Metals & Alloys: Material Science Textbook Excerpt

advertisement

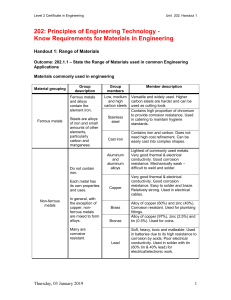

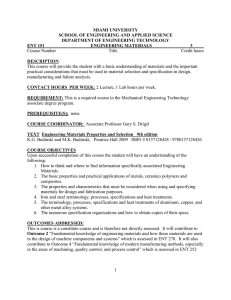

Naval Material Engineering Science and Metal A metal is a material that is typically hard, opaque, shiny, and has good electrical and thermal conductivity. Metals are generally malleable, that is, they can be hammered or pressed permanently out of shape without breaking or cracking as well as fusible (able to be fused or melted) and ductile (able to be drawn out into a thin wire). Astrophysicists use the term "metal" to collectively describe all elements other than hydrogen and helium. Thus, the metallicity of an object is the proportion of its matter made up of chemical elements other than hydrogen and helium. Steels Steels are iron–carbon alloys that may contain appreciable concentrations of other alloying elements; there are thousands of alloys that have different compositions and/or heat treatments. The mechanical properties are sensitive to the content of carbon, which is normally less than 1.0 wt.%. Some of the more common steels are classified according to carbon concentration namely: low, medium, and high-carbon types. Subclasses also exist within each group according to the concentration of other alloying elements. Low-carbon steels Low-carbon steels contain less than 0.25%C. it is not very responsive to heat treatments and strengthening is accomplished by cold work. It is soft, weak, tough, ductile, machinable, weldable and not expensive. They typically have a yield strength of 275 MPa (40,000 psi), tensile strengths between 415 and 550 MPa (60,000 and 80,000 psi), and a ductility of 25%EL. Typical applications include automobile body components, structural shapes (I-beams, channel and angle iron), and sheets that are used in pipelines, buildings, bridges, and tin cans. High-strength, Low-alloy (HSLA) steels It contains alloying elements such as copper, vanadium, nickel, and molybdenum in combined concentrations of >10 wt%. It is stronger than plain low-C steels. Most may be strengthened by heat treatment, giving tensile strengths in excess of 480 MPa (70,000 psi). They are ductile, formable and machinable. In normal atmospheres, the HSLA steels are more resistant to corrosion than the plain carbon steels Medium-Carbon Steels Medium-carbon steels contain 0.25-0.60 wt.% of carbon. It is stronger than low-carbon steels but less ductile and less tough. These alloys may be heattreated by austenitizing, quenching, and then tempering to improve their mechanical properties. It can only be heat treated in very thin sections and with very rapid quenching rates but with the addition of chromium, nickel, and molybdenum improve the capacity of these alloys to be heat-treated. Applications include railway wheels and tracks, gears, crankshafts, and other machine parts and high-strength structural components calling for a combination of high strength, wear resistance, and toughness. High-Carbon Steels The high-carbon steels, normally having carbon contents between 0.60 and 1.4 wt%. It is the hardest, strongest, and yet least ductile of the carbon steels. They are almost always used in a hardened and tempered condition, wear resistant and capable of holding a sharp cutting edge. The tool and die steels are high-carbon alloys, usually containing chromium, vanadium, tungsten, and molybdenum. These alloying elements combine with carbon to form very hard and wear-resistant carbide compounds (e.g., Cr23C6, V4C3, and WC). Stainless steels The stainless steels are highly resistant to corrosion (rusting) in a variety of environments, especially the ambient atmosphere. Their predominant alloying element is chromium; a concentration of at least 11 wt% Cr is required. Corrosion resistance may also be enhanced by nickel and molybdenum additions. Stainless steels are divided into three classes based on the predominant phase constituent of the microstructure— martensitic, ferritic, or austenitic. 1. Martensitic stainless steels are capable of being heat treated in such a way that martensite is the prime microconstituent. Additions of alloying elements in significant concentrations produce dramatic alterations in the iron–iron carbide phase diagram. 2. For austenitic stainless steels, the austenite (or ɣ) phase field is extended to room temperature. The austenitic stainless steels are the most corrosion resistant because of the high chromium contents and also the nickel additions; and they are produced in the largest quantities. 3. Ferritic stainless steels are composed of the α-ferrite (BCC) phase. Austenitic and ferritic stainless steels are hardened and strengthened by cold work because they are not heat treatable. Both martensitic and ferritic stainless steels are magnetic; the austenitic stainless are not. Cast Irons Theoretically, it contains > 2.14 wt.% of carbon. Usually contains between 3.0-4.5 wt.