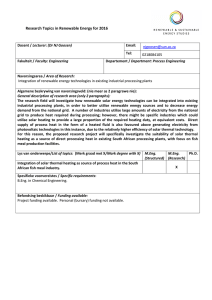

Retrofitting Residences for Energy Efficiency A Practical Approach Georges Khoury PRGR699B – Project July 29, 2022 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Retrofitting Residences for Energy Efficiency - A Practical Approach Table of Contents 1. Introduction 2. Step 1 – Where to Start? 2.1. Essential data 2.2. Optional data 2.3. Inspection-generated data 3. Step 2 – How to Treat the Collected Data? 3.1. Energy consumption baseline 3.1.1. Electricity connection and heating equipment physical inspection 3.1.2. Electrical energy consumed 3.1.3. Thermal energy consumed 3.2. The residence electrical load 3.2.1. Lights 3.2.2. Appliances 3.3. The residence cooling and heating load 3.4. The residence backup power 3.4.1. Generating sets 3.4.2. Uninterruptible power supply 3.4.3. Energy storage systems 3.5. The residence renewable power 4. Step 3 – What Can Be Done to Improve Energy Efficiency? 4.1. Improve the electrical load 4.1.1. Lights 4.1.2. Appliances 4.2. Improve the cooling and heating load 4.3. Improve the backup power 4.3.1. Generating sets 4.3.2. Uninterruptible power supply 4.3.3. Energy storage systems 4.4. Improve the renewable power 4.4.1. Solar photovoltaics 4.4.2. Solar water heating 2 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 4.4.3. Wind microturbine 4.4.4. Biomass heating 4.5. Explore potential renewable power 4.5.1. Solar photovoltaics 4.5.2. Energy storage systems 4.5.3. Solar water heating 4.5.4. Wind microturbine 4.5.5. Biomass heating 5. Conclusion Appendix – Wind Microturbine Data Sheet Additional Resources 3 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 1. Introduction The objective of this paper is to define a set of tools for increasing the energy efficiency of existing residences. The methodology is based on academic literature and work experience. The rationale of the process is to accept what cannot be controlled and to assess what can be, using the criteria of practicality and economics. The accompanying Excel workbook provides a convenient way of entering the collected data and performing calculations toward recommending energy efficiency measures. 2. Step One – Where to Start? The conventional approach would start by conducting an energy audit of the residence using software, such as EnergyPlus. The software methodology would map out the residence envelope material, the orientation, the fenestration, the electric and heating loads, the occupancy parameters and the ventilation/infiltration data. It will then run a simulation for the full year using localized weather and irradiation data. The output would be the energy consumed in kWh when taking into account cooling, heating and renewable energy systems. This is not the approach this paper follows. This paper starts by examining the empirical evidence, using 3 sets of data. 2.1. Essential data • The utility bills, having at least a couple of monthly consumption figures, in peak and off-peak conditions (usually summer and winter months) • The utility meter readings, preferably showing energy in and out of the residence • The fuel meter readings for the same months of the utility bills considered 2.2. Optional data • Logs of renewable energy history, showing energy produced, used and curtailed • Logs of backup power (generating set, UPS, Energy Storage System, etc.), showing power loss / time of use shift events, energy produced, fuel consumed, battery state of charge (at the beginning and the end of the event) and power quality metrics 2.3. Inspection-generated data • Inspection of the physical space, covering the building envelope specifications (walls, roof/ceiling, floor/ground, windows/skylights, doors, infiltration/ventilation), the orientation/exposure, the shading information (internal, architectural and external), the 4 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach space available for equipment to be recommended (solar panels, variable frequency drives, heat pumps) • Inventory of the electrical load components, listing the appliances with their power rating and energy classification (e.g., EPA Energy Star, EU Energy Label) and the lighting elements and their type (e.g., LED, CFL, incandescent) • Inventory / running inspection of the HVAC components, checking the type and rating, the starting and running current characteristics, the type of fuel used, the pumping system characteristics and the control devices (analog thermostat, digital thermostat, built-in thermostat) • Site dwellers’ habit survey, including space occupancy information, time of low and high usage of power, cooling and heating comfort temperature settings, level of activity within each zone of the site. 3. Step Two – How to Treat the Collected Data? The first task is to establish an energy consumption baseline. Reducing this value will be the main success criterion for the energy efficiency exercise. 3.1. Energy consumption baseline The values to be used to establish this baseline are the electrical and fuel monthly energy consumptions. Considering the residence as a black box where energy from different sources is the input while essential living conditions and comfort are the output. Electricity from the Grid Lighting Electricity from Renewable Sources kWhelectrical Appliances Electricity from Back-up Sources Electrical HVAC Equipment Fuel for Back-up Sources Cooling / Heating from HVAC Equipment Comfortable Indoor Temperature, airflow and Relative Humidity kWhthermal Fuel for HVAC Equipment 5 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 3.1.1. Electricity connection and heating equipment physical inspection The objective of this inspection is to collect information about the equipment specifications, rather than to survey any potential maintenance issues. The utility meter is to be checked for the type, connectivity, current readings and Amp rating. Downstream from it, the main distribution board is to be inspected; the objective is to verify there are no discernible faults and to sketch up the distribution schemes inside the residence (number and Amp rating of circuit breakers, main breaker Amp rating, renewable energy disconnect breakers and contactors/motorized switching breakers, test and monitor LEDs, etc. As for the boiler, the type and make are to be noted, along with the rating, the general condition and the overall pipework status. 