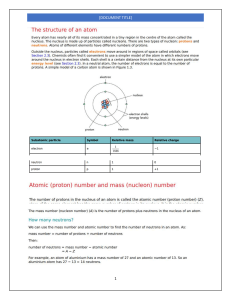

Line of Fire Safety Meeting Learning Session Manufacturing Learning from Incidents DSM-AC-201301 Copyright of Shell Downstream, Inc. Restricted 1 Instructions for use of this Engagement pack This engagement pack is designed for leaders to use with their staff. Sites must determine how best to conduct these engagements, a few options include: A safety stand down A regular safety meeting or team meeting Special engagements All discussed in one session or sections discussed over time. This powerpoint is made to be used in any of these ways. Sites may even want to add some of their own incidents as examples Copyright of Shell Downstream, Inc Restricted 2 Objectives This engagement pack is designed for leaders to use with their staff. The objectives of the engagement include: Provide a reminder about why stop work empowerment is important. Review Line of Fire hazards. Review some examples of Line of Fire hazards and potential barriers. Consider what actions you should take to address potential Line of Fire hazards. Copyright of Shell Downstream, Inc Restricted 3 What Happened – Some statistics from FIM Line of Fire Situations have resulted in: Half of the 81 Recordable Cases in 2013 40-50% of the Lost Time Incidents since January 2012 BOTH of the fatalities in M since 2010 In 2013 – Line of Fire Injuries were often associated with Maintenance or Construction Activities (75%) Involved hands or fingers in more than 50% of the injuries, 25% were head injuries Copyright of Shell Downstream, Inc Restricted 4 What Happened – Recent Fatalities in Other Shell Businesses PTP Malaysia May 2013 A technician was fatally injured when he attempted to open a water-tight door to a pump room. The door violently opened and struck the technician causing fatal injuries. It is likely that differential pressure was caused by an air leak from a control valve actuator. UAU Canada Jul 2013 Contract worker was fatally injured after being struck by a pipe during tie-in work. He was inside a trench preparing for a pipe to be welded when a separate section of pipe fell into the trench and struck him. Copyright of Shell Downstream, Inc DZA Australia 2013 A pedestrian walked through an operational loading area (a pedestrian exclusion zone) and was struck by a reversing forklift causing serious injuries. UI May 2012 Contractor was fatally injured when struck by a telescopic corrosion coupon retraction tool. UIN Oman Oct 2012 Incidents involving Line of Fire A worker stepped onto the bed of a mobile crane and entered the arc path of the counterweight. He was crushed and fatally injured when the counterweight was rotated. UI Malaysia Aug 2011 UIN Oman Mar 2012 A worker was run over and fatally injured by a reversing Heavy Goods Vehicle at a construction site One fatality involving a contractor staff when a wall collapsed at a site office renovation job Restricted 5 Identifying Hazards Helps Prevent Injuries According to US Occupational Safety and Health Administration (OSHA), hazards that represent 90% of all workplace injuries or fatalities can be categorized in the following four areas: Falls Electrical Shock Struck By Caught By / Caught Between Which of these involve Line of Fire? Copyright of Shell Downstream, Inc Restricted 6 What is Line of Fire? The path an object travels or can potentially travel is the Line of Fire. When you place yourself or any part of your body in a position where you are directly exposed to the path that the object travels or may travel you are exposed to a Line of Fire hazard. Exposure to a Line of Fire hazard can potentially result in injury or death. Copyright of Shell Downstream, Inc Restricted 7 Line of Fire Awareness Stay aware of the work environment around you and of the direction of movement of your body and equipment that is around you. Always anticipate what could happen if unexpected movement occurs. For example, before you bend over or step back/forward, are you exposed to potential line of fire hazards? Think about what could go wrong and how you can safely react instead of reacting by impulse or instinct alone. Personal protective equipment (PPE) may be a last line of defense from line of fire hazards and may not protect you from injury. Copyright of Shell Downstream, Inc Restricted 8 You are EMPOWERED to STOP WORK! Why stop work? To stop an injury or incident before it happens To address identified unsafe conditions or acts To reinforce a positive safety culture and safe work practices To promote safety awareness Copyright of Shell Downstream, Inc Restricted 9 10 Situations to AVOID LINE of FIRE INJURIES Line of Fire – the zone within work area where there is a risk of serious injury from machinery and equipment 1.Moving Vehicles / Heavy Equipment 2.Lifting / Hoisting 3. Working at Height / Dropped Objects 4.Tensioned Lines / Spring Loaded Devices 5.Objects with Roll or Fall Potential 6. Pressurized Equipment 7.Machinery & Tools 8. Electrical Equipment 9. Projectiles 10. Pushing / Pulling Copyright of Shell Downstream, Inc Restricted 10 What Line of Fire Situations have you seen that involve Moving Vehicles or Heavy Equipment? 