5S Implementation in Plastic Bag Manufacturing: A Case Study

advertisement

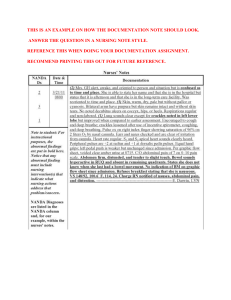

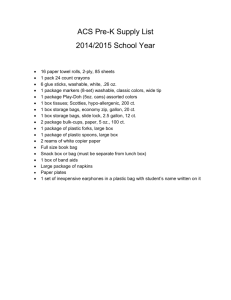

Cleaner Engineering and Technology 8 (2022) 100488 Contents lists available at ScienceDirect Cleaner Engineering and Technology journal homepage: www.sciencedirect.com/journal/cleaner-engineering-and-technology Implementation of 5S in a plastic bag manufacturing industry: A case study M.M. Shahriar, M.S. Parvez *, M.A. Islam, S. Talapatra Department of Industrial Engineering and Management, Khulna University of Engineering & Technology, Khulna, Bangladesh A R T I C L E I N F O A B S T R A C T Keywords: Lean manufacturing Process improvement 5S Lead time Non-value-adding operation Two of the eight wastes included in the lean manufacturing concept are ‘Waiting’ and ‘Motion’. They waste precious operating time and slow down the manufacturing cycle. The major purpose of this study is to use 5S, a lean manufacturing strategy, for reducing these two wastes. The study was conducted at a plastic bag manufacturing company in Bangladesh. The manufacturing process of plastic bags consists of three operations: blowing, printing, and sealing. All activities and sub-processes were recorded, examined, and classified into value-adding and non-value-adding operations, with idle times calculated for each operation. An appropriate step-by-step 5S technique was developed and executed to improve the operational efficiency of the blowing and printing operations by eliminating extra motions and waiting time spent searching for tools. Following the deployment of 5S in these areas, the total operational time was reduced by 8% for blowing and 18% for printing. The assessment was carried out satisfactorily and is documented in this report. Through this study, a window of opportunity for improvement has been explored, which may motivate other researchers to consider applying the 5S tool in their particular research areas as a tool to reduce non-value-adding operational time. 1. Introduction Toyota coined the phrase “lean manufacturing” in the 1950s with the purpose of removing waste or non-value-added operations from a manufacturing process. Positive benefits have been established for de­ cades in achieving production efficiency and reducing waste through the implementation of lean manufacturing techniques. Value stream map­ ping (VSM), Kanban, Kaizen, Standard work, 5S, 8 wastes, Total Pro­ ductive Maintenance (TPM), single minute exchange of dies (SMED), GEMBA, and failure mode effects analysis (FMEA) are some of the wellknown techniques for manufacturing facilities nowadays. The purpose of using all of these tools and techniques is to reduce all forms of waste by implementing less human effort, less inventory, less cost, and less time to produce products while delivering high quality goods in the most effective and economical way while maintaining long-term competi­ tiveness and customer satisfaction (Radnor et al., 2012). Defects, over­ production, overprocessing, waiting, transportation, inventory, motion, and non-utilized talent are the eight types of waste defined in the lean manufacturing concept (Ahmed and Chowdhury, 2018). All activities in the manufacturing process can be classified as Value Adding (VA), Non-Value Adding (NVA) and Support activities. Value-adding activities are defined as activities that transform a product that customers wish to pay for. Non-value-adding activities are those activities that add costs to the product without adding any value, and the cost will not be paid by the customer (Agrahari et al., 2015). They are considered waste. Support activities do not directly add value to the product but are required to execute the value-adding activities, for which customers do not pay. There must be some loss of motion and time when an excessive number of supporting activities are required to perform a single value-adding activity. In this aspect, lean approaches lead to significant benefits in the reduction of non-value-adding operations as waste. VSM is a tool that maps the process, identifies process gaps, and claims the process improvement part in a systematic manner. SMED decreases non-value-adding operational time by reducing process changeover time by making internal processes external. TPM also claims to be a very successful cost-cutting technique by organizing effective and responsive maintenance processes. All of these lean technologies are designed to fulfill the same purpose as lean manufacturing, which is to eliminate waste. Lean manufacturing techniques has been used in previous researches as tools to reduce operational lead time by removing non-value-adding or idle operational time. The 5S method is the cornerstone of the lean manufacturing system. It is a technology invented by Hiroyuki Hirano in Japan in the 1980s. Ho et al. (1995) considers 5S an industrial technique that makes an organization different from the rest. Through imple­ menting 5S methodology, management can build a secure, healthy, and * Corresponding author. Department of Industrial Engineering and Management, Khulna University of Engineering & Technology, Khulna, 9203, Bangladesh. E-mail address: msp.ipe@iem.kuet.ac.bd (M.S. Parvez). https://doi.org/10.1016/j.clet.2022.100488 Received 6 September 2021; Received in revised form 26 February 2022; Accepted 27 February 2022 Available online 8 April 2022 2666-7908/© 2022 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/bync-nd/4.0/). M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 safe working environment, and it can ensure compliance with standards, which will promote quality improvement within the organization (Sor­ ooshian et al., 2012). The 5S concept emphasizes simplifying the work environment, managing productive workplaces, and reducing waste while promoting health and safety (Cirjaliu and Draghici, 2016). This also seeks to create a better management culture and staff that can up­ hold good practices. 5S is a cleaning tool that encourages cleaner manufacturing in a systematic way. It not only brightens the production floor, but it also helps to clean up the entire process by reducing waste. By planning, managing, and regulating the production process, 5S makes a process easier, saves operational space, capital, and time, and produces goods with fewer defects. It establishes a disciplined, clean, and well-organized work atmosphere (Chapman, 2005). 5S is not only about housekeeping, it is a method that has proved its importance in warehouse mapping (Oey and Nofrimurti, 2018) and cost control of inventories (Randhawa and Ahuja, 2017a), in the healthcare sector for efficient patient response (Kanamori et al., 2015), in operational room settings (Nazarali et al., 2017), in school settings (Jiménez et al., 2015), in power plants for enhancing maintenance safety (Duran et al., 2017) and in increasing process quality and efficiency (Sharma and Lata, 2018). 5S is the pre­ requisite for the implementation of certain effective optimization tools, such as TPM (Singh et al., 2013), SMED (Ribeiro et al., 2019), System Dynamic Model (Omogbai and Salonitis, 2017) and AHP (Analytical Hierarchy Process) (Agrahari et al., 2015). It also encourages the use of TQM (Total Quality Management) tools by ensuring that the process is error-free (Randhawa and Ahuja, 2017b). Lack of an appropriate 5S system leads other lean tools to be ineffective. Regardless of the field where 5S was implemented, the researchers’ major goal was to make the entire process clean, operationally sound, and satisfying by locating and eliminating hidden scraps in a manufacturing process, regardless of their form. 5S is also an important tool for instilling motivation in workers (Radnor et al., 2012). Most companies now use 5S not only as a cleaning, sorting, organizing, and functioning tool, but also to reduce idle time and non-value-added operations in the production process. Unfortu­ nately, no research on 5S implementation in Bangladeshi SMEs has been found. This research is centered on the plastic bag manufacturing in­ dustry, which is a representative of the SMEs in Bangladesh. This study focuses on reducing idle or waiting time in manufacturing