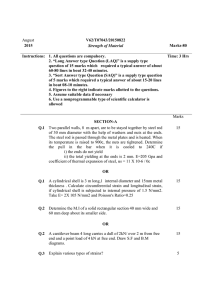

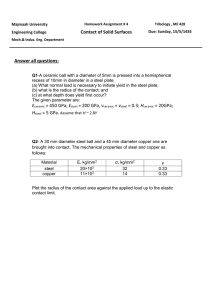

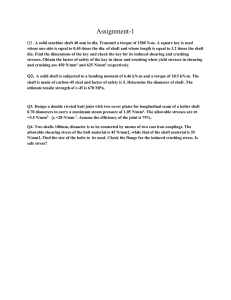

LAB MANUAL 3141907 Fundamentals of Machine Design Mechanical Engineering Department GOVERNMENT ENGINEERING COLLEGE, BHUJ INDEX Sr. Particulars CO No. 1. Design based problems on basics of stresses and CO1 strains 2. Theory and problems on Moment of Inertia of CO1 Planner Cross section 3. Design based problems on flexural stresses CO2 4. Design based problems on torsion CO2 5. Problems on design against static loading CO4 6. Design of joints (cotter and knuckle) and levers CO4 7. Design based problems on columns and struts CO3 8. Design of shafts and keys CO4 9. Design problems on power screws and CO4 threaded joints 10 Design against fluctuating loading . CO5 Practical: Basics of Stresses and Strains Attempt the following design-based problems: 1. A rod 200 cm long and of diameter 3.0 cm is subjected to an axial pull of 30 kN. If the Young's modulus of the material of the rod is 2 x 105 N/mm2, determine : (i) stress, (ii) strain and (iii) the elongation of the rod. [Ans. (i) 42.44 N/mm2 (ii) 0.000212 (iii) 0.0424 cm] 2. Find the Young's modulus of a rod of diameter 30 mm and of length 300 mm which is subjected to a tensile load of 60 kN and the extension of the rod is equal to 0.4 mm. [Ans. 63.6 GN/m2] 3. The safe stress for a hollow steel column, which carries an axial load of 2.2 x 103 kN is 120 MN/m2. If the external diameter of the column is 25 cm, determine the internal diameter. [Ans. 19.79 cm] 4. A member formed by connecting a steel bar to an aluminium bar is shown in Figure. Assuming that the bars are prevented from, buckling sideways, calculate the magnitude of force P, that will cause the total length of the member to decrease 0.30 mm, The values of elastic modulus for steel and aluminium are 2x 105 N/mm2 and 6.5 x 104 N/mm2 respectively. [Ans. 406.22 kN] 5. A brass bar, having cross-section area of 900 mm2, is subjected to axial forces as shown in Figure, in which AB = 0.6 m, BC = 0.8 m and CD = 1.0 m. Find the total elongation of the bar. Take E = 1 x 105 N/mm2. [Ans. -0.111 mm] 6. A steel rod of cross-sectional area 1600 mm2 and two brass rods each of cross-sectional area of 1000 mm2 together support a load of 50 kN as shown in Figure. Find the stresses in the rods. Take E for steel = 2 x 105 N/mm2 and E for brass = 1 x 105 N/mm2. [Ans. Stress in brass = 12.1 N/mm2 and stress in steel = 16.12 N/mm2]. 7. A rod is 3 m long at a temperature of 15 o C. Find the expansion of the rod when the temperature is raised to 95 o C. If this expansion is prevented, find the stress induced in the material of the rod. Take E = 1 x 105 N/mm2 and α = 0.000012 per degree centigrade. [Ans. 0.288 cm, 96 N/mm2] 8. Determine the changes in length, breadth and thickness of a steel bar which is 5 m long, 40 mm wide and 30 mm thick and is subjected to an axial pull of 35 kN in the direction of its length. Take E = 2 X 105 N/mm2 and Poisson's ratio = 0.32. [Ans. 0.0729 cm, 0.000186 cm, 0.000139 cm] 9. For the above problem, determine the volumetric strain and the final volume of the given steel bar. [Ans. 0.0000525, 6000317 mm3] 10. Determine the value of Young's modulus and Poisson's ratio of a metallic bar of length 25 cm, breadth 3 cm and depth 2 cm, when the bar is subjected to an axial compressive load of 240 kN. The decrease in length is given as 0.05 cm and increase in breadth is 0.002. [Ans. 2 x 105 N/mm2 and 0.33] 11. A steel bar 320 mm long, 40 mm wide and 30 mm thick is subjected to a pull of 250 kN in the direction of its length. Determine the change in volume. Take E = 2 X 105 N/mm2 and m = 4. [Ans. 200 mm3] 12. A metallic bar 250 mm x 80 mm x 30 mm is subjected to a force of 20 kN (tensile), 30 kN (tensile) and 15 kN (tensile) along x, y and z direction respectively. Determine the change in the volume of the block. Take E = 2 x 105 N/mm2 and Poisson's ratio = 0.25. [Ans. 