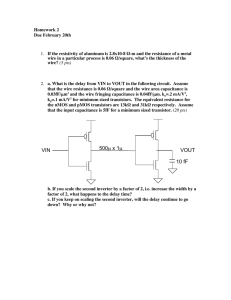

CSE493/593 MOS & Wire Capacitances [Adapted from Rabaey’s Digital Integrated Circuits, ©2002, J. Rabaey et al. and M. J. Irwin & Vijay Narayanan, PSU] Review: Delay Definitions Vin Vout Vin input waveform Propagation delay 50% tp = (tpHL + tpLH)/2 t tpLH tpHL Vout 90% output waveform signal slopes 50% 10% tf tr t CMOS Inverter: Dynamic Transient, or dynamic, response determines the maximum speed at which a device can be operated. VDD First focus Vout = 0 CL Rn Vin = V DD tpHL = f(Rn, CL) Next focus Sources of Capacitance Vout Vin CL M2 Vin Vout2 CGD12 M1 CG4 CDB2 M4 Vout CDB1 Vout2 Cw CG3 M3 intrinsic MOS transistor capacitances extrinsic MOS transistor (fanout) capacitances wiring (interconnect) capacitance MOS Intrinsic Capacitances Structure capacitances Channel capacitances Depletion regions of the reverse- biased pn-junctions of the drain and source MOS Structure Capacitances lateral diffusion Top view Source n+ Poly Gate xd xd Drain W n+ Ldrawn n+ Leff tox n+ Overlap capacitance (linear) CGSO = CGDO = Cox xd W = Co W MOS Channel Capacitances The gate-to-channel capacitance depends upon the operating region and the terminal voltages CGS = CGCS + CGSO S VGS CGD = CGCD + CGDO G + D - n+ n channel n+ CGB = CGCB p substrate B depletion region Review: Summary of MOS Operating Regions Cutoff (really subthreshold) VGS ≤ VT Exponential in VGS with linear VDS dependence ID = IS e (qVGS/nkT) (1 - e -(qVDS/kT) ) (1 - λ VDS) where n ≥ 1 Strong Inversion VGS > VT Linear (Resistive) VDS < VDSAT = VGS - VT ID = k’ W/L [(VGS – VT)VDS – VDS2/2] (1+λVDS) κ(VDS) Saturated (Constant Current) VDS ≥ VDSAT = VGS - VT IDSat = k’ W/L [(VGS – VT)VDSAT – VDSAT2/2] (1+λVDS) κ(VDSAT) NMOS VT0(V) 0.43 γ(V0.5) 0.4 VDSAT(V) 0.63 k’(A/V2) 115 x 10-6 λ(V-1) 0.06 PMOS -0.4 -0.4 -1 -30 x 10-6 -0.1 Average Distribution of Channel Capacitance Operation Region CGCB CGCS CGCD CGC CG Cutoff CoxWL 0 0 CoxWL CoxWL + 2CoW Resistive 0 CoxWL/2 CoxWL/2 CoxWL CoxWL + 2CoW Saturation 0 (2/3)CoxWL 0 (2/3)CoxWL (2/3)CoxWL + 2CoW Channel capacitance components are nonlinear and vary with operating voltage Most important regions are cutoff and saturation since that is where the device spends most of its time MOS Diffusion Capacitances The junction (or diffusion) capacitance is from the reverse-biased source-body and drain-body pn-junctions. S VGS G + D - n+ n channel n+ p substrate CSB = CSdiff depletion region CDB = CDdiff B MOS Capacitance Model CGS = CGCS + CGSO G CGD = CGCD + CGDO CGS CGD S D CSB CSB = CSdiff CGB B CGB = CGCB CDB CDB = CDdiff Transistor Capacitance Values for 0.25µ Example: For an NMOS with L = 0.24 µm, W = 0.36 µm, LD = LS = 0.625 µm CGSO = CGDO = Cox xd W = Co W = 0.11 fF CGC = Cox WL = 0.52 fF so Cgate_cap = CoxWL + 2CoW = 0.74 fF Cbp = Cj LS W = 0.45 fF Csw = Cjsw (2LS + W) = 0.45 fF so Cdiffusion_cap = 0.90 fF NMOS PMOS Cox Co Cj (fF/µm2) (fF/µm) (fF/µm2) 6 6 0.31 0.27 2 1.9 mj φb Cjsw (V) (fF/µm) 0.5 0.9 0.48 0.9 0.28 0.22 mjsw φbsw (V) 0.44 0.32 0.9 0.9 Review: Sources of Capacitance Vout Vin CL CG4 M2 Vin Vout2 CGD12pdrain M4 CDB2 ndrain M1 CDB1 Vout Vout2 Cw CG3 M3 intrinsic MOS transistor capacitances extrinsic MOS transistor (fanout) capacitances wiring (interconnect) capacitance Layout of Two Chained Inverters VDD PMOS 1.125/0.25 1.2µm =2λ Out In Metal1 Polysilicon 0.125 0.5 NMOS 0.375/0.25 W/L AD (µm2) NMOS 0.375/0.25 0.3 PMOS 1.125/0.25 0.7 GND PD (µm) 1.875 2.375 AS (µm2) PS (µm) 0.3 1.875 0.7 2.375 Components of CL (0.25 µm) C Term CGD1 Expression 2 Con Wn Value (fF) Value (fF) H→L L→H 0.23 0.23 CGD2 2 Cop Wp 0.61 0.61 CDB1 KeqbpnADnCj + KeqswnPDnCjsw 0.66 0.90 CDB2 KeqbppADpCj + KeqswpPDpCjsw 1.5 1.15 CG3 (2 Con)Wn + CoxWnLn 0.76 0.76 CG4 (2 Cop)Wp + CoxWpLp 2.28 2.28 Cw from extraction 0.12 0.12 CL ∑ 6.1 6.0 Wiring Capacitance The wiring capacitance depends upon the length and width of the connecting wires and is a function of the fan-out from the driving gate and the number of fan-out gates. Wiring capacitance is growing in importance with the scaling of technology. Parallel Plate Wiring Capacitance current flow L electrical field lines W H tdi dielectric (SiO2) substrate permittivity constant (SiO2= 3.9) Cpp = (εdi/tdi) WL Permittivity Values of Some Dielectrics Material Free space Teflon AF Aromatic thermosets (SiLK) Polyimides (organic) Fluorosilicate glass (FSG) Silicon dioxide Glass epoxy (PCBs) Silicon nitride Alumina (package) Silicon εdi 1 2.1 2.6 – 2.8 3.1 – 3.4 3.2 – 4.0 3.9 – 4.5 5 7.5 9.5 11.7 Sources of Interwire Capacitance Cwire = Cpp + Cfringe + Cinterwire = (εdi/tdi)WL + (2πεdi)/log(tdi/H) + (εdi/tdi)HL fringe interwire pp Impact of Interwire Capacitance (from [Bakoglu89]) Insights For W/H < 1.5, the fringe component dominates the parallel-plate component. Fringing capacitance can increase the overall capacitance by a factor of 10 or more. When W < 1.75H interwire capacitance starts to dominate Interwire capacitance is more pronounced for wires in the higher interconnect layers (further from the substrate) Rules of thumb Never run wires in diffusion Use poly only for short runs Shorter wires – lower R and C Thinner wires – lower C but higher R Wire delay nearly proportional to L2 Wiring Capacitances Poly Al1 Al2 Al3 Al4 Al5 Field 88 54 30 40 13 25 8.9 18 6.5 14 5.2 12 Interwire Cap Active 41 47 15 27 9.4 19 6.8 15 5.4 12 Poly 57 54 17 29 10 20 7 15 5.4 12 Al1 Al2 Al3 Al4 pp in aF/µm2 fringe in aF/µm 36 45 15 27 8.9 18 6.6 14 41 49 15 27 9.1 19 35 45 14 27 38 52 Poly Al1 Al2 Al3 Al4 Al5 40 95 85 85 85 115 per unit wire length in aF/µm for minimally-spaced wires Dealing with Capacitance Low capacitance (low-k) dielectrics (insulators) such as polymide or even air instead of SiO2 family of materials that are low-k dielectrics must also be suitable thermally and mechanically and compatible with (copper) interconnect Copper interconnect allows wires to be thinner without increasing their resistance, thereby decreasing interwire capacitance SOI (silicon on insulator) to reduce junction capacitance Resistance [Adapted from Rabaey’s Digital Integrated Circuits, ©2002, J. Rabaey et al.] Sources of Resistance Top view Poly Gate Drain n+ Source n+ W L MOS structure resistance - Ron Source and drain resistance Contact (via) resistance Wiring resistance MOS Structure Resistance The simplest model assumes the transistor is a switch with an infinite “off” resistance and a