SWEP II Technical Report: Mechanical Engineering Experience

advertisement

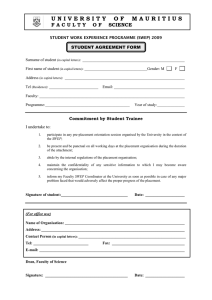

A TECHNICAL REPORT ON THE STUDENT WORK EXPERIENCE PROGRAMME II [SWEP II] FOR THE 2022/2023 ACADEMIC SESSION COMPILED BY BELLO EMMANUEL ADESHOLA (MEE/19/029) GROUP B2 SUBMITTED TO THE DEPARTMENT OF MECHANICAL ENGINEERING IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE AWARD OF BACHELOR OF ENGINEERING (B.Eng.) DEGREE IN MECHANICAL ENGINEERING AT OLUSEGUN AGAGU UNIVERSITY OF SCIENE AND TECHNOLOGY, OKITIPUPA, ONDO STATE, NIGERIA. September, 2023. CERTIFICATION This is to certify that this SWEP (SWEP II) report was written by BELLO EMMANUEL ADESHOLA with matriculation number: MEE/19/029 of the Department of Mechanical Engineering, Faculty of Engineering and Engineering Technology, Olusegun Agagu University of Science and Technology, Okitipupa, Ondo State. ………………………………………… BELLO EMMANUEL ADESHOLA (SWEP Student) Date and Signature ENG AKINSADE ………………………………………… ( MEE SWEP Coordinator ) Date and Signature ii DEDICATION I dedicate this SWEP II report to the almighty God, whose infinite mercy preserved and protected me throughout the SWEP II programme. I also dedicate this report to my loving parents, Mr and Mrs. Bello who supported me during the programme and to all who stood by me. iii ACKNOWLEGEMENT I would like to seize this opportunity to express my gratitude to the management of the Olusegun Agagu University of Science and Technology, Okitipupa (OAUSTECH) for their tremendous assistance and backing of the Student Work Experience Programme II (SWEP II), for each of the engineering students who participated in the programme had impacting life experience. I want to express my appreciation for the help, contributions, and attention provided by the Dean of the Faculty of Engineering and Head of the Department of Mechanical Engineering, Prof. A. O. Akinola, Head of the Department of Electrical and Electronics Engineering, Dr. Aiyelabowo, Head of the Department of Civil Engineering, Prof. Aderinola, as well as all Lecturers and Staffs of the Faculty in ensuring the programme's success. We were given permission to complete the works, and we understand the importance of hard work. iv ABSTRACT This technical report presents an overview of my experiences during my Student Work Experience Programme (SWEP II) at Olusegun University of Science and Technology. The training covers a period of 3weeks, during which I acquired valuable technical skills. It also aims to justify the relevance of the programme in equipping students with the necessary competence for the real world. The Students Work Experience Programme (SWEP) played a pivotal role in enabling students to gain practical knowledge and skills, which will be valuable when they find themselves in the labor market. My learning during this period was majored on the process and procedure of detection of fault and maintenance of engineering appliances and setup project. This experience was gained through participation in the Student Work Experience Programme II (SWEP II), which took place at Olusegun University of Science and Technology, Okitipupa. In this report, I will discuss my experiences, the knowledge I gained, and the practical skills I acquired during the training process, all of which contribute to shaping a certified and well-trained Mechanical Engineer. Each chapter of this report delves into the specific knowledge and practical work I undertook, starting from my first day at the work site to my final days at the work site. v LIST OF FIGURES Figure 2.1 Some Electrical tools Used ......................................................................................9 Figure 2.2: Faulty Socket Front-View .................................................................................... 11 Figure 2.3: Faulty Socket Back-View ..................................................................................... 11 Figure 2.4: Socket Repair ....................................................................................................... 11 Figure 2.5: Socket Replacement ............................................................................................. 11 Figure 2.6: Wall Socket Completion ....................................................................................... 11 Figure 3.1: Some tools used during Wood and Metal working process ................................ 14 Figure 3.2: Damaged Two sitter Bench .................................................................................. 16 Figure 3.3: Marking out .......................................................................................................... 16 Figure 3.4: Cutting process ..................................................................................................... 16 sFigure 3.5: Replacement & Resizing ..................................................................................... 17 Figure 3.6: Drilling of Holes ................................................................................................... 17 Figure 3.7: Fastening using Screw .......................................................................................... 17 Figure 3.8: Surface smoothening ............................................................................................ 17 Figure 3.9: Finished Project.................................................................................................... 17 Figure 4.1: Some tools used during concrete mixing and transport process ........................ 22 Figure 4.2: Aggregate Packing ............................................................................................... 24 Figure 4.3: Ground Preparation ............................................................................................. 24 Figure 4.4: Concrete Mixing ................................................................................................... 24 Figure 4.5: Stamping Process ................................................................................................. 24 Figure 4.6: Walkway Completion ........................................................................................... 