CELR 11 Strength of

material and concrete

Laboratory

INTRODUCTION

Dr. J SEVUGAN RAJKANNU

Assistant Professor

Department of Civil Engineering

National Institute of Technology

Tiruchirappalli

Course Learning Objectives

1. To find the Young Modulus, torsional strength, hardness and tensile strength of given

specimens

2. To find impact value and crushing value of coarse aggregates

3. To find the compressive strength of concrete cubes and bricks

4. To find stiffness of open coiled and closed coiled springs

5. To find the physical properties of given coarse aggregate, fine aggregate and cement

samples

Course content

1. Tests on springs - modulus of rigidity of the spring.

2. Stress-strain characteristics of HYSD bars.

3. Young’s modulus of the given material (steel or wood) by conducting bending test on

simply supported beam.

4. Brinel’s, Vickers, Rockwell hardness tester.

5. Normal consistency, fineness, Initial setting and final setting time of cement.

6.

7. Specific gravity of fine, coarse aggregates and Cement.

8. Fineness modulus of fine aggregate and coarse aggregate.

9. Impact strength, crushing strength and water absorption test on coarse aggregate.

10. Concrete mix design (IS method).

11. Compressive and spilt-tensile strength of concrete.

Course outcomes

On completion of the course, the students will be able to:

1. Evaluate Young Modulus, torsional strength, hardness and tensile strength of given

specimens.

2. Determine the strength of coarse aggregates.

3. Design concrete mixes and find the compressive strength of concrete cubes and bricks.

4. Find stiffness of open coiled and closed coiled springs.

5. Determine the physical properties of given coarse aggregates, fine aggregates and cement

samples.

LIST OF EXPERIMENTS

S.NO.

NAME OF EXPERIMENTS

1.

Tests on springs - modulus of rigidity of the spring.

2.

Stress-strain characteristics of HYSD bars.

3.

Young’s modulus of the given material (steel or wood) by

conducting bending test on simply supported beam.

4.

Brinel’s, Vickers, Rockwell hardness tester.

5.

Normal consistency, fineness, Initial setting and final setting

time of cement.

6.

Specific gravity of fine, coarse aggregates and Cement.

7.

Fineness modulus of fine aggregate and coarse aggregate.

8.

Impact strength, crushing strength and water absorption teston

coarse aggregate.

9.

Concrete mix design (IS method).

10.

Compressive and spilt-tensile strength of concrete.

11.

Charpy v notch test

12

Compression test and water absorption of bricks

PAGE NO.

RECORD OF LABORATORY EXPERIMENTS

CELR 11: STRENGTH OF MATERIAL AND

CONCRETE LABORATORY

Name:

Roll No:

B. Tech. Civil Engineering

Semester

DEPARTMENT OF CIVIL ENGINEERING NATIONAL

INSTITUTE OF TECHNOLOGY TIRUCHIRAPPALLI –

620015

JULY-NOVEMBER 2024

BONAFIDE CERTIFICATE

Certified that this is the bonafide record of work done by Mr./Mrs.

of semester B.Tech. Civil Engineering

during the academic year 2024 - 2025 in the STRENGTH OF MATERIAL AND CONCRETE

LABORATORY.

Head of the Department

Submitted for the institute practical exam held on

Faculty in-charge

2024 at Department of

Civil Engineering, National Institute of Technology, Tiruchirappalli – 620015.

Internal Examiner:

External Examiner:

Date:

Date:

EXPERIMENT NO. 1 (A)

Aim: To conduct test on the given spring and to determine the rigidity modulus and

spring constant.

Apparatus Required:

I. Spring testing machine

2. Meter Scale

3. Vernier Calipers

FormulaModulus of rigidity =

8𝑊𝐷3n

𝑑4 𝛿

where

W= average load(kg)

n=number of turns

δ = deflection

D= average diameter

d= diameter of coil

p=pitch(mm)

Procedure:

• The length of spring, the inner and outer diameter was noted,

the spring is placed in the correct position.

• Least count of dial gauge is noted.

• Load is applied and the deflection of the spring was noted down

for every 10 kg.

• The deflection is measured from the scale attached to the

machine and the same procedure is repeated for each

unloading.

• The spring constant and modulus of rigidity are calculated

analytically.

Graph:

The graph is plotted between load and deflection. Load is along Y-Axis and

deflection along X-Axis.

ObservationNo. of turns(n)=

Length of spring(L)=

Diameter of coil(d)=

Inner dia of spring(D1)=

Outer dia of spring(D2)=

Mean Diameter D=(D1+D2)/2=

Radius of coil= d/2=

Pitch = L/n=

S.No

Load

Axial Deformation (mm)

W(kg)

Loading

1.

2.

3.

4.

5.

6.

Unloading

Average

Spring

Constant

(K)

Modulus of

Rigidity (N)

(N/mm)

(N/mm^2)

Model Calculations:

Modulus of Rigidity (N)=

8𝑊𝐷3n

𝑑4𝛿

From Graph:

K= W/δ=

8𝐷3n 𝑊

N=(

)( )=

𝑑4

𝛿

Result:

i) Spring Constant (K)a) Analytically=

b) Graphically=

ii) Modulus of Rigidity (N)a) Analytically=

b) Graphically=

EXPERIMENT NO. 1 (B)

TEST ON OPEN COIL SPRING

Aim: To conduct test on the given spring and to determine the rigidity modulus and spring

constant.

Apparatus Required:

I. Spring testing machine

4. Meter Scale

5. Vernier Calipers

Formula8𝑊𝐷3n

Modulus of rigidity =

𝑑4𝛿𝑐𝑜𝑠𝛼

x(𝑐𝑜𝑠 2𝛼+

2𝑠𝑖𝑛2𝛼𝑛

𝐸

)

where

W= average load(kg)

n=number of turns

δ = deflection (mm)

D= average diameter (mm)

d= diameter of coil (mm)

p=pitch(mm)

N= Rigidity modulus (N/mm2)

α= 𝑡𝑎𝑛−1(

𝑝

)

2П𝑅

R= Radius of spring

Procedure:

• The length of spring, the inner and outer diameter was noted,

the spring is placed in the correct position.

• Least count of dial gauge is noted.

• Load is applied and the deflection of the spring was noted down

for every 10 kg.

• The deflection is measured from the scale attached to the

machine and the same procedure is repeated for each

unloading.

• The spring constant and modulus of rigidity are calculated

analytically.

ObservationNo. of turns(n)=

Length of spring(L)=

Diameter of coil(d)=

Inner dia of spring(D1)=

Outer dia of spring(D2)=

Mean Diameter D=(D1+D2)/2=

Radius of coil= d/2=

Pitch = L/n=

Graph:

The graph is plotted between load and deflection. Load is along Y-Axis and

deflection along X-Axis

S.No

Load

Axial Deformation (mm)

W(kg)

Loading

1.

2.

3.

4.

5.

6.

Unloading

Average

Spring

Constant (K)

(N/mm)

Modulus of

Rigidity (N)

(N/mm^2)

Model Calculations:

8𝑊𝐷3n

Modulus of Rigidity (N)=

x(𝑐𝑜𝑠

𝑑4𝛿𝑐𝑜𝑠𝛼

From Graph:

K= W/δ=

N=(

8𝑊𝐷3n

𝑑4𝛼𝑐𝑜𝑠𝛼

)x(𝑐𝑜𝑠2𝛼+2𝑠𝑖𝑛

Result:

i) Spring Constant (K)a) Analytically=

b) Graphically=

ii) Modulus of Rigidity (N)a) Analytically=

b) Graphically=

2𝛼𝑛

𝐸

)=

2

𝛼+

2𝑠𝑖𝑛2𝛼𝑛

𝐸

)

Experiment No. 2

STRESS-STRAIN CHARACTERISTICS OF HYSD BARS:

RELEVANT IS CODES:

• IS 1608 (2005): Mechanical testing of metals

AIM:

To determine the tensile strength, elastic and inelastic properties of HYSD Bar and to

study it's stress– strain behaviour. The specific properties to be determined are

1.

2.

3.

4.

5.

6.

Modulus of Elasticity

Ultimate Tensile Stress

Nominal and Actual Breaking Stress

Percentage Elongation

Percentage Reduction in Area

Proof Stress

APPARATUS REQUIRED:

1. Universal Testing Machine

2. Extensometer

3. Vernier callipers

4 Meter Scale

5. Punch for marking gauge length

PROCEDURE:

1. The given rod was weighed and it's length was measured. The average

diameter d was determined using the density of the specimen.