finite “on” resistance Ron VGS ≥ VT S Ron D However Ron is nonlinear, so use instead the average value of the resistances, Req, at the end-points of the transition (VDD and VDD/2) Req = ½ (Ron(t1) + Ron(t2)) Req = ¾ VDD/IDSAT (1 – 5/6 λ VDD) Equivalent MOS Structure Resistance The on resistance is inversely proportional to W/L. Doubling W halves Req For VDD>>VT+VDSAT/2, Req is independent of VDD (see plot). Only a minor improvement in Req occurs when VDD is increased (due to channel length modulation) Once the supply voltage approaches VT, Req increases dramatically 7 x105 (for VGS = VDD, VDS = VDD→VDD/2) 6 5 4 3 2 1 0 0.5 VDD(V) NMOS(kΩ) PMOS (kΩ) 1 1 35 115 1.5 2 1.5 19 55 2 15 38 VDD (V) 2.5 2.5 13 31 Req (for W/L = 1), for larger devices divide Req by W/L Source and Drain Resistance G D S RS RD RS,D = (LS,D/W)R where LS,D is the length of the source or drain diffusion R is the sheet resistance of the source or drain diffusion (20 to 100 Ω/) More pronounced with scaling since junctions are shallower With silicidation R is reduced to the range 1 to 4 Ω/ Contact Resistance Transitions between routing layers (contacts through via’s) add extra resistance to a wire keep signals wires on a single layer whenever possible avoid excess contacts reduce contact resistance by making vias larger (beware of current crowding that puts a practical limit on the size of vias) or by using multiple minimum-size vias to make the contact Typical contact resistances, RC, (minimum-size) 5 to 20 Ω for metal or poly to n+, p+ diffusion and metal to poly 1 to 5 Ω for metal to metal contacts More pronounced with scaling since contact openings are smaller Wire Resistance L H ρL R= A Sheet Resistance R R1 = = ρ L HW R2 = W Material Silver (Ag) Copper (Cu) Gold (Au) Aluminum (Al) Tungsten (W) ρ(Ω-m) 1.6 x 10-8 1.7 x 10-8 2.2 x 10-8 2.7 x 10-8 5.5 x 10-8 Material n, p well diffusion n+, p+ diffusion n+, p+ diffusion with silicide polysilicon polysilicon with silicide Aluminum Sheet Res. (Ω/) 1000 to 1500 50 to 150 3 to 5 150 to 200 4 to 5 0.05 to 0.1 Skin Effect At high frequency, currents tend to flow primarily on the surface of a conductor with the current density falling off exponentially with depth into the wire W H δ= √(ρ/(πfµ)) where f is frequency µ = 4π x 10-7 H/m δ= 2.6 µm for Al at 1 GHz so the overall cross section is ~ 2(W+H)δ The onset of skin effect is at fs - where the skin depth is equal to half the largest dimension of the wire. fs = 4 ρ / (π µ (max(W,H))2) An issue for high frequency, wide (tall) wires (i.e., clocks!) Skin Effect for Different W’s for H = .70 um % Increase in Resistance 1000 100 10 1 0.1 W = 1 um W = 10 um W = 20 um 1E8 1E9 1E10 Frequency (Hz) A 30% increase in resistance is observe for 20 µm Al wires at 1 GHz (versus only a 1% increase for 1 µm wires) The Wire transmitters schematic receivers physical Wire Models Interconnect parasitics (capacitance, resistance, and inductance) l reduce reliability l affect performance and power consumption All-inclusive (C,R,l) model Capacitance-only Parasitic Simplifications Inductive effects can be ignored l l if the resistance of the wire is substantial enough (as is the case for long Al wires with small cross