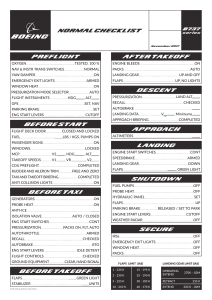

ATR NORMAL PROCEDURES Last Updated: 5th Nov 2017 TheAirlinePilots.com • Basic Learning Blocks • Departure Preparation • Exterior Inspection • Preliminary Cockpit Preparation (Safety Checks) • Cockpit Preparation • Final Cockpit Preparation • Departure Briefing / Abort Items • Engine 2 Start (Hotel Mode) • Load and Trim Sheet • Before Propeller Rotation • An Overview till “Before Taxi” • Before Taxi • Taxi • Before Takeoff • Takeoff • Climb • Cruise • Approach Briefing • Descent Preparation • Descent Procedure • Torque Preset • Standard Precision Approach • Non Precision Approach • Normal Low Visibility Circling Approach • Stabilized Visual Approach • Landing • Go Around 2 Engines • Parking • Do Items before Shutting Engine No 2 – Without GPU • Disclaimer 1 BASIC LEARNING BLOCKS Man, Machine Environment Exterior Inspection Preliminary Cockpit Prep Cockpit Prep ATIS & Takeoff Data Card Briefing & Checklist Engine 2 Start in Hotel Mode Load & Trimsheet Takeoff Data Card Before Prop Rotation Engine 1 Start Before Taxi Taxi Before Takeoff Takeoff Climb Cruise Descent & Approach Landing Parking 2 DEPARTURE PREPARATION CM1 Man • • CM2 Crew Documents Cabin Crew Briefing o Introduction / Documents o Flight Time, Altitude, WX / Turbulence o Security Code, Emergency Procedures o Special Instructions Machine Tech Log • Clearance • Previous snags and rectification • Periodic checks due MEL / DDG • Penalties • Procedures Documents mentioned in SOP (Ref: Chapter 2 page 4) Environment • • Weather Cabin Status (temperature, catering etc.) EXTERIOR INSPECTION – CM2 PARKING BRAKE ACCU PRESSURE …… CHECK 1600 PSI MINIMUM TAIL PROP MUST BE INSTALLED FOR BOARDING ON ATR72 3 PRELIMINARY COCKPIT PREPARATION – CM2 Life Can be Lived LOOSE ITEMS CBs LEVERS Easily EEC With WIPERS Human Beings HORIZON & BATTERY Mediating Peace MFC POWER Emergency Equipment Check 1 Gear Pins and Covers On Board Documentation On Board CB Lateral and Overhead Panels Check PL 1 & 2 GI Gust Lock ON CL 1 & 2 Fuel SO Flaps Lever & Indicator Set 2 Landing Gear Lever DOWN EEC 1 & 2 Depressed IN / No Light Wipers OFF STBY Horizon Erection Knob PULL to Cage Battery ON STBY Horizon Erection Knob Release 3 – Check No Flag MFC Auto Test Check 4 EMER & ESS Bus Supply Indication Arrows Illuminated UNDV No Light 5 DC External Power – Available ON 6 DC External Power – Not Available Hotel Mode ENG 2 Fire Test Perform Tailwind / Gusts < 10 knots. ATPCS Static Test Perform Fuel Pump 2 ON Prop Brake ON (In Tailwind – OFF) Wing Lights ON ENG Bleed OFF ENG 2 Start in Hotel Mode 7 Service Door Closed: • Loading complete • Catering uploaded Area Clear: • Refueling complete • AC van removed Wind direction to avoid exhaust wash over passenger door. 1 Life Jackets, Gloves, Goggles, Fire Extinguisher, Axe, Landing gear emergency Ext handle, Rope, Exit Hatch. Wear your JACKET, put on the GLOVES / GOGGLES. Hold FIRE EXTINGUISHER in one hand & AXE in the other. Step on the GEAR HANDLE, climb out of the HATCH and slide down the ROPE. 2 In accordance with actual flap position. Do not activate hydraulics with ground clearance. 3 10 secs after battery ON. 4 1A 2A flashing (only if cargo door panel closed), then 1B 2B flashing. 5 Check battery voltage on captain lateral console. 