2. The center point of the rod was marked using the punch and marks were made

on either side of the center mark at a distance of 5d.

3. The given rod was then fixed in the tension grips of the UTM such that the top

and bottom marks already made, coincides exactly with the top and bottom of

the wedge grips respectively. The extensometer was fixed firmly to the

specimen so that its axis coincides with that of the specimen. The zero error in

the extensometer and the testing machine are eliminated.

4. Extensometer readings are taken for different increment in loads which were

applied

within

the

elastic

limits.

5. Load was applied until yield point was reached. The extensometer was then

removed and the ultimate load and the breaking load were noted.

6. The final diameter, d' of the rod was measured at the neck of the ruptured

section. The broken parts were fixed together and the final length. I was

measured between the previously marked punch marks.

FORMULA:

𝜎

𝐸=

𝜀

Where

E -Young's Modulus

(Nmm2) σ σ -Direct Stress

(N/mm2)

ε - Strain

2. Area of the rod =

(п/4)xd^2

,

Where,

d-Diameter of the rod

(mm)

3. Ultimate Stress (Nm)- Ultimate load/Area of Cross-section

4. Nominal Breaking Stress (Nm)-Breaking Load/Area of Cross-section

5. Actual Breaking Stress (Nm)-Breaking Load/Final Area of Cross-section

6.Percentage Elongation –

7. Percentage Reduction in Area=

GRAPH:

The following graphs were drawn

1. Load vs Elongation

Elongation is taken along the X-axis and Load is taken along the Y-axis Strain

is taken along the X-axis and Stress is taken along the Y-axis

2) Stress vs Strain

Strain is taken along the X-axis and stress along the Y-axis.

OBSERVATION:

1. Weight of the rod (W) 2. Length of the rod (L) –

3. Density of the rod (p) –

4. Area of cross section of the rod(A)

5. Diameter of the rod (d) 6. Gauge Length –

7. Final Length 8. Final Diameter (d') –

9. Mean Diameter (d')10. Breaking Load –

11. Ultimate Load –

12. Extensometer gauge Length –

13. Least count of Extensometer –

CALCULATION TABLE:

Extensometer reading

S.

No

Load

(Tons)

Left

Right

Aver

age

Average

Extension

× LC

CALCULATIONS:

1. Area of the specimen, A –

2. Diameter of the specimen 3.

Percentage elongation –

4.

Percentage Reduction in Area -

Stress

(N/mm2)

Strain ×

10-4

Young’s

Modulus ×

105 (N/mm2)

5) Ultimate Stress (N/mm2) –

6. Nominal Breaking Stress (N/mm2) –

7. Actual Breaking Stress (N/mm2) –

8. Load –

9. Average Extensometer reading –

10 Stress, σ 11. Strain, ε 12. Young's Modulus, E=σ/ε –

13. Proof Stress (From Graph)

RESULT:

1. Young’s modulus (E) =

2. Ultimate tensile stress (N/mm2) =

3. Nominal breaking stress =

4. Actual breaking stress =

5. Percentage of elongation =

6. Percentage of reduction of area =

7. Proof stress =

Experiment No. 3

BENDING TEST ON SIMPLY SUPPORTED BEAM

AIM: To determine the young’s modulus of the beam material of a simply supported

beam with center or eccentric point load.

APPRATUS:

1. Simply supported beam

2. Dial gauge

3. Weights

THEORY:

When the loads are placed on the beam, it undergoes deflection. The

defection of the beam is determined with the help of the relation between defection

of beam and the loading system. The young’s modulus of the beam is obtained for

this purpose; similarly the deflection of the simply supported beam with an eccentric

point load is determined with the help of Macaulay’s method.

DESCRIPTION:

The apparatus consists of wood /steel beam resting on the simply supported edges;

the load (W) is applied at centre and the maximum deflection is measured at the

centre. For this load condition, the deflection at centre is given by =WL^3/48EI.

Where,

W= concentrated load at centre in ‘N’

L= length of beam in mm

δ = deflection of beam in mm

PROCEDURE:

1. Measure the breadth and depth of the beam at three sections along the span and

take the average values.

2. Apply the load at the centre ’C’ increasing order and measure the

corresponding deflections with the help of a dial gauge. Similarly apply the loads

from A and B as shown in figure to calculate the deflection with an eccentric point

load.

3. Tabulate the deflections corresponding to various loads.

4. Plot a graph between load and deflection from the graph corresponding to any two

convenient points.

δ =WL^3/48EI

PRECAUTIONS:

1. The beam must be loaded below its ultimate load. So that it may not fail

underloading.

2. Adjust the dial indicator at the exact place where deflection needs to be

calculated.

3. Note down the dial indicator readings carefully

4. Be sure that the distance marked on the beam is equal.

5. Before applying load do not forget to set the dial gauge pointer to the initial point.

6. Make sure there is nothing placed on the table except the apparatus a smallest

pressure on the table can spoil the experiment.

7. Make sure that the beam and load are placed in the proper position.

RESULT:

Young’s modulus (E) of beam material is

a) Analytically=

b) Graphically=

EXPERIMENT No. 4

(A) BRINELL HARDNESS TEST

AIM: To determine the hardness of the given specimen using Brinell hardness test.

APPARATUS: Brinell hardness testing machine, Aluminum specimen, Ball indenter.

DIAGRAM:

THEORY:

In Brinell hardness test, a steel ball of diameter (D) is forced under a load (F) on to a surface of test

specimen. Mean diameter (d) of indentation is measured after the removal of the load (F).

Its specifications as follows:

1. Ability to determine hardness up to 500BHN.

2. Diameter of ball (as indenter) used D= 2.5mm, 5mm, 10mm.

3. Maximum application load= 3000kgf

.4. Method of load application= Lever type

5. Capability of testing the lower hardness range= 1BHN on application of 0.5D2load.

PROCEDURE:

1. Insert ball of diameter ‘D’ in the ball holder of machine.

2. Make the specimen surface clean by oil, grease, dust etc.

3. Make contact between the specimen surface and ball using jack adjusting wheel.

4. Push the required button for loading.

Pull the load release level and wait for 15 seconds.

5. Remove the specimen from the support table and locate the Indentation.

6. View the indentation through microscope and measure the diameter ‘d’ of the indentation using

micrometer fixed on the microscope.

7. Repeat the procedure and take three readings.

OBSERVATIONS:

Test piece material

=

Diameter of the ball D =

Load section F/D2

=

Test load

=

Load application time

=

Least count of Brinell Microscope =

S.NO Ball Diameter

D in mm

BHN=

BHN=

Load applied F

in kgf

Diameter

of indentation

𝑳𝒐𝒂𝒅 𝑨𝒑𝒑𝒍𝒊𝒆𝒅 (𝒌𝒈𝒇)

𝒔𝒑𝒆𝒓𝒊𝒄𝒂𝒍 𝒔𝒖𝒓𝒇𝒂𝒄𝒆 𝒂𝒓𝒆𝒂 𝒐𝒇 𝒊𝒏𝒅𝒆𝒏𝒕𝒂𝒕𝒊𝒐𝒏

𝟐𝑷

𝝅𝑫(𝑫−√(𝑫𝟐−𝒅𝟐)

PRECAUTION:

1. Make sure that beam and load placed a proper position.

2. The cross- section of the beam should be large.

3. Note down the readings more carefully.

𝑃

D2

(B)

VICKERS HARDNESS TEST

AIM-To study the Vickers hardness testing machine & perform the Vickers hardness

test.

APPARATUS:

▪ Vickers Hardness Testing Machine.

▪ Diamond cone indenter,

▪ Specimen.

THEORY:

Very Hard materials (e.g. Mild steel, case hardened steel, etc.,) can be tested by the Vickers’

method. If moderately hard materials like Brass, Copper and Aluminum are tested in this

machine, the indenter makes a deep impression. Hence, a proper indentation cannot be made on

the specimen and the correct value of the hardness cannot be obtained for these materials by V.

H. Test.

VHN = Load Sloping or pyramidal area of the indentation

This test is similar to the Brinell hardness test similar relationship and eliminates most of the

errors. The produced impression is projected onto a focusing screen and the diagonals of the

impression are measured by means of the measuring equipment. Due to small impressions, it is

very suitable for testing polished and hardened material surfaces. This test is rapid and accurate.

The required load as calculated by P/D2 ratio is applied on the specimen for a standard time of

8- 10 seconds and BHN is calculated by the ratio of load and the spherical area of indentation.