1. MOVING VEHICLES/ HEAVY EQUIPMENT Copyright of Shell Downstream, Inc Restricted 11 1. Moving Vehicles/ Heavy Equipment - examples Copyright of Shell Downstream, Inc Stay out of the area when vehicles or heavy equipment are moving Be aware of the potential for movement when loading and unloading vehicles or equipment Restricted 12 1. Moving Vehicles/ Heavy Equipment What steps should you take to avoid Line of Fire Situations that involve Moving Vehicles or Heavy Equipment? Copyright of Shell Downstream, Inc Restricted 13 1. Moving Vehicles/ Heavy Equipment Here are some examples of precautions to take when moving vehicles and equipment at a job site: Use parking brakes and wheel chocks for parked equipment. Turn off the engine of the vehicle where possible. Be aware of the potential for movement of the vehicle and the load when loading and unloading. When/where possible move and stay out of the area when vehicles or heavy equipment are moving. Use/establish defined vehicle/equipment travel routes that are separate from pedestrian travel routes when possible. When you must work near moving vehicles or heavy equipment obtain operator’s attention prior to approaching vehicles/equipment. Copyright of Shell Downstream, Inc Restricted 14 What Line of Fire Situations have you seen that involve Lifting or Hoisting? 2. LIFTING / HOISTING Copyright of Shell Downstream, Inc Restricted 15 2. Lifting/Hoisting – An Incident Lowering basket with 15-ton cherry picker Using tag line to guide basket At 5 foot ( meter) level contractor employee placed hands on basket to position it Support bar failed & basket fell Tip of finger pinched between shackle and basket wall Copyright of Shell Downstream, Inc Avoid placing your hands on a suspended load. Use the proper tool, such as a tag line. Restricted 16 2. Lifting Lifting/Hoisting / Hoisting What steps should you take to avoid Line of Fire Situations that involve Lifting or Hoisting? Copyright of Shell Downstream, Inc Restricted 17 2. Lifting / Hoisting Here are some examples of precautions to take when lifting or hoisting: Never walk under a suspended load. Avoid placing your hands on a suspended load. Use the proper tool, such as a tag line. Secure all loads before lifting, loading, unloading and transporting. Obtain permission from the Lift Coordinator before entering a lifting/hoisting zone to perform work, even if for a short period. Verify that the lifting equipment is rated for the weight of the load and choose the appropriate equipment for the material being lifted. Verify rigging equipment is rated for the weight of the load and has been properly inspected. Copyright of Shell Downstream, Inc Restricted 18 What Line of Fire Situations have you seen that involve Working at Height or Dropped Objects? 3. WORKING AT HEIGHT / DROPPED OBJECTS Copyright of Shell Downstream, Inc Restricted 19 3. Working at Height / Dropped Objects Working on elevated deck to remove bolts Using an impact driver with a 1 ¼ inch socket Tool broke and the socket fell to the ground where other contractors were working. No injuries Netting was in place to prevent dropped objects, but there was a hole in the netting near the work. Copyright of Shell Downstream, Inc Near Miss – Struck By Incident Restricted 20 2. Working 3. Lifting/Hoisting at Height / Dropped Objects What steps should you take to avoid Line of Fire Situations that involve Working at Height or the Potential for Dropped Objects? Copyright of Shell Downstream, Inc Restricted 21 3. Working at Height / Dropped Objects Here are some examples of precautions to take when working at height and to prevent dropped objects: Secure equipment with roll/fall potential, such as tools, cylinders, pipes, and poles. Secure all loads before lifting, loading, unloading and transporting. Stay out of the line of fire. Secure Tools and equipment when climbing a ladder. Always use tool lanyards & tool bags when working at height. Survey work areas for any unsecured equipment before beginning the job. Use netting where possible. Barricade/limit access to the drop zone below any elevated work being performed above. Never drop or throw tools/equipment when performing elevated work. Use tool bags, hand lines and/or equipment to hoist or lower. Copyright of Shell Downstream, Inc Restricted 22 What Line of Fire Situations have you seen that involve Tensioned Lines or Spring Loaded Devices? 