6 Check: • BTC – Online, EMER & MAIN BATT – Charging. • EMER & ESS BUS Supply Indicator Arrows – Extinguished, UNDV Light – Extinguished. 7 “NAC Overheat Checklist” recommended to be kept open for ready reference when using hotel mode. 4 COCKPIT PREPARATION – CM2 Main Approach is to: (1) Extinguish White Lights (Except Probe Heat) (2) Test Systems (3) Flight Preparation. Note: Start with annunciator light test. All lights will illuminate except FUEL LO LVL and engine gauges. Short Transit Tests: ENGINE FIRE, FUEL QTY, ATPCS, AUTO PRESS. (Fuel, Fire, Power, Pressurization). 5 FINAL COCKPIT PREPARATION CM1 Call – “Final Cockpit Preparation Procedure” Parking Brake On (check pressure) Fuel Quantity (check and balanced) CM2 ATIS T/O Data Card (1st Part) Altimeters (Own + Standby) Signs ON Memo Panel GNSS Preparation Altimeters Landing Elevation Fuel Used - Reset OBJ and RTO TQ – Set / Check Check Torque, Seat Belts/Harness, Rudder Pedals NAVAIDs – Source and Course – Departure Briefing by PF Call – “Final Cockpit Preparation Proc Complete” 6 TAKEOFF BRIEFING – CM1 • • • • • This will be a left/right seat take off. Standard calls, 70/90 knots, V1, Rotate. If any malfunction occurs Before V1, you will announce the malfunction, I will call “STOP! MY CONTROLS” or “GO”. If the call is STOP! MY CONTROLS, I will select ground idle, apply brakes / reverse as required to bring the aircraft to a complete stop. You will monitor deceleration and advise ATC. When the aircraft has stopped and parking brakes are set, I will carry out the memory items. If the malfunction occurs After V1, take off shall be continued. No actions shall be taken other than silencing of Aural Warnings, retracting the landing Gear, advancing the PLs and Manual Feathering of the failed engine if required, until 400 feet AGL and aircraft flight path stabilized. Clean up, memory items, procedures and strategy for engine failure / fire should also be briefed e.g. In case of engine failure with no auto up trim, PL will be manually advanced to the ramp. With engine failure and no auto feather, PL will not be reduced before CL is set to feather. ABORT ITEMS BEFORE 60 KTS (Items Expected Fulfilment Time) After 60 it is up to CM1 to abort, based on the clause: “Any situation considered unsafe for takeoff by CM1” 1. ATPCS – Not Armed UPTO V1 P Pitch Pitch Disconnect D DC Gen Dual DC GEN Fault Failure Engine Failure Fire Engine Fire Flaps Flaps Unlock 2. NP – Exceeding 101% 3. ITT OAT > 15oC – 765oC (Red Mark) F OAT < 15oC – 2.01.04 (ITT Limit) 4. Configuration Warning DEPARTURE BRIEFING AIRFIELD Weather Terminal information – NOTAMS etc. Frequencies – VHF Communication to be used / set. STARTUP • • TAXI RUNWAY INFO TAKEOFF DEPARTURE SPECIAL PROCEDURES ATC Procedures (push and start procedures) A/C Procedures (engine limitations etc.) Routing to the anticipated runway Dimensions (Length, Width, Stopway) Surface Condition Lighting Anti-ice usage. Bleed On / Off. Configuration for Flaps. • • • • SID – Routing and Constraints Navigation Frequencies to be used. Related GNSS, NAV, EFIS and ADU selections. Altitudes: o Acceleration o Transition o MSA Weather (Circumnavigation etc.) Terrain Failures (Communication, MEL etc.) 7 ENGINE 2 START (HOTEL MODE) CM1 CM2 Ground Confirmation: • Service Door Closed • Area Clear STARTER ON