The diameter of the indentation is measured on the focusing screen of the machine.

SUITABLE APPLICATION:

•

The Vickers hardness test is used for hardness testing of all solid

materials,including metallic materials.

•

It is suitable for a wide range of applications.

•

It can also be used for a sub-group of hardness testing of welds.

EQUIPMENT DESCRIPTION:

Figure : Vickers Hardness Testing Machine.

PROCEDURE:

a) Clean the surface at the specimen

b) Fix the indenter in the hardness tester and switch on the power supply.

c) Place the specimen with a cleaned surface facing the indenter on the anvil at worktable.

d)

Focus the workpiece surface for clean visibility by rotating the hand wheel at the

worktableupwards and downwards.

e) Select the load specified (P) push button available on the right side at the hardness tester.

f)

Actuate the electric push button (Green Button) at the front for loading, the

loading leverstarts moving up words and reaches the study position.

g) Now release the loading lever slowly and bring it to the downward position.

h)

For major reading adjust the display at the indentation made by the indenter to

coincidewith the micrometer on the display screen.

i)

For major (minor) reading adjust the movable side at the micrometer and note

down thetotal reading.

j)

The measurement is to be made for two opposite corners of the diagonal

indentationdenoted as (l).

k) Repeat the above procedure for different material.

OBSERVATION AND CALCULATION:

Type of indenter = Diamond cone

S/No

Specimen

Load

applied

in Kg-F

Length of Indentationin

mm(l)

1

2

3

Vickers Hardness Number (VHN) =

Where,

P= Load applied in Kg

l= Average length of the diagonal L in mm

Least count of microscope=0.001mm

1st scale each division =0.1mm

2nd scale each division =0.01

3rd scale each division =0.001mm

PRECAUTIONS:

❖ The specimen should be well cleaned.

❖ Place the specimen properly.

Average

length

in mm

❖

Reading must be taken carefully and correctly.

RESULTS: Vickers hardness Number of the given specimen is

➢

Mild steel =

➢

Hardened mild steel =

CONCLUSION:

(C) ROCKWELL HARDNESS TESTER

AIM: To determine the hardness of the given Specimen using Rockwell hardness test.

APPARATUS: Rockwell hardness testing machine,

MATERIAL: soft and hard mild steel specimens, brass, Aluminum etc., Black diamond

coneindenter.

DIAGRAM:

THEORY:

Rockwell test is developed by the Wilson instrument co U.S.A in 1920. This test is an

indentation test used for smaller specimens and harder materials. The test is subject of IS:

1586. The hardness of a material is resistance to penetration under a localized pressure or

resistance to abrasion. Hardness tests provide an accurate, rapid and economical way of

determining the resistance of materials to deformation.

There are three general types of hardness measurements depending upon the manner in which

the test is conducted:

a. Scratch hardness measurement,

b. Rebound hardness measurement

c. Indention hardness measurement.

In scratch hardness method the material is rated on their ability to scratch one another and it is

usually used by mineralogists only. In rebound hardness measurement, a standard body is usually

dropped on to the material surface and the hardness is measured in terms of the height of its

rebound. The general means of judging the hardness is measuring the resistance of a material to

indentation. The indenters are usually a ball cone or pyramid of a material much harder than that

beingused. Hardened steel, sintered tungsten carbide or diamond indenters are generally used in

PROCEDURE:

1. Examine hardness testing machine

2. Place the specimen on the platform of a machine. Using the elevating screw raise the

platform and bring the specimen just in contact with the ball. Apply an initial load until the

small pointer showsred mark.

3. Release the operating valve to apply additional load. Immediately after the additional load is

applied, bring back the operating valve to its position.

4. Read the position of the pointer on the C scale, which gives the hardness number.

5. Repeat the procedure five times on the specimen selecting different points for indentation.

OBSERVATION TABLE:

S.NO

Specimens

Reading (HRC/)

1

2

Mean

3

1

Mild Steel

HRB =

2

High Carbon steel

HRC =

3

Brass

HRB =

4

Aluminum

HRB =

PRECAUTIONS:

1. The specimen should be clean properly

2. Take reading more carefully and

3. The test should not be made on specimens so thin that the impression shows through the

metal,nor should impression be made too close to the edge of a specimen.

APPLICATIONS:

1. In manufacturing Industries

2. Bearing Manufacturing industries

EXPERIMENT NO. 5

(A) DETERMINATION OF FINENESS OF CEMENT BY SIEVING

Theory: Cement is obtained by grinding various raw materials after calcination. The degree to

which cement is ground to smaller and smaller particles is called fineness of cement. The fineness

of cement has an important role on the rate of hydration and hence on the rate of gain of strength

and also on the rate of evolution of heat. Finer cement offers a greater surface area for hydration

and hence the faster development of strength although the ultimate strength is not affected.

Fineness also provides more cohesiveness to concrete and avoid separation of water at the top of

concrete (called bleeding). However, increase in fineness of cement increases the drying

shrinkage and cracking of the concrete.

Fineness of cement is tested either by sieving or by determination of specific surface using airpermeability apparatus. The specific surface is defined as the total surface area of all the particles

in cm2 per one gram of cement. Although determination of specific surface is more accurate to

judge fineness of cement, it is rarely used except for specific purpose. In contrast sieving is most

commonly used method to determine fineness of cement and is quite good for field works.

Objective:

Determination of fineness of cement by dry sieving.

Reference:

IS 4031 (Part-1):1988.

Apparatus:

IS-90-micron sieve conforming to IS: 460 (Part 1-3)-1985; Weighing balance;

Gauging trowel; Brush.

Material:

Ordinary Portland cement

Procedure:

1.

Weigh accurately 100 g of cement to the nearest 0.01 g and place it on a

standard 90 micron IS sieve.

2.

Break down any air-set lumps in the cement sample with fingers.

3.

Agitate the sieve by giving swirling, planetary and linear movements for a

period of 10 minutes or until no more fine material passes through it.

4.

Collect the residue left on the sieve, using brush if necessary, and weigh the

residue.

5.

Express the residue as a percentage of the quantity first placed on the sieve to

the nearest 0.1 percent.

6.

Repeat the whole procedure two more times each using fresh 100 g sample.

Observations:

Sl. No.

Weight of

sample taken

(W) (in g.)

Weight of

residue (R) (in

g.)

%age of residue

𝑅

(= × 100)

𝑊

Average % of

residue

1.

2.

3.

Result:

The percentage of residue of cement sample by dry sieving is

Conclusions:

percentage.

(B) CONSISTENCY TEST ON CEMENT

Theory: This test is conducted to calculate the amount of water to be added to the cement to

get a paste of standard consistency which is defined as that consistency which will permit the

Vicat plunger to penetrate to a point 5 to 7 mm from the bottom of the Vicat mould. This

experiment is done with the help of Vicat apparatus (Figure). The time taken between adding

of water to the cement and filling of mould of Vicat apparatus is called as gauging time which

should be between 3 to 5 minutes.

For finding out initial setting time, final setting time, soundness of cement and

compressive strength of cement, it is necessary to fix the quantity of water to be mixed in

cement in each case. Since different batches of cement differ in fineness, pastes with some

water content may differ in consistency when first mixed. For this reason, the consistency of

the paste is standardized by varying the water content until the paste has a given resistance to

penetration.

Figure: Vicat Apparatus

Objective:

Determination of percentage of water by weight of cement required to prepare a

standard acceptable (consistent) cement paste.

Reference:

IS 4031 (Part-4):1988.

Apparatus:

Vicat apparatus conforming to IS: 5513-1998; Weighing balance; Gauging

trowel; measuring cylinder.

Material:

Ordinary Portland cement; Water.

Procedure:

1.

Take 400 g of cement sieved through 90 micron IS sieve and keep it on a nonporous, non-absorbent plate.

2.

Add 120 ml of water (i.e. 30% by weight of cement) to the cement and mix

thoroughly with two trowels for 3 to 5 minutes till a uniform cement paste is

achieved.

3.

Fill the paste in mould and level with trowel. Shake or tap to remove air

bubbles.

4.

Place the nonporous plate and the mould under the plunger.

5.

Release the plunger gently to touch the surface of paste. Record the initial

reading.

6.

Release the plunger quickly and allow penetrating into the paste. When the

plunger comes to rest, note the final reading.

7.

Repeat the procedure with fresh paste varying the water percentage until the

plunger penetrates to a depth 5 to 7 mm from the bottom of the Vicat mould.

Observations:

Sl. No.