19.62 mm3] 13. A steel rod 4 m long and 20 mm diameter is subjected to an axial tensile load of 40 kN. Determine the change in length, diameter and volume of the rod. Take E = 2 x 105 N/mm2 and Poisson's ratio = 0.25. [Ans. 2.5464, 0.05092, 5598 mm3] 14. Derive the relation between E and G. Estimate the Young’s modulus (E) when the modulus of rigidity (G) is 0.80 x 105 N/mm2 and the Poisson’s ratio is 0.3. [Ans. 2.08 x 105 N/mm2] FMD 2. Moment of Inertia of Planner Cross section Objective Questions 1. Whenever the distributed loading acts perpendicular to an area its intensity varies __________ a) Linearly b) Non-Linearly c) Parabolically d) Cubically 2. The axis about which moment of area is taken is known as ____________ a) Axis of area b) Axis of moment c) Axis of reference d) Axis of rotation 3. What is the formula of theorem of perpendicular axis? a) Izz = Ixx – Iyy b) Izz = Ixx + Ah2 c) Izz – Ixx = Iyy d) none of the mentioned 4. What is the formula of theorem of parallel axis? a) IAD = IG + Ah b) IAB = Ah2 + IG c) IAB = IG – Ah2 d) IAB = IG + Ixx 5. What is the unit of Area moment of inertia (radius of gyration)? a) m4 b) m c) N d) m2 6. What will be the the area moment of inertia of a circular plate of diameter 10cm? a) 1.5cm b) 2.0cm c) 2.5cm d) 3cm Descriptive Questions 1. 2. 3. 4. Define Moment of Inertia. What is second moment of area? State and prove the parallel axis theorem State and prove the perpendicular axis theorem. 5. Give equation for the following by explaining each term used in that equation :a) Moment of inertia of a rectangular section. b) Moment of inertia of a triangular section about an axis passing through its centroid and parallel to base. c) Moment of inertia of circular section. 6. Find the centroid of shaded section shown in fig 1. 7. The irregular area (fig 2) has a moment of inertia about the AA axis of 35 (106) mm4. If the total area is 12.0(103) mm2, determine the moment of inertia of the area about the BB axis. The DD axis passes through the centroid C of the area. 8. Find the C.G. of an angle plate (fig 3) having thickness 10 mm and base 100 mm wide. Also find moment of inertia about horizontal axis passing through C.G. of an angle plate. 9. Determine the moment of inertia of Z section (Fig 4) about its centeroidal X-X and Y-Y axis. 10. The cross section area of bearing is shown by shaded area in fig 5. Find the moment of inertia about base a-a. 11. Prove that Moment of inertia of triangular section about its centerodial axis is IG = bh3 / 36 12. Find the moment of inertia of hollow circular section having outer and inner diameter are 55mm and 25mm respectively. Practical. Flexural Stresses Attempt the following design-based problems: 1. A steel plate of width 60 mm and of thickness 10 mm is bent into a circular arc of radius 10 m. Determine the maximum stress induced and the bending moment which will produce the maximum stress. Take E = 2 X 105 N/mm2• [Ans. 100 N/mm2; 100 Nm] 2. A cast iron pipe of external diameter 60 mm, internal diameter of 40 mm, and of length 5 m is supported at its ends. Calculate the maximum bending stress induced in the pipe if it carries a point load 100 N at its centre. [Ans. 7.34 N/mm2] 3. A rectangular beam 300 mm deep is simply supported over a span of 4 m. What uniformly distributed load per metre, the beam may carry if the bending stress is not to exceed 120 N/mm2? Take I = 8 X 106 mm4, [Ans. 3.2 kN/m] 4. A cast iron cantilever of length 1.5 metre fails when a point load W is applied at the free end. If the section of the beam is 40 mm x 60 mm and the stress at the failure is 120 N/mm2, find the point load applied. . [Ans. 1.92 kN] 5. A cast iron beam 20 mm x 20 mm in section and 100 cm long is simply supported at the ends. It carries a point load W at the centre. The maximum stress induced is 120 N/mm2. What uniformly distributed load will break a cantilever of the same material 50 mm wide, 100 mm deep and 2 m long? [Ans. 5 kN