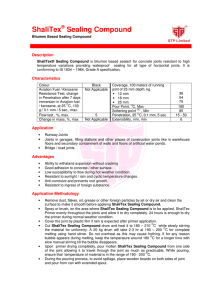

Method Statement & work Procedure of GROOVE FILLING Contractor – Banco Construction Pvt.Ltd. Client – GPS Renewables Pvt. Ltd. Location_ Jabalpur METHOD STATEMENT OF GROOVE FILLING WORKS LOCATION : PS‐JAB‐01 Purpose: Purpose of this document is to develop and provide safe method for groove filling work. Objec ve: This method defines health safety & Environment approach for Erec on of structure steel, Nut‐Bol ng, Welding, Cu ng work. Responsibili es : Be responsible for safe execu on and quality & safety of the work. Monitor the site ac vi es and ensure the job is progressing according to the project schedule and specifica on. ShaliTex® Sealing Compound Single component Bitumen Based Joint Sealing Compound Description: ShaliTex® Sealing Compound is bitumen based hot applied sealing compound for waterproofing concrete joints and has the ability to withstand extension without cracking. It has low susceptibility to flow during hot weather conditions. It is durable and plastic and at the same time offer resistance to ingress of solid foreign matter. ShaliTex® Sealing Compound is suitable for use in concrete constructions other than those which are subjected to spillage of kerosene or other petroleum oils. Product Information: Form, Colour Handling & Storage Packaging Shelf Life Handling Precaution s Black, Solid The material must be stored in a shaded area with minimum exposure to sunlight and UV. The containers should be protected from all sources of heat, ignition & extreme cold. Available in 20 kg and 200 kg capacity drums. 12 months when stored in unopened sealed conditions at 5°C to 35°C. As with all chemical products, care should be taken during use and storage to avoid contact with eyes mouth, skin and foodstuffs. Treat splashes to eyes and skin immediately. If accidentally ingested, seek immediate medical attention. Keep away from children and animals. Reseal containers after use. Technical Characteristics at 27°C, 55% RH: Density, gm / cc Extensibility, mm Flow Test, % 1.05 ± 0.05 Pour point °C 176 - 180 6-7 Softening Point °C 86 - 89 2-4 Penetration, dmm 15 - 28 Application Information ü Substrate Temperature - +5°C Min / +50°C Max ü Ambient Temperature - +5°C Min / +50°C Max ü Substrate Moisture Content - < 5% Application Methodology: • Remove dust, flakes, oil, grease or other foreign particles by jet or dry air and clean the surface to make it smooth before applying ShaliTex® Sealing Compound. • Spray or brush, by ShaliTex® Primer evenly throughout the joints and allow it to dry completely. 24 hours is enough to dry the primer during normal weather condition. • Cover the joint by plastic film if rain is expected after primer application. • Cut ShaliTex® Sealing Compound drum and heat it to 170 - 190°C while slowly stirring the material for uniformity. A 20 kg drum will take 2 - 3 hrs. at 190 - 200°C for complete melting using hand stirrer. Do not overheat as this may cause frothing. If for any reason bubble appears during melting, keep the temperature around 180°C for a longer time with slow manual stirring till the bubble disappears. • Upon primer drying completely, pour molten ShaliTex® Sealing Compound from one side of the joint allowing it to travel through the joint as much as practicable. While pouring, ensure that temperature of material is in the range of 180 - 200°C. • During the pouring process, to avoid spillage, place wooden boards on both sides of jointand pour from can with extended spout. Precautions• Heat the Joint Sealing Compound to a temperature which will permit easy pouring into the expansion joint above the ShaliTex® Expansion Joint Board. • This temperature should be well below that at which the Joint Sealing Compound undergoes decomposition, and should not exceed temperatures as, specified. • Primers are inflammable and should not be placed near a named flame. Health and Safety information When using ShaliTex® Sealing Compound, it’s important to follow these safety precautions to ensure safe handling and application: Personal Protective Equipment (PPE): Wear goggles, gumboots, nose covers, and hand gloves during application to protect against splashes and fumes 1.Handling Precautions: As with all chemical products, avoid contact with eyes, mouth, skin, and foodstuffs. Treat splashes to eyes and skin immediately. If accidentally ingested, do not induce vomiting and seek immediate medical attention Keep the product away from children and animals. Reseal containers after use to prevent contamination 2.Storage: Store in a shaded area with minimal exposure to sunlight and UV. Protect containers from all sources of heat, ignition, and extreme cold. Keep in tightly closed containers in a cool, dry area. Store away from oxidizing agents, peroxides, and foodstuffs. 