Water added

(in ml)

Percentage

Initial

Reading

Final

Reading

Height not

penetrated (in

mm)

Result:

The percentage of water required to achieve normal consistency of cement paste is

Conclusion:

.

EXPERIMENT NO. 5(C)

DETERMINATION OF SETTING TIMES OF CEMENT

Theory: Cement when mixed with water forms slurry which gradually becomes lesser and

lesser plastic, and finally forms a hard mass. In this process a stage is obtained when the cement

paste is sufficiently rigid to withstand a definite amount of pressure. The time to reach this stage

is called setting time. The setting time is divided into two parts: the initial setting time and the

final setting time.

Initial set is a stage where the cement paste stiffens to such an extent that the Vicat needle is

not permitted to move down through the paste within 5 ± 0.5 mm measured from the bottom of

the mould. In other words, the cement paste starts losing its plasticity. The time elapsed between

the moments that the water is added to the cement to the initial set is regarded as initial setting

time. Any crack that may appear after the initial set may not re-unite. Final setting time is the

time when the paste becomes so hard that the annular attachment to the needle under standard

weight only makes an impression on the hardened cement paste.

In order that the concrete may be mixed, transported and placed in position conveniently, it is

necessary that the initial set of cement is not too quick. But after, it has been laid; the hardening

should be rapid so that the structure can be made use of as early as possible. For ordinary Portland

cement, the initial setting time should not be less than 30 minutes while the final setting time

should not be more than 600 minutes.

The setting time of the cement is influenced by factors such as: percentage of water, amount of

kneading the paste, temperature and humidity of the environment. As per codal provisions, this

test should be conducted at temperature of 27𝑜 ± 2𝑜 𝐶 and 90% humidity.

Flash set and false set are two terms, which are generally encountered in relation to the setting

of cements. Flash set refers to the immediate stiffening of the cement paste due to violent reaction

of pure 𝐶3𝐴 with water. To prevent flash set gypsum is added to the cement clinker during

grinding. A phenomenon of abnormal and premature hardening of cement within a few minutes

of mixing with water is termed as false set. It differs from flash set in that no appreciable heat has

evolved, and remixing the cement paste without addition of water restores plasticity of the paste

and the concrete sets in normal manner without a loss of strength. This happens due to

dehydration of gypsum when it comes in contact with excessively hot clinkers during grinding.

Objective:

Determination of initial and final setting time of cement and determine

whether the values satisfy IS standards.

Reference:

IS 4031 (Part-5):1988

Apparatus:

Vicat apparatus conforming to IS: 5513-1998; Weighing balance; Gauging

trowel; measuring cylinder; stopwatch.

Material:

Ordinary Portland cement; Water.

Procedure:

1.

Prepare a uniform cement paste by gauging 400 g of cement with 0.85 times

the water required to give a paste of standard consistency. The procedure of

mixing and filling the mould is the same as standard consistency.

2.

Start the stopwatch or note down the time when water is added to the cement.

Determination of initial setting time:

3.

Place the test block confined in the mould and resting on the non-porous plate,

under the rod bearing the initial setting needle (with cross section 1 mm 2);

lower the needle gently until it comes in contact with the surface of the test

block and quickly release, allowing it to penetrate into the test block

4.

Repeat this procedure until the needle, when brought in contact with the test

block and released as described above, fails to pierce the block beyond 5.0 ±

0.5 mm measured from the bottom of the mould. Note the time.

5.

The difference of time between operations (2) and (4) provides the initial

setting time of cement.

Determination of final setting time:

6.

Replace the initial setting needle of the Vicat apparatus by the needle with an

annular attachment.

7.

The cement shall be considered as finally set when, upon applying the needle

gently to the surface of the test block, the needle makes an impression thereon,

while the attachment fails to do so.

8.

The interval of time between operation (2) and (7) provides the final setting

time of cement.

Observations:

•

Weight of given sample of cement is

•

The normal consistency of a given sample of cement is

•

Volume of water addend (0.85 times the water required to give a paste of standard

consistency) for preparation of test block

ml

Time in minutes :

Height in mm fails to penetrate

Initial setting time of cement (in min): Final

setting time (in min):

g.

%

Conclusion:

EXPERIMENT NO.6 (A)

DETERMINATION OF SOUNDNESS OF CEMENT

Theory: The ability of cement to maintain a constant volume is known as the soundness of the

cement. It is essential that the cement concrete shall not undergo appreciable change in volume

after setting. Unsoundness produces cracks, distortion and disintegration there by giving passage

to water and atmospheric gases which may have injurious effects on concrete and reinforcement.

The soundness of cement is ensured by limiting the quantities of free lime, magnesia and

sulphates as these compounds undergo a large change in volume.

Unsoundness in cement does not come to surface for a considerable period of time. Thus this

test is designed to accelerate the hydration of free lime by the application of heat thus discovering

the defects in a short time. Further, to minimize the shrinkage of cement paste, the test setup is

kept immersed in water bath.

This test is carried out with the help of “Le Chatelier’s apparatus” which consists of a small

split cylinder of spring brass or other suitable metal of 0.5mm thickness forming a mould 30 mm

internal diameter and 30mm high (Figure). On either side of the split mould are attached to

indicators with pointed ends, the distance from these ends to the center of the cylinder being 165

mm. The mould shall be kept in good condition with the jaws not more than 50mm apart.

Figure: Le- Chatelier apparatus

Objective:

Determination of soundness of cement by Le-Chatelier method.

Reference:

IS 4031 (Part-3):1988.

Apparatus:

Le- Chatelier apparatus conforming to IS: 5514-1969; Measuring cylinder;

Gauging trowel; Balance; Water bath.

Material:

Ordinary Portland cement; Water; Grease

Procedure:

1.

Weigh accurately 100 g of cement to the nearest 0.15 g and add to it 0.78

times the water required to give a paste of standard consistency (i.e. 0.78×P).

2.

Place the lightly greased mould on a lightly greased glass sheet and fill it

with cement paste, taking care to keep the edges of the mould gently together.

3.

Cover the mould with another piece of lightly greased glass sheet, place a

small weight on this covering glass sheet and immediately submerge the whole

assembly in water at a temperature of 27 ± 20 𝐶.

4.

Keep this assembly under water for 24 hrs. After this, take the mould out of

water and measure the distance between two indicators. Submerge the mould

again in the water.

5.

Bring the water to boiling with the mould kept submerged and keep it boiling

for 25 to 30 minutes.

6.

Remove the mould from the water, allow it to cool and measure the distance

between the indicator points.

7.

The difference between these two measurements represents the expansion of

the cement.

8.

Repeat the whole procedure two more times each using fresh 100 g sample.

Observations:

Samples:

Distance between pointers before boiling (D1) in mm

Distance between pointers after boiling (D2) in mm

Expansion of the cement = E1 = (D2- D1) in mm

Average expansion of the cement in mm

Result:

Average expansion of the cement is obtained is

Conclusions:

mm.

EXPERIMENT NO. 6 (B)

DETERMINATION OF SPECIFIC GRAVITY OF CEMENT

Theory: Specific gravity is defined as the ratio between weight of a given volume of

material and weight of an equal volume of water. In case of cement, specific gravity is

determined by use of a Le Chatelier’s flask (Figure). Sometimes, a specific gravity bottle may

be employed to a standard Le Chatelier’s flask. To determine the specific gravity of cement,

kerosene is used which does not react with cement. The specific gravity of OPC is generally

around 3.15.

Figure: Le- Chatelier flask

Objective:

Determination of specific gravity of cement using Le-Chatelier flash.

Reference:

IS 4031 (Part-11):1988.

Apparatus:

Le Chaterliers flask, weighing balance, kerosene (free from water).

Material:

Ordinary Portland cement; Water; Grease

Procedure:

1.

Dry the flask carefully and fill with kerosene or naphtha to a point on the stem

between zero and 1 ml.

2.

Record the level of the liquid in the flask as initial reading.

3.

Put a weighted quantity of cement (about 60 g) into the flask so that level of

kerosene rises to about 22 ml mark, care being taken to avoid splashing and to

see that cement does not adhere to the sides of the above the liquid.

4.

After putting all the cement to the flask, roll the flask gently in an inclined

position to expel air until no further air bubble rise3s to the surface of the

liquid.

5.

Note down the new liquid level as final reading.

Observations:

•

Weight of cement used in g. (W1)

:

•

Initial reading of flask in ml (V1)

:

•

Final reading of flask in ml (V2)

:

•

Volume of cement particle (V2 - V1)

:

•

Weight of equal volume of water in g. (W2)

:

•

Specific gravity of cement (W1/ W2)

:

Result and conclusion:

Specific gravity of the given cement obtained as

.