per m run] 6. A timber beam is 120 mm wide and 200 mm deep and is used on a span of 4 metres. The beam carries a uniformly distributed load of 2.8 kN/m run over the entire length. Find the maximum bending stress induced. [Ans. 7 N/mm2] 7. A timber cantilever 200 mm wide and 300 mm deep is 3 m long. It is loaded with a U.D.L. of 3 kN/m over the entire length. A point load of 2.7 kN is placed at the free end of the cantilever. Find the maximum bending stress produced. [Ans. 7.2 N/mm2] 8. A timber beam is freely supported on supports 6 m apart. It carries a uniformly distributed load of 12 kN/m run and a point load of 9 kN at 3.5 m from the right support. Design a suitable section of the beam making depth twice the width, if the stress in timber is not to exceed 8 N/mm2• [Ans. 230 mm x 460 mm] 9. A beam of I-section shown in Figure is simply supported over a span of 4 metres. Determine the load it can carry per metre length if the allowable stress is 30.82 N/mm2. [Ans. 2.5 kN per metre] 10. A beam is of T-section as shown in Figure. The beam is simply supported over a span of 4 m and carries a uniformly distributed load of 1.7 kN/m run over the entire span. Determine the maximum tensile and maximum compressive stress. [Ans. 8 N/mm2 and 4.8N/mm2] 11. A simply supported beam of length 4 m carries a point load of 16 kN at a distance of 3 m from left support. The cross-section of the beam is shown in Figure. Determine the maximum tensile and compressive stress at a section which is at a distance of 2.25 m from the left support. [Ans. 24.9 N/mm2; 27.84 N/mm2] Practical: Torsion Attempt the following design-based problems: 1. A solid shaft of 20 cm diameter is used to transmit torque. Find the maximum torque transmitted by the shaft if the maximum shear stress induced in the shaft is 50 N/mm2•. [Ans. 78539.8 Nm] 2. The shearing stress in a solid shaft is not to exceed 45 N/mm2 when the torque transmitted is 40000 N-m. Determine the minimum diameter of the shaft. [Ans. 16.49 mm] 3. Find the maximum torque transmitted by a hollow circular shaft of external diameter 30 cm and internal diameter 15 cm, if the shear stress is not to exceed 40 N/mm2. [Ans. 198.8 kN] 4. Two shafts of the same material and of same lengths are subjected to the same torque, if the first shaft is of a solid circular section and the second shaft is of hollow circular section, whose internal diameter is 0.7 times the outside diameter and the maximum shear stress developed in each shaft is the same,' compare the weights of the shafts. [Ans. 1.633:1] 5. Find the maximum shear stress induced ·in a solid circular shaft of diameter 20 cm when the shaft transmits 187.5 kW at 200 r.p.m. [Ans. 5.7 N/mm2] 6. A solid circular shaft is to transmit 375 kW at 150 r.p.m. (i) Find the diameter of the shaft if the shear stress is not to exceed 65 N/mm2• (ii) What percent savings in weight would be obtained if this shaft is replaced by a hollow shaft whose internal diameter equal to 2/3 of its external diameter; the length, the material, and maximum shear stress being the same? [Ans. (i) 12.29 cm (ii) 35.71%] 7. A hollow shaft is to transmit 337.5 kW at 100 r.p.m, If the shear stress is not to exceed 65 N/mm2 and the internal diameter is 0.6 of the external diameter, find the external and internal diameters, assuming that the maximum torque is 1.3 times the. mean. [Ans. 15.52 cm; 9.312 cm] Practical. Design Against Static Loading Attempt the following design-based problems: 1. A C-frame subjected to a force of 15 kN is shown in Figure. It is made of grey cast iron FG300 and the factor of safety is 2.5. Determine the dimensions of the crosssection of the frame. [t = 15.81 mm] 2. The link of S-shape made of a round steel bar is shown in Figure. It is made of plain carbon steel 45C8 (Syt = 380 N/mm2). The factor of safety is 4.5. Calculate dimensions of the link. [d = 23.38mm] 3. The frame of a 100 kN capacity press is shown in Figure. Material is grey cast