% C, hence it is very brittle. They become liquid easily between 1150 0C and 1300 0C. They are easily melted and amenable to casting. It is Inexpensive, machinable and wear resistant. The most common cast iron types are gray, nodular, white, malleable, and compacted graphite. NONFERROUS ALLOYS Non-ferrous alloys are metals that do not have any iron in them at all. It is not attracted to the magnet and do not rust easily when exposed to moisture. Copper and Its Alloys It is highly resistant to corrosion in diverse environments including the ambient atmosphere, seawater, and some industrial chemicals. Most copper alloys cannot be hardened or strengthened by heat-treating procedures; consequently, cold working and/or solid-solution alloying must be utilized to improve these mechanical properties. Aluminum and Its Alloys Aluminum and its alloys are characterized by a relatively low density (2.7 g/cm3 as compared to 7.9 g/cm3 for steel), high electrical and thermal conductivities, and a resistance to corrosion in some common environments, including the ambient atmosphere. Magnesium and Its Alloys The most outstanding characteristic of magnesium is its density, 1.7 g/cm3, which is the lowest of all the structural metals. Magnesium has an HCP crystal structure, is relatively soft, and has a low elastic modulus: 45 GPa. Consequently, most fabrication is by casting or hot working at temperatures between 200 and 350˚C. It has a moderately low melting temperature 651 ˚C. Titanium and Its Alloys Titanium and its alloys are relatively new engineering materials that possess an extraordinary combination of properties. The pure metal has a relatively low density (4.5 g/cm3), a high melting point [1668˚C], and an elastic modulus of 107 GPa (psi). Titanium alloys are extremely strong; room temperature tensile strengths as high as 1400 MPa (200,000 psi) are attainable, yielding remarkable specific strengths. The Refractory Metals Metals that have extremely high melting temperatures are classified as the refractory metals. Included in this group are niobium (Nb), molybdenum (Mo), tungsten (W), and tantalum (Ta). Melting temperatures range between 2468 ˚C for niobium and 3410 ˚C for tungsten. The Superalloys The superalloys have superlative combinations of properties. Most are used in aircraft turbine components, which must withstand exposure to severely oxidizing environments and high temperatures for reasonable time periods. The Noble Metals The noble or precious metals are a group of eight elements that have some physical characteristics in common. They are expensive (precious) and are superior or notable (noble) in properties, that is, characteristically soft, ductile, and oxidation resistant. The noble metals are silver, gold, platinum, palladium, rhodium, ruthenium, iridium, and osmium; the first three are most common and are used extensively in jewelry. Fabrication of Metals Forging Forging is mechanically working or deforming a single piece of a normally hot metal; this may be accomplished by the application of successive blows or by continuous squeezing. Forgings are classified as: 1. closed die - a force is brought to bear on two or more die halves having the finished shape such that the metal is deformed in the cavity between them 2. open die -two dies having simple geometric shapes (e.g., parallel flat, semicircular) are employed, normally on large workpieces. Rolling Rolling is the most widely used deformation process, consists of passing a piece of metal between two rolls; a reduction in thickness results from compressive stresses exerted by the rolls. Cold rolling may be used in the production of sheet, strip, and foil with high quality surface finish. Circular shapes as well as I-beams and railroad rails are fabricated using grooved rolls. Extrusion For extrusion, a bar of metal is forced through a die orifice by a compressive force that is applied to a ram; the extruded piece that emerges has the desired shape and a reduced cross-sectional area. Extrusion products include rods and tubing that have rather complicated cross-sectional geometries; seamless tubing may also be extruded. Drawing Drawing is the pulling of a metal piece through a die having a tapered bore by means of a tensile force that is applied on the exit side. A reduction in cross section results, with a corresponding increase in length. Rod, wire, and tubing products are commonly fabricated in this way. CASTING Casting is a fabrication process whereby a totally molten metal is poured into a mold cavity having the desired shape; upon solidification, the metal assumes the shape of the mold but experiences some shrinkage. Casting techniques are employed when: 1) the finished shape is so large or complicated that any other method would be impractical 2) a particular alloy is so low in ductility that forming by either hot or cold working would be difficult, and 3) in comparison to other fabrication processes, casting is the most economical. A number of different casting techniques are commonly employed, including sand, die, investment, lost foam, and continuous casting. solidify with the pressure maintained. A two-piece permanent steel mold or die is employed; when clamped together, the two pieces form the desired shape. When complete solidification has been achieved, the die pieces are opened, and the cast piece is ejected. However, this technique lends itself only to relatively small pieces and to alloys of zinc, aluminum, and magnesium, which have low melting temperatures. Figure 