3.1.2. Electrical energy consumed The monthly bill issued by the utility company providing grid electricity to the site lists the kWh consumption. In certain cases, the invoice goes beyond the energy-in quantification to include the energy-out from the site; this energy-out has its origin from the excess energy produced by an on-site power generation source. The ideal case to have a full picture is to have utility bills covering one full calendar year. If this is not possible, then 1-2 bills per season (summer and winter) can serve as a basis for an estimate of the electrical consumption. If the energy-out kWh reading is available, it cannot be used at face value; it can only be used in conjunction with the total kWh produced by the renewable or backup power source. As the objective is to determine the total kWh consumed, the part of renewable / backup energy consumed by the site needs to be calculated. The calculations go as follows: kWhelectrical, total = kWh imported from the grid + kWh generated by alternative source – kWh exported to the grid where Term kWh imported from the grid Definition consumption billed by the utility kWh generated by alternative source energy produced by renewable sources (solar, wind, etc.) or backup Notes minimum requirement: one value for peak consumption month and one value for off-peak consumption month the values correspond to the months considered for the grid energy as per above – these values need to be 6 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach sources (generating set, energy storage system, etc.) kWh exported to the grid energy credited by the utility collected from the renewable/backup system log or by reading a meter downstream from such system the values correspond to the months considered for the grid energy as per above 3.1.3. Thermal energy consumed This component of energy consumption is only relevant if fuel is used as a primary source for producing heat. Such fuels include natural gas, diesel, biomass, etc. Cooling via absorption chillers is not considered, because it is very rare to find it applied to residences. There are two ways of calculating thermal energy consumption. The direct one is: kWhthermal, total = kW rating of the boiler x number of hours the boiler is run per month this result is particularly useful in the case of natural gas since it is usually billed to the residence per kWh (or the equivalent m3/kWh). The other, indirect, way is to go by the volume of fuel purchased. The first instinct would be to go for the boiler fuel consumption figure as specified by the manufacturer; this is only accurate for brand new equipment. The fuel consumption depends on the age of the boiler and the regularity of its maintenance. The better option would be to ask the residence tenants for the fuel supply monthly bill – the volume of the fuel purchased can then be converted into kWhthermal, total. 3.2. The residence electrical load To calculate the electrical load, the inventory of lighting and appliances needs to be used, along with the schedule of the running of said lights and appliances. 3.2.1. Lights The information collected needs to be tabulated, along with the time of use. This should resemble something like this: Item Lighting Element Location Watt Rating Weekdays Number of Hours of Daily Operation Number of Weekdays in the Month Considered 1 LED Ceiling Lamp Living Room 23 5 23 Weekends and Holidays Number of Hours of Daily Operation 7 Number of Weekends and Holidays in the Month Considered kWh in the Month Considered 8 =23x(5x23+7x8)/1000 = 3.93 7 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 3.2.2. Appliances One would be tempted to use the same methodology used for lighting for other types of household appliances, including HVAC equipment. This would not be the accurate approach, especially when motors and compressors are involved. The better way would be to go for the manufacturer’s kWh calculations (e.g., one washing machine rated at 2000 W would consume 1.5 kWh / wash as per its manufacturer or a fridge rated at 140 W but whose manufacturer calculates a 358 kWh per year consumption). The tabulation needs to be modified as follows: Item Appliance Location Watt Rating 1 Washing Machine Fridge Bathroom Kitchen 2 kWh as per Manufacturer’s Calculation Number of Units per Month kWh in the Month Considered 2000 Unit of kWh used for Manufacturer’s Calculation Wash 1.5 14 =1.5x14=21 140 Year 358 1/12 =358/12 = 29.83 In addition, the phantom loads need to be considered for devices that are always plugged in and consume standby power. Manufacturers rarely list the standby power rating of appliances; the following table is derived from empirical measurements: Appliance TV Set-top box Washing machine Refrigerator Mobile phone charger Split air conditioner Rice Cooker Desktop Computer Electric heating table Sterilizer Drinking fountain Electrical water heater Induction cooker Microwave oven Stereo Extractor hood DVD players Standby Power (W) Min. Avg. Max. 0.3 4.4 14.0 0.4 4.5 7.4 0.0 1.7 5.4 0.0 3.4 13.0 0.0 0.4 2.9 1.1 6.4 50.0 0.4 13.2 50.5 1.9 3.6 6.6 1.5 2.6 3.7 0.6 1.0 2.4 0.0 2.4 17.0 0.5 1.4 3.0 1.3 2.8 5.6 0.3 0.8 1.4 4.6 10.0 16.7 0.0 1.1 5.1 0.3 4.1 7.8 Standby usage time (hours/day) Min. Avg. Max. 0.0 7.3 24.0 0.0 7.3 24.0 0.0 7.7 24.0 24.0 24.0 24.0 0.0 18.5 24.0 8.0 23.7 24.0 0.0 2.2 24.0 19.0 22.7 24.0 5.0 9.9 13.0 0.0 5.8 24.0 0.0 11.4 24.0 0.0 14.4 24.0 0.0 0.0 0.0 23.8 23.9 24.0 0.0 3.0 12.0 0.0 2.1 21.0 0.0 0.0 0.0 Source: Zhun (Jerry) Yu, Bin Hu, Yongjun Sun, Anbang Li, Jun Li, Guoqiang Zhang, Standby energy use and saving potentials associated with occupant behavior of Chinese rural homes, Energy and Buildings, Volume 154, 2017, https://doi.org/10.1016/j.enbuild.2017.08.070 3.3. The residence cooling and heating load The traditional method to calculate the cooling/heating load is to use software, such as DesignBuilder. This does not conform with the objective of this approach. The most practical 8 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach way to proceed is to assess the installed cooling/heating BTU or kW rating. The electrical consumption needed to cover the load has already been addressed. What is needed now is to inspect the cooling/heating load elements that affect the operation of the HVAC equipment, with an eye on reducing this operation as much as possible. The sensible and latent parts of the cooling/heating load need to be considered for each particular zone served by an HVAC piece of equipment. This translates practically, for normal residences, into individual rooms where HVAC equipment operates. The sensible part of the cooling/heating load is influenced by the following (already inspected): • Construction specifications of walls, ceilings/roofs and floors/grounds – while this aspect has a big impact, it is the most difficult to change/improve • Windows specifications – this is not limited to the windows themselves, but extends to the shading measures employed (e.g., curtains, shutters, overhangs, fins). This is easier to change/improve, but it is costly in most cases • Lighting and appliance load – which adds to the sensible heat component, but is already addressed elsewhere. The latent part of the cooling/heating load is influenced by the following (already inspected): • Ventilation/infiltration – this is fairly simple to change/improve, but it is restricted by code in many jurisdictions • Occupant number and level of activity – this is not a factor that can be changed by recommendation. It needs to be included as an immutable effect on the cooling/heating load. A