Bleed – Off Timing – Start (max starter run time) Start Selector – A+B for first flight, then alternate* Start P/B On – Call “STARTER ON” FUEL OPEN CL2 Feather – Call “FUEL OPEN” Timing Start ITT RISE (10 secs) Call – “IGNITION” CL – Fuel SO (if limits crossed) ** NH / OIL PRESSURE INCREASING Engine Parameters – Chek Call – “OIL PRESSURE” NH 45% Call – “NH 45%” Call – “STARTER OFF” *** ITT Max – Check **** Timing – Stop **** Call – “ITT XXX” NH 61.5% Call – “PARAMETERS STABILIZED” Start Selector – OFF DC Gen 2 Voltage – Check (Lateral Panel) DC GEN 2 Fault Light – Extinguished Advise Ground – Disconnect GPU DC BTC – Closed Bleed / Pack / X Valve – Open In Hotel Mode use PL2 as required. If Z > 5000 & SAT > ISA+25, then it can be increased to gust lock stop. * A+B also for battery start. Alternate: A=Odd, B=Even days (same logic for alternating ADC / ATC switches). ** If ITT tends to increase 900, or no ITT, or no NH – CL to Fuel SO, Start selector OFF (Memory Item). *** If not then Rotary Selector OFF. **** Max start time & ITT (limits 21.1.04). 8 LOAD AND TRIM SHEET RECEIVED CM1 CM2 Update GNSS and Announce: Check* and Announce: TOGW – Actual Fuel Block Fuel – ZFW – TO CG Cross check TOGW with trim sheet ** TO Data Card – Part 2 Runway Limiting – FOS TOGW Tables Runway Non Limiting – QRH Speeds Pitch Trim marked against CG Call and Set: • Speed Bugs: V1, VR, V2, White, Red *** • Set Speed Bugs Pitch Trim * Actual ZFW > Estimated ZFW by 1000 Kgs = New flight plan (OETB: FLT OPS / TECH / 14 / Fri Apr 21 2017) ** GNSS GW (TOW + taxi fuel) will be > than trim TOW. It may be used to calculate TO speeds (conservative). *** If V1 & VR same then set only VR. White bug is VmLB0 normal conditions. Red is VmLB0 icing conditions. 9 BEFORE PROPELLER ROTATION CM1 CM2 Cabin Secure Confirmation: • Doors Closed • Tail Prop on Board • Passengers as per Trim Ground Handling Confirmation: • Doors closed, Tail Prop removed. • Ready for push and start. ATC: Startup / Pushback Clearance Call – “Before Propeller Rotation Procedure” Door – Check Closed CDLS – On Beacon – Order Beacon – ON NWS – Off for push back (On after tow bar removed) Call – “Before Prop Rotation Procedure Complete” Ground Communication: • Advise Push and Start procedure. • Call Brakes Released and Off Blocks Time. Off Blocks Time – Record 10 AN OVERVIEW TILL “BEFORE TAXI” 11 BEFORE TAXI CM1 CM2 Ground Communication: • Parking Brake Set • Confirm Area Clear for Prop Rotation. • Report any Abnormality. “PROP AREA CLEAR” (check visually) PROP BRAKE OFF * HYD AUX Pump – ON CL2 AUTO ** CL2 Auto Set – Call “CL2 AUTO” NP – Stabilized PEC SGL CH – Call “SINGLE CHANNEL Call – “CL2 AUTO” LOW PITCH – Call “LOW PITCH” NP 71% (STABILIZED) ACW GEN2 Fault – Extinguished ACW BTC – Closed HYD PWR – No Light HYD IND – 3 x 3000 psi Call – “BEFORE TAXI PROCEDURE” Probe Heating – On Anti-Icing – As Required ICE DET PTT *** – Check Ice detection panel Anti-Skid Test – Perform (2.03.11) Flaps – 15 Call – “BEFORE TAXI PROCEDURE COMPLETE EXCEPT ENGINE 1” * During pushback: (1) Prop brake may be released (2) Engine 1 may be started. ** CL shall be set to AUTO once: (1) Pushback is complete (2) Parking brake is set (3) tow bar is removed. *** Push to test for 3 secs. 12 Before Taxi Procedure (Continued) ENGINE 1 START CM1 CM2 NH 