NDT Handbook, Third Edition Volume 2, PT

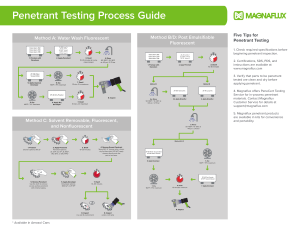

advertisement