iron FG300 and factor of safety is 2.5. Determine the cross-sectional dimensions at section XX. [t = 26.62 mm] 4. A bracket made of steel FeE200 (Syt = 200 N/mm2) and subjected to a force of 5 kN is shown in Figure. The factor of safety is 4. Determine its cross-sectional dimensions. [t = 33.5 mm] 5. Figure shows a C-clamp, which carries a load P of 25 kN. The cross-section of the clamp is rectangular. The ratio of width to thickness (b/t) is 2:1. The clamp is made of cast steel of grade 20-40 (Sut = 400 N/mm2) and the factor of safety is 4. Determine the cross-sectional dimensions. [t = 38.5 mm] Practical: Cotter- and Knuckle-joint; Levers Attempt the following design-based problems: 1. It is required to design a cotter joint to connect two steel rods of equal diameter. Each rod is subjected to an axial tensile force of 50 kN. Design the joint and specify its main dimensions. Draw the assembled view of the joint in an A3-size drawing sheet and show the principal dimensions. 2. It is required to design a knuckle joint to connect two circular rods subjected to an axial tensile force of 50 kN. The rods are co-axial and a small amount of angular movement between their axes is permissible. Design the joint and specify the dimensions of its components. Select suitable materials for the parts. Draw the assembled view of the joint in an A3-size drawing sheet and show the principal dimensions. 3. A lever-loaded safety valve is mounted on the boiler to blow off at a pressure of 1.5 MPa gauge. The effective diameter of the opening of the valve is 50 mm. The distance between the fulcrum and the dead weights on the lever is 1000 mm. The distance between the fulcrum and the pin connecting the valve spindle to the lever is 100 mm. The lever and the pin are made of plain carbon steel 30C8 (Syt = 400 N/mm2) and the factor of safety is 5. The permissible bearing pressure at the pins in the lever is 25 N/mm2. The lever has a rectangular cross-section and the ratio of width to thickness is 3:1. Design a suitable lever for the safety valve and show its major dimensions with a neat figure. 4. A right angled bell-crank lever is to be designed to raise a load of 5 kN at the short arm end. The lengths of short and long arms are 100 and 450 mm respectively. The lever and the pins are made of steel 30C8 (Syt = 400 N/mm2) and the factor of safety is 5. The permissible bearing pressure on the pin is 10 N/mm2. The lever has a rectangular cross-section and the ratio of width to thickness is 3:1. The length to diameter ratio of the fulcrum pin is 1.25:1. Calculate (i) The diameter and the length of the fulcrum pin (ii) The shear stress in the pin (ii) The dimensions of the boss of the lever at the fulcrum (iii) The dimensions of the cross-section of the lever. Assume that the arm of the bending moment on the lever extends up to the axis of the fulcrum. Practical: Columns and Struts Attempt the following design-based problems: 1. A solid round bar 4 metre long and 6 cm in diameter is used as a strut with both hands hinged. Determine the crippling load. Take E = 2 X 105 N/mm2. [Ans. 78.486 kN] 2. A column of timber section 10 cm X 15 cm is 5 metre long with both hands being fixed. If the Young's modulus for timber = 17.5 kN/mm2, determine: (i) Crippling load, and (ii) Safe load for the column if factor of safety = 3. [Ans. (i) 45.4 kN and (ii) 115.1 kN] 3. A solid circular bar 5 metre long and 4 cm in diameter was found to extend 4.5 millimetre under a tensile load of 48 kilo Newton. The bar is used as a Strut with both ends hinged. Determine the buckling load for the bar and also the safe load taking factor of safety as 3.0. [Ans. 2105.5 N and 701.8 N] 4. Determine Euler’s crippling load for an I-section joist 30 cm X 15 cm X 2 cm and 5 metre long, which is used as a Strut with both hands fixed. Take the Young's modulus for the joist as 2 X105 Newton per square millimetre. [Ans. 3.6 Mega Newton] 5. Determine the ratio of buckling