4. TENSIONED LINES / SPRING LOADED DEVICES Copyright of Shell Downstream, Inc Restricted 23 4. Tensioned Lines / Spring Loaded Devices Positioning a pre-fabricated steel support to the base of a large tank Chain block anchor hook failed when winching the support into position No injuries The chain block hook failed. It was attached to a securely braced piece of angle-iron (instead of a shackle connection). Be aware and stay clear of tensioned lines Copyright of Shell Downstream, Inc Restricted 24 2. Tensioned 4. Lifting/Hoisting Lines / Spring Loaded Devices What steps should you take to avoid Line of Fire Situations that involve Tensioned Lines or Spring Loaded Devices? Copyright of Shell Downstream, Inc Restricted 25 4. Tensioned Lines / Spring-Loaded Devices Here are some examples of precautions to take when working around or with tensioned lines or spring loaded devices Be aware and stay clear of tensioned lines, strapping, and coiled & spring-loaded devices such as cable, chain and rope. They can generate tremendous energy when compression or tension is released. Keep hands and your body away from rigging equipment such as cables and shackles while loading, lifting, and unloading. Be aware of hand and body placement when applying tension to rigging. Use tag lines whenever possible. Anticipate pipe movement when cutting pipe. Copyright of Shell Downstream, Inc Restricted 26 What Line of Fire Situations have you seen that involve Objects with the Potential to Roll or Fall? 5. OBJECTS WITH ROLL / FALL POTENTIAL Copyright of Shell Downstream, Inc Restricted 27 5. Objects with Roll / Fall Potential Machinist setting a 95 lb pump stuffing box head in a lathe As loosened one of the chuck jaws to center the box, it fell onto the lathe guides. Machinist’s gloved hand was crushed, fracturing his finger Do not use your body or hands to try to stop an unstable or shifting load Copyright of Shell Downstream, Inc Caught Between Restricted 28 5. Objects with Roll / Fall Potential A golf cart was raised 4.5 feet from the floor for inspection of the brakes While the mechanic was checking his paperwork, the cart suddenly tilted backwards and fell off of the jack. Damage to the golf cart cab was minor. The rear of the golf cart contained many items Secure all loads, especially top-heavy items. Do not work near or under equipment that could potentially fall. Potential Struck By Copyright of Shell Downstream, Inc Restricted 29 5. Objects with Roll / Fall Potential Loading two cylinders onto a flat bed truck with a fork lift Cylinders began to roll towards the opposite side of the truck A contractor worker attempted to stop the cylinders from falling off of the truck. The contractor worker was fatally injured. Potential Struck By Copyright of Shell Downstream, Inc Restricted 30 2. Objects 5. Lifting/Hoisting with Roll / Fall Potential What steps should you take to avoid Line of Fire Situations that involve Objects with either Roll or Fall Potential? Copyright of Shell Downstream, Inc Restricted 31 5. Objects with Roll / Fall Potential Consider these precautions if objects have the potential to roll or fall: If a load shifts, stay out of harm’s way (i.e., do not enter the line of fire). Do not use your body or hands to try to stop an unstable or shifting load. Secure equipment with roll/fall potential, such as tools, cylinders, pipes, pumps, engines, poles, etc. Secure all loads before lifting, loading, unloading and transporting. Secure all loads, especially top-heavy items and items being transported by forklift or flatbed. Survey work areas for any unsecured equipment or items before beginning the job. When loading objects with a roll/fall potential on a vehicle, use truck bed stakes and/or gates, as necessary. Survey your work area for any equipment that could fall. Do not work near or under equipment that could potentially fall. Copyright of Shell Downstream, Inc Restricted 32 What Line of Fire Situations have you seen that involve Pressurized Equipment? 6. PRESSURIZED EQUIPMENT Copyright of Shell Downstream, Inc Restricted 33 6. Pressurized Equipment Contractors were replacing a section of hot water piping by cutting it out, welding on flanges and installing a new section of piping. Plugs were placed in the open ends of the piping after it was cut. Two hours later, while welding on a flange, the plug suddenly blew out, followed by hot water and water vapor. The hot water injured three of the four contractors, one fatally. Keep your body out of the line of fire and think about the direction of the line of fire if pressure releases unexpectedly. Copyright of Shell Downstream, Inc Restricted 34 6. Pressurized Equipment Two contract employees returned to their worksite to remove plugs from an air fin exchanger that they had blinded earlier in the day. One contractor mistakenly began to loosen a plug that on an exchanger that was still in service. The plug blew out of the exchanger, and the release pushed him back against the rail of the deck. His hard hat and the air tool fell 27 meters (89 feet) to grade. The contractor was treated for minor injuries. Copyright of Shell Downstream, Inc Keep your body out of the line of fire and think about the direction of the line of fire if pressure releases unexpectedly. Restricted 35 2. Pressurized 6. Lifting/Hoisting Equipment What steps should you take to avoid Line of Fire Situations that involve Pressurized Equipment? Copyright of Shell Downstream, Inc Restricted 36 6. Pressurized Equipment The following are some precautions to consider when working with pressurized equipment: Verify zero energy state before cutting into or opening any equipment such as flanges, lines, couplings, hose connections, pumps, vessels, etc. Compressed cylinders must be secure and upright with caps installed at all times. Always assume that there is pressure on equipment before opening. Keep your body out of the line of fire and think about the direction of the line of fire if pressure releases unexpectedly. Be aware of body positioning when working with pressurized tools. Copyright of Shell Downstream, Inc Restricted 37 What Line of Fire Situations have you seen that involve Machinery or Tools? 