EXPERIMENT NO. 6 (C)

DETERMINATION OF COMPRESSIVE STRENGTH OF CEMENT

Theory: Among physical properties of cement, compressive strength is the most important

property. When cement is used for important structures, compressive strength test is always

carried out to ascertain quality of cement. Strength test is not made on plain cement due to

excess shrinkage and cracking of plain cement paste. The test is therefore carried out on

blocks of mortar made of cement, sand and water.

As the quality of sand from different sources varies, it is necessary to use sand of standard

quality for this test. The standard sand consists of well graded sand of quartz, light grey or

whitish in color and free of silts and organic impurities. As per IS 650: 1991, standard sand is

obtained from Ennore, Tamil Nadu which has the following particle size distribution:

Smaller than 2 mm but greater than 1 mm

Smaller than 1 mm but greater than 500 μ

Smaller than 500 μ but greater than 90 μ

: 33.33%

: 33.33%

: 33.33%

In the mortar, cement and sand are used in the proportion of 1:3. Mortar cubes of size 70.6

mm are prepared, compacted and cured properly before testing under direct compression. The

cubes are tested in compression testing machine at the end on three days, seven days and

twenty-eight days. For ordinary Portland cement of 43 grade, the average compressive

strength after 3, 7 and 28 days should not be less than 23 N/mm2, 33 N/mm2 and 43 N/

mm2 respectively.

Objective:

Determination of compressive strength of cement.

Reference:

IS 4031-1988 (Part-6).

Apparatus:

Vibration Machine, Poking Rod, Cube Mould of 70.6 mm size conforming to IS:

10080-1982, Balance, Gauging Trowel, Watch, Graduated Glass Cylinders, etc.

Material:

Ordinary Portland cement (43 grade); Water; Grease, Standard sand (IS: 6501966).

Procedure:

Preparation of cement mortar cubes:

1.

Take 200gms of cement and 600 g of standard sand (i.e. ratio of cement to

sand is 1:3) in a non-porous enamel tray and mix them with a trowel for one

minute.

2.

Add water cement (P/4+3)% of combined weight of cement and sand and mix the

three ingredients thoroughly until the mixture is of uniform color. (‘P’ is the

consistency of cement). The time of mixing should be less than three minutes and

not more than four minutes.

3.

Immediately after mixing fill the mortar into greased cube moulds of sizes

70.6 mm.

4.

Compact the mortar either by hand compaction in a standard specified manner

or on the vibrating table.

5.

Place the moulds in cabin at a temperature of 27º ± 2º C for 24 hours

6.

Remove the specimen from the moulds and submerge them in clean water for

curing.

Testing of cement mortar cubes:

7.

Take the cube out of water at the end of three days with dry cloth. Measure the

dimensions of the surface in which the load is to be applied. Let them be ‘L’

and ‘B’ respectively.

8.

Place the cube in compressive testing machine and apply the load uniformly at

the rate of 14N/mm2 per minute.

9.

Note the load at which the cube fails. Let it be ‘F’.

10. Calculate the compressive strength of the cube by using formula F/𝐴 . Where

A is the area of loaded surface (i.e. L×B).

11. Repeat the same procedure (steps 7 to 10) for other two cubes.

12. Repeat the whole procedure (Step 7 to 11) to find the compressive strength of

the cube at the end of 7 days and 28 days.

Observations:

(a) For 3 days strength:

Sl.

No.

Length (L) in mm

Breadth (B) in mm

Load (F) in N

1

2

3

Average =

compressive

strength in N/mm2

(b) For 7 days strength:

Sl.

No.

Length (L) in mm

Breadth (B) in mm

Load (F) in N

compressive

strength in N/mm2

1

2

3

Average =

(c) For 28 days strength:

Sl.

No.

Length (L) in mm

Breadth (B) in mm

Load (F) in N

1

2

3

Average =

Results:

The type and grade of cement :

The compressive strength of cement ate the end of

i)

3 days

:

. N/mm2.

ii)

7 days

:

. N/mm2.

iii)

28 days

:

. N/mm2.

Conclusion:

compressive

strength in N/mm2

EXPERIMENT NO.7(A)

SPECIFIC GRAVITY OF FINE AGGREGATES

Theory:

Specific gravity of an aggregate is defined as the ratio of the mass of solid in a given volume of

sample to the mass of equal volume of water at 4𝑜 𝐶. However, all rocks contain some small

amount of void, and the apparent specific gravity includes these voids. The specific gravity of

aggregates is an indirect measure of material’s density and its quality. A low specific gravity may

indicate high porosity and therefore poor durability and low strength.

Some of the pores contained by aggregates are permeable while others are impermeable.

Accordingly, two types of specific gravities are defined absolute specific gravity and apparent

specific gravity. If both the permeable and impermeable voids are excluded to determine the true

volume of solids, the specific gravity is called true or absolute specific gravity of the aggregate.

But true specific gravity has not much of practical use as volume of impermeable internal pores is

too difficult to determine.

In contrast, for the determination of apparent specific gravity the impermeable internal pore

is added to the effective volume of the aggregates (does not include the permeable pores).

Mathematically:

Apparent Specific Gravity =

mass of aggregate

mass of water occupying the volume equal to that of solids of

aggregate excluding permeable pores

The apparent specific gravity is realistic one to use for concrete mix proportioning. The apparent

specific gravity of most rocks lie between 2.6 to 2.7. Apparent specific gravity can be determined

on the basis of surface dry condition (SSD) or oven dry condition (OD), according to the moisture

condition of the aggregate.

In saturated surface dry (SSD) situation, the pores of the aggregate are fully filled with water

and the surface is dry. This condition can be obtained by immersing coarse aggregate in water for

24 h followed by drying of the surface with a wet cloth. When the aggregate is under the SSD

condition, it will neither absorb water nor give out water during the mixing process. Hence, it is a

balanced condition and is used as the standard index for concrete mix design.

In contrast, the oven dry condition is obtained by keeping the aggregate in an oven at a

temperature of 110o 𝐶 for 24 hrs. Due to heating, all the water from internal permeable pores gets

evaporated and hence it reaches a constant weight. When the aggregate is under OD condition, it will

absorb water during the concrete mixing process until the internal pores are fully filled with water.

Objective:

To determine specific gravity and water absorption of fine aggregate.

Reference:

IS: 2386 (Part-3)-1963.

Apparatus:

Pycnometer, 1000-ml measuring cylinder, thermostatically controlled oven,

taping rod, filter papers and funnel.

Material:

Fine aggregates (500 g)

Procedure:

1. Place 500 g of fine aggregate in a tray and cover it with distilled water at a

temperature of 22 to 32°C. Remove air entrapped in or bubbles on the surface of

the aggregate by gentle agitation with a rod. Keep the sample immersed under

water for 24 Hrs.

2. Carefully drain the water from the sample, by decanting through a filter paper.

Air dry the aggregate and solid matter retained on the filter paper, to remove the

surface moisture. When the material just attains a “free-running” condition,

weight the saturated and surface-dry sample (A).

3. Place the aggregate in the pycnometer and fill the remaining space by distilled

water. Eliminate entrapped air by rotating the pycnometer on its side, covering

the hole in the apex of the cone with a finger. Weight the pycnometer with this

condition (B).

4. Empty the contents of the pycnometer into a tray. Ensure that all the aggregate is

transferred. Refill the pycnometer with distilled water to the same level as before

and measure the weight at this condition (C).

5. Carefully drain the water from the sample, by decanting through a filter paper.

Oven-dry the aggregate in the tray at a temperature of 100 to 110oC for 24 hrs.

During this period, stir the specimen occasionally to facilitate proper drying.

Cool the aggregates calculate its weight (D).

6.

Cal

culate the specific gravity and apparent specific gravity as follows:

Specific gravity = {𝐷/ [𝐴 − (𝐵 − 𝐶)]}

(1)

Apparent Specific gravity = {𝐷/ [𝐷 − (𝐵 − 𝐶)]}

(2)

Where,

A = Weight in g of saturated surface-dry sample

B = Weight in g of pycnometer containing sample and filled with distilled

water

C = Weight in g of pycnometer filled with distilled water only

D = Weight in g of oven dried sample only.

