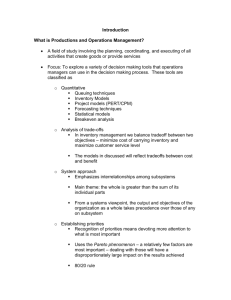

INTRODUCTION TO OPERATIONS MANAGEMENT Ferdous Sarwar, PhD Lecture 1 2 3 4 5 6 7 8 9 10 11 12 2 Topic Production Operations System Forecasting (Quantitative & Qualitative) Capacity Planning Location and Facility Layout Planning Work Design and Measurement Management of Quality Midterm Operations Scheduling (PERT/CPM) Inventory Control Materials Requirement Planning Just-in-time & Lean Management Supply Chain Management Scheduling Final Quiz Q1 Q2 Q3 Q4 WHAT IS OPERATIONS MANAGEMENT? 3 Operations Management is an area of management concerned with overseeing, designing, and controlling the process of production and redesigning business operations in the production of goods and/or services. Operations Management is the set of activities that creates goods and services by transforming inputs into outputs Focuses on carefully managing the processes to produce and distribute products and services. Inputs (customers and/or materials) Transformation Process (components) Outputs (goods and services) WHY STUDY OM? 4 Systematic Approach to Org. Processes Business Education/ Career Opportunities Operations Management Cross-Functional Applications Increase Competitive Advantage/Survival WHY STUDY OM? 5 OM is one of three major functions (marketing, finance, and operations) of an organization OM often includes substantial measurement and analysis of internal processes, because a great deal of focus is on efficiency and effectiveness of processes. Ultimately, the nature of how operations management is carried out in an organization depends very much on the nature of products or services in the organization. Historical Development of OM 6 Prior to 1900 Cottage industry produced custom-made goods. Watt’s steam engine in 1785. Whitney’s standardized gun parts in 1801. Industrial Revolution began at mid-century. Historical Development of OM (cont.) 7 Scientific Management (Frederick W. Taylor) Systematic approach to increasing worker productivity through time study, standardization of work, and incentives. Viewed workers as an interchangeable asset. Other Management Pioneers Frank and Lillian Gilbreth Motion study and industrial psychology Henry L. Gantt Scheduling and the Gantt chart Historical Development of OM (cont.) 8 Moving Assembly Line (1913) Labor specialization reduced assembly time. Hawthorne Studies Yielded unexpected results in the productivity of Western Electric plant workers after changes in their production environment. Led to recognition of the importance of work design and employee motivation. Historical Development of OM (cont.) 9 Operations Research (Management Science) Outgrowth of WWII needs for logistics control and weapons-systems design. Seeks to obtain mathematically optimal (quantitative) solutions to complex problems. OM Emerges as a Field 1950–1960, OM moved beyond industrial engineering and operations research to the view of the production operation as a system. Historical Development of OM (cont.) 10 OM Emerges as a Field 1950–1960, OM moved beyond industrial engineering and operations research to the view of the production operation as a system. The Marriage of OM and IT Integrated solutions approaches Business process reengineering Supply chain management Systems integration (SAP) Historical Development of OM (cont.) 11 Operations Management in Services OM concepts can apply to both manufacturing and service operations. Integration of Manufacturing and Services Conducting world class operations requires compatible manufacturing and service operations. Managerial Issues 12 Shift in balance of power to consumers Globalization of business and markets E-commerce Achieving higher levels of productivity Creating higher quality products Delivering better customer service Achieving shorter delivery times Reducing labor and material costs Top-down Approach to OM Strategy 13 Operations Strategy Decisions Strategic (long-range) Needs of customers (capacity planning) Tactical (medium-range) Efficient scheduling of resources Operational planning and control (short-range) Immediate tasks and activities An Operational-Level OM Perspective 14 OM’s function focuses on adding value through the transformation process (technical core) of converting inputs into outputs. Physical: manufacturing Locational: transportation Exchange:retailing Storage: warehousing Physiological: health care Informational: telecommunications Factors of Production 15 Land Labor Capital Enterprise The Transformation Process within OM 16 Productive Use of Resources 17 Input=Output + Waste Input/Input=Output/Input + Waste/Input 1=Productivity + Wastivity Productivity=Output/Input Operations Decision Making 18 Marketplace Corporate Strategy Finance Strategy Operations Strategy Marketing Strategy Operations Management People Materials & Customers Plants Parts Processes Planning and Control Input Products & Services Output The Transformation Process (value adding) Value Chain 19 Customer (requirements on suppliers) Input from Suppliers Conversion/Transformation Process Process primarily adds value to inputs to provide outputs to the customer Requirements on management Effective and efficient use of all factors of conversion/transformation Customer Requirements Output to Customer The Value Chain and Its Support Functions 20 Key OM Concepts 21 Efficiency - Doing something at the lowest possible cost Effectiveness - Doing the right things to create the most value for the organization Value - Quality divided by price Input-Transformation-Output Relationships for Typical Systems 22 OM’s Contributions to Society 23 Higher Standard of Living Ability to increase productivity Lower cost of goods and services Better Quality Goods and Services Competition increases quality Concern for the Environment Recycling and concern for air and water quality Improved Working Conditions Better job design and employee participation Services as a Percent of Gross Domestic Product (GDP) for Different Countries 24 Differences Between Goods and Services 25 Goods Services Tangible Intangible Can be inventoried Cannot be No interaction inventoried Direct interaction between customer and process between customer and process Most Products