jsa-visual-inspection-and-ultrasonic-thickness-measurement-on-pressure-vessels compress

advertisement

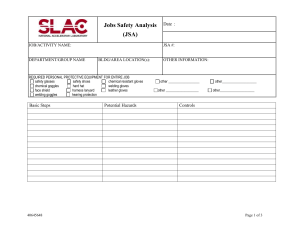

JOB SAFETY ANALYSIS Ref: – JSA-……. Facility / Site: CPF Location within Site: Chemical storage area Task Description: Visual inspection and ultrasonic thickness measurement on pressure vessels Permit No: 25459 REQUIRED REFERENCES Have the relevant Procedures, Standards, Guidelines, or Safe Work Practices been reviewed? Permit Type: COLD Date: 21.05.2019 JSA REVIEW Yes N/A Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the significant Task Steps, Hazards, and Controls. JSA REVIEWER (Supervisor or Designate): RISK ASSESSMENT Must existing Procedures or Work Practices be modified to perform this work? Yes No After mitigation, are there any hazards that continue to present a potentially significant risk? (Scenario-Based Risk Assessment required) Yes No Name / Signature: HBIB BOUSABBEH Company: MSBI WORK SITE VERIFICATION The Work Team has assessed the worksite conditions and confirms: The JSA addresses the applicable hazards and necessary controls. PPE REQUIRED DURING THIS TASK The Team has the appropriate resources (people and equipment) to do the job safely. HARD HAT SAFETY GLASSES Others that could be affected by the work have been informed. SAFETY SHOES / BOOTS FACE SHIELD GOGGLES TASK LEADER: Name / Signature: FALL PROTECTION FALL RESTRAINT Company:MSBI COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK GLOVES: Work Team Declaration: I acknowledge that I have reviewed the attached JSA, I understand my roles and responsibilities, and I will comply with the instructions for this task. COTTON LEATHER IMPACT PROTECTION Dust mask Work clothes OTHER PPE (specify): OTHER (specify): Name (print): Name (print): TASK STEPS (Number) POTENTIAL HAZARDS (What could go wrong?) Procedure or task unclear Miscommunication Workers involved in the tasks are not competent Incorrect tools or PPE 2- Preparation of pressure vessel surface, conduct ultrasonic thickness measurement on pressure vessels Wire brush failure causing hand injuries Slip or fall 3- Housekeeping Slips trips and falls Unsafe access Obstacles in work area 1- Work permit in place Name HAZARDS CONTROLS (How can harm be prevented?) PTW signed by authorised person. Ensure correct PPE available for task Carry out toolbox talk Clear access to work zone. All workers involved are competent and They understand the scope of the work and the hazards/risks associated with the task. Clean and arrange the work area. Be careful when used wire brush and equipment Wear adequate PPE’s Equipment pre-use check Wash your hand after handling and before eating Do not expose to extreme heat Make sure that all equipment are stored in the correct place HAZARD PORT MITIGATION STATES MSBI Emergency Response plan MSBI Emergency response Plan First Aid kit in place Keep work area tidy and clean Regular Housekeeping and keep all area free from hazards Position Prepared By Area Supervisor Checked By Area HSSE Supervisor Approved By PTW Coordinator Date Signed MSBI Emergency response Plan First Aid kit in place Spill kit in place