8 shows the sample of die casting process. Investment Casting For investment (sometimes called lost-wax) casting, the pattern is made from a wax or plastic that has a low melting temperature. Around the pattern is poured a fluid slurry, which sets up to form a solid mold or investment; plaster of paris is usually used. The mold is then heated, such that the pattern melts and is burned out, leaving behind a mold cavity having the desired shape. This technique is employed when high dimensional accuracy, reproduction of fine detail, and an excellent finish are require, for example, in jewelry and dental crowns and inlays. Also, blades for gas turbines and jet engine impellers are investment cast. Sand Casting With sand casting, probably the most common method, ordinary sand is used as the mold material. A two-piece mold is formed by packing sand around a pattern that has the shape of the intended casting. Furthermore, a gating system is usually incorporated into the mold to expedite the flow of molten metal into the cavity and to minimize internal casting defects. Sand-cast parts include automotive cylinder blocks, fire hydrants, and large pipe fittings. Lost Foam Casting A variation of investment casting is lost foam (or expendable pattern) casting. Here the expendable pattern is a foam that can be formed by compressing polystyrene beads into the desired shape and then bonding them together by heating. Alternatively, pattern shapes can be cut from sheets and assembled with glue. Sand is then packed around the pattern to form the mold. As the molten metal is poured into the mold, it replaces the pattern which vaporizes. Die Casting In die casting, the liquid metal is forced into a mold under pressure and at a relatively high velocity and allowed to Continuous Casting At the conclusion of extraction processes, many molten metals are solidified by casting into large ingot molds. The ingots are normally subjected to a primary hot-rolling operation, the product of which is a flat sheet or slab; these are more convenient shapes as starting points for subsequent secondary metal-forming operations (i.e., forging, extrusion, drawing). Using this technique, the refined and molten metal is cast directly into a continuous strand that may have either a rectangular or circular cross section; solidification occurs in a water-cooled die having the desired cross-sectional geometry. Furthermore, continuous casting is highly automated and more efficient. Figure 11 shows the schematic illustration of continuous casting CORROSION Corrosion is defined as the destructive and unintentional attack on a metal; it is electrochemical and ordinarily begins at the sur face. The problem of metallic corrosion is significant; in economic terms, it has been estimated that approximately 5% of an industrialized nation’s income is spent on corrosion prevention and the maintenance or replacement of products lost or contaminated as a result of corrosion reactions. The consequences of corrosion are all too common. Familiar examples include the rusting of automotive body panels and radiator and exhaust components. UNIFORM ATTACK Uniform attack is a form of electrochemical corrosion that occurs with equivalent intensity over the entire exposed surface and often leaves behind a scale or deposit. In a microscopic sense, the oxidation and reduction reactions occur randomly over the surface. GALVANIC CORROSION Galvanic corrosion occurs when two metals or alloys having different compositions are electrically coupled while exposed to an electrolyte. The less noble or more reactive metal in the environment experiences corrosion; the more inert metal, the cathode, is protected from corrosion. As examples, steel screws corrode when in contact with brass in a marine environment, and if copper and steel tubing are joined in a domestic water heater, the steel corrodes in the vicinity of the junction. Galvanic Series This represents the relative reactivities of a number of metals and commercial alloys in seawater. The alloys near the top are cathodic and unreactive, whereas those at the bottom are most anodic; no voltages are provided. CREVICE CORROSION Electrochemical corrosion may also occur because of concentration differences of ions or dissolved gases in the electrolyte solution and between two regions of the same metal piece. For such a concentration cell, corrosion occurs in the locale that has the lower concentration. PITTING CORROSION Pitting is another form of much localized corrosion attack in which small pits or holes form. They ordinarily penetrate from the top of a horizontal surface downward in a nearly vertical direction. It is an extremely insidious type of corrosion, often going undetected and with very little material loss until failure occurs. INTERGRANULAR CORROSION As the name suggests, intergranular corrosion occurs preferentially along grain boundaries for some alloys and in specific environments. The net result is that a macroscopic specimen disintegrates along its grain boundaries. SELECTIVE LEACHING Selective leaching is found in solid solution alloys and occurs when one element or constituent is preferentially removed because of corrosion processes. The most