7. MACHINERY & TOOLS Copyright of Shell Downstream, Inc Restricted 38 7. Machinery & Tools . Contractor was torquing flanges with a pneumatic wrench. Reached to steady a socket while the pneumatic tool was energizing. The ‘reaction bar’ rotated and crushed his finger against the adjacent nut. Never use your hand to hold sockets in place on torquing equipment. Copyright of Shell Downstream, Inc Restricted 39 7. Machinery & Tools Contractor employee was grinding a tack weld on the bottom of a pipe. He was positioned to obtain leverage for the task. During grinding, the grinder suddenly kicked back, knocking off his face shield and hard hat. The grinder blade stopped and contacted the contractor employee’s chin. The contractor employee sustained an abrasion to the chin. Be prepared for the movement of the tool when it starts to rotate. “Kickback” can occur when using rotating tools. Copyright of Shell Downstream, Inc Restricted 40 2. Machinery 7. Lifting/Hoisting & Tools What steps should you take to avoid Line of Fire Situations that involve Machinery or Tools? Copyright of Shell Downstream, Inc Restricted 41 7. Machinery & Tools The following examples are precautions to take when working with machinery and tools. Be aware of torque stresses generated by rotating equipment. Anticipate the unexpected rotation or movement of machinery. Never operate a tool or equipment without proper safety devices such as guards, keepers, etc. Be aware of hand placement to avoid pinch points. Never use your hand to hold sockets in place while torquing equipment. Secure equipment before starting work and be prepared for the movement of the tool or the equipment when it starts to rotate. “Kickback” can occur when using rotating tools . Be prepared for equipment rotation long after applied torque force has stopped -“Coasting”. Copyright of Shell Downstream, Inc Restricted 42 What Line of Fire Situations have you seen that involve Electrical Equipment? 8. ELECTRICAL EQUIPMENT Copyright of Shell Downstream, Inc Restricted 43 8. Electrical Equipment Stay out of the line of fire in case an arc flash occurs. Copyright of Shell Downstream, Inc Restricted 44 8. Electrical Equipment The following are examples of precautions for working around electrical equipment: Avoid working on or near energized electrical equipment. Make sure power is turned-off, and always follow lockout/ tagout procedures. When switching a breaker into position, stand out of the line of fire in case of an arc flash Stand clear when breakers are being closed remotely. If an electrician is working in an opened panel, stay away. Electrical rooms are not a safe place to “hang out” or come in from the weather. Copyright of Shell Downstream, Inc Restricted 45 What Line of Fire Situations have you seen that involve Projectiles? 9. PROJECTILES Copyright of Shell Downstream, Inc Restricted 46 9. Projectiles A contractor employee was assigned to “hammer test” cast steel caps to verify tightness. When struck, a piece of the steel cap broke, flew at high speed and struck the worker chipping a tooth. The contractor employee was wearing a face shield. Both the hammer and the cast steel cap were hard steel which caused the cap to break when impacted. Be aware of tasks that generate flying debris The debris entered underneath the face shield. Copyright of Shell Downstream, Inc Restricted 47 2. Projectiles 9. Lifting/Hoisting What steps should you take to avoid Line of Fire Situations that involve Projectiles? Copyright of Shell Downstream, Inc Restricted 48 9. Projectiles Consider these precautions when there is a potential of projectiles: Be aware of tasks that generate flying debris such as grinding, chipping, abrasive blasting, hydro-blasting, sawing, using hammers, opening bleeders, equipment, etc. Contain projectiles and/or barricade the area and restrict access. Position the tool to direct the projectiles in a safe direction, such as directing sparks from grinding into the firebox. Stay aware of your body position and think about the potential path of the projectile. Copyright of Shell Downstream, Inc Restricted 49 What Line of Fire Situations have you seen that involve Pushing or Pulling? 