tabulation of the information collected about the cooling/heating load in one room can go as follows: Location Envelope Information Bedroom 1 Ceiling / Roof Dimensions (m) 3x4 Floor / Ground 3x4 Wall 1 Specifications Wall 2 Specifications Wall 3 Specifications Wall 4 Specifications Window 1 Specifications 3x3 4x3 4x3 3x3 2x2 Window 2 Specifications Window 3 Specifications Window 4 Specifications - Construction Concrete, 30 cm thick, plaster, 5 cm rock wool insulation Concrete, 30 cm thick, plaster, 1 cm thick parquet, 5 cm rock wool insulation CMU, 20 cm thick, plaster, 5 cm air gap, no insulation CMU, 15 cm thick, plaster, no air gap, no insulation CMU, 15 cm thick, plaster, no air gap, no insulation CMU, 15 cm thick, plaster, no air gap, no insulation Double glazing, 6 mm clear glass, 12 mm air gap Remarks Indoor curtains, no shutters, no overhang, no fins, no obstacles 9 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach HVAC Equipment Type Wall Mounted Split A/C Make Model Cooling Rating (kW) Heating Rating (kW) EER Rated Capacity (BTU/h) Calculate d kWh Carrier 42QHA012VS 3.51 3.5 9.8 10,600 1.08 Ventilation/Infiltration Estimation ASHRAE Recommended Air Changes per (m3/h) Hour 25 0.5 Occupant Information Regular Occupancy Level of Activity 2 Sleeping / Seated, quiet ASHRAE ACH Equivalent in m3/h for Location =3x4x3x0.5=18 Preferred Thermostat Summer Setting (ºC) 18 Thermost at Setting ºC (Cooling) 18 Thermost at Setting ºC (Heating) 27 Remarks Preferred Thermostat Winter Setting (ºC) 27 Remarks 3.4. The residence backup power While not present at all residences, backup power is popular in areas with high exposure to extreme weather events (hurricanes, earthquakes, floods, forest fires) and areas with an unstable grid. The most common type of backup power is generating sets (either gas or diesel fired). Where there are critical loads (medical in-house equipment, communication devices), there could also be an uninterruptible power supply. And, bridging the gap between backup and renewable power are energy storage systems; these can be used to complement a solar photovoltaic installation, for instance, they can be used for load management (shifting consumption in case the utility has a “time of use” tariff in effect) or they can serve as backup as an alternative to generating sets. 3.4.1. Generating sets The only aspect of operating generating sets to optimize is their fuel consumption. Records of fuel purchase and control panel logs should provide enough information about historical operations from the energy produced to the amount of fuel burnt. The generating sets’ electrical connection points need to be inspected for the following: • Suitability and condition of the installed cabling and circuit breakers • Location of the connection bus and its potential for expansion • Location of control cabling and its potential for repurposing/replacement. 10 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 3.4.2. Uninterruptible power supply As with generating sets, the opportunities for optimization when it comes to UPS are limited to the electrical energy used to recharge the batteries. This, of course, supposes that the UPS is fairly efficient (>95% in most modern equipment). The UPS’s electrical connection points need to be inspected for the following: • Suitability and condition of the installed A/C cabling and circuit breakers • Suitability and condition of the installed D/C cabling and fuse holders/circuit breakers • Condition of the battery bank (battery age, number of discharge/recharge cycles, voltage at the entry to the inverter) and the interconnecting D/C wiring. 3.4.3. Energy storage systems The most common type of ESS is grid-connected lithium-ion battery banks. As for UPS, the only possible improvement in terms of energy efficiency is when the battery recharges. As the ESS is usually a self-contained system, the only inspection possible is for the battery age and the number of discharge/recharge cycles. The voltage level at the entry to the inverter is also important to check for any possible failure in the battery blocks. 3.5. The residence renewable power There are lots of possible variations of renewable power sources that could be installed at residences. The most practical ones are: • Solar photovoltaics • Solar water heating • Wind microturbines • Biomass heating. Carrying out an inspection to improve the efficiency of renewable power sources depends on the source: • Solar photovoltaics: o Positioning inspection: azimuth and tilt of the photovoltaic panels, external shading or panel inter-row shading, albedo conditions, cleaning regime o Electrical inspection: A/C and D/C cabling and breaker suitability, inverter rating, battery bank condition (if present), control cabling suitability 11 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach • Solar water heating: o Positioning inspection: azimuth and tilt of the thermal panels, external shading or panel inter-row shading, albedo conditions, cleaning regime o Mechanical inspection: water piping condition, water tank and pipe insulation condition, pump condition (if present) • Wind microturbine: o Positioning inspection: tower height, external obstacles o Electrical inspection: A/C and D/C cabling and breaker suitability, inverter rating, battery bank condition (if present), control cabling suitability • Biomass heating: o Boiler inspection: rating, biomass type, maintenance condition o Mechanical inspection: pipe insulation, radiator blockage, water tank insulation, heat exchanger condition. 4. Step Three – What Can Be Done to Improve Energy Efficiency? Now that the site data has been collected and analyzed, it is time to formulate recommendations to improve energy efficiency. The general approach will be as follows: • Describe the relevant measure • Rate the measure on a scale from “Easy” to “Impractical” • Rate the measure on a scale from “Cheap” to “Uneconomical”. 4.1. Improve the electrical load The electrical load in a typical residence is made up of lighting and appliances. The appliances, in this case, include HVAC equipment, as it is concerned with how to reduce electric consumption when this equipment is run, as opposed to reducing the reasons for this equipment is run, which is tackled in the cooling/heating load reduction section. 12 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 4.1.1. Lights Proposed Measure 1 Implementing the Measure Practicality Affordability Replace all light fixtures The easier approach would be to gradually with LED bulbs replace burnt-out light bulbs with LED ones Remarks 1- A wholesale replacement of all lighting fixtures with LED lights yields the best result in lowering lighting energy consumption. It is, however, neither practical nor affordable. 2- An alternative approach would be to proceed by zone, with the highest occupancy ones throughout the day being prioritized with the LED replacement effort. 