common example is the dezincification of brass, in which zinc is selectively leached from a copper–zinc brass alloy. STRESS CORROSION Stress corrosion, sometimes termed stress corrosion cracking, results from the combined action of an applied tensile stress and a corrosive environment; both influences are necessary. In fact, some materials that are virtually inert in a particular corrosive medium become susceptible to this form of corrosion when a stress is applied. Ceramics A ceramic is an inorganic nonmetallic solid made up of either metal or non-metal compounds that have been shaped and then hardened by heating to high temperatures. In general, they are hard, corrosion-resistant and brittle. The term ceramic comes from the Greek word keramikos, which means “burnt stuff,” indicating that desirable properties of these materials are normally achieved through a hightemperature heat treatment process called firing. Ceramic Crystal Structure Rock Salt Structure Perhaps the most common AX crystal structure is the sodium chloride (NaCl), or rock salt, type. The coordination number for both cations and anions is 6, and therefore the cation– anion radius ratio is between approximately 0.414 and 0.732. A unit cell for this crystal structure is generated from an FCC arrangement of anions with one cation situated at the cube center and one at the center of each of the 12 cube edges. Cesium Chloride Structure A unit cell for the cesium chloride (CsCl) crystal structure; the coordination number is 8 for both ion types. The anions are located at each of the corners of a cube, whereas the cube center is a single cation. Interchange of anions with cations, and vice versa, produces the same crystal structure. This is not a BCC crystal structure because ions of two different kinds are involved. Zinc Blende Structure A third AX structure is one in which the coordination number is 4—that is, all ions are tetrahedrally coordinated. This is called the zinc blende, or sphalerite, structure, after the mineralogical term for zinc sulfide (ZnS). AmXp-Type Crystal Structures If the charges on the cations and anions are not the same, a compound can exist with the chemical formula AmXp, where m and/or p≠1. An example is AX2, for which a common crystal structure is found in fluorite (CaF2). Calcium ions are positioned at the centers of cubes, with fluorine ions at the corners. AmBnXp-Type Crystal Structures It is also possible for ceramic compounds to have more than one type of cation; for two types of cations (represented by A and B), their chemical formula may be designated as AmBnXp. Classification of Ceramic Materials 1. Glasses a. Glasses b. Glass-ceramics 2. Clay Products a. Structural Clay products b. Whitewares 3. Refractories a. Fireclay b. Silica c. Basic d. Special 4. Abrasives 5. Cements 6. Carbons a. Diamond b. Graphite c. Fibers 7. Advanced Ceramics Fabrication and Processing of Ceramics Glass Forming Glass is produced by heating the raw materials to an elevated temperature above which melting occurs. Most commercial glasses are of the silicasoda-lime variety; the silica is usually supplied as common quartz sand, whereas Na2O and CaO are added as soda ash (Na2CO3) and limestone (CaCO3). Pressing Pressing is used in the fabrication of relatively thickwalled pieces such as plates and dishes. The glass piece is formed by pressure application in a graphite-coated cast iron mold having the desired shape; the mold is typically heated to ensure an even surface. Blowing Although some glass blowing is done by hand, especially for art objects, the process has been completely automated for the production of glass jars, bottles, and light bulbs. From a raw gob of glass, a parison, or temporary shape, is formed by mechanical pressing in a mold. This piece is inserted into a finishing or blow mold and forced to conform to the mold contours by the pressure created from a blast of air Drawing Drawing is used to form long glass pieces that have a constant cross section, such as sheet, rod, tubing, and fibers Polymers Naturally occurring polymers— those derived from plants and animals— have been used for many centuries; these materials include wood, rubber, cotton, wool, leather, and silk. Other natural polymers, such as proteins, enzymes, starches, and cellulose, are important in biological and physiological processes in plants and animals. Modern scientific research tools have made possible the determination of the molecular structures of this group of materials and the development of numerous polymers that are synthesized from small organic molecules. Many of our useful plastics, rubbers, and fiber materials are synthetic polymers. POLYMER MOLECULES The molecules in polymers are gigantic in comparison to the hydrocarbon molecules already discussed; because of their size they are often referred to as macromolecules. Within each molecule, the atoms are bound together by covalent interatomic bonds. Repeat units These long molecules are composed of structural entities, which are successively repeated along the chain. Monomer Refers to the small molecule from which a polymer is synthesized. Hence, monomer and repeat unit mean different things, but sometimes the term