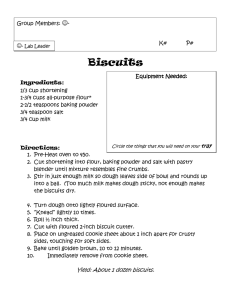

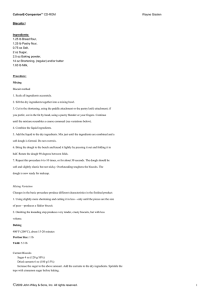

Paper No. 09 Paper Title: Bakery and Confectionery Products Module No. 11 Module Title: Biscuits: Classification and general aspects of manufacture Biscuit The term ‘Biscuit’ refers to the small round bread leavened with baking powder or soda and covers a large variety of sweet, salted, filled and coated biscuits. Biscuits are eaten by all sections of people across the board round the year. They are, thus, mass consumption items with number of varieties and shapes. The market is scattered. There are some dominant national and regional brands. Biscuits can be manufactured at a location which is close to the market. The basic ingredients of biscuit are flour, baking powder, salt, baking soda, sugar, shortening and milk solids. 1.1 Definition of biscuit As per Food Safety and Standards Regulations, 2009 - Regulation 5.7.15: Bakery products, Biscuits including wafer biscuits shall be made from maida, vanaspati or refined edible oil or table butter or desi butter or margarine or ghee or their mixture containing any one or more of the following ingredients, namely:- Edible common salt, butter, milk powder, cereals and their products, cheese cocoa, coffee extract, edible desiccated coconut, dextrose, fruit and fruits products, dry fruit and nuts, egg, edible vegetable products, ginger, gluten groundnut flour, milk and milk products, honey liquid glucose, malt products, edible oilseeds, flour and meals, spices and condiments, edible starches such as potato starch and edible flours, sugar and sugar products, invert sugar, jaggery, protein concentrates, vinegar and other nutrients and vitamins: Provided that it may contain food additives specified in these rules and in Appendix A: Provided further that it may contain artificial sweetener as provided in rule 47 under label declaration as provided in Article 2 of Regulation 4.2.1 Provided also that it shall conform to following standards, namely:(a) ash insoluble in dilute hydrochloric acid (on dry basis) shall not be more than 0.1 per cent. (b) acidity of extracted fat (as oleic acid) not exceeding 1.5 per cent.] It may contain Oligofructose (dietary fibres) upto 15% maximum subject to label declaration under Article 2 of Regulation 4.2.1. 1.2 Types of biscuit Classification of biscuits on the basis of chemical composition and processing methodology is difficult due to overlap. These are manufactured in varieties covering sweet, salted, filled and coated biscuits. a) BIS Classification (IS 1011:2002) The varietal differences of biscuits can be easily distinguished based on sensory attributes. This standard broadly classified the biscuits on the sensory basis into the following five types: Type I Sweet Type II Semi-sweet Type III Crackers Type IV Cookies Type V Speciality Biscuits Biscuit has nowadays become a food item of mass consumption and has got wide acceptance among all the levels and class of consumers. b) UK Classification: Biscuits are classified based on the formulation as follows: S.N. 1 Type of biscuit Hard dough biscuit 2 Short dough biscuit Description Dough used is similar to bread dough Mixing of flour is more to maximize gluten development Dough is elastic and extensible due to well developed gluten network during mixing Very low fat and sugar content relative to flour Example: Crackers, sweet and semisweet biscuits Dough more closely related to cake dough however water used is lesser than cake dough Mixing of flour is very little to minimize gluten development Higher fat or shortening than hard dough resulting into lower extensibility of gluten and hence easy breaking of biscuits Higher sugar in the formulation Soft dough biscuit: A subgroup of short dough biscuit with a more soft consistency which can be attributed to its higher sugar and fat content. c) USA Classification: This classification of biscuits is based on the method of processing and, in particular on the basis of the way biscuits are shaped. 1) Sheeting or cutting type: Here the dough is passed through laminators to produce sheets. These multilayer sheets are then fused into single sheet of desired thickness. This sheet is then passed onto cutter of various shape and sizes of cups/dies. The examples are creamcrackers, puff crackers, marie gold, salt n sugar cracker, fiftyfifty, krackjack, monaco etc. 2) Rotary molding type: The dough is in short crumb form and is directly fed in to rotator moulder with dies of various shape and size. The examples are Good day, Glucose chocochips biscuit etc. 3) Wire cutting type: Here soft short dough is passed through holes in extruders and these doughs are then wire cut in pieces which are directly dropped into oven band. Two three types of dough can be co-extruded from the die where the central dough could be jelly or jam .These ropes can be cut after or before baking. Examples are butter cookies, chocolate cookies. 4) Depositing type: Here the soft pourable short dough is passed out from extruder and directly laid on baking bands. The depositor may rotate to make swirls and twists on to the products. Cream treat biscuits are made by this method. 