10. PUSHING & PULLING Copyright of Shell Downstream, Inc Restricted 50 10. Pushing & Pulling - Example Contractor employee was in the process of tightening the last nut on a flange. He was pulling a combination wrench in the direction of his face. As he pulled on the wrench, it came off the nut striking him in the mouth. Contractor employee’s front tooth was knocked out. When pulling or pushing with wrenches, remain focused and anticipate the possibility of the fastener suddenly loosening or wrench slipping Copyright of Shell Downstream, Inc Restricted 51 10. Pushing & Pulling - Example Contractor employee removing bolts from a gate valve using a combination wrench. Box end of the wrench could not fit completely on the nut due to its position, so tried to reposition the nut with the open end of the wrench. The wrench slipped off the nut and struck the employee on the lip. Congested area which limited body position. Anticipate the possibility of sudden release during pulling or pushing and keep your body, face, and hands out of the line of fire Copyright of Shell Downstream, Inc Restricted 52 2. Lifting/Hoisting 10. Pushing & Pulling What steps should you take to avoid Line of Fire Situations that involve Pushing or Pulling? Copyright of Shell Downstream, Inc Restricted 53 10. Pushing / Pulling Consider these precautions when pushing or pulling is involved: Be aware of your body position when conducting work activities that involve pushing or pulling, such as using a wrench or pushing/pulling a cart. When pulling or pushing with wrenches, remain focused and anticipate the possibility of the fastener suddenly loosening or wrench slipping. Anticipate the possibility of sudden release during pulling or pushing and keep your body, face, and hands out of the line of fire. Copyright of Shell Downstream, Inc Restricted 54 10 Situations to AVOID LINE of FIRE INJURIES Line of Fire – the zone within work area where there is a risk of serious injury from machinery and equipment 1.Moving Vehicles / Heavy Equipment 2.Lifting / Hoisting 3. Working at Height / Dropped Objects 4.Tensioned Lines / Spring Loaded Devices 5.Objects with Roll or Fall Potential 6. Pressurized Equipment 7.Machinery & Tools 8. Electrical Equipment 9. Projectiles 10. Pushing / Pulling Copyright of Shell Downstream, Inc Restricted 55 CONCLUSIONS Exposure to line of fire hazards can result in injury or death. You are empowered to Stop Work (intervene) anytime a task cannot be completed safely. Stay out of the line of fire. Do not use your hands or body to stop a shifting load, projectile, etc. Personal protective equipment (PPE) is a last line of defense. Do not assume PPE will protect you from a line of fire hazard. If you find yourself in a line of fire situation, remove yourself from the line of fire immediately. Anticipate line of fire hazards and take steps to eliminate, mitigate or protect yourself from the hazard. Stay aware of the work environment around you and of the direction of movement of your body and equipment that is around you. Always anticipate what could happen if unexpected movement occurs. For example, before you bend over or step back/forward, are you exposed to potential line of fire Copyright of Shell Downstream, Inc Restricted 56 hazards? Closing What other insights do you have based on these incidents and your discussions today? What will you do differently as a result of learning from these incidents and examples? Copyright of Shell Downstream, Inc Restricted 57 Do the Right Thing! Achieve Goal Zero! Legal Disclaimer This document is made available for information only and on the condition that (i) it may not be relied upon by anyone, in the conduct of their own operations or otherwise; (ii) neither the Shell company issuing this document nor any other person or company concerned with furnishing information or data use herein (A) is liable for its accuracy or completeness, or for any recommendations or advice given in or any omission from this document, or for any consequences whatsoever resulting directly or indirectly from any use made of this document by any person, even if there was a failure to exercise reasonable care on the part of the Shell company or any other person or company as aforesaid: or (B) make any claim, representation or warranty, express or implied, that acting in accordance with this document will produce any particular results with regard to the subject matter contained herein, or satisfy the requirements of any applicable federal, state or local laws and regulations; and (iii) nothing in this document constitutes technical advice. If such advice is required it should be sought from a qualified professional adviser. The content of this document may (i) be based on, but not identical to facts relating to a third party incident about which Shell has become aware; (ii) contain Recommendations that are one, but not necessarily the only way, of addressing incident learnings. The companies in which Royal Dutch Shell plc directly and indirectly owns investments are separate entities. In this Learning From Incident Alert, the expression “Shell” is sometimes use for convenience where references are made to companies within the Shell group or to the group in general. Likewise, the words “we” and “our” are also used to refer to Shell companies in general or those who work for them. These expressions are also used where no useful purpose is served by identifying specific companies. Copyright of Shell Downstream, Inc Restricted 59