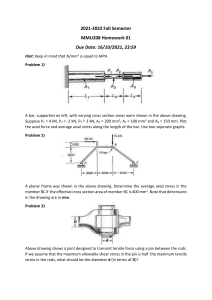

TOPIC 2 – Tension Members (Solution) SITUATION 2 Example 1: A 130 mm x 12 mm plate is used for tension member. It is connected to a gusset plate with 4-16 mm diameter bolt as shown. Assume Ae = An. Fy = 248 MPa and Fu = 345 MPa. Using NSCP 2015 provisions, a) Determine the gross area. b) Determine the net area. Solution: 𝐴𝑔 = 130(12) 𝑨𝒈 = 𝟏, 𝟓𝟔𝟎𝒎𝒎𝟐 Bolt diameter = 16 mm Nominal hole dimension = 18 mm Note: dh = dn + 2 mm An = [130 − 2(18 + 2)](12) 𝐀 𝐧 = 𝟏, 𝟎𝟖𝟎 𝐦𝐦𝟐 = Ae 0.85Ag = 0.85(130)(12) = 1,326 mm2 Ae < 0.85Ag ; ∴ Ok Example 2: Compute the critical net area of the riveted connection shown if the thickness of the plate is 12 mm. Diameter of rivets = 20 mm. SITUATION 3 Nominal hole diameter for 20 mm rivets = 22 mm (Refer to Table 510.3.3) dh = dn + 2 mm = 22 + 2 dh = 24 mm Considering route ABCD: (2 holes only) (50)2 Net width = 300 − 2(24) + 4(175) Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 1 of 10 TOPIC 2 – Tension Members (Solution) Net width = 255.5714 mm Considering route ABECD: (3 holes) (75)2 (25)2 Net width = 300 − 3(24) + 4(100) + 4(75) Net width = 244.1458 mm Use smaller net width, 𝑤𝑛 = 244.1458 mm Net area, 𝐴𝑛 = 𝑤𝑛 𝑡 An = 244.1458(12) 𝐀 𝐧 = 𝟐, 𝟗𝟐𝟗. 𝟕𝟓 𝐦𝐦𝟐 < 0.85𝐴𝑔 = 0.85(300)(12) = 3,060 mm2 Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 2 of 10 TOPIC 2 – Tension Members (Solution) Example 3: SITUATION 4 A single angle tension member 150 mm x 100 mm x 20 mm has two gage lines in its long leg and one in the short leg for 16–mm bolts. If the area of the angular section is 4480 mm2, compute the design net area. Solution: Bolt diameter = 16 mm Nominal dimension of hole = 18 mm dh = 18 + 2 = 20 mm g = 50 + 50 – 20 = 80 mm 6 𝐴𝑛 = 𝐴𝑔 − ∑ 𝐴ℎ𝑜𝑙𝑒𝑠 An = 4480 – 20(20) =4080 mm2 Path 1-2-4-5: An = 4480 – 20(20)(2) = 3680 mm2 Path 1-2-6-4-5: 502 502 An = 4480 – 20(20)(3) + 4(80) (20) + 4(50) (20) = 3686.25 mm2 Use Critical An = 3680 mm2 Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 3 of 10 TOPIC 2 – Tension Members (Solution) SITUATION 5 Example 4: A 130 mm x 12 mm plate is used for tension member. It is connected to a gusset plate with 4-16 mm diameter bolt as shown. Assume Ae = An. Fy = 248 MPa and Fu = 345 MPa. Using NSCP 2015 provisions, a. Determine the design strength based on LRFD. b. Determine the allowable strength based on ASD. From Example 1, 𝐴𝑔 = 1,560𝑚𝑚2 An = 1,080 mm2 = Ae Based on gross area (yielding): 𝑷𝒏 = 𝑭𝒚 𝑨𝒈 Pn = 248(1560) 𝐏𝐧 = 𝟑𝟖𝟔. 𝟖𝟖 𝐤𝐍 (on gross area) Based on net area (rupture): 𝑷𝒏 = 𝑭𝒖 𝑨𝒆 Pn = 345(1,080) 𝑷𝒏 = 𝟑𝟕𝟐. 𝟔𝟎 𝐤𝐍 (on net area) Based on gross area, Based on net area, Pn = 386.88 kN Pn = 372.60 kN LRFD (on gross area): ∅t Pn = (0.90)386.88 ∅𝐭 𝐏𝐧 = 𝟑𝟒𝟖. 