25 vi LIST OF TABLES Table 1.1: Grouping ..................................................................................................................5 Table 1.2: Work schedule .........................................................................................................5 Table 1.3: Time schedule ..........................................................................................................6 vii TABLE OF CONTENTS CERTIFICATION ..................................................................................................................... ii DEDICATION .......................................................................................................................... iii ACKNOWLEGEMENT ........................................................................................................... iv ABSTRACT ...............................................................................................................................v LIST OF FIGURES .................................................................................................................. vi LIST OF TABLES ................................................................................................................... vii Table of Contents .................................................................................................................... viii INTRODUCTION ......................................................................................................................1 1.1 Introduction to SWEP ..................................................................................................1 1.1.1 History of the Student Work Experience Programme (SWEP):...............................2 1.1.2 Aim of SWEP ........................................................................................................3 1.1.3 Objectives of SWEP ..............................................................................................3 1.1.4 Benefit of SWEP to student ....................................................................................3 1.2 Orientation ....................................................................................................................4 1.3 SWEP Programme Grouping and Work Schedule .........................................................5 1.4 Time Schedule ..............................................................................................................6 1.5 Preface ..........................................................................................................................6 2.0 ELECTRICAL SECTION ................................................................................................7 2.1 Electrical Review: Maintenance.................................................................................7 2.1.1 Predictive Maintenance ..........................................................................................7 2.1.2 Preventive Maintenance .........................................................................................7 viii 2.1.3 Corrective Maintenance .........................................................................................8 2.2 Electrical Tools .........................................................................................................9 2.3 Electrical Practical ...................................................................................................... 10 2.3.1 Wall Sockets Repairs .................................................................................................. 10 2.3.2 Identifying issues and causes................................................................................ 10 2.3.3 Repair Procedure: ................................................................................................ 10 3.0 MECHANICAL SECTION ............................................................................................ 12 3.1 Mechanical Review: Wood and Metal ......................................................................... 12 3.1.1 3.2 Metal Working ........................................................................................................... 13 3.2.1 Welding and Fabrication ...................................................................................... 13 3.2.2 Mild Steel ............................................................................................................ 13 3.3 Wood and Metal Working Tools Used During Practical .............................................. 14 3.4 Mechanical Practical Procedure .................................................................................. 15 3.4.1 3.5 4. Wood as an Engineering Material ........................................................................ 12 Dimensions of Measured Particle Boards for a Two Sitter-Bench......................... 16 Precautions taken during Practical ............................................................................... 18 CIVIL SECTION .............................................................................................................. 19 4.1 Civil Review: Concrete ............................................................................................... 19 4.1.1 Concrete Based on Quality ................................................................................... 19 4.1.2 Concrete Based on Components ........................................................................... 19 4.2 Concrete Mixing ......................................................................................................... 20 4.2.1 Material Selection ................................................................................................ 20 ix 4.2.2 Mix Design .......................................................................................................... 21 4.3 Tools Used During Practical ....................................................................................... 22 4.4 Civil Practical Procedure ............................................................................................. 23 4.5 Precaution taken during concrete stamping process ..................................................... 25 5.0 KNOWLEDGE, ACHIVEMENTS, CHALLENGES AND SOLUTIONS ...................... 26 5.1 Acquired Knowledge and Skills .................................................................................. 26 5.2 Achievements ............................................................................................................. 