3.Fire Safety: ShaliTex® Sealing Compound is inflammable. In case of fire, use dry powder, CO2, earth, sand, or foam as extinguishing media. Do not use water. Wear self-contained breathing apparatus and full protective clothing during firefighting. 4. Environmental Precautions: Prevent the compound from entering water courses. In case of spills, absorb onto inert material like sand or earth and put into suitable containers. 5. First-Aid Measures: Inhalation: Remove to fresh air and give oxygen/artificial respiration if needed. Skin Contact: Remove contaminated clothing, use a proprietary skin cleaner, then wash with soap and water. Apply skin cream. Eye Contact: Flush with clean water for a minimum of 15 minutes. 6. Clean-Up: Clean hands with warm soap water after application. NOTE: Always ensure adequate ventilation, especially in enclosed spaces, and follow the manufacturer’s instructions for safe use. If you’re unsure or need further guidance, consult with a safety professional or the product manufacturer. Stay safe! One Appendix 1 - Personal Protective Equipment (PPE) 11 For all tasks involving bitumen handling, a task Risk Assessment should be performed detailing the required PPE for the associated task. 2 3 PPE should be used when working with bitumen and should cover all parts of exposed skin to avoid direct contact. 1. Loading and unloading 4 Always use: • a safety helmet 1 and visor 2 . Eye goggles do not give full face protection • a neck apron to protect the back of the neck 3 • coveralls with additional high visibility 4 • heat resistant gauntlets/gloves 5 . Ensure that no bitumen can run into the gloves (see latest Eurobitume documentation) 5 • one piece protective coveralls 6 with 7 long sleeves and legs worn over rigger-style boots • safety footwear, calf length 8 . No shoes, sandals, clogs or trainers. 6 NOTES: During loading and discharging it is recommended to wear well fitting long sleeved gauntlets (see picture). 7 In general, there may be additional PPE requirements from local sites, e.g. Personal Dose Monitor (PDM) for hydrogen sulphide (H2S) during loading operations and lone worker alarm. 8 Appendix 1 JSA No: Step No JOB TITLE: Bituminous Coating of concrete foundations/columns on site Describe Job Step Potential Hazards Hazard Controls 1 Mobilization of Chemicals on site • Mishandling of chemicals • Manual handling • Chemicals with no proper containment • Highly flammable/combustible • Deliver awareness to workers about chemicals handling • Ensure careful handling/storage of chemicals • Use vehicle or wheel barrows while transportation of chemicals on site • Ensure use of appropriate PPE’s • All chemicals should in proper containment with its labelling • Place fire extinguisher at site 2 Bituminous coating of concrete foundations • Skin contacts with chemicals • Fire/explosion • Improper storage on site • Spillage • Awkward access (slip, trip) • Ensure use of appropriate PPE’s • Remove combustible material from site, secure loose objects at platform • Store chemicals at ventilated places • Do not keep chemicals un attendant • Keep access always clear from any kind of obstructions • Ensure availability of fresh water on site • Disposed of empty cans properly • Use controlled heating equipment. • Monitor temperature closely. • PPE: Heat-resistant gloves, face shield. 4 Improper heating of sealing compound, overheating, frothing Heating sealing compound 5 Pouring at incorrect temperature, spillage Pouring sealing compound • Use controlled pouring equipment. • Train workers on proper pouring techniques JSA No: Step No 6 JOB TITLE: Bituminous Coating of concrete foundations/columns on site Describe Job Step Lack of spillage prevention measures Potential Hazards Hazard Controls Placing wooden boards • Install barriers or guards. • Implement spillage prevention procedures.