𝟏𝟗 𝐤𝐍 ASD (on gross area): Pn /Ωt = 386.88/1.67 𝐏𝐧 /𝛀𝐭 = 𝟐𝟑𝟏. 𝟔𝟔 𝐤𝐍 LRFD (on net area): ∅t Pn = (0.75)372.60 ∅𝐭 𝐏𝐧 = 𝟐𝟕𝟗. 𝟒𝟓 𝐤𝐍 (design strength) ASD (on net area): Pn /Ωt = 372.60/2.00 𝐏𝐧 /𝛀𝐭 = 𝟏𝟖𝟔. 𝟑𝟎 𝐤𝐍 (allowable strength) Choose lowest. LRF ∅𝐭 𝐏𝐧 = 𝟐𝟕𝟗. 𝟒𝟓 𝐤𝐍 (design strength) ASD 𝐏𝐧 /𝛀𝐭 = 𝟏𝟖𝟔. 𝟑𝟎 𝐤𝐍 (allowable strength) Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 4 of 10 TOPIC 2 – Tension Members (Solution) Example 5: SITUATION 6 Given the following data of the slip-critical tension connection shown with 22-mm diameter bolts in standard holes with threads excluded from shear planes. Considering the plates only, compute the design tensile strength (LRFD) and the allowable tensile strength (ASD) using NSCP 2015. (Fy = 248 MPa, Fu = 400 MPa) Solution: • Based on gross area (yielding): 𝑷𝒏 = 𝑭𝒚 𝑨𝒈 Side Plate (350 mm x 12 mm): Ag = 350(12) = 4200 mm2 Pn = 248(4200) 2 Pn = 2083.2 kN Middle Plate (350 mm x 22 mm): Ag = 350(22) = 7700 mm2 Pn = 248(7700) = 1,909.6 kN Use the lower value. Therefore, Pn = 1,909.6 kN (based on gross area, middle plate governs) • Based on net area (rupture): 𝑷𝒏 = 𝑭𝒖 𝑨𝒆 Bolt diameter = 22 mm Nominal hole dimension = 24 mm Note: dh = dn + 2 mm Side Plate (350 mm x 12 mm): An = [350 − 3(24 + 2)](12) = 3,264 mm2 = Ae 0.85Ag = 0.85(350)(12) = 3,570 mm2 Ae < 0.85Ag ; ∴ Ok Pn = 400(3,264) 2 Pn = 2,611.2 kN Middle Plate (350 mm x 22 mm): An = [350 − 3(24 + 2)](22) = 5,984 mm2 = Ae 0.85Ag = 0.85(350)(22) = 6,545 mm2 Ae < 0.85Ag ; ∴ Ok Pn = 400(5,984) Pn = 2,393.6 kN Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 5 of 10 TOPIC 2 – Tension Members (Solution) Use the lower value. Therefore, Pn = 2,393.6 kN (based on net area, middle plate governs) Based on gross area, Based on net area, Pn = 1,909.6 kN Pn = 2,393.6 kN LRFD (on gross area): ∅t Pn = (0.90)1,909.6 ∅𝐭 𝐏𝐧 = 𝟏, 𝟕𝟏𝟖. 𝟔𝟒 𝐤𝐍 (design strength) ASD (on gross area): Pn /Ωt = 1,909.6/1.67 𝐏𝐧 /𝛀𝐭 = 𝟏, 𝟏𝟒𝟑. 𝟒𝟕 𝐤𝐍 (allowable strength) LRFD (on net area): ∅t Pn = (0.75)2,393.6 ∅𝐭 𝐏𝐧 = 𝟏, 𝟕𝟗𝟓. 𝟐𝟎 𝐤𝐍 ASD (on net area): Pn /Ωt = 2,393.6/2.00 𝐏𝐧 /𝛀𝐭 = 𝟏, 𝟏𝟗𝟔. 𝟖𝟎 𝐤𝐍 LRFD ∅𝐭 𝐏𝐧 = 𝟏, 𝟕𝟏𝟖. 𝟔𝟒 𝐤𝐍 (design strength) ASD 𝐏𝐧 /𝛀𝐭 = 𝟏, 𝟏𝟒𝟑. 𝟒𝟕 𝐤𝐍 (allowable strength) Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 6 of 10 TOPIC 2 – Tension Members (Solution) Example 6: SITUATION 7 Determine the LRFD design tensile strength and the ASD allowable tensile strength for an A36 (F y = 248 MPa and Fu = 400 MPa) L 150 x 150 x 10 that is connected at its ends with one line of four 22mm diameter bolts in standard holes 75 mm on center in one leg of the angle. Properties of L 150 x 150 x 10: Ag=2,927.47 mm2 x =40.34 mm Solution: • Based on gross area (yielding): 𝑷𝒏 = 𝑭𝒚 𝑨𝒈 Pn = (248)(2,927.47) 𝐏𝐧 = 𝟕𝟐𝟔. 