processes by identifying and eliminating those non-value-adding operations through step-by-step implementation of the 5S methodology. The authors pro­ posed and implemented a methodology that caused benefit to an orga­ nization after determining the primary problem and its main causes. In particular, it is necessary for the small-scale industry to improve oper­ ational efficiency and increase productivity in order to compete and prove its existence in the global market, which is constantly changing the demands for high-quality products at low cost. The 5S technique utilized in this case study contributed to a variety of outcomes, including reduced operational time and increased production. medication delivery delays. They used 5S in conjunction with DMAIC (Define, Measure, Analyze, Improve, Control; a lean manufacturing approach) and cut cycle time by more than 45%, contributing to a reduction in lead time. In their study Jiménez et al. (2012) used Lean manufacturing tech­ nologies (5S, Kanban, and Kaizen) to improve the inventory manage­ ment system of a wine producing industry. Their objective was to reduce production lead times by reducing and optimizing material-in-process inventories. Inventory costs were reduced by 8%–16%, with a 65% reduction in overall manufacturing lead time. Rojasra and Qureshi (2013), in their case study, implemented 5S in a small-scale industry with an emphasis on process performance improvement. Every industrial operation has certain non-value-adding sub-processes that can be identified and eliminated by using 5S. Using AHP (Analytical Hierarchy Process), a multicriteria decision-making tool, this study was conducted to identify value-adding and non-value-adding procedures. The implementation of 5S raised overall production efficiency from 67% to 88.8% in just one week. Sidhu et al. (2013) found that using the PDCA Cycle in conjunction with 5S, can be implemented at small scale industries. The first phase (Plan) included the development of the entire 5S implementation and methodology, as well as personnel training. The step-by-step 5S imple­ mentation process was used in the second phase (Do). The data were analyzed in the third step (Check), and it was determined whether the 5S implementation was successful or not. An audit schedule was estab­ lished in the final phase (Act) for continuous development and to assure the program’s long-term viability. The assembly line cycle time was reduced from 50 min to 41.50 min as a result of this implementation. In another case study, Choomlucksana et al. (2015) used lean manufacturing techniques such as 5S, visual control, and Poka-Yoke to discover waste reduction opportunities and increase the efficiency of production processes. The non-value-added operations were addressed first. The 5S approach was then used to improve the efficiency of the deburring and polishing procedures. The adoption resulted in a 62.5% reduction in polishing processing time, a 66.53% reduction in non-value-added operations, and a 1764 $/y reduction in overtime costs. In a case study conducted in the scientific equipment manufacturing industry, Gupta and Jain (2015) discovered that implementing the 5S tool resulted in overall workplace benefits such as reduced searching time and increased safety. In just 20 w, the tool searching time in the manufacturing process was decreased from 30 min to 5 min, and the audit score improved from 7 to 55. Another similar approach to 5S implementation employed by Gupta and Chandna (2020), also in a scientific equipment manufacturing company, showed that after 24 w of 5S implementation, the audit score improved from 6 to 72. In a one-year study, conducted in Tanzanian hospitals, Ishijima et al. (2016) used the 5S technique to improve hospital waiting times. The cluster Randomized Control Trial (c-RCT) approach was used to deter­ mine how long patients waited at various service points. After success­ fully adopting 5S, average patient waiting time in the recording area was reduced from 12.9 min to 4.6 min, while average patient waiting time in the medication room was reduced from 35.0 min to 22.5 min. Sangani and Kottur (2019) performed a time and motion study for several assembly line tasks to determine value-added and non-value-added time and operations. The 5S implementation process first started with identifying the garbage items in the process. They set up a two-bin storage system to increase FIFO usage, cleaned up the workstation, and set standards considering the 5M (Man, Machine, Material, Method, and Measurement) depicting in a fish-bone diagram and created an audit checklist. The study identified idle or non-value-adding process areas, with suggestions for resolving the sit­ uation of unavailability of nuts and bolts, as well as leaf spring material, which causes assembly line delays. Another well-established strategy for reducing operational time is SMED, which focuses on decreasing changeover time by making internal 2. A literature review on 5S implementation projects Implementing 5S for the purpose of reducing operational lead time is not a new methodology that has recently been created. Some researchers have found this simple technique to be far too effective to declare their experiments a tremendous success. During an operation, searching for tools or equipment accounts for a high number of motions that have no value and also kills valuable operational time. 5S has been employed to solve this challenge, with the purpose of reducing the number of motions that a worker must execute throughout an operation. Tools, equipment, and supplies must be arranged strategically for the most convenient and efficient access. Everything must have a place, and everything must be in its place. Bringing this persuasion into the practical field of imple­ mentation, Al-Araidah et al. (2010) conducted a case study in a very busy pharmacy at a local hospital with the goal of reducing patient 2 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 work external. The best results come from combining these approaches with 5S. Johnson et al. (2017) used 5S in conjunction with the SMED method in the scaffold making industry. They separated leftovers and sold them to the market, cleaned and standardized the tool storage space, and increased production by 15%–20% as a result of the com­ bined approach. 5S is an important part of SMED since it saves time while searching for tools being used during a changeover. In a case study, Azizi and Manoharan (2015) analyzed the process using VSM, applied SMED, and reported a significant reduction in changeover time from 145 s to 54 s. From the explanation above, it can be stated that 5S is an effective tool for identifying value-adding and non-value-adding activities, lowering operational lead time by removing non-value-adding process time, enhancing work efficiency, and increasing employee engagement in any workplace. This research will take a detour by introducing 5S in the plastic bag manufacturing business with the goal of minimizing nonvalue-adding operating time. • The willingness and ability of the workforce in the implementation of the 5S technique. • Creation of groups and committees at various levels; management needs to provide the required motivation for the initiative, for the actual implementation of the system, with low-level staff and su­ pervisors for the functional implementation of the system. • The functions and responsibilities of each group have been divided. The role of the authors was to engage in better teamwork at all levels. • A step-by-step approach has been clarified. • The next step was to review the past performance levels of the pro­ cesses involved in the manufacturing of plastic bags to determine idle time and operations for future performance improvements in this case. 4.1. Implementation phases in 5S 4.1.1. Sort (Seiri) The first S seeks to eliminate unnecessary items that are of no value and easy to dispose of in the workplace. The system for keeping every material in the enterprise in the right position is referred to as “Sorting”. The unnecessary materials and equipment, extra or rarely used in the workplace, cause the workplace to be demolished and work