strengths of two columns, one hollow and the other solid. Both are made of the same material and have the same length, cross-sectional area, and end conditions. The internal diameter of hollow column is 2/3 of its external diameter. [Ans. 2.6:1] 6. A hollow cylindrical cast iron column is 6 metre long with both ends fixed. Determine the minimum diameter of the column if it has to carry the safe load of 300 kilo Newton with the factor of safety of 4. Take the internal diameter as 0.7 times the external diameter. Take crushing stress = 550 N/mm2 and Rankine’s constant = 1/1600. [Ans. D = 9.53 cm, d = 6.67 cm] 7. A short length of tube, 5 cm internal diameter and 6 cm external diameter, failed in compression at a load of 250 kilo Newton. When 2.5 metre length of the same tube was tested as a strut with fixed ends, the load at failure was 150 kilo Newton. Assuming that crushing stress in Rankine’s formula is given by the first test, find the value of Rankine’s constant in the same formula. What will be the crippling load of this tube if it is used as a strut 3.2 metre long with one end fixed and the other hinged. [Ans. 1/6148, 78.5 kN] 8. A 1.5-metre long column has a circular cross section of 0.5 cm diameter. One of the ends of the column is fixed in direction and position and the other end is free. Taking factor of safety as 3, calculate the safe load using (i) Rankine formula with crushing stress 560 N/mm2 and Rankine constant = 1/1600 for pinned ends and (ii) Euler’s formula with E for C.I. = 1.2 x 105 N/mm2. [Ans. (i) 9.9 kN, (ii) 13.45 kN] Practical: Shafts & Keys Attempt the following design-based problems: 1. A centrifugal pump is driven by a 10 kW-power 1440-rpm electric motor. There is a reduction gearbox between the motor and the pump. The pump shaft rotates at 480 rpm. The design torque is 150% of the rated torque. The motor and pump shafts are made of plain carbon steel 40C8 (S yt = 380 N/mm2) and the factor of safety is 4. Assume (S sy = 0.5Syt ) Calculate: (i) diameter of the motor shaft ;and (ii) diameter of the pump shaft. [(i) 22.01 mm, (ii) 31.75 mm] 2. A transmission shaft is supported between two bearings, which are 750 mm apart. Power is supplied to the shaft through a coupling, which is located to the left of the left-hand bearing. Power is transmitted from the shaft by means of a belt pulley, 450 mm in diameter, which is located at a distance of 200 mm to the right of the left-hand bearing. The weight of the pulley is 300 N and the ratio of the belt tension of tight and slack sides is 2:1. The belt tensions act in a vertically downward direction. The shaft is made of steel FeE 300 (Syt = 300 N/mm 2) and the factor of safety is 3. Determine the shaft diameter, if it transmits 12.5 kW power at 300 rpm from the coupling to the pulley. Assume (Ssy = 0.5Syt) [45.31 mm] 3. A propeller shaft is required to transmit 50 kW power at 600 rpm. It is a hollow shaft, having an inside diameter 0.8 times of the outside diameter. It is made of steel (S yt = 380 N/mm2) and the factor of safety is 4. Calculate the inside and outside diameters of the shaft. Assume (Ssy =0.5Syt) [41.98 and 52.48 mm] 4. An intermediate shaft of a gearbox, supporting two spur gears A and B and mounted between two bearings C1 and C2, is shown in Fig. The pitch circle diameters of gears A and B are 500 and 250 mm respectively. The shaft is made of alloy steel 20MnCr5. (Sut = 620 and Syt = 480 N/mm2). The factors kb and kt of the ASME code are 2 and 1.5 respectively. The gears are keyed to the shaft. Determine the shaft diameter using the ASME code. [27.15 mm] 5. Assume the data of the intermediate shaft illustrated in Problem 4. The permissible angle of twist for the shaft is 0.25° per metre length and the modulus of rigidity is 79 300N/mm2. Determine the shaft diameter on the basis of torsional rigidity. [45.3 mm] 6. The cross-section of a fl at key for a 40-mm diameter shaft is 22 X 14 mm. The power transmitted by