3- When selecting the LED lighting, it is important to match the lumen value and light color of the light being replaced, so as not to cause any inconvenience to the occupants. 4- For any economic evaluation, it is important to take into account the lifespan of the LED bulbs (up to 25,000 hours) to get to the yearly energy savings to offset the capital expenditure of the measure. Proposed Measure 2 Implementing the Measure Use smart instead of At the time of replacement, it would be conventional LED lighting interesting to consider investing in smart LED Practicality Affordability bulbs Remarks 1- Going for smart LED gives the occupants control over the intensity of the light (and its color) and allows for timing / remote switching of the lights. 2- Although it could fit in a wider strategy of making the home “automated”, smart LED lights are available off the shelf and can function as a discrete system. 4.1.2. Appliances Proposed Measure 1 Implementing the Measure Replace old appliances The easier approach would be to gradually with ones having a class A replace end-of-life appliances with energy- energy label (EU) or efficiency labeled ones Practicality Affordability Energy Star (USA) Remarks 1- A wholesale replacement of all appliances with energy-certified ones yields the best result in lowering their energy consumption. It is, however, neither practical nor affordable. 13 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 2- An alternative approach would be to proceed by prioritizing the replacement of the most energy consumption first such as washing machines and electric water heaters. Proposed Measure 2 Implementing the Measure Practicality Affordability Replace air conditioners The air conditioner inverter or VSD (Variable with ones using “inverter” Speed Drive) has a lower energy consumption technology than traditional ones. Remarks 1- There could be an economic argument to warrant the wholesale replacement of air conditioners with inverter-type ones. It does imply, however, major installation works and high capital expenditure. Proposed Measure 3 Implementing the Measure Use a smart power strip to The easier way is to group the appliances (e.g. curb phantom loads audio-visual equipment, computing equipment, Practicality Affordability etc.) to limit the number of power strips Remarks 1- Smart power strips come with different configurations and price points. The simplest ones come with a timer that will make sure it turns off all connected loads after a certain time; this could be enough in most cases. 4.2. Improve the cooling and heating load The objective is to reduce the cooling and heating loads while keeping the residence within the ASHRAE recommended comfort zones (24ºC and 50% relative humidity during summer / 21ºC and 30% relative humidity during winter). By examining cooling and heating loads as per the below diagrams (from: Strategy guideline: Accurate heating and cooling load calculations), it becomes apparent that the aspects to address are: • Heat gain/loss through the walls, ceilings/roofs and floors/grounds • Solar heat gain/loss through the windows and skylights • Infiltration/ventilation heat gain/loss through the building envelope • Latent heat gain caused by the occupants and their activities – trying to change this implies a change of habits of the occupants, which is not something energy efficiency improvement should prioritize • Internal heat gain caused by electrical lighting and appliances – this has already been addressed in the electrical load improvement section. 14 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Heat Gain Locations Heat Loss Locations No major intervention can be made on the envelope without high expenditure and occupant inconvenience. The following measures are the most practical: Measures related to the walls, ceilings/roofs and floors/grounds Proposed Measure 1 Implementing the Measure Insulate the walls The easiest material to work with is rockwool / internally recycled fiber in rolls. It is applied to the Practicality Affordability internal surface of the walls and covered with a gypsum board that can be painted any color. Remarks 1- The operation is lengthy and messy. It is also recommended the occupants leave the residence while it is being carried out, because of dust and fumes 2- A relatively thin insulation layer (6 – 8 cm) and a 1.5 cm thick gypsum board will increase the wall R-value by 0.38 m2.K/W Proposed Measure 2 Implementing the Measure Insulate the ceiling if there The easiest material to work with is rockwool / is an attic recycled fiber in rolls. It is applied to the upper Practicality Affordability surface of the ceilings and is covered with plywood. 15 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Remarks 1- The operation is lengthy and messy. It is also recommended the occupants leave the residence while it is being carried out, because of dust and fumes 2- A relatively thin insulation layer (6 – 8 cm) and a 2 cm thick plywood board will increase the ceiling R-value by 0.38 m2.K/W 3- Alternative insulation material includes polyurethane or polystyrene and tiling. Proposed Measure 3 Implementing the Measure Insulate the roof if The easiest material to work with is applicable polyurethane / polystyrene in boards. It is Practicality Affordability applied to the exterior of the roof and tiled over. Remarks 1- The operation is lengthy and messy. As the work is done outside the residence, it is safe for the occupants to stay. 2- A relatively thin insulation layer (6 – 8 cm) and a 2 cm thick tile will increase the roof R-value by 0.45 m2.K/W. Proposed Measure 4 Implementing the Measure Insulate the floor The easiest material to work with is internally polyurethane / polystyrene in boards. It is Practicality Affordability applied to the exterior of the roof and is covered with tile or wood flooring. Remarks 1- The operation is lengthy and messy. It is also recommended the occupants leave the residence while it is being carried out, because of dust and fumes 2- A relatively thin insulation layer (6 – 8 cm) and a 2 cm thick tile or 1 cm thick wood flooring will increase the floor R-value by 0.45 m2.K/W. Measures related to the windows and skylights Proposed Measure 1 Implementing the Measure Replace This measure is only applicable if the current windows/skylights with windows/skylights are single-glazed. It triple or double-glazed involves dismounting the existing types window/skylight panes and replacing them Practicality Affordability with higher-efficiency ones. Remarks 1- The operation is very expensive. It should not take a long time to complete, as most of the work is done off-site and the actual on-site work consists of replacing window/skylight panes. 