𝟎𝟏 𝐤𝐍 (𝐛𝐚𝐬𝐞𝐝 𝐨𝐧 𝐠𝐫𝐨𝐬𝐬 𝐲𝐢𝐞𝐥𝐝𝐢𝐧𝐠) • Based on net area (rupture): Bolt diameter = 22 mm Nominal hole dimension = 24 mm Note: dh = dn + 2 mm An = 2,927.47 mm2 − (24 + 2)(10) = 2,667.47 mm2 𝑥̅ From Table 504.3.1 (Case 2), 𝑈 = 1 − 𝐿 𝑥̅ = 40.34 mm L = 3(75 mm) = 225 mm 40.34 = 0.8207 225 From Table 504.3.1 (Case 8), for 4 or more fasteners in the direction of loading, 𝑈 = 0.80. Use calculated 𝑈 = 0.82. Ae = U An = 0.8207(2,667.47 mm2 ) = 2,189.19 mm2 Pn = Fu Ae Pn = (400)(2189.19) 𝐏𝐧 = 𝟖𝟕𝟓. 𝟔𝟖 𝐤𝐍 (based on tensile rupture) 𝑈 =1− Based on gross section yielding, Pn = 726.01 kN Based tensile rupture strength, Pn = 875.68 kN LRFD (on gross section yielding): ASD (on gross section yielding): ∅t Pn = (0.90)726.01 Pn /Ωt = 726.01/1.67 ∅𝐭 𝐏𝐧 = 𝟔𝟓𝟑. 𝟒𝟏 𝐤𝐍 (design strength) 𝐏𝐧 /𝛀𝐭 = 𝟒𝟑𝟒. 𝟕𝟒 𝐤𝐍 (allowable strength) LRFD (on tensile rupture): ASD (on tensile rupture): (0.75)875.68 ∅t Pn = Pn /Ωt = 875.68 /2.00 ∅𝐭 𝐏𝐧 = 𝟔𝟓𝟔. 𝟕𝟔 𝐤𝐍 𝐏𝐧 /𝛀𝐭 = 𝟒𝟑𝟕. 𝟖𝟒 𝐤𝐍 Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 7 of 10 TOPIC 2 – Tension Members (Solution) Block Shear Example 7: SITUATION 8 The A572 Grade 50 (Fy = 345 MPa, Fu = 448 MPa) tension member shown is connected with three 18-mm bolts. For the given member, determine the following: a. LRFD design block shear rupture strength. b. ASD allowable block shear rupture strength. Properties of L 150 x 90 x 12: Ag = 2,751.45 mm2 x =21.16 mm Sol’n: Nominal hole dimension = 20 mm Note: dh = dn + 2 mm (a) and (b) For Block shear strength: 𝑷𝒏 = 𝟎. 𝟔𝑭𝒖 𝑨𝒏𝒗 + 𝑼𝒃𝒔 𝑭𝒖 𝑨𝒏𝒕 Anv = [250 − 2.5(20 + 2)](12) = 2,340 mm2 Ant = [62.5 − 0.5(20 + 2)](12) = 618 mm2 Ubs = 1.0 Pn = 0.6(448)(2,340) + 1.0(448)(618) 𝐏𝐧 = 𝟗𝟎𝟓. 𝟖𝟔 𝐤𝐍 𝑷𝒏(𝒎𝒂𝒙) = 𝟎. 𝟔𝑭𝒚 𝑨𝒈𝒗 + 𝑼𝒃𝒔 𝑭𝒖 𝑨𝒏𝒕 Agv = 250(12) = 3,000 mm2 Pn(max) = 0.6(345)(3,000) + 1.0(448)(618) 𝐏𝐧(𝐦𝐚𝐱) = 𝟖𝟗𝟕. 𝟖𝟔 𝐤𝐍 𝐏𝐧 > 𝐏𝐧(𝐦𝐚𝐱) ∴ Use 𝐏𝐧(𝐦𝐚𝐱) = 𝟖𝟗𝟕. 𝟖𝟔 𝐤𝐍 (for block shear rupture strength) a. LRFD block shear rupture strength ∅t Pn = 0.75(897.86 kN) = 𝟔𝟕𝟑. 𝟒𝟎 𝐤𝐍 b. ASD allowable block-shear rupture strength Pn /Ω𝑡 = (897.86 kN)/2.00 = 𝟒𝟒𝟖. 𝟗𝟑 𝐤𝐍 Engr. Sean Kenneth Anthony B. Pamintuan, CE, ME-1 PRINSTEEL Page 8 of 10 TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8) a) Allowable strength based on yielding (ASD) b) Design strength based on rupture (LRFD) - tensile rupture on the net area TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8 Page 1 TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8) As per Case 7, TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8 Page 2 TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8) c.) Ultimate strength based on block shear Considering only one side of a flange of block shear and assuming that the tensile force P is acting concentrically on the member. TOPIC 2 - TENSION MEMBERS (Block Shear - Example 8 Page 3