26 5.3 Challenges .................................................................................................................. 27 5.4 Solutions Proffered to the Challenges .......................................................................... 27 6.0 RECOMMENDATION AND CONCLUSION ............................................................... 28 6.1 Recommendation ........................................................................................................ 28 6.2 Conclusion .................................................................................................................. 28 x INTRODUCTION 1.1 Introduction to SWEP SWEP stands for the Student Work Experience Programme. It is an initiative set up by the federal government of Nigeria to encourage undergraduates in tertiary institutions to obtain practical work experience while still studying. The importance of preparing university engineering graduates with essential expertise, knowledge, and proficiency in utilizing both hand and machine tools in their profession cannot be overemphasized. It is crucial to have engineers who have received comprehensive training, including lectures, workshops, laboratories, and realworld industry experience. An engineer with the drive and aptitude for entrepreneurship, particularly in establishing small-scale industrial and engineering ventures, can significantly accelerate industrial development. The Student Work Experience Programme (SWEP) is an intensive engineering training programme aimed at providing students with fundamental practical knowledge and a practical orientation essential for cultivating self-reliant and skilled engineers. This programme focuses on equipping student engineers with essential skills in general engineering practice, emphasizing the use of hand and power tools for material cutting, concrete mixing, welding and fabrication. SWEP serves as a hands-on, intensive programme, offering exposure to fundamental engineering skills involving the use of simple hand tools, equipment, and operation of common machines. Furthermore, it acts as a platform to integrate skills related to in-house entrepreneurship development. The design of the Student Work Experience Programme (SWEP) goes beyond mere skill acquisition; it endeavors to instill the right team spirit and expose students to the fundamental expectations of the professional world. Through SWEP, students not only acquire technical skills but also develop crucial teamwork abilities necessary for success in their future engineering careers. 1 1.1.1 History of the Student Work Experience Programme (SWEP): The Student Work Experience Programme (SWEP) is an engineering training programme that was initiated in 1974. It began with the participation of 748 students from 11 higher education institutions. Over the years, the programme has undergone growth and development, expanding its scope to encompass thousands of students from various institutions. In 1978, the program involved about 5,000 students from 32 institutions. The Federal Government of Nigeria recognized the significance of the programme and started providing funding through the National University Commission (NUC) and the National Board for Technical Education (NBTE). The programme was managed under the SWEP/SIWES banner with supervision from these governmental bodies for a period of five years from 1979 to 1984. In 1985, the Federal Government further institutionalized the programme with the enactment of Decree No. 16. This decree mandated that students enrolled in specialized engineering, technical, business, applied sciences, and applied arts programs undergo supervised industrial attachments as an integral part of their studies. In the same vain the ITF was directed by the Federal Government to take charge and resume responsibility for the management of SWEP/SIWES in collaboration with the supervising agencies, i.e. National Universities Commission (NUC), the National Board of Technical Education (NBTE) and the National Commission for College of Education (NCCE). Following the resumption of management of SWEP/SIWES by the ITF in 1984 the scheme has witnessed rapid expansion. Between 1985 and 1995, the numbers of institutions and the students participating in SWEP/SIWES rose from 141 to 57,433 respectively. Between 1995 and 2003, a total of 176 institutions and 210,390 students participated in SWEP/SIWES. This rose to 204 while the number of students from theses institutes who participated in the scheme was 535,210, from 2003-2011 the institutions participated in the scheme improved up to 215 while the number of student increased to 610,122 (ITF 2011) industrial work experience in Human resource Development in Nigeria. 2 1.1.2 Aim of SWEP The aim of SWEP is to create an opportunity for students of various disciplines in Nigerian tertiary institutions to gain industrial work experience in their chosen fields of study, in relevant industries and establishments. This helps them to acquire necessary skills, which are needed in the advancement of their career in their field of study after graduation. 1.1.3 Objectives of SWEP 1. To cultivate a senses of professionalism and ethical behavior in student. 2. To provide students with industrial skills and needed experience while in the course of study 3. To help student gain clarity about their career goals and aspirations. 4. To prepare specialists who will be ready for any working situations immediately after graduation. 5. To improve students’ employability by providing them with relevant work experience. 6. To enlighten students on the pitfalls to avoid in the business world as well as to maximize profit in their various fields. 7. To make the transition from school to the labor market easier for the students. 8. To expose the students to work methods not taught in the classroom and to provide access to production equipment 1.1.4 Benefit of SWEP to student 1. Blend theoretical knowledge acquired in institutions with relevant production skills required in work organization. 2. Exposes students to industrial demands, trends, and practices. 3. Students gain competitive edge in the job market by showcasing real-world experience. 4. Provides students with networking opportunities within the industry. 5. Appreciate the connection between their courses of study and other related disciplines in the production of goods and services. 