16 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 2- The measure can be done while the occupants are on site. They would have to put up with dust and construction noise. Proposed Measure 2 Implementing the Measure Use blackout curtains on This measure consists of installing new / windows/skylights replacing existing curtains hanging in front of Practicality Affordability windows/rolling under skylights. Remarks 1- The operation is moderately expensive, depending on the material and brand of the curtains chosen. It should not take a long time to complete, as most of the work is done off-site and the actual on-site work consists of taking out the old curtains and installing the new ones 2- There might be an issue with the amount of light the curtains would block. To get the best results, the curtains needs always to be drawn, which might force a lengthier use of indoor lighting. Measures related to Infiltration/ventilation Proposed Measure 1 Implementing the Measure Seal any air leak around This measure consists of sealing any air leak in the residence outer the horizontal and vertical joints of walls, perimeter ceilings/roofs, floors/grounds, in the openings Practicality Affordability around windows/skylights and doors and in/around any exhaust ducting (kitchen hob, fireplace). Remarks 1- It is imperative to conduct an air leak test for the entire residence before deciding the economic feasibility and extent of this measure. Air leak tests need to be carried out by professionals and might be expensive, depending on the size of the residence 2- The choice of material to use depends on the size of the air leak and its location/nature. It can range from caulk to foaming agents, with different price points and the extent of labor involved. Proposed Measure 2 Implementing the Measure Controlling the relative This consists in controlling the extent of time humidity brought on by the ventilation system is run and by using ventilation smart dehumidifiers to be placed in each zone Practicality Affordability of the residence. Remarks 1- This measure becomes necessary in the event air tightness of the residence is achieved. For the comfort of the occupants, a certain number of air changes 17 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach per hour needs to happen (this is governed by local building standards). Mechanical ventilation might need to be implemented, with the negative impact of higher relative humidity, depending on the outside air conditions. 2- A thermostat with humidity sensors can control the running time of the mechanical ventilation. It can also turn on and off any local smart dehumidifiers, which could provide comfortable conditions, without the need to run energy-intensive air conditioning. 4.3. Improve the backup power As previously discussed, backup power is called upon when the main sources of steady power falter; this is slightly nuanced when it comes to energy storage systems, as they can be used to complement the renewable power sources and/or to shift electricity consumption to a time of day where the utility tariffs are more advantageous (usually evenings on weekdays and weekends). Improvement is, however, restricted to proper maintenance and, more importantly, to a reduction in fuel consumption (generating sets) or utility electricity (UPS and ESS). 4.3.1. Generating sets To make generating sets more energy efficient, it is important to limit their running time and to reduce the consumption of fuel (diesel or natural gas usually) when they do have to run. Proposed Measure 1 Implementing the Measure Limit the runtime of By design, the generating sets turn on when generating sets (if there is there is a loss of utility power. Connecting renewable power present) them in sync with the renewable power Practicality Affordability inverters would stop them from running when there is enough renewable power to sustain the load. Remarks 1- In practice, an external control board (such as the DEIF ASC-4 https://www.deif.com/products/asc-4-solar/) needs to be installed and connected by control wiring to the renewable inverter and the generating set 2- While the capital expenditure for the equipment/material is not large, the installation work might prove to be difficult and expensive, depending on the site conditions. 18 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Proposed Measure 2 Implementing the Measure Conduct maintenance on The generating set needs to be serviced the generating set regularly (every 6 months or 250 hours of Practicality Affordability operation, whichever occurs first). This includes oil and filter changes. In addition, it is recommended to clean the carbon deposits and ensure the water / coolant are at the right temperature and mixture level Remarks 1- This is a regular exercise. Having the right service agreement in place will reduce breakdowns and improve the performance of the generating set. Proposed Measure 3 Implementing the Measure Reduce the load connected Running through the load connected to the to the generating set generating set might lead to some of it being Practicality Affordability disconnected. With a reduced load, the generating set will operate more efficiently. Remarks 1- This is an exercise in identifying which loads are critical to warrant being backed up. If loads are not deemed sensitive enough, they can be excluded from the generating set distribution panel. 4.3.2. Uninterruptible power supply The only measure of energy efficiency to be conducted with UPS (besides the replacement of the UPS equipment with more efficient hardware) is to reduce the electricity used to recharge the batteries. Proposed Measure 1 Implementing the Measure Practicality Affordability Charge the batteries only Battery charging cables need to be connected from renewable power (if to the renewable power inverter distribution present) board. Remarks 1- There is no major capital expenditure involved. The cable rerouting work might, however, prove to be difficult and expensive, depending on the site conditions. Proposed Measure 2 Implementing the Measure Charge the batteries from Battery charging is to be permitted only when the utility only during off- the off-peak utility tariff is in force. Practicality Affordability peak tariff 19 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Remarks 1- The way to make sure the batteries are only charged during a certain time interval is the replace the circuit breaker feeding the charger with a smart circuit breaker, which can be programmed to close during the specified window. 4.3.3. Energy storage systems To make the ESS more energy efficient, the same logic applied to the UPS needs to be followed: reduce the electricity used to recharge the batteries. Proposed Measure 1 Implementing the Measure Practicality Affordability Charge the batteries only Battery charging cables need to be connected from renewable power (if to the renewable power inverter distribution present) board. Remarks 1- There is no major capital expenditure involved. The cable rerouting work might, however, prove to be difficult and expensive, depending on the site conditions. Proposed Measure 2 Implementing the Measure Charge the batteries from Battery charging is to be permitted only when the utility only during off- the off-peak utility tariff is in force. Practicality Affordability peak tariff Remarks 1- The way to make sure the batteries are only charged during a certain time interval is the replace the circuit breaker feeding the charger with a smart circuit breaker, which can be programmed to close during the specified window. 