efficiencies to be reduced. Sorting is an excellent method for transforming a clut­ tered layout into an efficient and clean one. The following criteria are included in the sorting: 3. The case The production process of plastic bags in a Bangladeshi firm was chosen as the case study in this research. The company featured in this study produces plastic bags for garment packaging. The cost of raw materials for producing plastic bags is increasing and fluctuating with an unpredictable trend. Entrepreneurs engaged in the production of plastic bags face major challenges. For this reason, any positive contribution to plastic bag manufacturing will have a significant impact on its produc­ tivity. With a view to optimizing the process of production of plastic bags, the authors have attempted to analyze and develop the production process of plastic bags in the light of the challenges presented. The plastic bag manufacturing process is divided into three parts. The first is a blowing operation in which the petrochemicals are mixed, and the single screw extruder melts the polymer and pushes it into a tubular die, where it extrudes a thin plastic film. The second step is to print the plastic bag using the printing blocks. The third step is the sealing process, in which one part of the plastic bag is sealed while the other remains open for use. The plastic bag industry offers an enormous variety of product forms, such as rolls, sheet plastic bags, single plastic bags, hanger plastic bags, plastic bags with gussets, flap plastic bags, and so on, in a variety of colors and sealing requirements. When transitioning from one process to another, the parameters of the plastic-bag manufacturing system change, which requires a significant amount of setup time and can be viewed as a waste of valuable operational time. The focus of this case study was on determining those non-value-adding operational times and motions and eliminating them through the application of lean concepts in order to improve productivity. • What needs to be done? • When is it required? The implementation steps include: • Determine what is necessary and what is not. • Deciding on whether those unnecessary items would be located. It was decided to either remove or dispose of it. 4.1.2. Set in order (Seiton) The second step in the 5S implementation is to select the unorga­ nized items and place them where they fit best, avoiding congestion. The basic strategy for implementing this step is to try to use as much of a visual approach as possible with the aim of avoiding time losses during search and proof of mistakes. The basic guidelines for applying the Seiton approach include: • Collect and analyze the previous data for at least one year and analyze it in order to establish a sorting relationship. • Store related items in combination. • In separate rows, store different items. • Do not stack, rack, or shelf items together. • Each item and storage area are clearly labeled (visual control). 4. Methodology The 5S approach can be extended to most job situations in a limited period of time due to its basic nature. The case was examined. Every activity and flow of the job, from input to finished goods, was docu­ mented, and photos and videos were taken to research and evaluate all processes. Each method was developed and implemented separately for the activities being carried out to identify anomalies in the production process, such as material movements, changeovers, changeover times, operating sequences, completion times of the project, use of the work areas, etc. Performance is measured by variables such as time savings, productive use of resources, better management of the workplace, and improved working conditions. Prior to the implementation of 5S, as discussed by Mane and Jaya­ deva (2015), certain criteria were decided as requirements prior to 5S implementation, as: Labeling is for other people, particularly if the area owner is absent. The benefit is decreased search time. Labeling should be in the local language so that less educated workers may understand it. To avoid any Musculoskeletal Disorders (MSDs) and injuries during carrying or lift­ ing, ergonomic standards must be followed for maintaining the sorted items in their appropriate areas, whether the items are at a permissible distance or height. 4.1.3. Shine (Seiso) Once the unnecessary items have been thrown away and the neces­ sary items have been sorted and set in order, the next step is to clean the work area. The purpose of this stage is to remove and replenish the station as well as the root cause of waste, dirt, and damage. This step must involve all employees in how they will clean up and how often it needs to be cleaned up (Gapp et al., 2008). Pollution, dirt, and waste 3 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 5. Implementation results & discussion cause impairment, indifference, inefficiency, poor production, and ac­ cidents in the workplace (Rahman et al., 2010). The workplace should be cleaned at regular intervals. After use, all tools and equipment should be restored to their own locations. Although it is imperative that a cleaning schedule be established along with the tasks assigned to all personnel working in the designated areas, a specific time interval should be allocated after which these items must be cleaned. Another issue that needs to be considered is that the unclean area is more sus­ ceptible to causing potential injury to workers. Items that required cleaning have been identified. Training should be conducted to raise awareness among employees about the maintenance of clean resources and the damage to free resources. 5.1. Understanding the process gaps As previously stated, the manufacturing of plastic bags comprises mostly of three operations: blowing, printing, and sealing. Some of the plastic bag items do not have to be printed as per customer demand, and sometimes the extruded plastic bag is sold in a roll called ‘Roll Poly’ and does not require printing or cutting operation after blowing. The overall process of plastic bag production is summarized and shown in Fig. 1. Each of the three operations consists of a number of processes that need to be carefully studied before any development activity is carried out in that area. Blowing, the inauguration of the production of plastic bags, performs the task of making roll poly from poly granules by heating. In general, two forms of plastic are made of polypropylene (PP) and polyethylene (PE). The machines in the blowing process are different depending on the form of polymer. The heat chamber of the system heats the sucked poly granules with the intention of transforming them into molten poly. For PE, air is blown not only to control the shape of the plastic bag, but also for cooling purposes. On the other hand, the sizer and air blown through are provided to control the shape of the poly and cold water for cooling the heated poly in the context of the PP. As there is a chance of flaming up, cooling is needed. As the shape of the plastic bag is controlled by the sizer, different sizes of the sizers are needed. It’s a challenge to keep the Sizers organized. The changeover time depends on the organization of the Sizers. It was found that the organization of the sizers was not appropriate (Fig. 2). As a result, the majority of the changeover time was spent looking for the appropriate sizer for production. Fig. 3 depicts the operational process flow of blowing with the appropriate time required. The blowing operation has eight subprocesses, while looking for sizers takes up 12.12% (Fig. 3) of the total operational time, which is a considerable amount of time in the manufacturing base and can be reduced by sorting and organizing those sizers. After blowing, the roll of poly is taken to the printing area. The printing operation is carried out either on both sides or on the front or back of the plastic bags according to the customer’s requirements. Changeover time is higher for this procedure due to its convoluted configuration. The first step in this operation is to find the exact printing block. It’s difficult since a number of blocks are stored, varying from customer to customer. The blocks are different in