the shaft to the hub is 25 kW at 300 rpm. The key is made of steel (Syc =Syt = 300 N/mm2) and the factor of safety is 2.8. Determine the length of the key. Assume (Ssy = 0.577 Syt) [53.05 mm] 7. It is required to design a square key for fixing a pulley on the shaft, which is 50 mm in diameter. The pulley transmits 10 kW power at 200 rpm to the shaft. The key is made of steel 45C8 (Syt = Syc = 380 N/mm2) and the factor of safety is 3. Determine the dimensions of the key. Assume (Ssy = 0.577Syt) [12.5 X 12.5 X 25 mm] 8. A flat key is used to connect a pulley to a 45-mm diameter shaft. The standard cross section of the key is 14 X 9 mm. The key is made of commercial steel (Syc = Syt =230 N/mm2) and the factor of safety is 3. Determine the length of the key on the basis of shear and compression considerations, if 15 kW power at 360 rpm is transmitted through the keyed joint. Assume (Ssy = 0.5S) [32.95 and 51.26 mm] Practical. Power Screws & Threaded Jts Attempt the following design-based problems: 1. A double-threaded power screw, used for lifting a load, has a nominal diameter of 30 mm and a pitch of 6 mm. The coefficient of friction at the screw threads is 0.1. Neglecting collar friction, calculate: (i) efficiency of the screw with square threads; and (ii) efficiency with Acme threads (2Θ= 29°). [(i) 57.76 %, (ii) 56.96 %] 2. A double-threaded power screw is used to raise a load of 5 kN. The nominal diameter is 60 mm and the pitch is 9 mm. The threads are Acme type (2Θ= 29°) and the coefficient of friction at the screw threads is 0.15. Neglecting collar friction, calculate: (i) the torque required to raise the load; (ii) the torque required to lower the load; and (iii) the efficiency of the screw for lifting load.[(i) 36.39 N-m, (ii) 7.06 N-m, (iii) 39.35%] 3. A 50 kN capacity screw jack consists of a square-threaded steel screw meshing with a bronze nut. The nominal diameter is 60 mm and the pitch is 9 mm. The permissible bearing pressure at the threads is 10 N/mm2. Calculate: (i) the length of the nut; and (ii) the transverse shear stress in the nut. [(i) 63 mm (ii) 8.42 N/mm2] 4. A triple-threaded power screw, used in a screw jack, has a nominal diameter of 50 mm and a pitch of 8 mm. The threads are square and the length of the nut is 48 mm. The screw jack is used to lift a load of 7.5 kN. The coefficient of friction at the threads is 0.12 and the collar friction is negligible. Calculate: (i) the principal shear stress in the screw body; (ii) the transverse shear stresses in the screw and the nut; and (iii) the unit bearing pressure. State whether the screw is selflocking. [(i) 4.39, (ii) 2.37 and 1.99, (iii) 2.16 N/mm2] Practical. Design Against Fluctuating Load Attempt the following design-based problems: 1. A rectangular plate, 15 mm thick, made of a brittle material is shown in Figure. Calculate the stresses at each of three holes of 3, 5 and 10 mm diameter. [161.82, 167.33 and 200 N/mm2] 2. A shaft carrying a load of 5 kN midway between two bearings is shown in Figure. Determine the maximum bending stress at the fillet section. Assume the shaft material to be brittle. [20.39 N/mm2] 3. A plate, 10 mm thick, subjected to a tensile load of 20 kN is shown in Figure. The plate is made of cast iron (Sut = 350 N/mm2) and the factor of safety is 2.5. Determine the fillet radius. [2.85 or 3 mm] 4. A 25 mm diameter shaft is made of forged steel 30C8 (Sut = 600 N/mm2). There is a step in the shaft and the theoretical stress concentration factor at the step is 2.1. The notch sensitivity factor is 0.84. Determine the endurance limit of the shaft if it is subjected to a reversed bending moment. [59.67 N/mm2] 5. A 40 mm diameter shaft is made of steel 50C4 (Sut = 660 N/mm2) and has a machined surface. The expected reliability is 99%. The theoretical stress concentration factor for the shape of the shaft is 1.6 and the notch sensitivity factor is 0.9. Determine the endurance limit of the shaft. [112.62 N/mm2]