4.4. Improve the renewable power For solar photovoltaics / water heating and wind microturbines, the goal is to maximize the capture of the energy source (solar radiation and wind). As for biomass, the higher the calorific value of the fuel, the better the output is. 4.4.1. Solar photovoltaics 4.4.2. Solar water heating The yield of any solar system (photovoltaic or thermal) is affected by the positioning of the solar panels and the shading they are subject to. When checking the mounting of the solar panels, two figures need to be inspected: 20 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach • The solar panel elevation angle (vertical tilt). The optimal value for year-round yield is for the elevation angle to be set at the site latitude (e.g., for Beirut this would be 33.88º) • The solar panel azimuth angle (horizontal orientation in relation to the equator). The optimal value is 180º for Northern Hemisphere sites and 0º for Southern Hemisphere ones. Shading on solar panels originates from two sources: • External obstacles: nearby terrain higher than the site, trees, antennas or poles • Self-shading from other photovoltaic panel rows. Proposed Measure 1 Implementing the Measure Change the elevation and If the panel existing angles depart significantly azimuth angles of the from the optimal values, then they need to be solar photovoltaic panels shifted towards the optimal by modifying the Practicality Affordability location and height of their supporting metallic structure. Remarks 1- This is a very delicate operation: the panels need to be dismounted first without damaging them; the metallic structure needs then to be relocated to the new azimuth direction, which implies its legs being dislodged and then affixed to the horizontal surface (roof, ground) again. As for the elevation, if the vertical part of the structure is welded, it needs to be replaced to accommodate the new position 2- This measure is only to be carried out by professionals, which means incurring moderate to high labor costs. Proposed Measure 2 Implementing the Measure Remove external obstacles The only external obstacles that can be Practicality Affordability controlled are ones on the site: trees that can be trimmed, antennas/poles that can be moved, etc. Remarks 1- If measure 1 needs to be taken, then the external obstacles to be cleared are the ones affecting the panels in their new position. 21 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Proposed Measure 3 Implementing the Measure Eliminate inter-row If the solar panels are installed in more than shading one row, then the higher rows might cast a Practicality Affordability shade on the ones below them. The solution is to increase the space between the metallic structures holding each row of panels. Remarks 1- The minimum inter-row distance between rows can be determined empirically by observing the shades at different times of a solar day. Alternatively, there are online calculators to facilitate the task (e.g., https://www.renvu.com/Inter-row-Spacing-Calculator) 2- The ease of this operation depends on the construction of the existing metallic structures. If the two structures are welded, then the horizontal beams holding the two structures together need to be replaced. 3- In any case, all panels must be dismounted with care before attempting any work on this measure. This is only to be carried out by professionals, which means incurring moderate to high labor costs. Proposed Measure 4 Implementing the Measure Cleaning the solar panels The solar panels need to be cleaned regularly Practicality Affordability to improve their yield. Remarks 1- The cleaning frequency depends on the local climate. The dustier it gets, the more frequent cleaning must be carried out. This can range from once per season to once per day, depending on the site conditions 2- The best results are achieved by using distilled water. Depending on the dirtiness, a soft sponge and a mild detergent might be needed. Proposed Measure 5 Implementing the Measure Practicality Affordability For solar water heating The water system needs to be descaled, the systems, check the water tank and pipe insulation checked for wear and tank, pump and piping tear and the pump inspected for a proper run. Remarks 1- This should be carried out at least once a year, before the winter season 2- There could be an expenditure element if the pump and tank need to be replaced, as opposed to the pump shaft being repaired or the leaking water tank being welded. 4.4.3. Wind microturbine Improving the energy yield of a wind microturbine is limited to clearing any obstruction and to placing it at the appropriate height. 22 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach The minimum clearance required for the microturbine to function properly is 8 to 11 m above all surrounding obstructions that are within a 90 m radius from the microturbine position. As for elevation, the best results are achieved when the microturbine is placed between 1.51 and 1.79 times above the original height of the building at its front face. Proposed Measure 1 Implementing the Measure Remove external obstacles The only external obstacles that can be Practicality Affordability controlled are ones on the site: trees that can be trimmed, antennas/poles that can be moved, etc. Remarks 1- If the obstacle cannot be moved then, alternatively, the microturbine tower can be relocated to have a clearer horizon. This is an expensive affair that requires dismounting the microturbine and relocating the tower structure. It is also a job for professionals, so labor costs need to be considered. Proposed Measure 2 Implementing the Measure Install the microturbine at If the height of the existing tower is a higher level significantly below the recommended value, Practicality Affordability then a new higher tower must be installed. Remarks 1- This is a drastic measure and should only be taken when the original height prevents the microturbine from yielding energy well below the design yield as determined by consulting the global wind atlas (https://globalwindatlas.info/). 