61.5% Call – “PARAMETERS STABILIZED” Start Selector – OFF DC GEN 1 Fault Light – Extinguished DC BTC – Check No Light Bleed / Pack / X Valve – Check No Light CL1 AUTO CL1 Auto Set – Call “CL1 AUTO” NP – Stabilized PEC SGL CH – Call “SINGLE CHANNEL Call – “CL1 AUTO” LOW PITCH – Call “LOW PITCH” NP 71% (STABILIZED) ACW GEN1 Fault – Extinguished ACW BTC – Open Communication Hatch – Closed XPDR – As Required Nose wheel Steering – On Overhead Panel – Check No light * Call – “BEFORE TAXI PROCEDURE COMPLETE” * Except exhaust mode fault light for 2 min 13 TAXI CM1 CM2 CLEARANCE Ground Clearance – Obtain (Connections / chocks removal and hand signal after scanning CAP for failures not requiring ground assistance. On first sector also check operation of taxi, takeoff, landing, strobe and beacon light) Taxi Clearance – Obtain Off Blocks Time – Announce* Off Blocks Time – Record Taxi / TO Lights – Order Taxi / TO Lights – ON Left Clear – Announce Right Clear – Announce BRAKES – CHECK PL – Taxi Power Parking Brake – From ON to EMER Check – No Movement Brake Pedals – Pressed Call – My Brakes Call – Your Brakes Parking Brakes – Released Check – No Movement Brake Pedals – Pressed Call – My Brakes Brake Pedals – Released Call – Your Brakes Check – No Movement TAXI PROCEDURE HDG SEL MODE – LO BANK IAS MODE – V2 + 5 Call – “TAXI PROCEDURE” COUPLING – PF Side TO CONFIG – TEST** SCAN INSTRUMENTS FOR FAILURE FLAGS ATC DEPARTURE CLEARANCE Cross Check: • GNSS (RWY, SID, Route) • ADU (Altitude/FL, ALT displayed) • NAV Settings TO BRIEFING BY PF *** Call – “TAXI PROCEDURE COMPLETE” * If not announced earlier during pushback. ** *** For any changes to the airfield briefing done earlier. Items to review include: • Fuel and TOGW • Flaps and V Speeds • ADU IAS and FL • Runway, Acceleration Altitude and Departure (SID, Heading/Track, Level etc.) • Engine out strategy / Bleeds off takeoff etc. N.B: PL in reverse for not more than 10 secs in tailwind. Max taxi speed: Straight 25, turns 15, sharp turns 10kts. 14 BEFORE TAKEOFF CM1 CM2 BEFORE LINE UP Call – “BEFORE TAKE OFF PROCEDURE” Gust Lock – Release Flight Controls – Check * CCAS – RCL + TO INHIB Overhead Panel – All Lights Extinguished Except Anti-Icing if required XPDR – As Required (STBY or ON) Cabin Report – Obtain WX Radar – TST then WX ** APM Selector – T/O Weight *** Airflow – Normal Call – CABIN CREW TO YOUR STATIONS FOR T/O AT LINE UP Approach / Runway – Clear TCAS – Auto and XPDR – ALT **** Landing Lights & Strobes – ON Landing Lights & Strobes – Order Bleed Valves – OFF Rudder CAM – Centered Lateral FD Bar Centered – RWY HDG X-Check HDG Bug – Runway Heading Call – “BEFORE T/O PROCEDURE COMPETE” * For roll check spoiler light illuminated. CM2 to call “Blue Lights ON”. Check Aileron lock light is extinguished. ** STAB button to be pressed 4 times in 3 Secs to take WX radar out of forced standby mode on ground. If WX radar is selected OFF, no terrain information will be displayed. Even in case of radar failure, select STBY position. *** Selector must be moved even if the weight is same as previous flight (to min TOW – then to nearest TOW). To be done before 30 knots (or it will calculate its own less accurate TOW). Selector change in flight has no effect. **** To be done when entering the runway after receiving line up