3 1.2 Orientation The SWEP programme for the 2022/2023 session commenced on the 18th of October, 2023. It kicked off with an orientation session featuring speeches from various Engineering Lecturers and Technologists. The following individuals addressed the students: Engineer Akinsade (Mechanical SWEP Coordinator). Engineer Tunde (Electrical SWEP Coordinator). Engineer Oloruntande (Civil SWEP Coordinator). During the orientation, these experts provided valuable insights into SWEP, which stands for Student Workmanship Experience Programme, an integral part of engineering institutions in Nigeria. The programme aims to bridge the gap between theoretical knowledge and practical skills, connecting university coursework with the realities of the engineering field. Key points and statements made during the orientation by the coordinators and technologists included: Engineer Oloruntande emphasized the importance of taking SWEP seriously, underscoring the notion that "No knowledge is a waste." He encouraged students to fully engage in the program. Engineer Akinsade stressed the significance of SWEP as a vital prerequisite program within the institution's assessment structure for engineering students. He highlighted that SWEP I and SWEP II constitute 400-level semester courses and urged students to approach them diligently. Engineer Tunde urged students to show respect not only to the coordinating lecturers but also to the technologists, emphasizing that any student disrespecting a technologist would face severe consequences. In conclusion, Eng. Tunde and Eng. Akinsade provided students with guidance on report writing and filling SWEP logbooks, offering detailed instructions on how these tasks were to be completed. 4 1.3 SWEP Programme Grouping and Work Schedule Table 1.1: Grouping GROUP A (MORNING) GROUP B (AFTERNOON) GROUP A1 GROUP B1 CVE/20/001 – CVE/20/036 CVE/19/001 – CVE/19/029 EEE/20/001 – EEE/20/028 EEE/19/001 – EEE/19/028 MEE/20/001 – MEE/20/032 MEE/19/001 – MEE/19/025 GROUP A2 GROUP B2 CVE/20/037 – CVE/20/069 CVE/19/030 – CVE/19/056 EEE/20/029 – EEE/20/057 EEE/19/029 – EEE/19/057 MEE/20/033 – MEE/20/071 MEE/19/026 – MEE/19/049 GROUP A3 GROUP B3 CVE/20/070 – CVE/20/096 + CVE/DE/22/001 – 009 CVE/19/057 – CVE/19/085 + CVE/DE/20/001 – 011 EEE/20/058 – EEE/20/076 + EEE/DE/22/001 – 012 EEE/19/058 – EEE/19/084 + EEE/DE/20/001 – 013 MEE/20/072 – MEE/20/098 + MEE/DE/22/001 – 006 MEE/19/050 – MEE/19/086 + MEE/DE/20/001 – 009 Table 1.2: Work schedule Mechanical Repairing of chairs and tables. Electrical Repairing and fixing electrical fitting. Civil Creation of pathway/walk path and repairs. 5 1.4 Time Schedule Table 1.3: Time schedule 19/09/2023 20/09/2023 21/09/2023 25-26/09/2023 27-28/09/2023 2-3/10/2023 A1 CVE EEE MEE CVE EEE MEE A2 EEE MEE CVE EEE MEE CVE A3 MEE CVE EEE MEE CVE EEE B1 CVE EEE MEE CVE EEE MEE B2 EEE MEE CVE EEE MEE CVE B3 MEE CVE EEE MEE CVE EEE 1.5 Preface 04/10/2023 CLOSING GROUP In the process of grouping my Matric Number MEE/19/029 fell in Group B2. This fascinating approach of grouping and time scheduling, made students irrespective of engineering discipline either skilled or unskilled, worked together as a team to achieve the desired work goal placed before them. In the course of teaching and practice (hands on experience), my fellow students and I gained valuable insight in the fields of Mechanical, Electrical and Civil Engineering. It has been a privilege to be a part of this programme, enabling us to fully comprehend the knowledge impacted and recognize that engineering is a collective endeavor aimed at making a positive impact in the developing world. In this report, I will embark on reviewing and documenting the practical proceedings. Join me on this journey as we delve into the details. 6 2.0 ELECTRICAL SECTION 2.1 Electrical Review: Maintenance Mr. Akinwumiju Kehinde, the technologist in charge of Electrical project, defines maintenance as the processes of ensuring equipments are kept in good working order. Electrical maintenance refers to the systematic and proactive process of inspecting, servicing, repairing, and managing electrical systems and equipment to ensure their safe, reliable, and efficient operation. We explore three primary types of maintenance practices: predictive maintenance, preventive maintenance, and corrective maintenance. Predictive and preventive maintenance are routine maintenance. 2.1.1 Predictive Maintenance Predictive maintenance is a proactive approach to maintenance that relies on data and technology to forecast equipment failures. Key features of predictive maintenance include: 1. Data Analysis: Utilizes data from sensors and monitoring systems to continuously track equipment condition. 2. Advanced Algorithms: Algorithms analyze data to detect trends, anomalies, or signs of impending failure. 3. Scheduled Maintenance: Maintenance activities are scheduled based on predictions, minimizing downtime and reducing the risk of unexpected breakdowns. 4. Cost Efficiency: Optimizes maintenance costs by addressing issues before they become critical. Predictive maintenance is particularly valuable in electrical systems for identifying potential problems before they disrupt operations. 2.1.2 Preventive Maintenance Preventive maintenance involves planned, routine maintenance tasks aimed at preventing equipment failure. Key aspects of preventive maintenance include: 7 1. Scheduled Inspections: Equipment is inspected and serviced at regular intervals, such as monthly or annually. 2. Replacement of Parts: Worn or damaged parts are replaced before they fail to prevent disruptions. 3. Lubrication and Cleaning: Equipment is regularly lubricated, cleaned, and calibrated to ensure optimal performance. 4. Record Keeping: Maintenance records are kept to track service history and plan future maintenance. 5. Cost Control: While it incurs regular maintenance costs, preventive maintenance can reduce the likelihood of costly breakdowns. In electrical maintenance, preventive strategies are vital to ensuring system integrity and minimizing unexpected downtimes. 2.1.3 Corrective Maintenance Corrective maintenance is reactive and involves repairing equipment after it has failed. Key characteristics of corrective maintenance include: 1. Emergency Response: Maintenance teams respond to unexpected breakdowns or failures. 