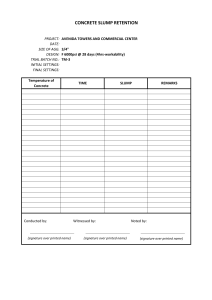

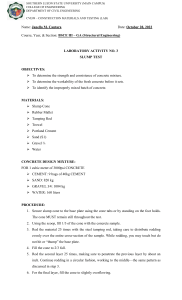

Checking Concrete Workability: Slump Test The workability of fresh concrete is its ease of handling, placing, and compacting without segregation or loss of homogeneity. A simple and commonly used method to measure workability is the slump test, which checks the consistency of the concrete mix. What is the Slump Test? The slump test measures how much freshly mixed concrete subsides (drops in height) after being placed in a standard cone-shaped mold and then removed. The reduction in height indicates the workability and consistency of the concrete. How to Perform the Slump Test 1. Equipment Required: Slump Cone: A conical mold, 30 cm high, with a 20 cm diameter base and a 10 cm diameter top. Tamping Rod: A 50 cm long and 20 mm diameter metal rod for compacting concrete. Flat Surface: A non-absorbent, level surface for testing. 2. Procedure: Layering: Fill the slump cone with concrete in three equal layers. Tamping: Rod each layer 25 times with the tamping rod to ensure proper compaction. Ensure the rod penetrates into the layer below during tamping. Leveling: Strike off any excess concrete on the top to level it with the edge of the cone. Lifting the Cone: Carefully and vertically lift the cone without disturbing the concrete. Measure the Slump: Measure the difference in height (in centimeters) between the top of the mold and the highest point of the concrete after it subsides. This value is referred to as the slump (A). Important Notes: The cone and tamping rod should be clean before each test. The slump test must be conducted on a moist, non-absorbent surface to ensure accuracy. Perform the test three times and use the average slump for comparison. The allowable slump variation is ±20% of the specified value. Significance of the Test: Workability Assessment: Higher slump values indicate more fluid and workable concrete, while lower values suggest stiffer mixes. Quality Control: Ensures the mix meets the required specifications for the project. Avoidance of Errors: Helps identify issues like too much water (leading to segregation) or insufficient water (causing poor compaction). Typical Slump Values for Different Applications: Low Slump (10–40 mm): For pavements or low-workability mixes. Medium Slump (50–90 mm): For general reinforced concrete work. High Slump (100–150 mm): For highly flowable mixes used in complex formwork or pumpable concrete.