their lettering and design. Taking an exact block out of a variety of blocks is a daunting job for the machine operators. The block is connected to a specific printing cylinder. The periphery of the printing cylinder should be equal to either the length of the plastic bag if the next operation is bottom sealing, or the width of the plastic bag if the next operation is side sealing. After that, the block-leaded printing cylinder is installed in the printing ma­ chine. The color plate, which is filled with color according to the cus­ tomer’s requirements, is attached to the printing cylinder in the machine. The block gives the impression of color on the plastic bag due to the rotation of the printing cylinder. Fig. 4 shows the operating pro­ cess flow of the printing process with the corresponding time required. The printing operation is divided into seven subprocesses, with the block collection and placement on the cylinder of the printing roller ac­ counting for 34.78% (Fig. 4) of the total operational time. This is a significant amount of time that can be reduced by organizing those printing blocks in a rack with appropriate buyer information labeling. The text on the blocks is too small to read, and the blocks themselves are small. Since the blocks are unorganized, certain blocks may have been used incorrectly, resulting in incorrect bag printing. The author looked at the last three months’ data on the number of customer complaints and discovered that there were eight complaints about incorrect printing on the plastic bag. It caused a great deal of poly bag waste and could harm the company’s reputation with customers. After the printing process has been finished, the printed roll poly is moved to the sealing section, where the plastic bag is cut or sealed from 4.1.4. Standardize (Seiketsu) It is important to maintain the area after the organization and cleaning of a production area. That is why the organization develops standardized procedures, rules, and expectations for the maintenance of continuous activity in all areas. Standardization involves the creation of visual guidelines for keeping the workplace organized and clean. This is a way of creating a consistent means of carrying out the tasks outlined above on a daily basis. The aim is to ensure that this order and regularity are maintained, standardized, and prevented. Standards should be highly communicative, descriptive, and comprehensible. During plan­ ning and transformation, this should be communicated to all partici­ pants in the process at the specific workplace, including directory to workers. Check sheets have been implemented, and the method used has been documented. The shop floor manager and supervisors were involved in the check sheet activity. Everyone could immediately and easily see what was required to complete the task. The plant must also include the creation of procedures and basic daily check sheets in the workplace. The checklists should give a visual signpost to verify that the daily 3S requirement is followed as best practice in the workplace. 4.1.5. Sustain (Shitsuke) The Japanese ‘Shitsuke’ denotes the ability to do things the way they should be done. It improves and encourages employees to act in a pos­ itive manner. The Fifth S is essential for understanding and imple­ menting, as it involves proactive changes in employee behavior at all levels of a company (Kobayashi et al., 2008). This feature is also important for maintaining daily routine continuity. At this level, self-discipline in their daily work must be maintained at all times. The ability to maintain discipline is crucial following the successful adoption of the 5S method. The four phases of 5S provide powerful, visible, and easily quantified effects. This level necessitates a great deal of self-discipline and training. The individuals involved in maintaining 5S functioning and implementing it successfully are the most important factor. This is by far the hardest step to accomplish and execute. The implementation method here is “expressed ideals.” Trainers and team members work together to achieve common goals. 5S involves coaching to ensure that people accomplish the simplest tasks correctly. Train employees to use the 5S approach on a regular basis so that it gets ingrained in the company’s culture. Every employee should understand the importance of health, order, and cleanliness, and they should be willing to take the necessary efforts to ensure the quality of the pro­ duction floor. Employees should be given awards and incentives for successfully implementing the 5S method in their workplace. It will increase staff interest, enthusiasm, morale, and commitment in the implementation of 5S. Continuous improvement includes a clear understanding, correct structure and processes, worker support and management, and adapt­ ability to 5S. Audit plans should be developed. Maintaining standardi­ zation by frequent monitoring or implementation audits maintains a catalog of this technique. Workers’ participation and morale in support of 5S should be very high. It is also important to preserve the efficiency of the other 4S. 4 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 1. The plastic bag production process flow chart. a number of sub-processes that require more time to execute. Searching for large weight sizers in blowing and tiny blocks in printing, for example, occupies important operating time and leaves workers fatigued and demotivated. The principles of Time-Based Competition (TBC) and Quick Response Manufacturing (QRM) are used to reduce cycle time (Filho and Saes, 2013), where these terms refer to any strategy that emphasizes time as the most important factor in achieving manufacturing excellence. VSM is a useful method for identifying waste from both value-added and non-value-added activities by accurately mapping all processes, sub­ processes, material and information flow, and inventory levels at various stages (Ismail et al., 2014). Not only does it focus on identifying value-adding and non-value-adding operations in processes, but it also checks for process gaps and work-in-process (WIP) inventories that in­ crease the overall process time and inventory costs (Saraswat et al., 2015). In this research, simple process sequence charts were utilized to achieve the same purpose (identifying value-adding and non-value-adding operations). Blowing and printing are each counted as separate steps. A single blowing machine is used for the blowing oper­ ation, and a single printing machine is used for the printing activity, both of which require two operators to operate. There are no sub­ processes or sub inventories involved that can be visualized using VSM. As a result, the authors discovered that depicting the processes through a process sequence chart using a time and motion study would be feasible. Fig. 2. Arrangement of sizers in rack before implementing 5S (The large sizers are at the top of the rack, as shown by the red rectangle). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.) the roll poly. This section is the last operation in the manufacturing of plastic bags. Two types of sealing operations, bottom sealing and side sealing, are performed according to customer requirements. In the context of the bottom sealing, the heater and the cutting blade are ar­ ranged in a row. The up and down movement of the blades is regulated by the length of the plastic bag. On the other hand, a heater is used to make joints on both sides and to cut a poly roll for side sealing opera­ tions. The movement of the heater up and down is regulated by the width of the plastic bag. For this process, a flap can be put in a plastic bag. In order to provide a small hole for a plastic bag, a punch machine is mounted in the room so that air can be released from the plastic bag. Fig. 5 shows the operating process flow of the sealing process with the time required. The sealing operation is simple and automatic. For development purposes, the authors did not consider any such areas to be updated in this process. Operators were discovered to be making needless motions and wasting time when searching for sizers in blowing and blocks in printing. The average search time for each sizer was 105 s (Fig. 3) and 437 s for each printing block (Fig. 4). Those issues were studied by the author, and it was found that the high search time was due to the inorganization of the printing blocks and the sizer. This was not only about consuming precious working time, but it also posed health con­ cerns. The sizers were randomly stored, and there were no sequences for keeping them in the rack (Fig. 5). Rather, the large sizers were placed on the upper part of the rack, which could fall down when searching and could cause an accident (Fig. 5, marked by the red square). This has been influenced by the changeover time. These three primary operations have 5.2. 