clearance. Note: GNSS legs page for T/O & SID, PROG till TOD. 15 TAKEOFF CM1 CM2 SETTING POWER Announce – TAKEOFF, V1__, TIME__ Control Column – Hold (into wind) Fuel Used – Check Call – “ATPCS ARMED” PL in Notch – Call “SET POWER” START TIME (5 min for TO power and 10 min for RTO power in case of single engine operation) ENGINE PARAMETERS – Obtain by 60 Knots • ATPCS – Armed Light Illuminated • RTO – FDAU Bug • Torque – Manual Bug • NP – 100% (+0.8, -0.6) • ITT – Within Limits (Max 765C at OAT >15C For OAT <15C see ITT Limits 2.01.04) Call – “POWER SET” AT 70 / 90 KNOTS (90 knots for narrow “less than 98 feet” runways) Call – “70/90 KNOTS” Speed – Check on CM1 ASI Speed – Cross Check CM2 ASI with STBY ASI I / YOU HAVE CONTROLS PF * PM Call – V1 Rotate – 8o then FD bars Call – “ROTATE” Call – “GEAR UP” Call – “POSITIVE RATE” (VSI + PA) Gear Up – Select Yaw Damper – Engage Taxi / TO Light – Off AT ACCELERATION ALTITUDE Call – “ACCELERATION ALTITUDE” ADU IAS – Increase PL – Check in Notch PWR MGT – Climb PL – In Notch TQ / NP – Check Climb Setting Call – “CLIMB SEQUENCE” ADU IAS – 170/160 ** BLEEDS – ON *** Call – “CLIMB SEQUENCE COMPLETE” Call and Set – “SET SPEED BUG 170/160” Set and Call – “170/160 SET” * T/O by line captain if vis < 2Km, x-wind > 20 knots, slippery / contaminated runway, braking action < good. ** Higher of 170 (ATR72) / 160 (ATR42) or Icing Bug +10. *** If bleeds were not ON “Pack 2 Fault” illuminates for 6s to avoid pressure shocks. 16 TAKEOFF (continued) PF PM ACCELERATION TO BUG SPEED Call – “WHITE / RED BUG” 1 Call – “FLAPS 0” Select Flaps 0 – Call when indicated 2 ACCELERATION TO BUG + 10 SPEED Call – “WHITE / RED BUG + 10” Call – “SET HIGH BANK” 3 Set High Bank and Announce TRANSITION ALTITUDE Call – “TRANSITION ALTITUDE” Call – “STANDARD SET, PASSING FL__ NOW” 4 Call – CHECKED 5 1 Red one is the icing bug for icing conditions while white is for normal conditions. 2 Before configuration changes, PM will check speed and call “Speed Check”. 3 With autopilot engaged, PF can set High Bank himself. 4 CM1 will set STBY Altimeter. 5 Call the difference if more than +/- 50 feet. Note: In case of high transition altitude carry out the “After Take Off” checklist above the line. 17 CLIMB SPEED SCHEDULE 160 ATR 42 / 170 ATR 72 Normal VX White Bug with LO Bank VY White Bug + 10 (recommended for ATR 72 till 5000 feet AGL) High Speed Climb 190 (conditions permitting) Above 5000 feet AGL for ATR 72 Red Bug PROCEDURE T Transition Altitude T Ten Thousand • Landing Lights • Seat Belts Sign (weather / turbulence permitting at 5000 feet on short sectors) • Pressurization T Tilt – WX Radar CRUISE PF PM AT TOC TOC Fuel and Time – Record SAT – Check Cruise Parameters – Compute (QRH) Call – “COMPUTE CRUISE PARAMETERS” Speed and TQ Bugs – Set Call – “CRUISE PARAMETERS COMPLETE” Cruise Parameters and SE Ceiling – Record AT CRUISE SPEED Torques – Check PWR MGT – Cruise (Set and Call) * Check “Actual Torque” matches with “Selected Cruise Torque” Cruise Parameters – Cross Check (with Ops Data) DURING CRUISE Antenna Tilt – Weather Radar A Aircraft Systems – Check Periodically B Boundaries – FIR / Area Procedures C Company ** D Documentation (Flight plan, flight log, debrief etc.) E Enroute Alternate Weather F Fuel – Check Periodically G GNSS – Enter actual wind/temp, check DEST RAIM * This is for ATR 72. For 42 PWR MGT to Cruise can be set on Level off (ALT Green). ** Departure message to company can also be relayed during climb (time permitting, above 10,000 feet, outside TMA) comprising of: Blocks off and Airborne time, ETA, Actual ZFW and any special message or reason of delay). 