2. Downtime: Corrective maintenance often results in unplanned downtime, which can be costly. 3. Replacement of Faulty Parts: Failed components or parts are replaced or repaired to restore functionality. 4. Minimal Planning: Corrective maintenance lacks the structured planning of predictive and preventive approaches. 5. Emergency Costs: Corrective maintenance tends to be more expensive due to emergency repairs and potential production losses. While corrective maintenance is often a last resort, it is essential for addressing unexpected electrical failures swiftly and effectively. It is been admonished that selecting the most appropriate approach or a combination of these methods depends on the specific needs, goals, and resources of the electrical system in question. 8 2.2 Electrical Tools These tools are vital for ensuring the safety, reliability, and performance of electrical systems. 1. Multimeter: Measures voltage, current, and resistance for diagnostics and circuit checks. 2. Voltage Tester: Detects live circuits, enhancing safety. 3. Screwdrivers: Insulated versions secure screws on electrical components. 4. Pliers: Essential for bending, twisting, and gripping wires with insulated handles. 5. Wire Strippers: Removes wire insulation for proper connections. 6. Circuit Tester: Identifies faulty circuits and outlets. 7. Cable and Conduit Cutters: Ensures precise cable and conduit cuts. 8. Spanner and Rench : use to fasten nuts and bolts 9. Fish Tapes and Pulling Grips: Route wires through tight spaces. 10. Cable Ties and Fasteners: Secure and organize cables. 11. Safety Equipment: Protects against electric shock. 12. Tool Bag/Toolbox: Keeps tools organized and accessible. Pliers Multimeter Tester Gloves and Screw Drivers Figure 2.1 Some Electrical tools Used 9 2.3 Electrical Practical Group B2 did the repair and maintenance of wall sockets in mega hall and lecture rooms. Procedure in the repair and maintenance of wall socket are highlighted below: 2.3.1 Wall Sockets Repairs Tools and Materials Used: Screwdrivers and pliers, Replacement sockets. 2.3.2 Identifying issues and causes 1. Common issues with wall sockets include burnt socket, loose sockets, and damage face plate. 2. Burnt socket are caused by plugging in multiple high-wattage appliances into a single socket which overload it, leading to overheating and eventually causing the socket to burn. 2.3.3 Repair Procedure: 1. Safety First: we ensured turning off the power to the affected socket at the circuit breaker or fuse box. 2. Inspect Damage: We carefully examined the burnt socket to assess the extent of damage. If it's were severely damaged the entire socket were replaced. 3. Wire Connections: Damages limited to the faceplate or cover part were remove and replaced with a new one. 4. Loose Sockets: carefully remove the socket cover. Tighten any loose screws or connections within the socket. Note: 1. If a wall socket has no power, check the circuit breaker or fuse box for tripped breakers or blown fuses. If this doesn't resolve the issue, call a qualified electrician. 2. Wall Sockets Maintenance: Keep wall sockets clean and free from dust and debris. 10 Figure 2.3: Faulty Socket Back-View Figure 2.2: Faulty Socket Front-View Figure 2.4: Socket Repair Figure 2.5: Socket Replacement Figure 2.6: Wall Socket Completion 11 3.0 MECHANICAL SECTION 3.1 Mechanical Review: Wood and Metal Exploring the artistry of wood and metal craftsmanship with Mr. Samagbeyi, our expert mechanical technologist, we uncover the essence of wood-its genesis in the heart of trees. In our exploration, we delve briefly into the two primary categories of wood: 1. Softwood: Derived from gymnosperm trees, typically evergreen conifers like Fir, Redwood, Pine, Cedar, and Spruce. 2. Hardwood: Wood obtained from angiosperm or flowering plants, which do not produce cones or needles. Examples include Walnut, Cherry, Oak, Mahogany, and Maple. 3.1.1 Wood as an Engineering Material Mr. Samagbeyi explained wood as an engineering material highlighting various advantageous properties: 1. Workability: Wood is highly workable, allowing for easy cutting, shaping, carving, and joining. Woodworking processes are diverse, enabling engineers to achieve intricate designs. 2. Strength and Stiffness: Wood possesses impressive strength and stiffness properties, making it suitable for load-bearing applications in engineering structures and buildings. 3. Biodegradability: Wood is biodegradable and can be returned to the environment without harm, aligning with sustainable engineering practices. 4. Durability: Properly treated and maintained wood exhibits excellent durability, resisting decay, pests, and other environmental factors. 5. Energy Efficiency: Wood's low thermal conductivity contributes to energy-efficient building designs, reducing the need for heating and cooling systems. 6. Versatility in Engineering Products: Wood is utilized in various engineering products, including structural components, furniture, flooring, decking, cabinetry, and more. 12 3.2 Metal Working In our discussion on metalworking, Mr. Samagbeyi highlighted the difference between temporary and permanent joints: Temporary joints allow easy disassembly without damaging components, illustrated by examples like bolts, screws, and snap-fit connections, vital for flexibility and reusability in many applications. On the other hand, permanent joints provide enduring and robust connections. Techniques like welding, soldering, and brazing create these lasting connections, crucial in applications where structural integrity and long-term stability are paramount. These joint explanations were crucial in our practical to assign where they are to be used. 3.2.1 Welding and Fabrication Mr. Samagbeyi further shed light on welding and fabrication, He explained that welding stands as a critical technique within metalworking, enabling the fusion of multiple metal pieces into strong and permanent joints. Additionally, He emphasized the significance of fabrication, which involves the shaping and assembling of metal components into finished products. Cutting, bending, and machining precede welding or fastening, underscoring fabrication's vital role in producing completed metal structures and products. 