.98 COMPARISON OF PROJECTED AND ACTUAL INCOME. ACTUAL EXPENDITURE AND ACTUAL PROFIT/LOSS Table 9 – Comparison of Projected and Actual Income, Expenditure and Profit/Loss for Broiler Reared at ASJA Boys College Charlieville. Income Expenditure Profit/Loss Projected ($) Actual ($) $409.50 $385.00 24.50 $441.48 $324.50 $116.98 Difference Between Projected and Actual 31.98 60.50 92.48 1. Comparison between Projected and Actual Income The actual income from this project amounted to $441.48, exceeding the projected budget by $31.98. This increase was attributed to several factors: The broilers' live weight was higher than anticipated, with a projected weight of 16.38 kg compared to an actual weight of 16.98 kg. The selling price of broilers at the time of sale was $26.00/kg live weight, which was higher than the projected $25.00/kg. Only 1½ packs of Nutrival powder were used instead of the projected 2 packs, resulting in an additional $20.00 in income. 2. Comparison between Projected and Actual Expenditure The actual expenditure for this project was $324.50, which was $60.50 less than the projected amount. The reduced costs were due to the following reasons: The cost of each chick was $12.00, which was $3.00 less than anticipated. The price of broiler finisher feed was $15.00 lower than projected. The broiler starter feed cost $7.50 less than expected. Only 1½ packs of Nutrival powder were used instead of the projected 2 packs, saving $20.00. 3. Comparison between Projected and Actual Profit and Loss This activity generated a profit of $116.98, which was $92.48 higher than projected. The increased profit was due to the following factors: The broilers' live weight exceeded projections by 0.6 kg. The market price for live weight was higher than anticipated, selling at $26/kg instead of the projected $25/kg. Reduced expenditure on inputs, including broiler feed and Nutrival powder. 4. Recommendations to increase Profits Look for bulk purchase discounts or lower-cost suppliers for broiler feed, chicks, and supplements like Nutrival powder. Gradually increase the number of birds reared while maintaining efficient production practices to benefit from economies of scale. Consider processing broilers into packaged meat or value-added products, such as preseasoned cuts, to increase profit margins. Time the sale of broilers to coincide with periods of high market demand, potentially commanding higher prices.