4.4.4. Biomass heating The efficiency is bettered by using biomass with the highest possible calorific value. The following is a list of energy density values by volume for different biomass fuels: Fuel kWh/m3 Wood chips (30% moisture content) 870 Logwood (stacked – air dry: 20% moisture content) 1,400 – 2,000 Wood (solid – oven dry) 2,100 – 3,200 Wood pellets (10% moisture content) 3,100 Miscanthus (bale – 25% moisture content) 500 – 650 Source: https://www.forestresearch.gov.uk 23 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach In addition, the boiler system efficiency can be improved by: Proposed Measure 1 Implementing the Measure Perform maintenance on As 1 millimeter of scale build-up can increase the boiler fuel consumption by 2%, it is important to Practicality Affordability clean the boiler. Remarks 1- Preventive maintenance includes the cleaning of airways, cleaning the heat exchanger and combustion chamber, testing of safety equipment and flue gas analysis to check combustion efficiency Proposed Measure 2 Implementing the Measure Perform maintenance on This concerns the hot and cold water piping, the rest of the system the piping insulation, the pump, the heating Practicality Affordability elements and the domestic hot water tank. Remarks 1- This kind of preventive maintenance starts with a visual inspection: leaks (from the pipes, the pump, the heating elements and the water tank) and wear and tear of the insulation. Descaling the piping can also be carried out easily. 2- If leaks are detected, then it becomes a plumbing job and could imply medium to high labor costs, depending on the extent of the damage. 4.5. Explore potential renewable power The objective is to determine the site appropriateness and readiness for renewable power. Once this is proven, then proper design and installation work needs to be carried out. This is beyond the scope of this document, but the additional resources listed give a good indication of the process needed to acquire renewable power. 4.5.1. Solar photovoltaics The first task is to ascertain the existence of enough space to install solar panels. This calculation starts by determining the electrical load that needs to be covered by the solar photovoltaic system. The kW required is then divided by the kW peak value of a generic solar photovoltaic panel (in this case, it is the Longi Hi-MO5 module, with a 550 kWp rating and dimensions of 2.26 m x 1.13 m). 10% additional space needs to be taken into consideration for maintenance and access. As an example, for a 3 kW load: Area for solar panels = Load W / module Wp x module area x 1.1 = 3000 / 550 x 2.26 x 1.13 x 1.1 = 15.32 m2 24 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach If this space is available, then the next task is to determine the average energy yield per month of the site location. The College Hall at the American University of Beirut has the following coordinates: Latitude: 33.900745 Longitude: 35.482203 Assuming the same 3 kW load is located at the College Hall, then the system would consist of 6 panels with a rating of 3300 Wp. To determine the yield, a free online resource developed by the European Union can be used. Entering the site coordinates, the kWp rating and an estimate of losses (14% is an industry convention), the EU Photovoltaic Geographical Information System can then be accessed via the following link: https://re.jrc.ec.europa.eu/api/v5_2/PVcalc?lat=33.900745&lon=35.482203&peakpow er=3&loss=14&optimalangles=1&outputformat=json&browser=1 The resulting json file has the following values: Month Average daily energy Average monthly energy production (kWh) production (kWh) January 9.36 290.12 February 11.31 316.76 March 13.96 432.76 April 15.68 470.51 May 16.91 524.28 June 17.79 533.82 July 17.74 550.08 August 17.33 537.14 September 16.54 496.22 October 14.26 442.16 November 11.82 354.58 December 9.48 293.78 If these values are deemed acceptable, then the next step would be to proceed with the proper design and execution of the solar photovoltaic system. To help with that, a site survey needs to be conducted: • accessibility of the solar panel space for future maintenance • shading from outside sources • cable routing 25 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach • electronic equipment location • connection to the residence electric panel • in case batteries are part of the system, a well-ventilated indoor or shaded outdoor space needs to be found. 4.5.2. Energy storage systems Energy storage systems (ESS) sit at the intersection of backup and renewable power. An energy storage system, most likely consisting of a lithium-ion battery bank, can run in conjunction with a solar photovoltaic installation or as a stand-alone system. In either case, the system size depends on the autonomy it provides, as expressed in kWh of energy. The battery depth of discharge needs also to be taken into consideration (it rarely should exceed 80%). As most systems can operate in parallel, adding to the system’s autonomy is accomplished by adding a new battery bank (preferably of the same rating). The most appropriate configuration is the “hybrid” one, which can be connected to a solar photovoltaic panel array (and replace the existing inverter, if applicable) or that can supply A/C power to the load (in a similar topology to a standby UPS). The space required for an ESS is not large and there are outdoor type ones, making their installation more flexible. It is best to keep the ESS at 25ºC and away from a direct source of heat, to ensure optimum efficiency. 4.5.3. Solar water heating A more empirical approach is used to determine the area required for solar water heating panels. All tables and figures come from the solar domestic water heating handbook (cited in the additional resources section). To use the same example of the College Hall location, and assuming the need to heat 200 liters of water per day and a temperature differential of 45ºC, the daily energy required would be: Q = ρ x V̇ x Cp x (THot – TCold) where ρ is the water density and Cp is the water specific heat capacity Q = 1 x 200 x 4.18 x 45 = 37620 kJ = 10.45 kWh The yearly required energy is then: Q = 365 x 10.45 = 3814 kWh 26 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach The reference classifies Lebanon as a tropical / sunbelt country. This puts a limit of 70% on the energy to be derived from the sun (known as the solar fraction). The remaining 30% of the energy needed has to come from electrical sources. The energy from the solar system is then 0.7 x 3814 = 2670 kWh. The reference gives Lebanon irradiation for a collector at 30% tilt and facing South equal to: 1,800 kWh/m2 x 97% = 1,746 kWh/m2 For a collector efficiency of 35%, the usable irradiation is then: 1,746 kWh/m2 x 35% = 611 kWh/m2 The collector area can then be calculated as follows: Collector area = 2670 / 611 = 4.37 m2 If this area is available, then the next step is to make sure it is practical to install the solar water heating system: • accessibility of solar panel space for future maintenance • shading from outside sources • connection to the residence water supply • water tank location 27 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach • place for pumps (if needed) and pipe routing • control panels and cable routing. If all the conditions are favorable, a solar water heating system should not be complicated to install. 