3.2.2 Mild Steel Mild steel was emphasized as the metal to be used due to its excellent properties. It valued for woodworking for these reasons: 1. It strength and durability makes it suitable for woodworking applications, providing stability and support. 2. It versatility in shaping makes it easy to manipulate and shape to desired forms. 3. It ease to join, welding mild steel is a straight forward process, enabling secure connections. 4. Mild steel is cost-effective choice, aligning with budget consideration while maintaining quality and durability. 13 3.3 Wood and Metal Working Tools Used During Practical 1. Screwdriver: A crucial tool for inserting and removing screws, a fundamental fastener in woodworking. 2. Hammer: A versatile tool used for driving nails into wood, adjusting work pieces through striking, and shaping or bending metal when needed. 3. Measuring Tools: These include rulers, calipers, and measuring tapes, crucial for precise measurements and dimensions. 4. Hand Drill: An essential tool for creating holes in both metal and wood materials. 5. Safety Gear: Including gloves, goggles, helmets, and aprons to ensure safety during work. 6. Hacksaws: used for cutting through metal components. 7. Vice: Secures work pieces, ensuring stability and safety for both metal and wood projects. 8. Hand saw: used for making straight and curved cuts in woods. 9. Sand paper: used for smoothing and finishing wood surfaces preparing it for surface finish. 10. Welding Machines: used for fusing and joining metal parts. 11. Bench Saw: Stationary cutting tool for precise and efficient wood cutting tasks. 12. Center Punch: Hand tool used to mark a point by creating a small dent, ensuring accurate hole drilling in metal and wood. Hand Drill Table Saw Figure 3.1: Some tools used during Wood and Metal working process 14 3.4 Mechanical Practical Procedure Restoring a two-seater bench crafted from a combination of wood and metal necessitates a deep understanding of the unique properties of each material. This understanding is vital for a precise inspection and focused repairs, ultimately ensuring the bench regains its stability, comfort, and aesthetic appeal. Below are the lists of careful procedure carried out to restore a two-seater bench, addressing both wood and metal component. 1. Thorough assessments of the furniture were done, examining both wooden and metal component. 2. Damaged areas were identified, encompassing issues such as missing or broken wooden board, loose bolts and nuts, cracks in the wood and structural instability in both wood and metal components. 3. The necessary repair and maintenance materials, including replacement particle boards, bolts, nuts, and paint, were provided. 4. The damaged parts were carefully disassembled, ensuring no further harm to the furniture. 5. Irreparably damaged wooden components were marked for replacement. 6. Precise measurements were taken using a measuring tape to determine the dimensions for the replacement particle boards. 7. Particle boards were accurately marked out and cut to the respective sizes based on the earlier measurements. 8. Holes were carefully drilled into both metal and wooden materials to allow for the fastening of bolts and nuts. 9. Broken particle boards were replaced, with the use of bolts and nuts as fastener to securely fasten the particle boards to the metal support system. 10. The rough surface areas were thoroughly cleaned and smoothed using sandpaper. 11. Painting and polishing were skillfully done after smoothing the metal and wooden surfaces to enhance the furniture’s aesthetic appeal. 12. Final inspections and adjustments were made to ensure the furniture’s stability, appearance, and functionality met the desired standards. 15 3.4.1 Dimensions of Measured Particle Boards for a Two Sitter-Bench 42cm by 35cm Sitter-board 42cm by 19.2cm Back-board 34cm by 9.5cm Side-board 96cm by 35cm Bottom-board 109.5cm by 38cm Table Top-board 101cm by 33.5cm Front board Figure 3.3: Marking out Figure 3.2: Damaged Two sitter Bench Figure 3.4: Cutting process 16 Figure 3.5: Replacement & Resizing Figure 3.6: Drilling of Holes Figure 3.7: Fastening using Screw Figure 3.8: Surface smoothening Figure 3.9: Finished Project 17 3.5 Precautions taken during Practical In the practical restoration process, several precautions were taken to ensure a safe and effective restoration of the two-seater bench. 1. All individuals involved in the restoration wore appropriate safety gear. 2. The work area was organized and kept clear of any unnecessary items to prevent accident and to provide enough space for work and movement. 3. Adequate ventilation was ensured in the work area to dispel dust generated during the restoration process, maintaining a healthy working environment. 4. Safety guidelines for using power tools, such as drills and saws, were strictly followed, including proper handling, correct usage, and switching off when not in use. 5. During the disassembly of damaged parts, caution was taken to avoid causing further harm or damage to the furniture components. 6. When using paints or chemicals for polishing, appropriate precautions were observed, such as proper disposal and careful handling to prevent spills or exposure. 7. Accurate measurements were taken during the replacement of components to ensure a precise fit and alignment, avoiding unnecessary alterations. 8. Bolts and nuts were securely fastened to the wood and metal components, ensuring stability and structural integrity of the bench. 9. When applying paint, a smooth and even coat was carefully applied, allowing adequate drying time between layers to achieve a polished finish. 10. After the restoration, a thorough inspection was conducted to verify the stability, aesthetics, and overall quality of the restored bench before it was deemed complete. 18 4. 4.1 CIVIL SECTION Civil Review: Concrete The Civil lecture kicked off with a captivating introduction by Engineer Akomolafe, who described concrete as "a harmonious fusion of fine aggregate, coarse aggregate, water, and cement in precise proportions, resulting in a sturdy and unified substance." He further provided a comprehensive breakdown of concrete, categorizing it based on quality and components with clear explanations. 