5S implementation in the Sizer storing area 5.2.1. Sorting The first step in the implementation of 5S in this area was to sort out the required and unnecessary items. But there were no unnecessary items found in this section that could be removed from that area. There are other questions that need to be answered in section 4.1.1, which is the frequency of the sizers used in a certain period. For this purpose, the data of the sizers used in the last 13 months has been collected from the industry management team to determine the frequency and hierarchy of the sizers used. The size range of the available sizers was 4–36 inches. The Sizers were divided into 7 categories based on their size. Fig. 6 shows the distribution of data on the number of sizers used in the last 13 months. The aim was to find out which sizers had been used more often before. It was a requirement for the sizers to be grouped according to their frequency of use. When organizing, the highest frequency was given the highest priority. Employee participation played an important role in the sorting process, as they participated actively, and the results were visible through improved working conditions at the workplace. 5.2.2. Setting in order According to the National Institute for Occupational Safety and Health (NIOSH), the permissible range of vertical manual lifting to avoid Musculoskeletal Disorders (MSDs) or injury is between 76.2 cm and 177.8 cm (Garg, 1995). The average height of the racks on the manufacturing floor was observed to be 213.3 cm, which is greater than the NIOSH limit, and the lower row of the rack was observed to be just 5 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 3. The blowing operations sequence chart. Fig. 4. The Printing operations sequence chart. 10 cm above the floor, which also falls short of the NIOSH standard. To keep the sizers, the uppermost row of the rack was given the last priority, and the lowermost row was given the second last priority because both rows violated the NIOSH requirements that the authors followed (Fig. 7). The big sizers with less frequency of usage were kept at the bottom of the rack on the ground to ensure protection during the collection or movement of those large sizers. 5.2.3. Shining the place In the third step (shine), the entire work area was cleaned and, with the help of the workers of that unit, all the sizers were marked with black paint on the body of the sizer according to their size (Fig. 8). These sizers were then ordered sequentially, giving the highest priority to the sizers that were used most. There were some sizers that didn’t have the size that was written on them. So, it was very difficult to find unwritten scale sizers. There were the other sizers that had been written down, but most 6 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 5. The Sealing operations sequence chart. Fig. 6. Blowing Sizers used in last 13 months. of them were not clear enough to read the size written on them. audits, the operation head will conduct weekly audits, and the central auditors from the management team will conduct monthly audits. The concept was warmly welcomed, and the corporate management announced incentives or remunerations for staff who maintain the most efficient floor. The supervisor responsible for this area shall check, at a regular interval of 24 h, whether: 5.2.4. Standardize In the next step (standardize), in order to sequentially arrange the sizers on the rack, the area in which the sizers were kept according to their size was written and attached to that particular area of the rack (Fig. 9). It will standardize the system and reduce the time required to search for the sizers in each row of the rack. ✓ The Sizers are placed in their right positions after they have been used. ✓ The racks are either swept or not. ✓ If the size written on the Sizers is erased or not, if it is not clear to read, then take immediate action to write it down. ✓ The labels that are hanging on racks with size ranges are torn out or ok; if it is being found torn out, it has to be reprinted and hang on the corresponding area for that specific set of Sizers. 5.2.5. Sustaining the improvements Fig. 10 reveals that the average time of the sizer searching and lifting process was decreased from 105 s to 35 s after a step-by-step adoption of 5S in the blowing operation. Previously, searching for sizers in the blowing operation contributed 12.12% of the whole operational time, which is now minimized to 4.40% after 5S implementation. The final ‘S’ is to sustain the aforementioned procedures, which should be done on a regular basis. For this objective, an auditing format (checklist) with a point of marking has been established. Management and supervisors are also included among the auditors. The supervisors will conduct daily 7 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 7. Sizers after setting in order in the rack (The storage of large sizers from the bottom is indicated in red). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.) Fig. 8. Marking the sizers according to their size. 5.3. 5S implementation in the ‘printing Block’ storing area The blocks required for printing on the plastic bag, were found to be unorganized in the rack with insufficient lighting facilities (Fig. 11). These blocks are very small compared to the Sizers. The company deals with hundreds of customers, and it stores blocks of different designs from different customers for printing purposes. The blocks are often reused in every repeat order received from the same customer. That’s why there’s a need to store these blocks in a standard way to minimize search time. 5.3.1. Sorting The first step in the implementation of 5S is to separate the necessary and unnecessary items. For this purpose, data on the printing blocks used in the last 13 months has been collected from the industry man­ agement team. Fig. 12 shows the number of blocks used by different customers over the last 13 months. Any of the blocks found to be unused in the last 13 months have been picked as unwanted items and removed from the print area and disposed of in a sensible way. Fig. 9. Marking on the racks according to the size range of the sizers. 5.2.6. Benefits • By comparing Figs. 3 and 10 for ‘Sizers collection and lifting’ oper­ ation, the average search time for Sizers decreased from 105 s to 35 s (66.67%) and the overall operating time decreased by 8% (from 866 s to 796 s) • Safety with proper Ergonomic standards were ensured in that area by separating and organizing the Sizers in a standard way. 5.3.2. Setting in order In the next step, setting the blocks in order, there was a problem of arranging the blocks customer-wise as the items (blocks) were of different sizes and may be lost if the arrangement is not done properly. In order to overcome the problem, the authors decided to store the 8 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 10. Blowing process sequence chart after implementation of 5S. Fig. 11. Previous unorganized condition of blocks in the rack. blocks in books (Fig. 13). Each book contains the blocks of a single customer. The books were made with the sacks that contain poly-granulates, which become waste after the granules have been consumed. It’s very flexible to use. The blocks were attached to the book pages with dilute adhesives so that the blocks could be extracted quickly from the books if they needed to be used. Data from the last 13 months was analyzed to find out which customer ordered more printed plastic bags (Fig. 2). Priority was given when the blocks were organized from the first row of the rack to the last. There was no specific cleaning schedule prior to the implementation of 5S. Cleaning was carried out in an unorthodox way. A cleaning schedule has been planned during the implementation of the 5S. 5.3.4. Standardize In the fourth step, the standardization of the system starts with the labeling of the chambers by the names of books containing customerwise separated blocks. The block search operation became so easy as to give a high degree of satisfaction to the workers who had previously found it very unsatisfactory (Fig. 14). 