monomer or monomer unit is used instead of the more proper term repeat unit. THE CHEMISTRY MOLECULES OF POLYMER When all of the repeating units along a chain are of the same type, the resulting polymer is called a homopolymer. Chains may be composed of two or more different repeat units, in what are termed copolymers. Polymers may be synthesized in which side-branch chains are connected to the main branched polymer ones. These are fittingly called branched polymers. The branches, considered to be part of the main-chain molecule, may result from side reactions that occur during the synthesis of the polymer. In crosslinked polymers, adjacent linear chains are joined one to another at various positions by covalent bonds, crosslinking is achieved either during synthesis or by a nonreversible chemical reaction. Often, this crosslinking is accomplished by additive atoms or molecules that are covalently bonded to the chains. Many of the rubber elastic materials are crosslinked; in rubbers, this is called vulcanization. THERMOPLASTIC THERMOSETTING POLYMERS AND Thermoplastics (or thermoplastic polymers) soften when heated (and eventually liquefy) and harden when cooled— processes that are totally reversible and may be repeated. Thermosetting polymers or thermosets are network polymers. They become permanently hard during their formation and do not soften upon heating. Classification of Composite Materials PARTICLE-REINFORCED COMPOSITE The two subclassifications of particle-reinforced composites are the Large particle and dispersion- strengthened composites. The distinction between these is based on the reinforcement or strengthening mechanism. Large-particle Composites The term “large” is used to indicate that particle–matrix interactions cannot be treated on the atomic or molecular level; rather, continuum mechanics is used. For most of these composites, the particulate phase is harder and stiffer than the matrix. These reinforcing particles tend to restrain movement of the matrix phase in the vicinity of each particle. Polymers with Filler Cermets Concrete Dispersion-strengthened Composites For dispersionstrengthened composites, particles are normally much smaller, with diameters between 0.01 and 0.1 m (10 and 100 nm). Metals and metal alloys may be strengthened and hardened by the uniform dispersion of several volume percent of fine particles of a very hard and inert material. The dispersed phase may be metallic or non-metallic; oxide materials are often used. FIBER-REINFORCED COMPOSITES Fiber-reinforced composites are subclassified by fiber length: continuous and discontinuous. Moreover, as fiber length(l) increases, the fiber reinforcement becomes more effective. Fibers for which its length is greater than the critical length (lc) (normally l > 15 lc) are termed continuous; discontinuous or short fibers have lengths shorter than this. For discontinuous fibers of lengths significantly less than the matrix deforms around the fiber such that there is virtually no stress transference and little reinforcement by the fiber. To affect a significant improvement in strength of the composite, continuous. the fibers must be THE FIBER PHASE An important characteristic of most materials, especially brittle ones, is that a small diameter fiber is much stronger than the bulk material. On the basis of diameter and character, fibers are grouped into three different classifications: whiskers, fibers, and wires. Whiskers Fibers Wires POLYMER–MATRIX COMPOSITES Polymer–matrix composites (PMCs) consist of a polymer resin as the matrix and fibers as the reinforcement medium. These materials are used in the greatest diversity of composite applications, as well as in the largest quantities, considering their room-temperature properties, ease of fabrication, and cost. They may be reinforced with glass, carbon, and aramid fibers. Glass Fiber–Reinforced Polymer (GFRP) Composites Carbon Fiber–Reinforced Polymer (CFRP) Composites Aramid Fiber–Reinforced Polymer Composites Other Fiber Reinforcement Materials Polymer-Matrix Materials CERAMIC-MATRIX COMPOSITES Ceramic materials are inherently resilient to oxidation and deterioration at elevated temperatures; were it not for their disposition to brittle fracture, some of these materials would be ideal candidates for use in high temperature and severe-stress applications, specifically for components in automobile and aircraft gas turbine engines. CARBON–CARBON COMPOSITES One of the most advanced and promising of engineering materials is the carbon fiber– reinforced carbon-matrix composite, often termed a carbon– carbon composite; as the name implies, both reinforcement and matrix are carbon. These materials are relatively new and expensive and, therefore are not currently being used extensively. HYBRID COMPOSITES A relatively new fiber-reinforced composite is the hybrid, which is obtained by using two or more different kinds of fibers in a single matrix; hybrids have a better all-around combination of properties than composites containing only a single fiber type. A variety of fiber combinations and matrix materials are used, but in the most common system, both carbon and glass fibers are incorporated into a polymeric resin.