Observations:

Weight in g of saturated surface-dry sample (A)

Weight in g of pycnometer containing sample and

filled with distilled water (B)

Weight in g of pycnometer filled with distilled water

only (C)

Weight of oven dried- sample only (D)

Specific gravity = {𝐷/ [𝐴 − (𝐵 − 𝐶)]}

Apparent Specific gravity = {𝐷/ [𝐷 − (𝐵 − 𝐶)]}

Results and discussions:

Following results are obtained for the provided fine aggregate specimen:

a) Specific gravity

:

.

b) Apparent specific gravity

:

.

Conclusion:

EXPERIMENT NO. 7 (B)

SPECIFIC GRAVITY OF COARSE AGGREGATES

Theory: For design of concrete mix, information about the specific gravity and water

absorption of the coarse aggregates are required. Specific gravity of aggregate provides valuable

information on its quality and properties. If the specific gravity is above or below than the value

normally assigned to a particular type of aggregate; it may indicate that shape and grading of

aggregate has altered. It is also important in determination of moisture contact and in many

concrete mix design calculations. It is also required for the calculation of volume yield of

concrete.

Objective:

To determine specific gravity and water absorption of coarse aggregate.

Reference:

IS: 2386 (Part-3)-1963.

Apparatus: Balance of capacity 5kg weight, box wire basket 200mm in diameter, water

container for immersing the wire basket, absorbent cloth for surface drying of the

sample and thermos static drying oven.

Material:

coarse aggregates (5 Kg),

Procedure:

8. A sample of not less than 2 Kg of the aggregate shall be thoroughly washed to

remove finer particles and dust, drained and then placed in the wire basket and

immersed in distilled water at a temperature between 22°C to 32°C with a cover

of at least 5 cm of water above the top of the basket.

9. Immediately after immersion the entrapped air shall be removed from the sample

by lifting the basket containing it 25 mm above the base of the tank and allowing

it to drop 25 times at the rate of about one drop per second.

10. The basket and aggregate shall remain completely immersed during the

operation and for a period of 24 ± l/2 hours afterwards.

11. The basket and the sample shall then be jolted and weighed in water at a

temperature of 22°C to 32°C (weight A).

12. The basket and the aggregate shall then be removed from the water and allowed

to drain for a few minutes, after which the aggregate shall be gently emptied

from the basket on to one of the dry clothes, and the empty basket shall be

returned to the water and weighed in water (weight B).

13. The aggregate placed on the dry cloth shall be gently surface dried with the

cloth, transferring it to the second dry cloth when the first will remove no further

moisture. The aggregate shall then be weighed (weight C).

14. The aggregate shall then be placed in the oven in the shallow tray, at a

temperature of 100 to 110°C and maintained at this temperature for 24 ± l/2

hours. It shall then be removed from the oven, cooled in the airtight container

and weighed (weight D).

15. The specific gravity, apparent specific gravity and water &sorption shall be

calculated as.

Specific gravity = {𝐷⁄ [𝐶 − (𝐴 − 𝐵)]}

(1)

Apparent Specific gravity = {𝐷/ (𝐷 − (𝐴 − 𝐵))}

(2)

Where,

A = Weight in g of aggregate and basket in water

B = Weight in g of empty basket in water

C = Weight in g of the saturated surface - dry aggregate in air

D = Weight in g of oven dried aggregate in air.

Observations:

Weight of aggregate and basket in water (A)

Weight of empty basket in water (B)

Weight of the saturated surface - dry aggregate in air (C)

Weight of oven dried aggregate in air (D)

Specific gravity = [𝐷/ (𝐶 − 𝐴 + 𝐵)]

Apparent Specific gravity = [𝐷/ (𝐶 − 𝐷)]

Results and discussions:

Following results are obtained for the provided coarse aggregate specimen:

a) Specific gravity

:

.

b) Apparent specific gravity

:

.

CONCLUSION:

EXPERIMENT NO. 8

FINENESS MODULUS OF FINE AND COARSE AGGREGATE

(A) FINENESS MODULUS OF FINE AGGREGATE

Objective: To determine fineness modulus of fine aggregate and classifications based on IS:

383- 1970

Apparatus:

Test Sieves conforming to IS: 460-1962 Specification of 4.75 mm, 2.36 mm, 1.18 mm, 600

micron, 300micron, 150 micron, Balance, Gauging Trowel, Stop Watch, etc.

Theory:

The sieve analysis is conducted to determine the particle size distribution in a sample of

aggregate, which is known as gradation.

Procedure:

1. The sample shall be brought to an air-dry condition before weighing and sieving. The air-dry

sample shall be weighed and sieved successively on the appropriate sieves starting with the

largest.

2. Material shall not be forced through the sieve by hand pressure. Lumps of fine material, if

present, may be broken by gentle pressure with fingers against the side of the sieve.

3. Light brushing with a fine camel hairbrush may be used on the 150-micron and 75-micron IS

Sieves to prevent aggregation of powder and blinding of apertures.

4. On completion of sieving, the material retained on each sieve, together with any material

cleaned from the mesh, shall be weighed.

Observation:

I S Sieve size

4.75 mm

2.36 mm

1.18 mm

600 microns

300 microns

Total

Weight Retained

on Sieve

Percentage

of Percentage

of Cumulative

Weight Retained Weight Passing Percentage

(%)

(%)

Passing (%)

of

Graph: Draw a graph between Percentage of Weight Passing (%) Vs Sieve size.

Result:

Conclusion:

(B) FINENESS MODULUS OF COARSE AGGREGATE

Objective: To determine the particle size distribution of coarse aggregates by sieving.

Apparatus:

Test. Sieves conforming to IS: 460-1962 Specification of 80 mm, 40 mm20 mm, 10 mm, 4.75

mm, Balance, Gauging Trowel, Stop Watch, etc.

Theory:

Grading refers to the determination of the particle-size distribution for aggregate. Grading limits

and maximum aggregate size are specified because grading and size affect the amount of

aggregate used as well as cement and water requirements, workability, pumpability, and

durability of concrete. In general, if the water-cement ratio is chosen correctly, a wide range in

grading can be used without a major effect on strength. When gap-graded aggregates are

specified, certain particle sizes of aggregate are omitted from the size continuum. Gap-graded

aggregates are used to obtain uniform textures in exposed aggregate concrete.

Procedure:

1. The sample shall be brought to an air-dry condition before weighing and sieving. This may be

achieved either by drying at room temperature or by heating at a temperature of 100‖ to 110°C.

The air- dry sample shall be weighed and sieved successively on the appropriate sieves starting

with the largest.

2. Material shall not be forced through the sieve by hand pressure.

3. On completion of sieving, the material retained on each sieve, together with any material

cleaned from the mesh, shall be weighed.

I S Sieve

Weight Retained

on Sieve

Percentage

of Percentage

of Cumulative

Weight Retained Weight Passing Percentage

(%)

(%)

Passing (%)

80 mm

40 mm

20 mm

10 mm

4.75 mm

Total

Result:

Graph: Draw a graph between Percentage of Weight Passing (%) Vs Sieve size.

of

Conclusion:

EXPERIMNET NO. 9

IMPACT VALUE, CRUSHING VALUE AND WATER ABSORPTION TEST OF

AGGREGATE

(A) IMPACT VALUE OF AGGREGATE

Objective: To determine the impact value of coarse aggregate

Apparatus: An impact testing machine of the general form shown in Fig and complying with

the following:

1. A cylindrical steel cup of internal dimensions: Diameter 102 mm, Depth 50 mm and not less

than mm thick.

2. A metal hammer weighing 13.5 to 14.0 kg, the lower end of which shall be cylindrical in

shape, 100.0 mm in diameter and 5 cm long, with a 2 mm chamfer at the lower edge, and casehardened. The hammer shall slide freely between vertical guides so arranged that the lower

(cylindrical) part of the hammer is above and concentric with the cup.

3. Means for raising the hammer and allowing it to fall freely between the vertical guides from

a height of 380.0 mm on to the test sample in the cup, and means for adjusting the height of fall

within 5 mm. Sieves-The IS Sieves of sizes 12.5, 10 and 2.36 mm, Tamping Rod, balance of

capacity not less than 500 g, Oven etc.

Theory:

The aggregate impact value gives a relative measure of the resistance of an aggregate to sudden

shock or impact, which in some aggregates differs from its resistance to a slow compressive

load.

Procedure:

1. The test sample shall consist of aggregate the whole of which passes a 12.5 mm IS Sieve and

is retained on a 10 mm IS Sieve. The aggregate comprising the test sample shall be dried in an

oven for a period of four hours at a temperature of 100 to 110°C and cooled.