section) if the rise and fall times of the applied signals are slow enough When the wire is short, or the cross-section is large, or the interconnect material has low resistivity, a capacitance only model can be used When the separation between neighboring wires is large, or when the wires run together for only a short distance, interwire capacitance can be ignored and all the parasitic capacitance can be modeled as capacitance to ground Simulated Wire Delays Vin L/10 L/4 L Vout L/2 L 2.5 2 1.5 1 0.5 0 0 0.5 1 1.5 2 2.5 3 time (nsec) 3.5 4 4.5 5 Wire Delay Models Ideal wire l l same voltage is present at every segment of the wire at every point in time - at equi-potential only holds for very short wires, i.e., interconnects between very nearest neighbor gates Lumped C model l when only a single parasitic component (C, R, or L) is dominant the different fractions are lumped into a single circuit element Driver - When the resistive component is small and the switching frequency is low to medium, can consider only C; the wire itself does not introduce any delay; the only impact on performance comes from wire capacitance Vout RDriver cwire capacitance per unit length l good for short wires; pessimistic and inaccurate for long wires Vout Clumped Wire Delay Models, con’t Lumped RC model total wire resistance is lumped into a single R and total capacitance into a single C good for short wires; pessimistic and inaccurate for long wires l l Distributed RC model circuit parasitics are distributed along the length, L, of the wire l - c and r are the capacitance and resistance per unit length Vin r∆L r∆L r∆L r∆L r∆L c∆L c∆L c∆L c∆L c∆L l VN Delay is determined using the Elmore delay equation N τDi = ∑ ckrik k=1 Vin (r,c,L) VN Elmore Delay Models Uses Modeling the delay of a wire Modeling the delay of a series of pass transistors Modeling the delay of a pull-up and pull-down networks Distributed RC Model for Simple Wires A length L RC wire can be modeled by N segments of length L/N l The resistance and capacitance of each segment are given by r L/N and c L/N τDN = (L/N)2(cr+2cr+…+Ncr) = (crL2) (N(N+1))/(2N2) = CR((N+1)/(2N)) where R (= rL) and C (= cL) are the total lumped resistance and capacitance of the wire For large N τDN = RC/2 = rcL2/2 Delay of a wire is a quadratic function of its length, L The delay is 1/2 of that predicted (by the lumped model) Step Response Points Voltage Range Lumped RC Distributed RC 0 → 50% (tp) 0.69 RC 0.38 RC 0 → 63% (τ) RC 0.5 RC 10% → 90% (tr) 2.2 RC 0.9 RC 0 → 90% 2.3 RC 1.0 RC Time to reach the 50% point is t = ln(2)τ = 0.69τ Time to reach the 90% point is t = ln(9)τ = 2.2τ Example: Consider a Al1 wire 10 cm long and 1 µm wide l l Using a lumped C only model with a source resistance (RDriver) of 10 kΩ and a total lumped capacitance (Clumped) of 11 pF t50% = 0.69 x 10 kΩ x 11pF = 76 ns t90% = 2.2 x 10 kΩ x 11pF = 242 ns Using a distributed RC model with c = 110 aF/µm and r = 0.075 Ω/µm t50% = 0.38 x (0.075 Ω/µm) x (110 aF/µm) x (105 µm)2 = 31.4 ns t90% = 0.9 x (0.075 Ω/µm) x (110 aF/µm) x (105 µm)2 = 74.25 ns Poly: t50% = 0.38 x (150 Ω/µm) x (88+2×54 aF/µm) x (105 µm)2 = 112 µs Al5: t50% = 0.38 x (0.0375 Ω/µm) x (5.2+2×12 aF/µm) x (105 