4.1.1 Concrete Based on Quality Concrete quality classification allows for a more precise and efficient application in construction. Two primary categories were recognized: 1. Pure Concrete: This category features higher cement content, designed to provide the concrete with the necessary strength to withstand specific design loads. It's the right choice when structural integrity and load-bearing capacity are paramount. 2. Weak Concrete: As the name implies, weak concrete contains lower cement content. It is predominantly used for ground stabilization before reinforcing structures. Its primary role is to create a stable base for further construction. Note: Concrete's quality based on categorization ensures that the right mix is used in the right place, optimizing structural stability, durability, and overall performance. 4.1.2 Concrete Based on Components Eng. Akomolafe emphasized that concrete can be categorized into different types based on its components; each designed to meet specific structural requirements: 1. Mass Concrete: Mass concrete is characterized by its composition, which excludes any form of reinforcement. It primarily consists of cement, water, fine aggregates, and coarse aggregates. This type of concrete is often employed in projects where additional strength 19 from reinforcement is unnecessary, such as in certain foundations or non-structural elements. 2. Reinforced Concrete: Recognizing concrete's weakness to tension and its strength in compression, Eng. Akomolafe explained reinforced concrete as bolster to concrete’s tensile strength. Reinforcement is introduced, typically in the form of steel. This strategic addition enhances the structural capabilities of concrete, making it a preferred choice for a wide range of construction applications. It is widely used in the development of buildings, bridges, and infrastructure projects to ensure structural integrity and durability. Notable keynote: The choice between mass and reinforced concrete is influenced by the specific requirements and load-bearing capacity of a structure. Furthermore, he cautioned against placing reinforcement directly on natural ground, highlighting the importance of proper foundation practices in construction. By doing so, we ensure that the strength and integrity of our structures are upheld, as guided by the expertise of Eng. Akomolafe. 4.2 Concrete Mixing Concrete mixing was defined as the process of combining cement, aggregates (such as sand and gravel), water, and sometimes additional additives to create a homogeneous and durable building material. The mixing ratio, referred to as the concrete mix design, which specifies the proportions of these ingredients to achieve the desired properties and strength for a particular concrete application. 4.2.1 Material Selection It was emphasized that the selection of the right materials is a fundamental decision in construction, shaping the strength and durability of the structure. The core materials and their roles in the concrete mix: 20 1. Cement: Cement serves as the binding agent in concrete, and in Nigeria, popular options include Portland cement, Dangote cement, and Lafarge cement. The choice depends on factors such as the desired strength and durability of the concrete. 2. Aggregates: Aggregates were divided into two categories: fine (sand) and coarse (gravel or crushed stone). Fine aggregates contribute to workability, while coarse aggregates provide structural strength. The selection of aggregates ensures the concrete mix aligns with the intended application. 3. Water: Water plays a vital role in concrete by hydrating the cement, initiating the chemical reactions that lead to the hardening of the material. The quality and quantity of water are carefully controlled to achieve the desired consistency and strength in the concrete mix. 4. Optional Admixtures: These include plasticizers, accelerators, and retarders. They enhance workability, speed up or slow down setting times, allowing the concrete mix to meet specific project requirements. 4.2.2 Mix Design The mix design process entails establishing the ideal proportions of cement, aggregates, and water to achieve the desired strength, workability, and durability in concrete. The Mixing ratios are typically expressed as weight or volume ratios, ensuring the precise composition of concrete for various applications. In the civil practical programme, the mix ratio consistently used was 1:3:6, which signifies 1part of cement, 3 parts of sand, and 6 parts of coarse aggregates. The 1:3:6 mix demonstrates moderate strength, with concrete structures prepared with this mix expected to attain strengths ranging from approximately 20 to 25 Megapascals (MPa). The 1:3:6 mix level of strength allows for versatile application, including: residential building (foundations, floor slabs), light commercial structures, pavement. Walkways were the focus of the practical project, and the 1:3:6 mix proved to be well suitable for the walkways, and residential pavements projects. 21 4.3 Tools Used During Practical 1. Shovel: The shovel was utilized for multiple tasks, including transferring (sand, concrete, and aggregate). It also played a significant role in the mixing process. 2. Trowels: Trowels were used for smoothing and finishing the surface of freshly poured concrete, ensuring a level and polished appearance. 3. Wheelbarrow: Wheelbarrows facilitated the movement of sand, aggregate, and concrete mix around the construction site. 4. Hand Tamper: Hand tampers were employed for compacting and leveling the surface of the concrete. 5. Head Pan: Head pans were used for carrying smaller quantities of materials, such as sand, aggregates, and cement. 6. Digger: Diggers were used for digging trenches, breaking rocks, and removing excess soil to create a suitable foundation for the concrete. 7. Pegs and Lines: Wooden pegs and lines were utilized to mark the layout and boundaries of the pavement construction. 8. Screed Board: A wooden screed board was instrumental in achieving a level and smooth concrete surface during the finishing process. 9. Bubble Level: Bubble levels were employed to guarantee that surfaces were both level and plumb. 10. Stamper: Stampers were used for impressing patterns onto the concrete during practical work. Bubble Level Trowel Wheelbarrow Figure 4.1: Some tools used during concrete mixing and transport process 22 Shovel 4.4 Civil Practical Procedure In the process of creating a beautifully stamped concrete floor, students in group B2 carefully followed a series of steps to ensure a high-quality and visually appealing result. 