2. The measure shall be filled about one-third full of the aggregate and tamped with 25 strokes

of the rounded end of the tamping rod. The net weight of aggregate in the measure shall be

determined to the nearest gram (Weight A)

3.The impact machine shall rest without wedging or packing upon the level plate, block or floor,

so that it is rigid, and the hammer guide columns are vertical.

4. The cup shall be fixed firmly in position on the base of the machine and the whole of the test

sample placed in it and compacted by a single tamping of 25 strokes of the tamping rod.

5. The hammer shall be raised until its lower face is 380 mm above the upper surface of the

aggregate in the cup, and allowed to fall freely onto the aggregate. The test sample shall be

subjected to a total of 15 such blows each being delivered at an interval of not less than one

second.

6. The crushed aggregate shall then be removed from the cup and the whole of it sieved on the

2.36 mm IS Sieve until no further significant amount passes in one minute. The fraction passing

the sieve shall be weighed to an accuracy of 0.1 g (Weight. B).

7. The fraction retained on the sieve shall also be weighed (Weight C) and, if the total weight

(C+B) is less than the initial weight (Weight A) by more than one gram, the result shall be

discarded, and a fresh test made. Two tests shall be made.

Calculation:

The ratio of the weight of fines formed to the total sample weight in each test shall he expressed

as a Percentage

Aggregate Impact Value = 𝑩 𝒙𝟏𝟎𝟎

𝑨

A = weight (in gm) of saturated surface dry sample,

B = weight (in gm) of fraction passing through appropriate sieves

Result:

The aggregate Impact value of given sample of coarse aggregate is ................ %

Conclusion:

(B) CRUSHING VALUE OF AGGREGATE

Objective: To determine crushing value of coarse aggregate.

Apparatus:

A 15-cm diameter open-ended steel cylinder, with plunger and base-plate, of the general form

and dimensions shown in Fig. , straight metal tamping rod, A balance of capacity 3 kg, readable

and accurate to one gram, IS Sieves of sizes 12.5, 10 and 2.36 mm, For measuring the sample,

cylindrical metal measure of sufficient rigidity to retain its form under rough usage and of the

following internal dimensions: Diameter 11.5 cm and Height 18.0 cm .

Theory:

The aggregate crushing value gives a relative measure of the resistance of an aggregate to

crushing under a gradually applied compressive load.

Procedure:

1. The material for the standard test shall consist of aggregate passing a 12.5 mm IS Sieve and

retained on a 10 mm IS Sieve and shall be thoroughly separated on these sieves before testing.

2. The aggregate shall be tested in a surface-dry condition. If dried by heating, the period of

drying shall not exceed four hours, the temperature shall be 100 to 110°C and th aggregate shall

be cooled to room temperature before testing.

3. The appropriate quantity may be found conveniently by filling the cylindrical measure in three

layers of approximately equal depth, each layer being tamped 25 times with the rounded end of

the tamping rod and finally leveled off, using the tamping rod as a straight edge.

4. The weight of material comprising the test sample shall be determined (Weight A) and the

same weight of sample shall be taken for the repeat test.

5. The apparatus, with the test sample and plunger in position, shall then be placed between the

platens of the testing machine and loaded at as uniform a rate as possible so that the total load is

reached in 10 minutes. The total load shall be 400 kN.

6. The load shall be released and the whole material removed from the cylinder and sieved on a

2.36 mm IS Sieve for the standard test. The fraction passing the sieve shall be weighed (Weight

B).

Calculation:

The ratio of the weight of fines formed to the total sample weight in each test shall be expressed

as a percent B

Aggregate Crushing Value= 𝑩 𝒙𝟏𝟎𝟎

𝑨

A = weight (in gm) of saturated surface dry sample,

B = weight (in gm) of fraction passing through appropriate sieves

Result:

The aggregate crushing value of the given sample of coarse aggregate is ............... %.

Conclusion:

(C) WATER ABSORPTION TEST ON COARSE AGGREGATE

Objective: To find the water absorption of given aggregate sample.

Apparatus: 1. A balance of capacity not less than 3kg, readable and accurate to 0.5 gm and of

such a type as to permit the weighing of the vessel containing the aggregate and water.

2. A well-ventilated oven to maintain temperature of 100ºCto 110ºC.

3. A wire basket of not more than 6.3mm mesh.

4. A container for filling water and suspending the basket.

Procedure:

1. Take the given sample of dry aggregate in the wire basket and immersed in distilled water.

2. Keep the aggregate immersed in water for 24±.5hr.

3. Then the weight of saturated aggregate is noted,w.

4. The aggregate is placed in oven for 24 hours, then cooled in airtight container and weighted

W.

Formulae Required:

Water absorption (in%) =

𝑤−𝑊 𝑥100

𝑊

Observations and Calculations:

Weight of dry aggregate sample=

Weight saturated aggregate (w) =

Weight of oven dried aggregate Sample after dried it for 24hr in oven (W) =

Water absorption =

Result:

Water absorption of aggregate sample =

Conclusion:

Inference:

EXPERIMENT NO. 10

CONCRETE MIX DESIGN (IS METHOD)

Objective: To design the normal mix of concrete (any grade) using IS codes (IS 10262: 2019

& IS 456:2015)

Materials Required:

1. Cement

2. M-Sand

3. Coarse Aggregates (12.5 mm & 20 mm)

4. Water

5. Superplasticizer

DATA FOR MIX PROPORTIONING:

a. Grade designation

b. Type of cement

c. Maximum nominal size of aggregate

d. Minimum cement content & Maximum cement content

e. Maximum water-cement ratio

f. Workability

g. Maximum temperature of concrete at the time of placing.

h. Whether an admixture shall or shall not be used and the type of admixture and the

condition of use

Procedure:

1. Selection of grade of concrete

2. Determination Target Mean Strength (Fm)

Fm= fck + 1.65×S

where

Fm – Target mean compressive strength at 28 days in N/mm2

fck – Characteristic compressive strength at 28 days in N/mm2

S - Standard Deviation in N/mm2 ( Reference : Table 2 (IS

10262))

3. Selection appropriate air content: for example, 1% for 20 mm size aggregates

(Reference: Table 3 (IS 10262)

4. Selection of Water cement ratio (Reference: Table 5 (IS 456) & Fig. 1 (IS 10262))

5. Selection of Water content (Reference: Table 4 (IS 10262))

NOTE: The water content in Table is for angular coarse aggregate and for 25 to 50 mm

slump range. For the desired workability (other than 25 to 50 mm slump range), the required

water content may be established by trial or an increase by about 3 percent for every

additional 25 mm slump. When superplasticizer is used, the water content may be reduced.

Based on trial data, the water content reduction of 23 percent is considered.

6. Determination of volumes of concrete constituents by using specific gravity formula

(cement, aggregates, admixtures if any)

EXPERIMENT NO. 11A

MEASUREMENT OF WORKABILITY OF CONCRETE

BY SLUMP CONE TEST

Theory:

Concrete is said to be workable if it can be easily mixed, placed, compacted and finished. A

workable concrete should not show any segregation or bleeding. Segregation is said to occur

when coarse aggregate tries to separate out from the finer material and a concentration of

coarse aggregate at one place occurs. This results in large voids, less durability and strength.

Bleeding of concrete is said to occur when excess water comes up at the surface of concrete.

This causes small pores through the mass of concrete and is undesirable.

Unsupported fresh concrete flows to the sides and a sinking in height takes place. This

vertical settlement is known as slump. The slump is a measure indicating the consistency or

workability of cement concrete. It gives an idea of water content needed for concrete to be

used for different works. To measure the slump value, the test fresh concrete is filled into a

mould of specified shape and dimensions, and the settlement or slump is measured when

supporting mould is removed. The slump increases as water content is increased. For

different works, different slump values have been recommended. The following table

indicates the relationship between the degree of workability and slump value.

Degree of workability

Very Low

Low

Medium

High

Slump value (in mm)

0-25

25-50

50-100

100-175

Slump test is adopted in the laboratory or during the progress of the work in the field for

determining the consistency of concrete where nominal max., size of aggregates does not

exceed 40 mm. The pattern of slump indicates the characteristics of concrete in addition to

the slump value. If the concrete slumps evenly it is called true slump. If one half of the cone

slides down, it is called shear slump. In case of a shear slump, the slump value is measured as

the difference in height between the height of the mould and the average value of the

subsidence. Shear slump also indicates that the concrete is non-cohesive and shows the

characteristic of segregation. Any slump specimen, which collapses or shears off laterally

gives incorrect results and at this juncture the test is repeated only true slump should be

measured.