µm)2 = 4.2 ns Putting It All Together RDriver rw,cw,L Vout Vin Total propagation delay consider driver and wire τD = RDriverCw + (RwCw)/2 = RDriverCw + 0.5rwcwL2 and tp = 0.69 RDriverCw + 0.38 RwCw where Rw = rwL and Cw = cwL The delay introduced by wire resistance becomes dominant when (RwCw)/2 ≥ RDriver CW (when L ≥ 2RDriver/Rw) l For an RDriver = 1 kΩ driving an 1 µm wide Al1 wire, Lcrit is 2.67 cm Design Rules of Thumb rc delays should be considered when tpRC > tpgate of the driving gate Lcrit > √ (tpgate/0.38rc) l actual Lcrit depends upon the size of the driving gate and the interconnect material rc delays should be considered when the rise (fall) time at the line input is smaller than RC, the rise (fall) time of the line trise < RC l when not met, the change in the signal is slower than the propagation delay of the wire so a lumped C model suffices Nature of Interconnect Pentium Pro (R) Pentium(R) II Pentium (MMX) Pentium (R) Pentium (R) II No of nets (Log Scale) Local Interconnect Global Interconnect 10 100 1,000 Length (u) 10,000 100,000 Source: Intel Overcoming Interconnect Resistance Selective technology scaling scale W while holding H constant l Use better interconnect materials lower resistivity materials like copper l - As processes shrink, wires get shorter (reducing C) but they get closer together (increasing C) and narrower (increasing R). So RC wire delay increases and capacitive coupling gets worse. - Copper has about 40% lower resistivity than aluminum, so copper wires can be thinner (reducing C) without increasing R use silicides (WSi2, TiSi2, PtSi2 and TaSi) l silicide - Conductivity is 8-10 times better than poly alone polysilicon SiO2 n+ Use more interconnect layers l p n+ reduces the average wire length L (but beware of extra contacts) Wire Spacing Comparisons Intel P858 Al, 0.18µm Intel P856.5 Al, 0.25µm Ω - 0.05 M4 Ω - 0.33 M3 Ω - 0.33 M2 Scale: 2,160 nm Ω - 0.07 M6 Ω - 0.08 M5 M5 Ω - 0.12 Ω - 1.11 IBM CMOS-8S CU, 0.18µm M1 Ω - 0.17 M4 Ω - 0.49 M3 Ω - 0.49 M2 Ω - 1.00 M1 Ω - 0.10 M7 Ω - 0.10 M6 Ω - 0.50 M5 Ω - 0.50 M4 Ω - 0.50 M3 Ω - 0.70 M2 Ω - 0.97 M1 From MPR, 2000 Comparison of Wire Delays 1 Normalized Wire Delay 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 Al/SiO2 Cu/SiO2 Cu/FSG Cu/SiLK From MPR, 2000 Inductance When the rise and fall times of the signal become comparable to the time of flight of the signal waveform across the line, then the inductance of the wire starts to dominate the delay behavior Vin l r g l r c g l r c g l r c g c Vout Must consider wire transmission line effects l Signal propagates over the wire as a wave (rather than diffusing as in rc only models) - Signal propagates by alternately transferring energy from capacitive to inductive modes More Design Rules of Thumb Transmission line effects should be considered when the rise or fall time of the input signal (tr, tf) is smaller than the time-of-flight of the transmission line (tflight) tr (tf) < 2.5 tflight = 2.5 L/v l For on-chip wires with a maximum length of 1 cm, we only worry about transmission line effects when tr < 150 ps Transmission line effects should only be considered when the total resistance of the wire is limited R < 5 Z0 = 5 (V/I)