1. Ground Preparation: The students prepare the ground by clearing and compacting to create a stable base for the concrete floor. 2. Concrete Mix: The concrete mix was prepared according to specific requirements, utilizing a precise ratio of 1 part cement, 3 parts sand, and 6 parts granite. The concrete mix was rigorously mixed with water, with a focus on obtaining a consistency suitable for proper placement and compaction. 3. Concrete Pouring: The uniformly mixed concrete was poured onto the prepared ground. To ensure a level and smooth surface, students used hand trowels for the finishing touch. 4. Compaction: Students used hand hamper to eliminate air voids and ensure the concrete thoroughly filled the formwork. This step enhanced the concrete's strength and durability. 5. Stamped Mortar Application: Stamped mortar, consisting of cement, was carefully sprinkled over the concrete surface. Following this, a layer of polythene nylon was applied to the floor. 6. Stamping Process: To create the desired stamped pattern, students employed stamping molds. The molds were placed on the concrete floor, and students meticulously stamped throughout the specified area. 7. Curing: Curing is a crucial step in concrete work. The next day, the stamped floor was thoroughly wetted, ensuring that it retained the necessary moisture for proper curing and hardening. 23 Figure 4.2: Aggregate Packing Figure 4.3: Ground Preparation Figure 4.4: Concrete Mixing Figure 4.5: Stamping Process 24 Figure 4.6: Walkway Completion 4.5 Precaution taken during concrete stamping process 1. We made sure that there was no bleeding (gushing out of a mixture of sand and cement during concrete mixing). 2. We wore our personal protective equipment(PPE) i.e Work shop coat, boot etc 3. The concrete mixing ratio was followed throughout the mixing process 4. We ensure the concrete is homogeneous and consistence. 5. We ensure that the concrete was made near the area of work. 6. We ensure the weather was favorable for the general work. 25 5.0 KNOWLEDGE, ACHIVEMENTS, CHALLENGES AND SOLUTIONS 5.1 Acquired Knowledge and Skills 1. My understanding of wood and metal properties has deepened considerably. I now appreciate the importance of precision in measurements to achieve a perfect fit. 2. In the course of my electrical practical experience, I have grasped the significance of prioritizing predictive and preventive maintenance as crucial for minimizing downtime, cost reduction, and ensuring the reliability of electrical systems. 3. Through my civil practical sessions, I have gained valuable insights into the concrete mixing process, which includes meticulous material selection, mix design, and precise ratios to attain the desired properties and strength. 4. I have learned the vital importance of using the appropriate tools for each task, which enhances both efficiency and performance. Moreover, I now recognize that safety should be a top priority, with the use of proper safety equipments (PPE) being imperative to prevent accidents and injuries across all engineering fields. 5.2 Achievements 1. Together with my fellow students, we achieved the successful restoration of two-seater benches at Mega hall, effectively addressing issues related to both wood and metal components. 2. I successfully identified and resolve issues on wall sockets, including rectifying burnt sockets and tightening loose connections. 3. Collaborating with my fellow students, we accomplished the creation of a stamped concrete walkway using a well-balanced 1:3:6 mix ratio. 26 5.3 Challenges 1. The civil practical experience presented a challenging task in achieving a homogeneous mixture, requiring students to be mindful of the weather conditions and engage in thorough mixing. 2. Attaining precision in measurements and proficiently handling tools such as drills and table saws posed certain challenges that demanded technical expertise. 3. Working with electrical components came with inherent safety risks, and addressing corrective maintenance could be costly due to the need for emergency repairs. 4. Ensuring proper safety precautions added to the challenge of each engineering field. 5.4 Solutions Proffered to the Challenges 1. To solve the problem of manual mixing which involves a lot of man power, SWEP management should provide a mixer to thoroughly combine the ingredients and weather condition should be considered before mixing. 2. I employ students to develop technical expertise by practicing with tools and getting familiar with works in their field. 3. Students should use electrical safety gloves and test electrical circuits before working on them using multimeter. 4. Ensuring we practice predictive and preventive maintenance so as to reduce the cost spent on corrective maintenance. 5. Students should develop the interest in adhering and implementing safety procedures which will grant them safety in their work practice. 27 6.0 RECOMMENDATION AND CONCLUSION 6.1 Recommendation Based on my enriching experience in the Student Work Experience Programme II (SWEP II) at Olusegun Agagu University of Science and Technology, I wholeheartedly recommend the continuation and expansion of this program for future students. I believe that by continuing and possibly expanding SWEP II, the university can provide students with a significant advantage in their future careers. It not only enhances their engineering skills but also instills in them a strong work ethic and a commitment to industry standards. 6.2 Conclusion The SWEP II programme was truly transformative and feasible. This experience instilled in me the importance of attention to detail, adherence to safety protocols and responsibility associated with the maintenance of engineering equipment and facilities. I am grateful for the valuable insights and experiences gained during SWEP II, and I look forward to applying this newfound knowledge and expertise in my future endeavors as an engineer. It is a commendable initiative, and I am confident that its continuation and growth will benefit future students, the university, and the engineering field as a whole. I highly recommend that the program be sustained and further developed to ensure that more students can access this astonishing opportunity for professional growth and development. 28