Are a “Bundle” of Goods and Services 26 An Expanded Definition of Quality 27 Quality is important in all functional areas of an organization. Quality is now much more than the technical requirements for manufactured goods. Service quality (customer relationships) is equally important. A New Paradigm for OM 28 Post-War U.S. Dominance in Manufacturing Available capacity built to support the war effort Pent-up demand for consumer goods Destruction of overseas production capabilities Proactive Operations Function Add value to products, increase profit margins. Compete on dimensions other than costs: Quality Speed of delivery Process flexibility The Ever-Changing World of OM 29 Increased Global Competition Transformation into a global economy Pressure to excel on multiple competitive dimensions Increased emphasis on logistics Advances in Technology Information technology (IT) Internet and e-commerce (B2B) Automation and robotics Ford Escort 2013 30 Ford’s Global Network to Support the Manufacturing of the Escort 31 Linking OM to Customers and Suppliers 32 Benefits of Buffering the Transformation Process The process was not disturbed by environmental interaction. The process was often more efficient than input and distribution processes. Productivity was maximized when processes operated at continuous rates. Process management skills were different from those of other functional activities. 33 Linking OM to Customers and Suppliers Disadvantages of Buffering the Transformation Process Information lag in interaction with other functional activities. Lack of communication between customers and the shop floor for problem solving. Value Chain Steps an organization requires to produce a good or a service regardless of where they are performed. Line and Staff Jobs in OM 34 Inputs Provided by OM to Other Functional Areas 35 WHAT OPERATIONS MANAGERS DO? 36 Plan Organize Staff Lead Control Planning 37 The process of deciding what to do. Planning is forward looking. When planning is operational, the planning horizon is shorter and the level of detail within is greater. When strategic, the planning horizon is long and done in less detail. Planning(contd.) 38 Effective planning seeks to answer questions such as: What should the firm do? The output of this process are goals and objectives. When must the firm achieve these goals? The output is a schedule defining milestones and due dates. Who is responsible for doing it? The outputs are assigned responsibilities. How should this be done? The outputs may be directions or plans of action. How should performance be measured? The output includes standards of performance. ANALYSING 39 The process of making sense of data that is often: poorly structured, incomplete, inconsistent, inaccurate, and/or available in overwhelming quantities. Analysis supports the planning process by providing the “facts” in useful formats that can then be used to evaluate business alternatives. Analyzing also supports management’s control activity by providing the basis for corrective actions. ORGANIZING 40 The process of building organization structures and interrelated task coordination teams. In the past, organizing dealt mostly with humans, but increasingly it involves data-gathering. A good organizer seeks for The right person The right information In the right form At the right time DIRECTING/IMPLEMENTING 41 An action-oriented process that carries out the outputs of the first three management activities. This is where money is made and lost (!). In this process, management expends resources to perform the tasks defined by the planning process. CONTROLLING 42 The process of measuring the results of the other four management activities. Were the plans any good? Did the analysis provide meaningful information to the other processes? How well did we organize our resources to get the job done? How well did we do it? 10 CRITICAL DECISIONS 43 Service, product design Quality management Process, capacity design Location Layout design Human resources, job design. Supply-chain management Inventory management Scheduling Maintenance ENVIRONMENTAL CONCERNS 44 Solid Waste Liquid Waste Atmospheric Pollution Noise Pollution SECTION OF OM 45 Procurement (Purchasing) Practices reviews guidelines for buying various materials from suppliers and vendors - materials, including computers, services from lawyers, insurance, etc. Management Control and Coordinating Function includes a broad range of activities to ensure that organizational goals are consistently being met in an effective and efficient fashion SECTION OF OM 46 Product and Service Management the major activities involved in product and service management are similar to those in operations management. However, operations management is focused on the operations of the entire organization, rather than managing a product or service. Quality Management is crucial to effective operations management, particularly continuous improvement. More recent advancements in quality, such as benchmarking and Total Quality Management, have resulted in advancements to operations management as well. SECTION OF OM 47 Inventory Management Costs can be substantial to store and move inventory. Innovative methods, such as Justin-Time inventory control, can save costs and move products and services to customers more quickly. Logistics and Transportation Management Focused on the flow of materials and goods from suppliers, through the organization and to the customers, with priority on efficiency and cost effectiveness. SECTION OF OM 48 Facilities Management Depnds a great deal on effective management of facilities, such as buildings, computer systems, signage, lighting, etc. Configuration Management It's important to track the various versions of products and services. Consider the various versions of software that continually are produced, each with its own version number. Distribution Channels The means of distribution depend very much on the nature of the product or service. WHERE ARE THE OM JOBS? 49 Technology/methods Facilities/space utilization Strategic issues Response time People/team development Customer service Quality Cost reduction Inventory reduction Productivity improvement