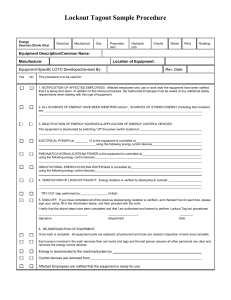

Top Benefits of Using Valve Lockout Devices in Industrial Environments Safety is paramount in industrial environments where complex machinery, hazardous materials, and high-pressure systems are prevalent. Among the many tools used to ensure worker safety, valve lockout devices play a crucial role. These devices prevent the unintended operation of valves, securing machinery or pipelines from accidental energy release. Implementing valve lockout tagout devices is not just a regulatory requirement but also a critical component of a robust safety culture. Here, we explore the top benefits of using valve lockout devices in industrial settings. 1. Enhanced Worker Safety Valve lockout devices act as a physical barrier, preventing the accidental opening or closing of valves. This is especially crucial when workers are performing maintenance or repairs on machinery connected to the valves. These devices effectively isolate hazardous energy sources, including liquids, gases, and steam, thereby reducing the risk of injuries or fatalities caused by unexpected energy releases. For instance, in chemical processing plants, a sudden release of toxic gases due to an unintentional valve operation can have disastrous consequences. Valve lockout devices eliminate such risks, safeguarding workers and the environment. 2. Compliance with Safety Regulations Industrial safety standards, such as OSHA’s Lockout Tagout regulations, mandate the use of lockout devices to control hazardous energy during maintenance activities. Non-compliance with these regulations can lead to hefty fines, legal complications, and reputational damage. Valve lockout devices help industries meet these compliance requirements efficiently. By incorporating these tools into a formal LOTO program, organizations can demonstrate their commitment to safety and avoid penalties associated with regulatory violations. 3. Prevention of Equipment Damage Accidental valve operations can lead to severe equipment damage, especially in systems involving high pressures or temperatures. For example, opening a valve connected to a high-pressure steam line can cause equipment failure, costly repairs, or even complete system shutdowns. Valve lockout devices ensure that valves remain in their intended position, minimizing the risk of mishandling and preventing damage to critical industrial assets. This proactive measure protects the organization’s investment in machinery and infrastructure. 4. Improved Operational Efficiency Safety measures like valve lockout devices contribute significantly to operational efficiency. By securing valves during maintenance, workers can focus on their tasks without the fear of accidental energy release. This creates a more controlled and predictable work environment, reducing downtime and enhancing productivity. Additionally, avoiding unplanned disruptions caused by mishandled valves ensures smoother operations and better adherence to production schedules. Over time, this leads to substantial cost savings and improved performance metrics. 5. Versatility Across Applications Valve lockout devices are available in various types and sizes, making them versatile tools for different applications. Industries such as oil and gas, pharmaceuticals, food processing, and manufacturing can all benefit from their use. Common types of valve lockout devices include: ● Ball Valve Lockouts: Ideal for locking ball valves in the open or closed position. ● Gate Valve Lockouts: Gate valve lockout devices are designed to secure gate valves of various sizes. ● Butterfly Valve Lockouts: Specifically made for butterfly valves, ensuring precise control. ● Plug Valve Lockouts: Used for controlling plug-type valves. This versatility allows industries to implement valve lockout solutions tailored to their specific needs, ensuring comprehensive safety coverage. 6. Promotion of Accountability Valve lockout devices are often used in conjunction with locks and tags that display the name or identification of the individual who applied the lockout. This fosters accountability, as only authorized personnel can remove the lockout device once their tasks are complete. Such a system ensures clear communication among team members and reduces the chances of misunderstandings or premature valve operations. It also strengthens the overall safety culture within the organization. 7. Reduction of Workplace Accidents Statistics show that many workplace accidents occur due to the unexpected release of hazardous energy. By using valve lockout devices, industries can significantly reduce the likelihood of such incidents. These devices are particularly effective in high-risk environments, such as chemical plants, where even a minor mistake can lead to disastrous outcomes. Investing in valve lockout devices is, therefore, a practical way to reduce workplace accidents and create a safer environment for employees. 8. Cost Savings in the Long Run While the upfront cost of purchasing valve lockout devices may seem like an additional expense, the long-term financial benefits far outweigh the initial investment. By preventing accidents, minimizing equipment damage, and avoiding regulatory fines, organizations can save substantial amounts over time. Moreover, enhanced safety measures often lead to lower insurance premiums, further contributing to cost savings. 9. Increased Employee Confidence When workers see that their organization prioritizes their safety by implementing tools like valve lockout devices, it boosts morale and confidence. Employees feel valued and are more likely to perform their duties efficiently in a safe and secure environment. A positive safety culture also encourages workers to report potential hazards, leading to proactive measures that further improve workplace conditions. 10. Support for Sustainability Goals In industries dealing with hazardous substances, accidental energy release can have severe environmental impacts. Valve lockout devices help prevent such incidents, supporting sustainability goals by protecting the environment and reducing waste caused by equipment damage or operational disruptions. Conclusion Valve lockout devices are indispensable tools in industrial safety. They not only protect workers from hazardous energy but also ensure regulatory compliance, prevent equipment damage, and enhance operational efficiency. Their versatility, cost-effectiveness, and role in promoting accountability make them a vital component of any comprehensive Lockout Tagout program. By investing in high-quality valve lockout devices, industries can create a safer, more productive, and sustainable work environment. Safety is not just a regulatory requirement - it’s a responsibility that protects lives, assets, and the future of the organization.