5.3.3. Shining the work area Blocks in the rack were found lying or hanging randomly, and the area was uncleansed by dirty blocks sticking printing inks to it. In this phase, the entire area was cleaned up by the valiant efforts of the staff, for which they are truly appreciable. Block books were kept customerhierarchy-wise in different rack chambers. Sufficient lighting facilities were provided in that area to make the searching procedure convenient. 5.3.5. Sustaining the improvements The average time for the process of block searching and setting it up with a cylinder has been lowered to 210 s from 437 s after a step-by-step implementation of 5S in the printing operation, as shown in Fig. 15. Before implementation, searching for blocks in a printing operation contributed 34.78% of the whole printing operational time, which is 9 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 12. The frequency of blocks used for different customers. ✓ The blocks are cleaned after the operation done. Because the area should not be filthy with colors disseminating here and there. ✓ The blocks are placed in their proper location after they have been used. ✓ If the blocks are getting detached from the book, use other adhesive that may result in good stickiness. ✓ The racks are either swept or not. ✓ The labels that are hanging on racks with size ranges are either torn out or okay; if they are found torn out, they have to be reprinted and hung in the corresponding area for that specific set of blocks. 5.3.6. Benefits • Comparing Fig. 4 with Fig. 15, the average searching time for blocks was decreased from 437 s to 210 s (66.66%) and the whole opera­ tional time was reduced by 18% (from 1256 s to 1029 s). • In the three months following the deployment of 5S, the number of customer complaints about printing errors decreased from eight to one (section 5.1). Fig. 13. Book containing printing blocks. 5.3.7. Barriers in implementing 5S Many scholars have addressed the difficulties of applying 5S from a practical standpoint in their investigations. The authors also mentioned various difficulties that they encountered when implementing 5S. These are as follows: • The biggest problem in implementing 5S has been recognized as a lack of support from senior management (Singh and Ahuja, 2015). • Changing employees’ perceptions of their jobs is another obstacle to implementing 5S. The majority of them believe they are performing the same tasks and that they are already performing properly (Chandrayan et al., 2019). • Because of a lack of sufficient training and employee motivation, any type of development, whether 5S or any other technique, stays just as a concept (Singh and Ahuja, 2015). Employees generally believe that their primary goal is to boost productivity rather than to clean or organize the workplace. This problem can be considerably overcome by providing sufficient training and motivation to employees about the aim of the 5S program, which is not to increase their work but to boost productivity. Fig. 14. Block keeping cabinet after implementation of 5S. now minimized to 20.40% (Fig. 15) after 5S implementation. For sus­ taining the system an auditing format like as for finding the Sizers, has been established for this purpose also. The audit team will be the same as it has been declared for the sizers part. The supervisor responsible for this area shall check, at a regular interval of 24 h, whether: 10 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Fig. 15. Printing process sequence chart after 5S implementation. and blowing areas was completed in a single day. Setting the standards for block and sizers in the fourth phase took about three days to com­ plete. The management gave past data, which was used to create stan­ dards. When it came to defining standards, the authors consulted with management and made a priority. The fourth phase, ‘Standardization,’ is very important since it ensures that the standards are consistent with the company’s business standards and are achievable for the company; otherwise, the standards need to be revised. The data from the previous 13 months was used to create the prioritization chart for grouping blocks and sizers. These client priorities, as well as the priority for the structure of blocks and sizers, will change as the marketplace changes. The au­ thors’ prioritization method should be used again after a three-month gap to see if the priorities have altered. The 5S standards will be altered as a result of the shift in priority. Not only has the 5S program reduced search time, but it has also made 5S awareness training more accessible to everyone from upper management to machine operators. This will encourage management to pursue other initiatives in which the 5S methodology can be used to create significant changes. The most difficult aspect of adopting 5S is the fifth phase, which involves main­ taining the development standards that have been established and adhering to them on a daily basis. This is how the 5S was implemented in these two parts of the plastic bag manufacturing process (blowing and printing), resulting in the elimination of the two wastes of ‘waiting’ and ‘motion,’ bringing in cleaner and safer production. Employees that are directly involved in the processes, as well as management who are prepared to advocate for and conduct audits on a daily basis, are all equally accountable for making the 5S project viable. 5S visual posters were provided, written in the local language to help participants grasp the program’s purpose. Posters at the workplace to continually impress upon staff the need to adhere to the 5S system holistically. Some noti­ fications and position charts were placed in the authorized regions to prevent any erroneous steps toward 5S installation. Ikuma and Nahmens (2014) highlighted that 5S initiatives should be integrated with organizational objectives by the top management throughout the organization. StrEong commitment and support from the top management is the most important success factor for implementing 5S in any company. The commitment should also be provided by the senior management for intensive training and development. • Ineffective 5S can be caused by a lack of communication and a lack of team spirit (Chandrayan et al., 2019). When there is a need for support or development in the 5S program, it should be addressed and communicated. • The inability to deploy 5S due to a lack of resources (Singh and Ahuja, 2015). • A 5S system that has been in place for a while may collapse due to a lack of competent leadership (Singh and Ahuja, 2015). • There is a lack of clarity in the company about the aim of imple­ menting 5S. There should also be a clarification that 5S is a long-term process that cannot be built in a day or a week; it takes a specific period of time to become sustainable, which should be highlighted and acknowledged by the employees (Chandrayan et al., 2019). • Establishing ineffective and short-term 5S standards. • If management does not declare any prizes or incentives for staff, it may reduce their motivation to implement any development pro­ gram (Randhawa and Ahuja, 2017b). • Inadequate record-keeping and auditing systems for assessing and maintaining the 5S program. The effectiveness of 5S can be ensured by the comprehensive participation of the management of the 5S audit and feedback on the execution of the technique by the authorities (Chapman, 2005). Another barrier mentioned by the authors to 5S adoption is workers’ unwill­ ingness to change, particularly those who have worked in the same field for a long time