18 APPROACH BRIEFING AIRFIELD Weather Terminal information – NOTAMS etc. Fuel – Extra Holding * • NAV Frequencies • Routing and Constraints • Transition Level • MSA • NAV Frequencies • Approach and Minima • Transition Level • MSA • Obstacles • Restricted / Prohibited areas STAR APPRPOACH GOAROUND RUNWAY TAXI SPECIAL PROCEDURES ATC Procedure Aircraft Procedure Dimensions (Length, Width, Distance beyond G/S) Surface Condition Lighting Routing and Parking Weather (Circumnavigation etc.) Terrain Failures (Communication, MEL etc.) * Extra Holding Fuel Calculation A. Fuel Consumption Vs Distance = Fuel Flow / Ground Speed (in Kg / Nm) B. Fuel Required to Destination = Distance to go x A (in Kg) C. Fuel Over Destination = Fuel On Board - B (in Kg) D. Extra Holding Fuel = C – Reserves (in Kg) E. Extra Holding Time = D/10 (in minutes based on a FF of 600 Kg/h. For exact value see FCOM 3.06) 19 DESCENT PREPARATION PF PM Weather, Landing Information and Data Card CCAS – RCL (by CM1) Landing Elevation GNSS Preparation Go Around Torque (QRH) NAVAIDS – Source and Course Minima, Bugs & Briefing AT TOD Seatbelt Signs – Recycle x 2 * Hold Time over Destination – Calculate * To get “Cabin Secure” report for captain in 10 mins. 20 DESCENT PROCEDURE SPEED SCHEDULE Normal 200, 220, 240 Turbulence Emergency 180 VMO (no structural damage) For TOD and descent calculations, see the article: Managing a Descent Profile. URL: http://www.theairlinepilots.com/forumarchive/concepts-procedures/managing-descent-profile.pdf PROCEDURE T Tilt – WX Radar T Ten Thousand • Landing Lights • Seat Belts Sign (weather / turbulence permitting at 5000 feet on short sectors) • Pressurization (Cabin Altitude, Rate, Delta P) * T Transition Level ** C Company – ETA, A/C serviceability, special handling requests etc. * Max delta P at landing 0.35 psi. ** PF: Call “QNH X Set, Passing X Now”. PM: “Checked” or diff if > +/- 50. CM1 sets standby altimeter QNH. TORQUE PRESET DECELERATION HEIGHT = IAS x 10. This is for a 3o path with no wind correction. 21 STANDARD PRECISION APPROACH PF 1 PM ON INTERCEPT HEADING Speed and Bug 170 knots 2 Speed Bug – 170 ILS Frequency / APP MODE – Select and Arm NAV Source – Identify Call – “LOC / GS WHITE” Call – VOR Alive LOC STAR • • • • Call: • LOC STAR • DUAL ILS • RWY HEADING Call – RUNWAY AXIS CONFIRMED Set ILS Frequency / Course Set HDG Set V/L Arc Mode GS ALIVE Call – “FLAPS 15” Set – FLAPS 15, Call when indicated 3 Speed Bug – White Bug + 10 GS ONE DOT Call – “GEAR DOWN” Gear Down – Call when 3 greens indicated PWR MGT – TO Taxi / TO Lights – ON Call – “Cabin Crew to Your Stations for Landing” Call – “FLAPS 25” (at three greens) 4 Set – FLAPS 25, Call when indicated GS HALF DOT Set – FLAPS 35 / 30, Call when indicated Call – “FLAPS 35 / 30” TLU – Check LO Speed Speed Bug – V APP GS STAR Call – “GS STAR, SET MISSED APP ALT” Set and Call – Missed APP ALT Speed vs Icing Conditions (Icing AOA LT) – Check STANDARD CALLS 5 1000 Feet: • CONTINUE or • GOAROUND, SET POWER, FLAPS 1 NOTCH RA on EADI – RADIO ALTIMETER ALIVE Minimum: • LANDING or • GOAROUND, SET POWER, FLAPS 1 NOTCH DH/MDA +100 – HUNDRED ABOVE 1000 – 1000 FEET (Stabilized Approach) 6 DH/MDA – MINIMUMS 1 Line captain to land if vis < 2Km, X wind >20kts, runway contaminated / slippery or any other abnormality. 