4.5.4. Wind microturbine To determine the suitability of installing a wind microturbine, the site mean wind speed needs to be investigated. Another free web resource, the Global Wind Atlas (https://globalwindatlas.info/) can be used to get the wind mean speed for a specific location. This can be used with a typical microturbine performance curve to estimate the yearly energy yield for the site. Taking again the College Hall, the website returns the following mean wind speed at 10 m height: From the chart, the wind mind speed at 50% is 3.19 m/s. The yearly energy yield is then calculated by interpolation in the yield table included in the microturbine datasheet (3 kW microturbine by Ryse Energy, included in the Appendix). It is 1525 kWh. If this value is deemed acceptable, then the next step would be to check for the space to erect the tower for mounting the microturbine. The height of this structure, along with the combined weight of the microturbine and the metal / concrete, need to undergo a structural 28 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach analysis to take into account the various forces affecting the structural integrity and, ultimately, the operation of the microturbine. Only then can one proceed to make the proper design and execution of the wind power system. To facilitate this, the following needs to be inspected: • accessibility of the microturbine space for future maintenance • obstructions from outside sources • electronic equipment location • cable routing • connection to the residence electric panel. 4.5.5. Biomass heating Installing biomass heating can be a relatively simple (but not cheap) procedure or it can be complicated and expensive. This depends on the existence or not of a fossil fuel burning boiler (natural gas or diesel fired). If it is a matter of replacing an existing boiler, then the job is to dismantle the old boiler, install the biomass boiler and connect it to the pipe/pump system and the exhaust system. New controls are to be installed. The only constraint caused by the new system is that a storage room for the biomass fuel is needed, with a way to be filled from outside the residence. If no heating system exists, then the first step is to calculate the residence heating load. Specialized software exists but is often expensive. A free online resource, the Hunt Heating Heat Load Calculator (https://www.huntheat.com.au/support/heat-load-calculator/) can be used for the planning and budgeting phase. Once the heating load is calculated, the boiler can be selected. The rest of the plant needs to be designed as well: heating elements in each room (radiator, underfloor heating), hot water tank for domestic hot water, pump, piping connections, controls, exhaust flues, etc. The space constraint is compounded as well: enough room for the boiler, the pumps and fuel storage need to be available (usually 10 m2 is the minimum area needed). 29 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Other elements to consider are: • accessibility of the boiler room for future maintenance • way to unload the biomass fuel safely and quickly (large diameter pipe from the truck position to the storage room, ramp to roll fuel unto when it is unloaded from the truck). 5. Conclusion Two important issues need to be considered when performing any energy efficiency improvement measure: • the economic feasibility of the endeavor • and the decision to install an overarching building management system or not. Economic feasibility The easiest method to determine the economic feasibility of any energy efficiency measure is to calculate its Net Present Value (NPV). The inputs for this calculation are: • Investment amount: capital expenditure required to implement the measure (including equipment, material and labor); any tax incentives, grants or subsidies need to be taken into account • Measure duration (t): time in years where the original measure can still yield positive effects (e.g., solar PV panels have a useful life of 25 years, which means any measure involving these panels has a 25-year duration) • Yearly savings: difference between the baseline scenario and the improved scenario, in terms of money per year (e.g., if the initial yearly energy bill is USD 1200 and the bill becomes USD 900 after implementing the measure, then the savings are USD 300 per year) • Discount rate (i): interest rate applicable if the investment amount is to be borrowed; in the case of a residential type of loan, it is most practical to use the interest rate a bank can offer (minus any subsidies). 30 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach The NPV is then calculated using the formula: 𝑛 𝑁𝑃𝑉 = ∑ 𝑡=1 𝑌𝑒𝑎𝑟𝑙𝑦 𝑆𝑎𝑣𝑖𝑛𝑔𝑠 𝑎𝑡 𝑦𝑒𝑎𝑟 𝑡 (1 + 𝑖)𝑡 The accompanying Excel file calculates the NPV automatically when all values are entered. Any positive NPV indicates that the measure is economically feasible. Building management system The discussion has so far been about discrete measures, with the effect of each being evaluated locally to where the measure is applied. An alternative would be is to group the impact of all measures in one centralized location, where the residence occupants can see the improvements in real-time. The information would be collected via sensors and meters and fed into an algorithm that will enhance monitoring by sending alarms, alerts and notifications and by stopping any harmful event automatically. An example of such a system would be the Johnson Controls OpenBlue building management system: While the benefit of a building management system is mostly about the convenience of the occupants, integrating all measures might lead to synergistic savings. In this case, the NPV of such a system can be calculated to justify its purchase. 31 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Appendix – Wind Microturbine Data Sheet 32 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach 33 PRGR699B – Project Retrofitting Residences for Energy Efficiency – A Practical Approach Additional Resources • Office of Energy Efficiency & Renewable Energy, US Department of Energy https://www.energy.gov/eere/energy-efficiency • Energy Star (USA) https://www.energystar.gov/ • European Product Registry for Energy Labelling https://eprel.ec.europa.eu • The Energy Saving Trust (UK) https://energysavingtrust.org.uk/ • National Renewable Energy Lab (USA) https://www.nrel.gov/ • ASHRAE Consumer Center https://www.ashrae.org/technical-resources/free-resources/consumer-center • Burdick, A., Strategy guideline: Accurate heating and cooling load calculations (2011). Washington, D.C.; U.S. Dept. of Energy, Energy Efficiency & Renewable Energy, Building Technologies Program • TIWARI, G. N., SHYAM, & TIWARI, A. (2016). Handbook of Solar Energy: Theory, analysis and applications. Springer. • Qiang Wang, Jianwen Wang, Yali Hou, Renyu Yuan, Kun Luo, Jianren Fan, Micrositing of roof mounting wind turbine in urban environment: CFD simulations and lidar measurements, Renewable Energy, Volume 115, 2018 • Laughton, C. (2010). Solar domestic water heating: The Earthscan expert handbook for planning, design, and installation. Washington, DC: Earthscan. 34