and operate in a traditional manner. To increase employee adaptability to changes with less disruption, it is critical to adopt Kaizen with small incremental changes inside the 5S program. Through the incorporation of incremental improvements at work, the 5S method is better presented and more sustainable (Suárez-barraza et al., 2012). The unused and filthy printing blocks stained with inks were recognized and disposed of in a reasonable manner during the first phase (sorting). Almost 30% of the blocks (about 18 kg) were disposed of in that region as a result of this operation, which was the first step toward cleaner production. The more useless items on the floor, the more difficult the job becomes to accomplish. The first two steps of sorting and setting things in order took only two days. The cleaning of the printing 11 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 ‘Motivation’ is the first thing that needs to be conveyed to the workforce. When employees value working to a specific standard rather than working as they please, an organization achieves consistency (Agrahari et al., 2015). Some employees may have a belief that they are not being paid for performing these 5S activities. In this situation, a list including all responsibilities has been prepared in detail. Such responsibilities have been addressed and recognized by the team, and they have been motivated that it is a part of their job for which they are being paid. The authors were able to persuade the management team that if the standard procedure is not followed, all of the 5S efforts will be worthless. Based on the author’s recommendation, the management team agreed to declare incentives for employees who take the best care of the first 4S item. There was previously a culture at that company that rewarded its employees by declaring ‘Employee of the Month,’ and after 5S was implemented, 5S became another category for making the best selection of the best employee. The improvements seen over a period have been highlighted on the production board with a skill matrix, and employees have been recognized for their contributions. activities are critical to the success of 5S initiatives in an organization. Leadership is also important in the 5S program’s execution. The 5S strategy should not be viewed as a one-time project; rather, it necessi­ tates uniformity and consistent standards in order to ensure long-term success. The primary objective of this study was to apply and construct 5S concepts with the goal of increasing productivity by minimizing non-value-added operating time, which was successfully created and established. Any development achieved by this effort will provide the manufacturer with a competitive advantage over his com­ petitors, resulting in higher productivity. This research could be useful in manufacturing operations that generate a lot of waste for searching tools. The methods utilized in this study can be directly adapted and applied by plastic bag manufacturers. Industries such as plastic bag manufacturing industries in Bangladesh have less capital to invest and operate on a razor-thin profit margin. In most Bangladeshi organiza­ tions, the top management team holds the belief that quality implies incurring additional money. When the profit margin and investment are both modest, it is better to use these lean approaches instead of investing in new machinery to enhance productivity. In those circumstances, this study will serve as a motivation for them to make low-cost quality en­ hancements that will help them improve their productivity and quality. 6. Conclusion The global market is challenging manufacturers’ growing re­ quirements for high-quality products with low cost and shorter lead times. Newer technologies are being incorporated. Every day, new methods of operation are being developed. For this purpose, the decision-makers of industries are forming a propensity among them­ selves to avoid the expense of improving the shop floor. So, any kind of cost-free change is always welcomed and embraced by them. The pur­ pose of this study was to reduce waste and motion from processes in order to achieve manufacturing process excellence. This study started with an understanding of the poly bag manufacturing processes, fol­ lowed by an assessment of the process gaps and the creation of a thor­ ough 5S checklist to ensure that the established standards are maintained. In a specific plastic bag manufacturing company, the author used the 5S technique in five stages to establish standards and maintain them by constant checking with a checklist. Consistent organization of blowing sizers and printing blocks in their storage racks is part of the process. An improvement in the storage system of these items resulted in a reduction of unnecessary movements in searching for tools directly engaged in operation. The 5S methodology resulted in an 8% reduction in sizer searching time and an 18% reduction in block searching time for the printing operation in the plastic bag manufacturing process. After implementation, sizer searching and lifting time account for 4.40% of total blowing operational time (previously 12.12%), reducing 20.40% (previously 34.78%) of block searching and setting time. This is the contribution of removing two wastes: unnecessary motion and waiting time from both operations, as well as adding value in the form of a cleaner work environment. When comparing three months of data before and after implementing 5S, customer complaints about printing decreased from eight to one. That instance, introducing 5S not only helped decrease unnecessary motions, but it also helped reduce printing waste by organizing the blocks. The safety of workers has been ensured by identifying and separating the heavy-weighted large sizers and the small sizers, following ergonomic considerations. This study analyzed the case and developed a solution model that did not cost anything. Even the books that have been used for storing the printing blocks were made of plastic sacks, which are thrown out after the raw materials inside are consumed and considered to be waste, avoiding the cost of new estab­ lishments. 5S housekeeping is essential in maintaining a positive manufacturing environment. Workers’ confidence has been boosted indirectly as a result of the 5S training, which will lead them making self-motivated improvements at work, which can have a long-term impact on the industry’s gross profit. The audit procedure and schedule have been developed and driven by the audit team. Effective teamwork, improved communication between departments, top-tobottom employee engagement, autonomous culture, and kaizen 7. Limitations and future scopes Among the eight lean wastes, this research only refers to two (waiting and motion) rather than the other six. It should be noted that the authors concentrated solely on two sub-processes (blowing and printing) where operational inconsistencies were discovered predomi­ nantly and physically. There could be a top-to-bottom process study to find other inconsistencies, and there should be some chances created for the contributors by the organization to eliminate the other six wastes. Researchers or company personnel may also use the newest bench­ marking techniques to highlight 5S implementation strategies that distinguish it from other successful organizations. Conflict of interest Authors declares no conflict of interest relevant to this article. Funding No funding was provided to the authors to conduct this study. Declaration of competing interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgement Authors are thankful to the following plastic bag manufacturing in­ dustry and to the management team for welcoming and helping us during the study. The authors are grateful to the workers who have made every effort to establish this study. This was impossible to implement without the support and cooperation of the workers in that industry. References Agrahari, R.S., Dangle, P.A., Chandratre, K.V., 2015. Implementation of 5S methodology in the small scale industry A case study. Int. J. Sci. Technol. Res. 4, 180–187. Ahmed, S., Chowdhury, S.I., 2018. Increase the efficiency and productivity of sewing section through low performing operators improvement by using eight wastes of lean methodology. Global J. Res. Eng. 18, 44–60. Al-Araidah, O., Momani, A., Khasawneh, M., Momani, M., 2010. Lead-time reduction utilizing lean tools applied to healthcare: the inpatient pharmacy at a local hospital. J. Healthc. Qual. 32, 59–66. https://doi.org/10.1111/j.1945-1474.2009.00065.x. 12 M.M. Shahriar et al. Cleaner Engineering and Technology 8 (2022) 100488 Qual. Manag. Bus. Excel. 