2 170 or icing bug + 10 (in icing conditions), whichever is higher. 3 Before configuration changes, PM will check speed and call “Speed Check”. 4 For a Flaps 25 landing CM1 to press “LDG FLAPS 25” pushbutton – ON then call for Flaps 25. 5 All FMA changes to be read by PF. 6 Below 1000ft in IMC (500 in VMC): LOC 1/3 & G/S within ½ Dot. Speed +10/-5. V/S 1000 fpm. 22 NON-PRECISION APPROACH PHASE CONFIGURATION Clean Inbound to IAF Speed 160 / 170 (ATR 42 / 72) / Red bug + 10 (Icing) Flaps – 15 Outbound Leg Speed – White Bug +10 Intercepting Final Course Gear – Down Flaps – 25 Speed – White Bug +10 Within 5o of Inbound Course or 1 NM before FAF/FAP Established Inbound Flaps – 35 / 30 (ATR 42 / 72) Speed – VAPP Go Around Altitude – Set * VS – Set 0 FT / MIN 0.3 NM before FAF / FAP VS – Set required rate of descent Start Descent Before Landing Checklist 100 ABOVE MINIMUM PF PM Call – “100 ABOVE” ** AT MDA +30 Call – “MINIMUM” VISUAL REFRENCES OBTAINED – AP OFF and LAND ADU – Stand By NOT OBTAINED – GO AROUND * Set when present altitude is below the Go Around altitude by 300 feet. In case of not following CDFA technique, MDA will be set on ADU and after ALT GREEN is displayed at MDA, Go Around altitude will be set. ** Rest of the standard call outs are the same as for a standard approach. 23 24 LANDING PF PM RA Call Outs – 80 (CAT II A/P Off), 50, 20, 10 Monitor Flare 1 PL – GI Idle Gate Auto Retraction – Check LOW PITCH LIGHTS With 2 Engines – Normal Reverse 2 Engines 2 Illuminated, Call – “2 LOW PITCH” 2 With 2 Engines – Reverse Not Allowed 2 Engines 1 Illuminated, Call – “NO REVERSE” With 1 Engine – Reverse with Care 1 Engine 1 Illuminated, Call – “1 LOW PITCH” 70 / 90 KNOTS Call – “70 / 90 KNOTS” CM1 CM2 Call – “I HAVE CONTROL” Control Wheel – Hold forward and into the wind Nose Wheel Steering – Control BACKTRACKING / RUNWAY VACATED Call – “After Landing Procedure” TCAS – STBY Trims – Set XPDR – As Required Flaps – Zero Gust Lock – Engage Flight Controls – Check Radar – STBY ADU – STBY / Reset Landing Light / Strobe – Off Probe, Window Heat, Anti & De-ice – Off ATPCS 3 – Test (Last flight of the day) Bleed Off Engine 1 and Punch Clock AFTER AT LEAST TWO MINUTES OF ENG RUNNING AT GI 4 CL1 Feather 5 Fuel SO 6 ACW BTC – Closed 7 Call – CL1 Feather Fuel SO – Order Call – “After Landing Procedure Complete” After landing checklist is not challenge and response, it’s a do list by CM2 1 Pitch on landing for ATR 72 should never cross 8o. PM to Call “Pitch 7 degrees” if pitch reaches 7o. 2 Return to GI by 40 knots to avoid flight control shaking. ATPCS Test (dynamic test: once a day – Ref: 2.03.24). Do not perform engine test while taxing as ACW and both Main Hydraulic pumps may be temporarily lost (loss of normal braking). 3 4 Assists in reducing residual heat build-up in engine nacelle. Manufacturer recommendation is 1 minute. 5 Before FTR, check HYD pressure for normal braking 6 Before Fuel SO (last flight) – FTR for 45 secs (Manufacturer time is 20) for oil capacity check by maintenance. 