1.3 Biscuit manufacture process There are various established processes commercially available and being practiced by different manufacturers. The process of manufacturing of biscuits mainly involves the following three steps: a) Mixing b) Shaping or forming c) Baking As the mixing and baking steps are common to manufacture of all types of biscuits the differences in the finished product arises due to the different shaping and forming methods. Mixing Mixing is commonly defined as a process designed to blend different ingredients into a uniform, homogenous mixture. The major ingredients are flour, fat, sugar and others as per the desired final one would like to have. For this step, all ingredients are put together in right proportion for dough formation. These are then fed into mixers where mixing is done and dough is prepared for moulding/cutting. There are three types of mixers being used for mixing of ingredientsa) Vertical spindle mixer b) Horizontal mixer c) Continuous mixer S. Mixer Features Image N . 1 Vertical Portable dough trough spindle Spindle with horizontal mixer paddle or arms Dough is mixed by upward and downward movement Mixer blades for cutting action rather than kneading Advantageous being suitable for any product Disadvantage is the slow operating speed (max. 20 rpm) 2 3 Horizontal mixer Horizontal bowl mounted on a rigid frame that encloses the drive motor Mixer bowl designed to tilt so as to eject the dough from the tilted position Blades of variable shapes to perform cutting, scraping or kneading action Advantage - high speed, continuous dough supply to processing line, complete automation, uniform mixing A rotor or screw operates within a barrel jacketed for temperature control Continuous feeding of ingredients Mixing is variable from gentle blending and dispersing to vigorous or high intensity kneading by varying the arrangements of different mixing arms along the length of the barrel Constant supply of dough to processing line Small in size relative to horizontal type Continuous mixer Disadvantage- suitable for single purpose or similar type of products only, high cost. Shaping or forming The forming process is specific for each biscuit, cookie type. There are three processes by which shaping or forming of biscuits is achieved1) Sheeting and cutting 2) Rotary molding 3) Extrusion Sheeting and cutting method: This method of forming is used for the production of crackers, semisweet biscuits and selected soft doughs. Mixing (Previous step) Dough Making thick sheet Reincorporation Even reduction of sheet thickness Scrap dough Cutting out the shape Formed dough pieces Fig 1. Process flow chart for Sheeting and cutting method of forming biscuits Rotary molding: The rotary molding process offers advantages over sheeting and cutting that there is no scrap to recycle and very less labour requirement. This process is used for dry and crumbly doughs only. Dough hopper Pulling of dough down by feed roller Forcing of dough into cavity of the engraved roller Scrap dough Scraping of excess dough Dropping of dough pieces on a conveyor belt Dough pieces for baking Fig 2. Process flow chart for Rotary molding method of forming biscuits Extrusion method: In this method of dough forming, the dough is extruded through a row of dies which is cut by a wire or blade mounted on a frame that moves through the dough just below the die nozzle outlet. Dough hopper Forcing of dough into pressure chamber Extrusion of dough through die Cutting of extruded dough by wire mounted on a frame Dropping of dough pieces on a conveyor belt Dough pieces for baking Fig 3. Process flow chart for Extrusion method of forming biscuits Baking This is the area where we pass these moulded/ formed wet biscuit into baking oven .The biscuits are baked on desired temperatures. Various type of heating are available now-a-days as per the convenience and cost. Different types of oven are available for baking products. Cooling The hot product obtained from baking must be cooled to room temperature prior to packaging for several reasons Being warm, reduced firmness of the baked product so as to withstand packaging process Packaging material shrinkage due to contact to hot product Hot packed product may continue release some steam causing condensation inside the packaging. Cooling can be achieved either by placing the baked product at ambient conditions or by forced air cooling. Whitley method of biscuit making For the simplest biscuit preparation Whitely P.R. (1970) method is used. According to this method the following recipe is used for biscuit manufacture– S. No. Ingredient 1 White flour (maida) Quantity (g) 64 2 3 4 5 6 7 8 9 10 11 Sugar (powdered) Shortening Skim milk powder Glucose Ammonium bicarbonate Baking powder Sodium bicarbonate Common salt Vanilla Water 18 16 1 1 0.5 0.3 0.2 0.4 0.02 (ml) as required for proper consistency (ml) The various steps of biscuit manufacture like ingredient mixing, cutting, baking and cooling are described as follows. Creaming of fat and sugar in a mixer Addition of well mixed blend of flour, baking powder and skimmed milk powder Addition and mixing of water containing sugar, salt, ammonium biacarbonate, sodium bicarbonate and flavour Preparation of dough Sheeting Cutting Baking at 200oC for 8-9 min Cooling Machineries used in biscuit manufacturing process For the manufacture of biscuits the following machines are primarily used by the baking industry: Flour Shifter Stainless Steel Mixer GMS Churner Fat Churner Cotton Conveyor Laminator Teflon coated cutting, stamping & punching machine Electrically/ Diesel operated baking oven Cooling conveyor Packing & sealing machine