19, 245–262. https://doi.org/10.1080/ 14783360701600704. Mane, A.M., Jayadeva, C.T., 2015. 5S implementation in Indian SME: a case study. Int. J. Process Manag. Benchmark. 5, 483–498. https://doi.org/10.1504/ IJPMB.2015.072327. Nazarali, S., Rayat, J., Salmonson, H., Moss, T., Mathura, P., Damji, K.F., 2017. The application of a “6S Lean” initiative to improve workflow for emergency eye examination rooms. Can. J. Ophthalmol. 52, 435–440. https://doi.org/10.1016/j. jcjo.2017.02.017. Oey, E., Nofrimurti, M., 2018. Lean implementation in traditional distributor warehouse - a case study in an FMCG company in Indonesia. Int. J. Process Manag. Benchmark. 8, 1–15. https://doi.org/10.1504/IJPMB.2018.088654. Omogbai, O., Salonitis, K., 2017. The implementation of 5S lean tool using system dynamics approach. Procedia CIRP 60, 380–385. https://doi.org/10.1016/j. procir.2017.01.057. Radnor, Z.J., Holweg, M., Waring, J., 2012. Lean in healthcare: the unfilled promise? Soc. Sci. Med. 74, 364–371. https://doi.org/10.1016/j.socscimed.2011.02.011. Rahman, M.N.A., Khamis, N.K., Zain, R.M., Deros, B.M., Mahmood, W.H.W., 2010. Implementation of 5S practices in the manufacturing companies: a case study. Am. J. Appl. Sci. 7, 1182–1189. https://doi.org/10.3844/ajassp.2010.1182.1189. Randhawa, J.S., Ahuja, I.S., 2017a. Evaluating impact of 5S implementation on business performance. Int. J. Prod. Perform. Manag. 66, 948–978. https://doi.org/10.1108/ IJPPM-08-2016-0154. Randhawa, J.S., Ahuja, I.S., 2017b. 5S–a quality improvement tool for sustainable performance: literature review and directions. Int. J. Qual. Reliab. Manag. 34, 508–529. https://doi.org/10.1108/BIJ-10-2012-0068. Ribeiro, P., Sá, J.C., Ferreira, L.P., Silva, F.J.G., Pereira, M.T., Santos, G., 2019. The impact of the application of lean tools for improvement of process in a plastic company: a case study. Procedia Manuf. 38, 765–775. https://doi.org/10.1016/j. promfg.2020.01.104. Rojasra, P.M., Qureshi, M.N., 2013. Performance improvement through 5S in small scale industry: a case study. Int. J. Mod. Eng. Res. 3, 1654–1660. Sangani, R., Kottur, V.K.N., 2019. Enhancement in productivity by integration of 5S methodology and time and motion study. In: Proceedings of International Conference on Intelligent Manufacturing and Automation. Springer, Singapore. https://doi.org/10.1007/978-981-13-2490-1_50. Saraswat, P., Kumar, D., Kumar Sain, M., 2015. Reduction of work in process inventory and production lead time in a bearing industry using value stream mapping tool. Int. J. Manag. Value Supply Chain. 6, 27–35. https://doi.org/10.5121/ ijmvsc.2015.6203. Sharma, K.M., Lata, S., 2018. Effectuation of lean tool “5S” on materials and work space efficiency in a copper wire drawing micro-scale industry in India. Mater. Today Proc. 5, 4678–4683. https://doi.org/10.1016/j.matpr.2017.12.039. Sidhu, B.S., Kumar, V., Bajaj, A., 2013. The “5S” strategy by using PDCA cycle for continuous improvement of the manufacturing processes in agriculture industry. Int. J. Res. Ind. Eng. J. homepage 2, 10–23. Singh, A., Ahuja, I.S., 2015. Review of 5S methodology and its contributions towards manufacturing performance. Int. J. Process Manag. Benchmark. 5, 408–424. https:// doi.org/10.1504/IJPMB.2015.072320. Singh, R., Gohil, A.M., Shah, D.B., Desai, S., 2013. Total productive maintenance (TPM) implementation in a machine shop: a case study. Procedia Eng. 51, 592–599. https://doi.org/10.1016/j.proeng.2013.01.084. Sorooshian, S., Salimi, M., Bavani, S., Aminattaheri, H., 2012. Case report: experience of 5S implementation. J. Appl. Sci. Res. 8, 3855–3859. Suárez-barraza, M.F., Ramis-pujol, J., Ramis-pujol, J., 2012. An exploratory study of 5S: a multiple case study of multinational organizations in Mexico. Asian J. Qual. https://doi.org/10.1108/15982681211237842. Azizi, A., Manoharan a/p, T., 2015. Designing a future value stream mapping to reduce lead time using SMED-A case study. In: Procedia Manufacturing. Elsevier B.V., pp. 153–158 Chandrayan, B., Solanki, A.K., Sharma, R., 2019. Study of 5S lean technique: a review paper. Int. J. Prod. Qual. Manag. 26, 469–491. https://doi.org/10.1504/ IJPQM.2019.099625. Chapman, C.D., 2005. Clean House with Lean 5S. Quality Progress, United States. Choomlucksana, J., Ongsaranakorn, M., Suksabai, P., 2015. Improving the productivity of sheet metal stamping subassembly area using the application of lean manufacturing principles. Procedia Manuf. 2, 102–107. https://doi.org/10.1016/j. promfg.2015.07.090. Cirjaliu, B., Draghici, A., 2016. Ergonomic issues in lean manufacturing. Procedia - Soc. Behav. Sci. 221, 105–110. https://doi.org/10.1016/j.sbspro.2016.05.095. Duran, O., Capaldo, A., Acevedo, P.A.D., 2017. Lean maintenance applied to improve maintenance efficiency in thermoelectric power plants. Energies 10, 1–21. https:// doi.org/10.3390/en10101653. Filho, M.G., Saes, E.V., 2013. From time-based competition (TBC) to quick response manufacturing (QRM): the evolution of research aimed at lead time reduction. Int. J. Adv. Manuf. Technol. 64, 1177–1191. https://doi.org/10.1007/s00170-012-4064-9. Gapp, R., Fisher, R., Kobayashi, K., 2008. Implementing 5S within a Japanese context: an integrated management system. Manag. Decis. 46, 565–579. https://doi.org/ 10.1108/00251740810865067. Garg, A., 1995. Revised NIOSH equation for manual lifting: a method for job evaluation. AAOHN J. 43, 211–216. https://doi.org/10.1177/216507999504300408. Gupta, S., Chandna, P., 2020. A case study concerning the 5S lean technique in a scientific equipment manufacturing company. Grey Syst. Theor. Appl. 10, 339–357. https://doi.org/10.1108/gs-01-2020-0004. Gupta, S., Jain, S.K., 2015. An application of 5S concept to organize the workplace at a scientific instruments manufacturing company. Int. J. Lean Six Sigma 7, 63–83. https://doi.org/10.1108/BIJ-10-2012-0068. Ho, S.K., Cicmil, S., Fung, C.K., 1995. The Japanese 5-S practice and TQM training. Train. Qual. 3, 19–24. https://doi.org/10.1108/09684879510098222. Ikuma, L.H., Nahmens, I., 2014. Making safety an integral part of 5S in healthcare. Work 47, 243–251. https://doi.org/10.3233/WOR-121576. Ishijima, H., Eliakimu, E., Mshana, J.M.H., 2016. The “5S” approach to improve a working environment can reduce waiting time: findings from hospitals in Northern Tanzania. TQM J 28, 664–680. https://doi.org/10.1108/TQM-11-2014-0099. Ismail, A., Ghani, J.A., Ab Rahman, M.N., Md Deros, B., Che Haron, C.H., 2014. Application of lean six sigma tools for cycle time reduction in manufacturing: case study in biopharmaceutical industry. Arabian J. Sci. Eng. 39, 1449–1463. https:// doi.org/10.1007/s13369-013-0678-y. Jiménez, E., Tejeda, A.S., Pérez, M., Blanco, J., Martínez, E., 2012. Applicability of lean production with VSM to the Rioja wine sector. Int. J. Prod. Res. 50, 1890–1904. https://doi.org/10.1080/00207543.2011.561370. Jiménez, M., Romero, L., Domínguez, M., Espinosa, M. del M., 2015. 5S methodology implementation in the laboratories of an industrial engineering university school. Saf. Sci. 78, 163–172. https://doi.org/10.1016/j.ssci.2015.04.022. Johnson, A., Prasad, S., Sharma, A.K., 2017. Manufacturing lead time reduction in a scaffold making industry using lean manufacturing techniques - a case study. Int. J. Mech. Eng. Technol. 8, 137–148. Kanamori, S., Sow, S., Castro, M.C., Matsuno, R., Tsuru, A., Jimba, M., 2015. Implementation of 5S management method for lean healthcare at a health center in Senegal: a qualitative study of staff perception. Glob. Health Action 8. https://doi. org/10.3402/gha.v8.27256. Kobayashi, K., Fisher, R., Gapp, R., 2008. Business improvement strategy or useful tool? Analysis of the application of the 5S concept in Japan, the UK and the US. Total 13