7 ACW BTC may be checked closed to avoid loss of ACW bus on ground. 25 GO AROUND – 2 ENGINE PF PM INITIAL ACTIONS CALL – “GO AROUND, SET POWER, FLAPS 1 NOTCH” Flaps – Retract 1 Notch GA P/B on PL – Depress Power – Check and Adjust (TQ & NP = 100%) Rotate – GA Pitch Attitude (8o) Call – “GA POWER SET, FLAPS __” PL – Advance to Ramp POSITIVE RATE OF CLIMB Call – “POSITIVE RATE” Call: • Gear Up – Select GEAR UP • HDG • LO BANK • IAS to VGA Yaw Damper – On Taxi / TO light – Off Set and Call – HDG / LO BANK / IAS to VGA Call – Gear Up, Flaps __ (when indicated) Call and Set – “SET SPEED BUG VGA” Set and Call – “XXX SET” ACCELERATION ALTITUDE – 1000ft ADU IAS – Increase PL – In Notch PL Retard – In Notch PWR MGT – CLB Call – CLIMB PROCEDURE TQ / NP – Check Climb Setting ADU IAS – 170/160 Call – “CLIMB PROCEDURE COMPLETE” Call and Set – “SET SPEED BUG 170/160” Set and Call – “170/160 SET” WHITE / RED BUG FLAPS 0 With Flaps 25 during acceleration, select Flaps 15 at WB or VGA+15 whichever is earlier. BUG +10 SET HIGH BANK AFTER T/O CHECKLIST 26 GO AROUND ACTIONS – 3 STAGES WITH 3 STEPS IN EACH STAGE 27 PARKING CM1 CM2 1 MARSHALLER IN SIGHT (LAST TURN) HYD Pressure – Check 3 x 3000 psi Taxi / TO Light – Off Call – “HYDRAULIC CHECK” GNSS – Position Ref page for GS check AT THE GATE • • Parking Brake – ON Call – “ON BLOCKS TIME” Call – “A2 TAKE YOUR POSITION” (on PA for ATR 72) • • • Call – CL2 Feather 2 Communication Hatch – Open NWS – OFF (if towing is anticipated) CL2 – Feather 3 • NP – Stabilized XPDR – STBY Call – “PROP STATIONARY” • • • • Call – “CHECK PROP STATIONARY” Beacon – Off Call – OK FOR THE DOORS 5 Seat Belt Signs: o ATR 42: OFF o ATR 72: OFF After Tail Prop on Position Call on PA: • CABIN CREW OK FOR THE DOORS • HAND OVER TAIL PROP (ATR 72) Confirm from Ground: • Chocks ON – For Releasing Brakes • Tail Prop on Position – For Disembarking Call – OK TO DISEMBARK (ATR 72) GPU Connect – After Voltage Check on Lateral Panel Note – Fuel Used CL 2 – Fuel SO 6 Reset – FU Indicator Stick Shaker / Pusher Test – Last Flight of the Day (FCOM 02.03.24) 1 If possible park into the wind after coordinating with ATC (Hotel mode NAC Overheat issue). 2 First shut engine 1 if not done during taxi. 3 On last flight maintain FTR position for 45 secs (manufacturer time 20) – Oil capacity check by maintenance. 4 Prop brake when NP stabilized. UNLK light illuminates then extinguishes. Ensure propeller area is clear. 5 After confirmation from ground personnel that chocks are in place and safety cones have been installed. 6 Without GPU, open cargo door before shutting engine 2 (to avoid load on battery). Set Bleed 2 OFF until ITT stabilizes, before shutting engine 2. 28 DO ITEMS BEFORE SHUTTING ENGINE NO 2 – WITHOUT GPU • • • • • • • • Bleeds 1 & 2 – OFF EMG light – Disarm Fuel pump 1 – OFF Fuel pump 2 – OFF (After Engine 2 shut down) VOR/ILS 1 & 2 – OFF Both EADI & EHSI – OFF ADF 1 & 2 – OFF VHF 1 & 2 – OFF Was this document helpful? Click here to Answer! Disclaimer: "ATR Normal Procedures" are personal notes of the undersigned for training only. These notes do not sanction any pilot to violate his/her Company's Standard Operating Procedures, Aircraft Manuals or Manufacturer's Recommendation. This article will not be updated anymore. 29