Although, slump test is popular due to the simplicity of apparatus used and simple

procedure, unfortunately, the simplicity is also often allows a wide variability and many time

it could not provide true guide to workability. For example, a harsh mix cannot be said to

have same workability as one with a large proportion of sand even though they may have the

same slump.

The slump cone experiment is conducted in an apparatus called slump cone (Figure 6).

This apparatus essentially consists of a metallic mould in the form of a frustum of a cone

having the internal dimensions as under: Bottom diameter: 20 cm, Top diameter: 10 cm,

Height: 30 cm and the thickness of the metallic sheet for the mould should not be thinner than

1.6 mm.

Figure 6: Slump cone and types of slump

Objective:

To determine the workability of freshly mixed concrete by the use of slump

test.

Reference:

IS: 7320-1974, IS: 1199-1959, SP: 23-1982.

Apparatus:

Slump cone, tamping rod, metallic sheet, weighing machine and scale.

Material:

Cement, sand, aggregate and water

Procedure:

1. Clean the internal surface of the mould thoroughly and place it on a smooth

horizontal, rigid and non-absorbent surf ace, such as of a metal plate.

2. Consider a W/C ratio of 0.5 to 0.6 and design mix of proportion about 1:2:4 (it

is presumed that a mix is designed already for the test). Weigh the quantity of

cement, sand, aggregate and water correctly. Mix thoroughly. Use this freshly

prepared concrete for the test.

3. Fill the mould to about one fourth of its height with concrete. While filling,

hold the mould firmly in position

4. Tamp the layer with the round end of the tamping rod with 25 strokes

disturbing the strokes uniformly over the cross section.

5. Fill the mould further in 3 layers each time by 1/4th height and tamping evenly

each layer as above. After completion of rodding of the topmost layer strike of

the concrete with a trowel or tamping bar, level with the top of mould.

6. Lift the mould vertically slowly and remove it.

7. The concrete will subside. Measure the height of the specimen of concrete after

subsidence.

8. The slump of concrete is the subsidence, i.e. difference in original height and

height up to the topmost point of the subsided concrete in millimetres.

Observations:

W/C ratio

Slump Value

Result:

The slump of concrete is:

mm.

Conclusions:

The slump value indicates that the concrete has Very low/ Low/ Medium/ High degree of

workability.

EXPERIMENT NO. 11B

MEASUREMENT OF WORKABILITY OF CONCRETE

BY COMPACTION FACTOR TEST

Theory:

This test is adopted to determine workability of concrete where nominal size of aggregate

does not exceed 40 mm. It is based on the definition, that workability is that property of

concrete, which determines the amount of work required to produce full compaction. The test

consists essentially of applying a standard amount of work to standard quantity of concrete

and measuring the resulting compaction. The compaction factor is defined as the ratio of the

weight of partially compacted concrete to the weight of fully compacted concrete. It shall be

stated to the nearest second decimal place. The relationship between degree of workability

and compaction factor are:

Degree of workability

Very Low

Low

Medium

High

Compaction Factor

0.75- 0.80

0.80- 0.85

0.85- 0.92

>0.92

Compaction factor test is more sensitive and precise than slump test and is particularly

useful for concrete mixes of very low workability. Such concrete may show zero to very low

slump value. Also, compaction factor (C.F.) test is able to indicate small variations in

workability over a wide range. Compaction factor test proves the fact that with increase in the

size of coarse aggregate the workability will decrease. However, compaction factor test has

certain limitations. When maximum size of aggregate is large as compare with mean particle

size; the drop into bottom container will produce segregation and give unreliable comparison

with other mixes of smaller maximum aggregate sizes. Moreover, the method of introducing

concrete into mould bears no relationship to any of the more common methods of placing and

compacting high concrete.

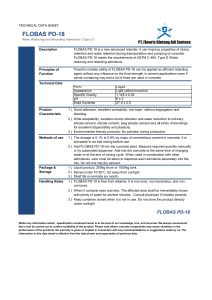

Compaction factor test apparatus consists of two conical hoppers, A and B, mounted

vertically above a cylindrical mould C. The upper hopper A has internal dimensions as: top

diameter 250 mm; bottom diameter 125 mm and height 225 mm. The lower hopper B has

internal dimensions as: top diameter 225 mm; bottom diameter 125 mm and height 225 mm.

The cylinder has internal dimensions as: 150 mm diameter and 300 mm height. The distances

between bottom of upper hopper and top of lower hopper, and bottom of lower hopper and

top of cylinder are 200 mm in each case. The lower ends of the hoppers are fitted with quick

release flap doors. The hoppers and cylinders are rigid in construction and rigidly mounted on

a frame. These hoppers and cylinder are rigid easily detachable from the frame. Figure 7

shows the diagram of a compaction factor test apparatus.

Figure 7: Compaction factor test apparatus

Objective:

To measure the workability of concrete by compaction factor test.

Reference:

IS: 1199-1959, SP: 23-1982.

Apparatus:

Compaction Factor Apparatus, tamping rod, metallic sheet, weighing machine

and scale.

Material:

Cement, sand, coarse aggregate and water

Procedure:

1. Prepare a concrete mix for testing workability. Consider a W/C ratio of 0.5 to

0.6 and design mix of proportion about 1:2:4 (it is presumed that a mix is

designed already for the test). Weigh the quantity of cement, sand, aggregate

and water correctly. Mix thoroughly. Use this freshly prepared concrete for the

test.

2. Place the concrete into the upper hopper up to its brim.

3. Open the trapdoor of the upper hopper. The concrete will fall into the lower

hopper.

4. Open the trapdoor of the lower hopper, so that concrete falls into the cylinder

below.

5. Remove the excess concrete above the level of the top of the cylinder; clean the

outside of the cylinder.

6. Weigh the concrete in the cylinder. This weight of concrete is the "weight of

partially compacted concrete", (W1).

7. Empty the cylinder and refill with concrete in layers, compacting each layer

well (or the same may be vibrated for full compaction). The top surface may be

struck off-level.

8. Find cut weight of the concrete in the fully compacted state. This weight is the

“Weight of fully compacted concrete" (W2).

Observations:

•

•

•

Weight of partially compacted concrete (W1)

Weight of fully compacted concrete (W2)

Compaction factor (F) = 𝑊𝑊1 /𝑊𝑊2

:

:

:

Kg

Kg

.

Result:

The compaction factor of concrete is:

.

Conclusions:

The compaction factor value indicates that the concrete has Low/ Medium/ High Degree of

workability.

EXPERIMENT NO. 12A

TESTS FOR DETERMINATION OF COMPRESSIVE STRENGTH

OF CONCRETE

Theory:

One of the important properties of concrete is its strength in compression. The strength in

compression has a definite relationship with all other properties of concrete i.e. these

properties improved with the improvement in compressive strength. Thus, with this single

test one judge that whether Concreting has been done properly or not. In India cubical moulds

of size 15 cm × 15cm × 15 cm are commonly used.

The concrete is prepared with definite proportion is poured in the mould and

tempered properly so as not to have any voids. After 24 hours these moulds are removed and

test specimens are put in water for curing. The top surface of this specimen should be made

even and smooth. This is done by putting cement paste and spreading smoothly on whole area

of the specimen. These specimens are tested by a compression testing machine after 3, 7 or

28 daysofcuring. Load should be applied gradually at the rate of 14 N/mm2 per minute till the

Specimens fails. Load at the failure divided by area of specimen gives the compressive

strength of concrete. At least three specimens are tested at each selected age. The failure of

the specimen is called as ‘hour glass’ type failure. This happens due to lateral restraint

provided by the plates to the cubes.

Practically, the compression testing system develops a complex system of stresses due to

end restraints provided by steel platens of the compression testing machine (CTM). Under

compression loading, due to the “poisons effect”, the cube specimen also undergoes lateral

expansion. However, the steel platens don’t undergo lateral expansion to the same extent that

of concrete. Thus, there exist a differential tendency of lateral expansion between steel plates

and concrete cube faces. As a result of this, tangential forces are induced between the end

surfaces of the concrete specimen and the adjacent steel platens of CTM. Therefore, in

addition to the applied compressive stress; lateral shearing stresses are also effective in these

specimens. The effect of this shear decreases to words the center of the cube. Thus, the cube

has near vertical crack at the cube's center and sometimes, the cube may completely

disintegrate leaving a relatively undamaged central core. Figure 8 shows, typical failure

patterns of the concrete cube.

Figure 8 : Failure patterns of concrete cubes